Floats on mounting bar

Up to several switches can be located in one tank, each of which has its own function: one controls the auxiliary pump, the other the main one, the third acts as an emergency water level sensor, the fourth monitors the overflow. In any case, the number of floats is determined by the number of connected pumps, as well as the need for protective devices in the system. Fasteners of several floats are made on a special mounting bar. In its role, you can successfully use a plastic pipe, securely fixed in the tank. Floats-switches are fixed on the rod at a distance from each other so as not to interfere with the work of a neighbor. The cable of each switch is fastened with clamps. There are situations when the need dictates the use of several rods at once for attaching floats. Taking into account the working conditions and the specifics of the project, the number of float-switches necessary for organizing the work of a particular system is determined.

There are two types of float switches:

- Lightweight - for a system that controls water supply or water discharge;

- Heavy - designed to control drainage or fecal pumps.

Float in pump device item description

Both drainage and submersible float pumps operate under conditions in which debris can enter the liquid or it can end. In the first case, solid waste fractions can severely damage the system. In order to avoid this, the pumps are equipped with shut-off floats, which operate when there is no water or if there is a large amount of debris in it.

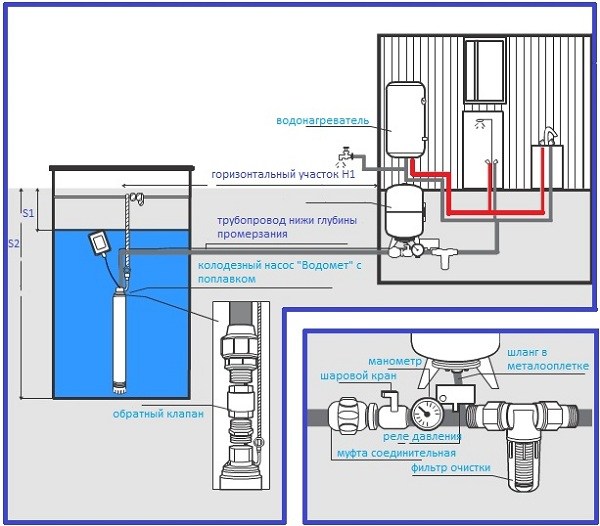

The pumps can be placed and operated in various tanks, wells or wells. Depending on where the unit is used, the function of the float may differ. However, in all cases, the tasks of floats include:

- Adjustment of the main pump;

- Adjusting the operation of the auxiliary pump and increasing its efficiency;

- Water level alarm;

- Overflow alarm.

A liquid level indicator is required in order to prevent the pump from running dry. The overflow alarm is necessary to exclude the possibility of overfilling the tank in which the pump is located. Often this leads to a short circuit of the device.

1 Working principle and features

1.1

Types of float drainers

The classification of drains is carried out depending on the method of their location. There are submersible and surface type pumps. There are also units with a vertical float switch.

1.2

Drainage pump with built-in submersible float

The submersible drainer has a sealed housing, which allows it to function when completely immersed in water. Such designs are often more powerful than surface type pumps, since they need to lift the pumped liquid to a greater height, which requires high pressure.

Compared to surface drainage pumps, the submersible unit has the following advantages:

- Minimum noise during operation;

- High productivity;

- Versatility - such pumps are capable of pumping liquid with a large amount of mechanical impurities;

The disadvantages include:

- The complexity of the repair, due to the violation of the tightness of the body during disassembly;

- The need for periodic cleaning of the pump and float switch, as they clog very quickly in dirty water;

- Limitation - a submersible drainer is not able to pump out effluents from shallow water bodies (a minimum depth of 30 centimeters is required, as this requires constant cooling of the electric motor with water)

1.3

Drainage pumps with built-in surface type floats

In such devices, sewage is taken in through a sleeve - a rubber hose, or a PVC pipe that descends into the waste liquid, while the pump housing itself is located on the ground surface. The float switch on an extended cable is lowered into the wastewater along with the hose.

The main advantages of such pumps are ease of installation and maintenance. The disadvantages include the noise that the device emits during pumping water. The cooling of the power unit in such devices is carried out by means of a pumped liquid.

