Getting rid of fistulas

Before sealing a leak in a sewer pipe, you should understand how to fix it.

You can use the first method:

- wrap the damaged area with a rubber gasket;

- tighten with clamp.

There is also an alternative method:

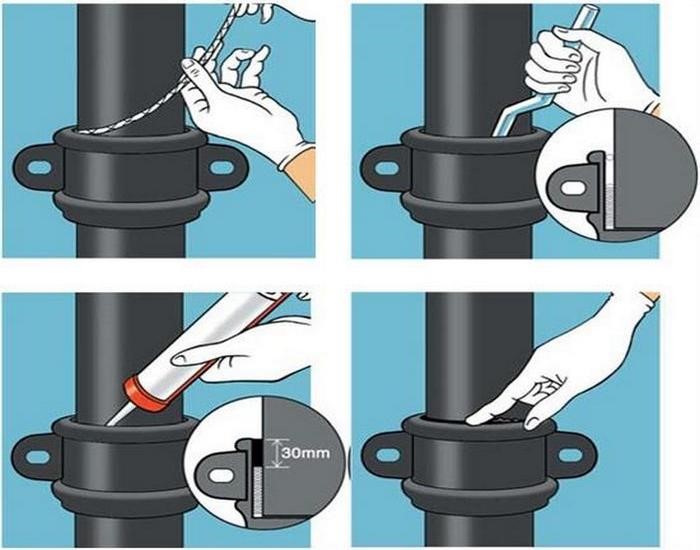

- if a large fistula occurs, you will need to use a repair sleeve;

- cut a piece of rubber to the size of the clutch;

- tighten well - the leak should stop.

It is worth noting that special plugs can be found on sale. They are installed in places of cleaning. You can additionally put on a rubber gasket on the plug. The solution to how to seal a cast-iron sewer pipe, if the leak continues, can be additional sealing of the plug with silicone.

If a leak has formed at the joint, then the joint on top of the sealing layer is additionally filled with liquid glass, that is, silicate glue.

How to seal the joint of plastic and cast iron pipes

If a cast-iron sewer pipeline is leaking, the owner of the house can replace the damaged segment with a piece of pipe made of the same material. But there is an alternative in the form of a plastic product. However, in this case, it is necessary to know the nuances of how to seal a sewer pipe, consisting of components that differ in their characteristics.

To achieve a good result, first of all, you should purchase rubber or polymer adapters. Having done this, you can get to work. First you need to clean the cast-iron socket from rust and dirt. To improve the level of tightness, it is recommended to degrease it afterwards. Next, a layer of silicone sealant is applied to the inner surface of the socket. The same operation must be performed on the outer surface of the adapter pipe. Then this structural element is carefully inserted into the socket. Upon completion of the polymerization process, the nozzle, together with the plastic part, is connected to the pipeline. If there is no spare pipe, the best solution to fix the leak is to use a metal clamp.

In order for the clamp to perform its task, it must be of the correct diameter.

You can purchase such a mount already with a rubber seal, or you can cut a piece of suitable size yourself. The clamp is generally a universal solution to many problems associated with pipe repair.

Do not discount the easiest way to seal the joints of sewer pipes: sealing them with paint. Although this method is rarely used, it also gives good results. And on any type of sewer pipes. It is carried out in two stages: first, the socket must be hammered with a cloth and filled with paint. Then, using a screwdriver, the contents of the socket are well compacted. After the resulting mass has solidified, you can begin to operate the repaired wastewater drainage system.

The choice of a suitable option for sealing sewer pipes is influenced by the following factors: the location of the pipeline and the material from which it is made. But know that you can do this work with your own hands. To do this, it is enough just to clearly set a task for yourself, carefully study the instructions for the use of a particular material and follow the prompts of common sense.

Sealant for pvc sewer pipes is a special composition that provides protection for joints from leakage. In addition, it provides ease of installation and helps to cope with emergency situations. In this article, we will consider what types of sealants are for pvc pipes and cast iron channels.

The most common sealing methods

Silicone sealants.This material is a mastic that can harden when exposed to air. One of the advantages of silicone sealant is the absence of the need for pre-treatment of the pipe surface with primers. For its manufacture, silicone rubber is used, into which special additives are added to enhance the degree of adhesion and, accordingly, the strength of the sealing layer.

