How does it work

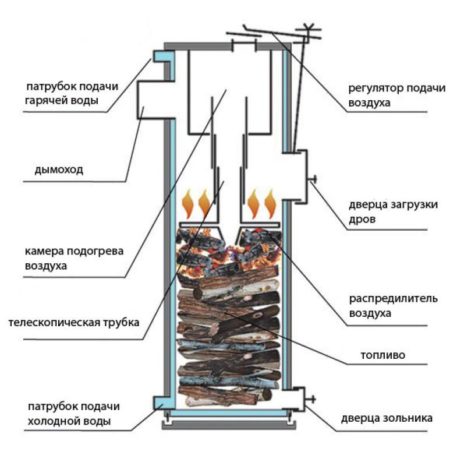

The equipment is a simple, two-chamber device. Other fuel is added to the upper chamber as needed. Its bottom is mesh, so with the time of combustion, the remains and products of combustion under the influence of gravity fall into the lower chamber. When filling out, you need to delete them from there. The grating located between the chambers is usually made of strong, refractory metals. Most often it is cast iron.

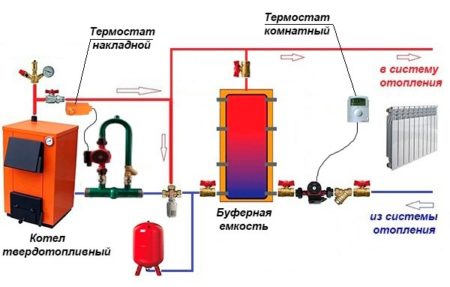

To automate the process, a number of devices can be installed that would control the draft and operation of the furnace. In the absence of automatic control systems, the operation is carried out due to the natural pressure difference between the external and internal environment. A boiler with the addition of a long-burning system and automation is much easier to maintain, but takes up large areas. The cost of such equipment is also much higher.

The automation includes a pressure sensor and an air supply system. By controlling the supply of oxygen to the furnace, it is possible to adjust the burning rate. The more free gases in the boiler, the higher the burning rate of the fuel cells. Reducing access leads to a decrease in heat transfer from the boiler. However, the duration of burning increases.

The temperature indicator is regulated by a system of sensors. If desired, you can set the operating modes of the boiler. When a certain temperature is set, which was set on the control display, the sensor is triggered and sends a signal to the electronics to turn off the fan.

After that, access to air and the burning rate are significantly reduced. Conversely, when the temperature drops in the furnace, the ventilation system is activated and the coal begins to ignite. Taking into account these features of the functioning of the boiler, it is possible to derive the rules for the operation and introduction of fuel.

How to reduce coal consumption

An increase in the coal consumption rate, after several years of operation of the boiler, is quite common. The increase in costs is primarily due to the clogging of the heat exchanger and the chimney with soot. It is recommended to completely clean the chimney and internal components of the boiler at least 2 times a year.

To reduce coal consumption, it is required to heat the boiler correctly. To reduce the amount of soot, carry out the laying of fuel in layers - firewood-charcoal. Such styling will provide maximum heat transfer. The change in coal consumption occurs, depending on the efficiency of the boiler. Therefore, the greater the efficiency, the lower the fuel consumption.

Another way to reduce coal consumption is to burn with exceptionally high-quality fuel. Cheap raw materials, brown coal, have a high percentage of underburning, quickly clog the chimney and heat exchanger and, as a result, are more expensive than anthracite.

How does a coal boiler work

What is a coal fired boiler? This is a simple installation that consists of two compartments. Coal is placed in the upper furnace. After it burns out, ash and slag remain, which fall into the lower compartment and are removed from there as needed. Between the chambers there is an ordinary grate made of durable cast iron.

Such furnaces can be additionally equipped with complex automation, which allows you to transfer the operation of the installation to an autonomous mode and control traction. If there is no automation, coal stoves operate using natural circulation. The first type of device has several operational advantages, but long-burning furnaces cost much more than simple devices.

Automation works extremely simply. Thanks to it and the operation of the fan, it is easy to control the flow of oxygen into the furnace.The more it is, the stronger the coal burns, and the faster the fuel burns out, giving off the maximum amount of heat. Restriction of access to oxygen leads to the opposite effect. The fuel burns more slowly, the amount of heat given off decreases, but the burning time of coal increases.

The heating temperature is regulated by a special temperature sensor. Boiler operating modes can be programmed. If the set temperature is reached, the sensor activates and turns off the fan. At the same time, the oxygen supply is reduced, and the furnace burns out more slowly. When the temperature drops, the fan turns on and begins to intensively pump oxygen into the furnace. The coal is on fire again. If we take into account such features of the operation of a solid fuel boiler, it becomes clear when and how to put coal into the furnace.

Heating water supply sewerage boiler house

We work around the clock throughout:

Moscow region, Vladimir, Kaluga, Tula, Tver

Contacts

1 How does a coal fired boiler work?

2 What kind of coal to choose for the firebox?

3 How to use solid fuel installations correctly?

3.1 Preparing the stove for kindling

3.2 How to melt coal correctly?

4 How to remove the ash?

5 Conclusion

As a rule, those who install autonomous boiler equipment in their home for the first time face problems with its operation. Not everyone, for example, knows how to properly heat a boiler with coal, what type of solid fuel to choose for the designated purposes

Specialists draw attention to the fact that any furnace must be handled with extreme caution, carefully observing all fire safety standards. It is also useful to familiarize yourself in advance with the features of the selected equipment.

What coal to choose for the firebox

What is coal? This is a product of plant origin, which includes carbon and non-combustible impurities. It is they who form ash and slag-like substances after burning. The ratio of the two components is different everywhere. It is this, as well as the “age” of natural fuel, that determines the grade of coal. Specialists distinguish several varieties.

The "youngest" type of coal is lingit. It has a rather loose structure. If you pick up a lump of lingit, it will quickly crumble and lose its shape. Such coal is most often used in thermal power plants, but lingit is not suitable for home heating.

In addition to lingit, brown, black coal, and anthracite are also mined - the most ancient carbon deposits. All varieties have different levels of humidity. In brown coal, for example, the humidity is 50%, in anthracite its threshold does not exceed 7%. Therefore, anthracite has the highest specific heat. Its indicators are 9 thousand kcal / kg. A smaller indicator for coal is 5.5 kcal / kg. In the brown variety, the specific heat is only 3 kcal / kg. Given all this, it is easy to understand what type of fuel to purchase to heat the house.