1.4

Drainage fecal pumps

Fecal pumps are used to pump sewage from septic tanks and cesspools. In fact, they are an improved version of a conventional drain, and can fully perform all of its functions. A feature of such devices is increased power - since fecal effluents are generally much thicker than ordinary sewage.

The fecal pump has an additional structural element - a special mesh that crushes large waste. According to the location method, such a device is identical to conventional drains: there is a submersible and surface fecal pump.

1.5

Vertical drains

Such pumps are equipped with a vertical float switch, which allows automatic pumping of water from confined spaces. Most often, vertical float pumps are used to drain failed pipelines. If necessary, they can be operated as conventional drains.

1.6

Main manufacturers

Today, the range of drainage pumps in the domestic market is clearly divided into two categories: budget devices, which include a variety of domestic and Chinese manufacturers, and expensive foreign pumps.

An analysis of supply and demand showed that in the category of budget drains, the Malysh pumps are the best option, while Grundfos is the leader in the segment of high-quality devices.

1 Description of the float switch

Submersible and drainage pumps operate in conditions where the liquid can suddenly run out or become contaminated. In this case, further pumping of water already mixed with a large amount of dirt can seriously damage the system. Therefore, it is mandatory to have a float switch for pumps in order to prevent damage due to dry running. Some floats require self-installation, while other pumps come with an internal float.

They are placed in a variety of reservoirs - from tanks in wastewater pumping systems to drinking water wells. And the tasks that floats perform, depending on the place of use, may vary. It is also possible to put more than one float in one tank, each of them performs different tasks:

- control over the operation of the main pump;

- control over the operation of an additional (auxiliary) pump, as well as improving its efficiency;

- level sensor;

- overflow sensor.

The level sensor is necessary so that the submersible pump does not run dry and thus does not suck in heavily polluted water, which leads to a breakdown of the entire station. An overflow sensor is required to keep the water tank from overflowing. Depending on the type of container, this can lead to serious problems, up to a short circuit.

1.1 Varieties of floats for pumps

Float switches are connected to various types of pumps, and can also be built-in. To install a separately purchased float on the pump does not require much effort and extensive knowledge.A pump with an integrated float is much simpler, albeit more expensive, if you need to provide the system with float control as quickly as possible.

There is a light drain pump with a built-in float switch and a heavy one. The first type is suitable for a pump with a float used in water supply - wells, wells. And also in systems of water disposal. The second drainage pumps with a built-in float, heavy, imply, firstly, a polluted environment, and secondly, difficult operating conditions. Drainage pump with a float of the second type is used in drains: sewer, rainwater, drainage.

You should start your choice of a water level sensor by defining goals - for water supply to a summer house, farm, house, watering a plot, an easy one is better suited. To organize a sewer system, drainage or waste, it is recommended to purchase a heavy unit.

1.2 Specifications of the float switch

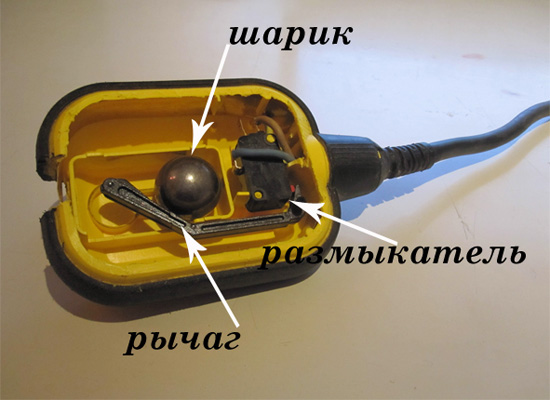

The body of the device is made of plastic materials of various shapes. It requires absolute tightness and water tightness. The float consists of the following elements:

- floating body made of plastic;

- electrical switch;

- lever for switch contacts;

- steel ball;

- three wires in a cable.

The wires are connected: one to a closed contact, the other to an open one, the third is common. There are floats with two wires. They break the electrical circuit if it is necessary to turn off the submersible pump and connect the circuit if it is necessary to turn it on again. Three-wire switches are universal, they are suitable for monitoring not only dry running, but also overflow. There is one common and two wires, between which the modes are switched.