The work takes a minimum of time and does not require professional skills. For extrusion, a mounting gun is used. If it is not at hand, and the sewer pipe flows at the joints, you can use a simple hammer, the handle of which will serve as a piston. Upon completion of the vulcanization process, silicone mastic will turn into a kind of substance similar in properties to rubber.

Table number 1. Consumption of silicone sealant

Other types of mastics

Fragile types of sewers (cast iron, ceramics) can be sealed with epoxy. Such pipes require a stronger and more reliable connection, which epoxy glue does an excellent job of. To seal seams and emergency areas, epoxy resin is mixed with a hardener and applied to the joint. The mass dries quickly, serves for a long time and reliably, is resistant to aggressive acids and alkalis.

When sealing a cast-iron socket, Portland cement can be used. This substance dries quickly and provides reliable protection against leaks and accidents. A sanitary winding is applied to the end of the pipe; resin strands can be used for thick channels. The end is inserted into the socket, compacted and filled with Portland cement. This design will last for many years. True, when dismantling it, your followers will have a lot of difficulties. But that is another story.

«>

adblock detector

Types of sealants used and the rules for their application

The construction industry produces sealing materials designed to seal the joints of sewer pipes. This:

Sealing self-adhesive tapes. Strips 3-15 cm wide are made from bitumen or rubber. They can be reinforced with fiberglass, covered with a protective layer of aluminum foil. They are used to reinforce coupling joints, tie-in points or sealing cracks in communications.

- polymer sealants. Viscous formulations of silicone rubber, acrylic or polyurethane cure at room temperature. They have thermal and water resistance, good adhesion to the pipe material. Acidic, vinegar-smelling substances are not recommended for working with metal, as they cause corrosion. More expensive neutrals are safer in this regard.

- Portland cement. Clinker, calcium silicate and gypsum powder hardens quickly when combined with water. To increase elasticity, modifiers are added to the mass. It is applied to sealing of designs from cast iron.

- Sulfur technical. Inexpensive material is produced in the form of powder or lumps. It is crushed and mixed with finely ground kaolin, heated to a temperature of 150°C. In molten form, it is poured into the socket of cast-iron pipes.

- bituminous sealants. Compositions with additives of rubber or polymers are applied hot or cold. They have high elasticity, water resistance, but become brittle at temperatures below -35°C.

- Thiokol sealants. Heat-resistant, elastic and durable compositions are very unpretentious, have high adhesion to plastic, metal or concrete. Suitable for gluing joints of pipes made of various materials. The base of the adhesive is mixed before work with a hardener and a vulcanization accelerator.

Sealing tapes are designed to process joints from the outside. Remove the protective film, slightly stretching, apply overlapping layers. They wrap the pipe above and below the joint by 15-20 cm.The surface is pre-cleaned of dirt and dust to ensure a snug fit of the strip.

Paste bituminous, polyurethane or silicone sealants are applied to the inner edge of the socket, connected to another part, left until completely cured. Most often, such compositions are used when assembling the joint of cast-iron and plastic pipes. The viscous layer ensures the tightness of the interface, compensates for the different degree of temperature deformations of the two materials.

Types of materials for waterproofing sewer pipes

To protect the joints of sewer pipes from internal and external influences, today the construction market provides a large selection of materials, including:

- self-adhesive tapes;

- silicone sealants;

- Portland cement;

- technical sulfur;

- epoxy resins;

- bituminous mastics;

- jute rope.

In everyday life, sealant tapes and building silicone are most widely used, which is caused by the availability of the material and its ease of use. However, other options also deserve attention, as they allow you to achieve sealing of sewer pipes at the same or higher level.

The result of poor-quality sealing of the pipeline

Technical sulfur

Sealing an old cast-iron sewer can be very difficult. Technical sulfur was often used to repair cast iron pipes. But for its application, it was necessary to heat the composition to a plastic state. A special vessel was used (a bath for heating sulfur). In addition to the high temperature and fire hazard, there was another risk factor in such work - toxic gas was released during combustion. Therefore, I had to work in a respirator. Now it is possible to seal the pipe in safer ways, so technical sulfur is practically not used.

Expert advice and possible difficulties

When laying and repairing the sewer system, professional plumbers recommend:

- Rigidly fix the structures during installation using clamps.

- Do not increase the slope of the pipe above 15%. If the angle is steeper, the water will not have time to wash away the waste that has settled on the walls.

- Cracks in the cast-iron pipe should be sealed with a bandage soaked in cement mortar and a clamp.

- If the system does not provide an angle of inclination for free flow, use special superchargers for sewage.

- Regularly inspect drainage lines.

Assembling the sewer system in compliance with the norms, sealing critical joints and careful operation will help the structure last for a long time.

The sewer system will reliably perform the functions assigned to it only if its installation ensures the absence of potential leaks. This applies to both the correct laying of pipes and the complete sealing of their joints. Builders usually check whether the sewerage is leaking, and if not, the commission signs the act of acceptance of the object into operation. But due to wear, the joints of sewer pipes can leak. How to prevent this phenomenon, and what to do if it does occur?

Sealing a pipe joint with PVC cement

adhesive tape

This type of sealing can be used both for sealing and protecting joints, and for strengthening sealing plugs, fittings, tie-ins, corners and bends. The main advantage of the tape is its ease of use. In several layers, it is wrapped around the pipe on the desired section of the sewer. This ensures reliable and long-term operation of the system, protection against corrosion and the effects of currents, and waterproofing of joints.

The tape must be applied to a dry surface. Before its winding, the pipe is cleaned of dirt and liquid, degreased. Next, we overlap the problem area so that the previous round overlaps with the new half of the width. We keep the tape in tension, do not create folds.

Sealing concrete rings

So that sewer septic tanks do not become a source of environmental pollution, it is necessary to carry out a thorough waterproofing of concrete rings. Various sealing methods are used:

- plastering the inner surface with moisture-resistant compounds;

- spraying on the outside of an elastic film using a special apparatus;

- coating with cold or hot mastics;

- pasting with rolled materials;

- impregnation with penetrating solutions;

- sealing seams with bentonite expanding clay, bituminous pastes.

Coating waterproofing of wells

Coating waterproofing of wells

A good effect is the treatment of rings with bituminous mastics and additional protection with a clay lock. The clay around the septic tank is covered in layers, compacted with a manual rammer.

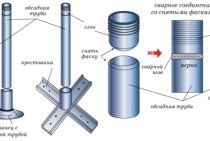

Methods for repairing cast iron pipes

When craftsmen decide how to cover up a cast-iron sewer pipe, they have several options to choose from:

- wind strands;

- upset strands;

- use a solution of asbestos cement as a putty.

However, before starting any work, the pipe should be cleaned to a metallic sheen.

In cases where sewer pipes made of cast iron are morally and physically worn out, they are completely dismantled for replacement.

This work is done in several steps:

- with the help of a grinder, a section of the pipe is cut to the joint;

- the socket is freed from the remnants of cement and stuffing;

- the remaining section of the pipe is cut with a grinder in several places to make an emphasis on the lever;

- a crowbar is inserted into the slots and the pipe is loosened along the axis;

- the last piece of the pipe is removed from the socket;

- rubber coupling-adapter is mounted in the old socket;

- a new plastic sewer pipe is mounted in the adapter.

Why sealing sewer pipes is necessary

Sealing sewer systems at home performs the following tasks:

- prevents the leakage of sewage and the penetration of an unpleasant odor from the sewer into residential premises;

- protects the floors of the house from the corrosive effects of drains;

- prevents flooding and destruction of the foundation, basement floors, basements and other underground structures.

With poor protection of the joints, the volume of effluents increases, which increases the pressure on the pipe and the following line connections.

Scheme of sealing sewage systems in modern construction.

Leakage of sewage into the environment can lead to contamination of drinking wells and soil, death of plants, diseases of livestock and residents of the house.

Check valves and water seals, which are equipped with plumbing and the general system of the house, reduce the risk of overpressure and clogging of the pipeline.

However, with poor-quality installation, ground movement, or strong temperature drops, gaps form at the pipe joints, through which drains leak.

The treatment of joints with dense sealants makes it possible to exclude the penetration of liquids and biogas between the elements of the sewer system.

PVC sewer pipe sealing

Installation of sewerage systems from PVC pipes consists of simple operations - the end of one element is inserted into the socket of another. Rubber o-ring ensures a tight connection. Over time, the material of the ring ages, and if the joint is under even a slight deforming stress, a leak occurs.

There are two ways to troubleshoot:

- Dismantling of the structure with replacement of the gasket and subsequent assembly of the site.

- Sealing a leaking joint with sealant without dismantling.

In the first case, a viscous sealant is used, in the second, a self-adhesive tape.

Assembling a system of PVC pipes with sealant

PVC sewer pipes are sealed in the following sequence:

- Clean the surfaces to be joined from dust with a cloth moistened with a degreaser.

- A thin layer of adhesive is applied to the inside of the socket and the outer end of the pipe to be connected.

- Insert the element without effort, slightly pressing.

- Hold the link for a few seconds until the composition dries.

Remove residual sealant with a tissue. Allow the adhesive to fully harden for 5-15 minutes.

Sealing PVC pipes without dismantling

To repair the joint without dismantling, free the site for free access. Use sealing tape, such as self-curing silicone repair tape.

Work is carried out according to the scheme:

- The tape is stretched to increase the length by 3 times.

- Wrap the damaged area with an overlap of up to 50% of the strip width.

- Lay several layers as tightly as possible.

Important. The repair tape is convenient because it seals even wet, uneven or greasy surfaces.

Silicone rubber vulcanizes within seconds.

Popular sealant brands brief product description

The reliability of the connection depends not only on the type of sealant, but also on the manufacturer. Good compounds harden quickly, adhere to any surface and provide water resistance for 10-30 years of operation.

The most popular brands in the plumbing market include Tytan, Krass, S 400, Dow Corning, Ceresit, Ciki Fix, Belinka and Moment.

Titanium Sealant has excellent adhesion to most known surfaces.

Tytan

Under this brand, silicone sealants are produced with special sanitary additives to avoid the appearance of rot and mold even in conditions of high humidity and poor ventilation.

Tytan Professional pastes are recommended for installation of critical joints and joints with high load. Sealants of the S 400 brand also have good biological stability.

Dow Corning

Dow Corning polymer paste is high performance.

Dow Corning polymer sealants provide greater strength. Thick pastes penetrate deep into the seams and gaps, do not drain when applied. The adhesive strength of these agents allows them to be used as adhesives.

Dow Corning pastes tolerate temperature changes very well. The operating range is -65…+260°С. The material withstands a short-term increase in temperature up to +315°C.

The finished coating is resistant to fats, gasoline, detergents and aggressive chemicals. Dow Corning sealants are often used in industrial installations.

Ciki Fix

Ciki Fix Sealant is available as a colorless polymer foam. The material compacts quickly and provides high adhesion to the surface. The finished coating is resistant to wastewater and aggressive detergents. It can be used in the installation of plastic, metal and ceramic pipelines.

Krass

Under the Krass brand, one-component formulations are produced that quickly harden in air.

The coating is characterized by minimal shrinkage, which is important when installing sewer networks. Due to its high strength and elasticity, the sealant prevents deformation of the joint

Krass pastes are suitable for protecting plastic pipes. For metal and combined joints, it is recommended to choose other materials.

Belinka

Belinka sealants are also made on the basis of one polymer - silicone rubber. They are a thick paste that penetrates well into the recesses, does not flow into the pipe during operation. Due to the lack of slip, it is suitable for processing vertical joints. The hardening of the paste occurs under the influence of moisture from the environment.

Belinka compounds are used for both internal and external sewage. During operation, excess paste can be removed with a special solvent or detergents, and after solidification - only by mechanical means.

How and with what to seal the joint when changing from cast iron to plastic

One of the common problems in the sewerage system is the replacement of outdated cast-iron pipes with plastic ones.

In apartment buildings, during major repairs, a cast-iron wastewater riser is almost always left, to which a plastic sewer pipeline is then attached. During the work, the old cast-iron tee is dismantled and a new one made of PVC is inserted in its place, dismantling and installation are carried out in the following sequence:

- Remove the old tee. It is held in a cast-iron socket by means of chasing - that is, a recessed tarred linen cord is smeared with cement or filled with sulfur.

- The tee can be cut or notched with a grinder and then smashed with a hammer (this is very dangerous, you can damage the socket) and then gradually remove the remnants of the sealing materials with a chisel, a sharp screwdriver and a hammer.

Rice. 13 Dismantling the cast iron tee

- In the absence of a grinder, sulfur can be melted with a gas burner (in this case, good ventilation and respiratory protection from sulfur fumes should be ensured), and then the tee can be removed by gradually loosening.

- If the chasing is made of cement, it is gradually knocked out with a thin flat screwdriver using a hammer.

- A universal way to clean the bell from chasing can be drilling it with a drill with a thin long drill.

- Clean up the chimney. After removing the old tee, the socket of the hole is cleaned of dirt with sharp objects, a metal brush and wiped dry.

- They put an adapter ring on the sewer sealant. A sealant is applied to the inner surface of the cast-iron socket and a rubber adapter is inserted (make sure that it fits snugly against the socket), after which a plastic tee is easily attached to it.

Rice. 14 Connection of plastic and cast iron water pipes

Self-adhesive tape

This type of sealant is a relative novelty on the market, which did not prevent it from becoming one of the most popular sealing agents very quickly. Most often, the tape is used for waterproofing metal-plastic and PVC pipes. It consists of a bituminous rubber base and an aluminum or copper layer designed to protect the base from ultraviolet radiation.

The structure of the self-adhesive tape

- High waterproofing efficiency combined with ease of use.

- The high-strength basis providing the long term of operation.

- Complex protection of the pipeline: waterproofing, anticorrosion, dielectric.

- The possibility of using not only for sealing joints, but also for sealing plugs, tie-ins, turning corners, bends and other sewerage elements.

- High speed waterproofing of sewer pipes with the ability to quickly eliminate emergency leaks.

Advantages of silicone sealant

The composition of the silicone sealant includes a silicone polymer and additives that increase its strength, adhesion and accelerate the curing time. Basically, silicone is used for internal sealing of joints, its advantage is the following factors:

- High adhesion of the material with metals, plastics, ceramics, glass, enamel, stone.

- The material provides a long-term elastic connection without cracks.

- The temperature range of silicone is from -50 to +180 C., high-temperature domestic varieties are able to work at temperatures up to +260 C. and for a short time up to +350 C.

Sealing cast iron structures

To seal the joints of cast-iron pipes with their own hands, they use tarred tow made of linen or jute fiber. The work is carried out according to the algorithm:

- Strands are wound on the end of the pipe.

- The structure is inserted into the socket, the fiber is compacted with a special tool - chasing.

- Fill the voids with a solution of Portland cement in a ratio of 9: 1 or fill with a viscous sealant.

Tow fill the joint at 2/3 of the height.When wet, the strands swell, taking up all the free space. You can use a mixture of dry asbestos fiber and cement in a ratio of 1:2. Before use, the ingredients are mixed with water.

Why seal sewer pipes?

Leaks in pipes occur due to installation errors, as a result of wear of pipeline parts or mechanical damage associated with freezing or shock. Violation of tightness can occur due to improper design, non-observance of slope angles and docking of communications. Increased pressure occurs in the connecting nodes, which causes them to deform and, as a result, to leak.

Sealing joints between sewer pipes is carried out in order to:

- Eliminate leakage to the external environment. Polluted effluents, falling into the ground, cause contamination of soil and water. The smell of sewage is nothing but a mixture of gases harmful to human breathing - methane, hydrogen sulfide, ammonia, released during decay of organic waste.

- Prevent flooding of underground structures. A large amount of emissions can erode soils under foundations, fill cellars, basements or basements. The aggressive composition of sewage water causes corrosion of building materials.

Sewage washed away the base of the highway

Sewage washed away the base of the highway

- Protect pipelines from external leaks. When groundwater is absorbed from the soil, sand and earth enter the system. They accumulate in the lumen of the pipes, additionally clog the sewer.

- Extend the service life of communications. Rubber gaskets in the joints age over time, lose their elastic properties. The process is aggravated by temperature changes, alkaline or acidic reaction of wastewater. The tightness of the system is lost, dismantling and costly repairs are required.

To choose the best sealing method, take into account the type of sewer system, the material and design of the pipes. Installation must initially be carried out without errors leading to depressurization. Otherwise, the efforts to glue the joints will be wasted.

Cold welding

Cold welding is a mixture of epoxy resin with special fillers. It is they that give the created product the required qualities, including strong surface adhesion. Thus, the roughness present on the attached surfaces only contributes to their more reliable adhesion to each other.

In appearance, cold welding resembles two-color plasticine. Before use, it must be kneaded and mixed both colors until a uniform shade is obtained. This mixture should then be pressed as quickly as possible to a clean, dry and thoroughly degreased leak.

One of the significant advantages of this material is its excellent adhesion to the surface on which moisture is present. Thus, if a sewer pipe leaks at the joint, the use of cold welding allows you to quickly seal the existing leak.

Cold welding will help to quickly fix the problem in the sewer

The connection created in this way will become reliable after 1 ˗ 24 hours. The exact time depends on the amount of material used and temperature conditions. But in any case, for this period you will have to refuse to use the sewer.

Why sealing sewer pipelines is necessary

Sewer pipelines in the private sector, unlike urban conditions, need improved sealing for the following reasons:

- Soil instability. Loosely connected pipes placed under a layer of earth, when flooded with groundwater or during a spring flood, as a result of weakening or subsidence of the soil, can disperse, which will lead to depressurization of the joint and ingress of wastewater into the soil.

- Temperature effect.In winter, during severe frosts, freezing of the soil to the area where the sewer line is located can occur - this will lead to freezing of sewage drains and the formation of a plug. If liquid is subsequently introduced, the tubulars may rupture under pressure or as ice expands as a result of thawing.

- temperature fluctuations. When hot drains enter the sewer system, hotter areas at the joints can expand, leading to leaks.

- temporary aging. Over time, the tightness of the sewer line connections decreases due to the loss of their physical properties by the material of manufacture and rubber rings in the pipes. This can cause depressurization of the connection and leakage of drains.

Fig 2. The method of sealing pipes made of cast iron

- Difficulty repairing leaks. Since a private sewer line is usually located underground with a slight slope, it is quite difficult to determine the location of the leak - if it occurs at a high point, then the drains will flow down the slope, making it difficult to find. In most cases, you will have to dig out the entire highway in order to carry out repairs.

- Increased damage from leaks. When it enters the soil, sewage, together with groundwater, can reach the aquifer with a shallow well or well. This will lead to the contamination of water with pathogenic bacteria, as a result of which residents may be left without drinking water.

- Strong regular leaks can cause an unpleasant odor due to the presence of gases harmful to humans in the air: hydrogen sulfide, ammonia, methane.

Almost the same problems will have to be faced, with the exception of contamination of water, soil and unpleasant odors, in the event of a depressurization of an underground water main, if it consists of pipe sections and does not have a welded joint.

Pipe Sealant Selection Guide

The choice of sealants is largely determined by the material of the elements on which it is applied and the type of pipeline - in everyday life it is a plumbing, gas, heating or sewer system.

Rice. 10 Sealant for PVC sewer pipes - application

Sealants for sewer pipes

When deciding how to seal a sewer pipe, one should first of all proceed from the material of its manufacture, while several types are considered:

PVC. The PVC sewer pipeline has internal rubber rings at the joints, so it does not need to use any sealants. If it lies underground or in places with loads on the highway, it can be additionally reinforced with bituminous tape.

Ceramics. Due to its high cost and complexity of installation, ceramic sewerage is rarely used in households; internal rubber rings are used to seal joints in pipes, so sealant is not required when connecting them. If a leak is found in the sockets of the sewer pipes, bituminous mastic can be poured, resin-impregnated bundles or outer tape can be used.

Cast iron. For sealing cast iron, inexpensive materials are usually used that have a rigid structure after drying - sulfur, cement, epoxy.

Rice. 11 Use of silicone for heating systems

Sealants for heating pipes

The temperature in the pipelines of domestic heating systems rarely exceeds 90 C. Therefore, almost all known sealants can work in it.

When connecting the elements of the heating system, heat-resistant materials are often used - silicone neutral sealant, FUM tape, plumbing thread or flax fiber, anaerobes form a high-quality thread connection.

Sealants for water pipes

In water supply systems, all of the above sealants for heating systems are used, if the pipes are made of plastic, acid silicone can be additionally used.

Rice. 12 Sealants for water lines - application example