The wires are different in color. Common, as a rule, is the black wire. The blue wire shuts off the system when the pumping pump starts to "run aground" and there is too little water in the tank (for example, in a well). The brown wire regulates the pump when the tank is full.

Depending on the length of the wire from the weight to the float, the values at which the pump turns on or off will change. Thus, they are easy to manually adjust to prevent overflow or dry running. It is also worth considering that the float should turn off the work at a time when the pump is still under water with a small margin.

The steel ball adjusts the position of the lever depending on the position of the float itself. The lever, in turn, switches contacts to turn the float pump on or off. Magnets are used to fix the ball in the required positions. The inclination at which the ball moves from one position to another is most often 70 degrees, but it should be clarified when buying a device.

Features of the float switch for water level control:

- degree of protection against penetration IP - 68;

- mains voltage 220 volts plus or minus 10 percent;

- operating temperature range from 0 to +60°C ;

- 8 amperes - maximum switching current for reactive load;

1.3 How does the automatic float switch work? (video)

Equipment classification

Float sensors can independently control the liquid level or send a signal to the control circuit. According to this principle, they can be divided into two large groups: mechanical and electrical.

Mechanical devices

Mechanical valves include a wide variety of float valves for the water level in the tank. The principle of their operation is that the float is connected to the lever, when the liquid level changes, the float moves this lever up or down, and it, in turn, acts on the valve, which shuts off (opens) the water supply. Such valves can be seen in toilet cisterns.They are very convenient to use where you need to constantly add water from the central water supply system.

Mechanical sensors have a number of advantages:

- simplicity of design;

- compactness;

- safety;

- autonomy - do not require any sources of electricity;

- reliability;

- cheapness;

- ease of installation and configuration.

But these sensors have one significant drawback: they can control only one (upper) level, which depends on the installation site, and regulate it, if possible, then within very small limits. On sale, such a valve may be called a "float valve for containers."

Electrical sensors

An electric liquid level sensor (float) differs from a mechanical one in that it does not shut off the water itself. The float, moving when the amount of liquid changes, acts on the electrical contacts that are included in the control circuit. Based on these signals, the automatic control system decides on the need for certain actions. In the simplest case, such a sensor has a float. This float acts on the contact through which the pump is turned on.

Reed switches are most often used as contacts. A reed switch is a sealed glass bulb with contacts inside. The switching of these contacts occurs under the action of a magnetic field. Reed switches are miniature in size and can be easily placed inside a thin tube made of non-magnetic material (plastic, aluminum). A float with a magnet moves freely along the tube under the action of the liquid, when it approaches, the contacts are triggered. The whole system is installed vertically in the tank. By changing the position of the reed switch inside the tube, you can adjust the moment of operation of the automation.

https://youtube.com/watch?v=HFM-k0jItxM

If you need to monitor the upper level in the tank, then the sensor is installed at the top. As soon as the level falls below the set level, the contact closes and the pump turns on. Water will start to increase and when the water level reaches the upper limit, the float will return to its original state and the pump will turn off. However, such a scheme cannot be applied in practice. The fact is that the sensor is triggered at the slightest change in level, after which the pump turns on, the level rises, and the pump turns off. If the water flow from the tank is less than the supply, a situation arises when the pump constantly turns on and off, while it quickly overheats and fails.

Therefore, water level sensors for pump control work differently. The container has at least two contacts. One is responsible for the upper level, it turns off the pump. The second defines the position of the lower level, upon reaching which the pump turns on. Thus, the number of starts is significantly reduced, which ensures reliable operation of the entire system. If the level difference is small, then it is convenient to use a tube with two reed switches inside and one float that switches them. With a difference of more than a meter, two separate sensors are used, installed at the required heights.

Despite the more complex design and the need for a control circuit, electric float sensors allow you to fully automate the process of controlling the liquid level.

If bulbs are connected through such sensors, they can be used to visually control the amount of liquid in the tank.

Float maintenance and repair

Subject to the operating rules, the float to turn on the pump will work for a long time and properly. If the element is used in clean water conditions, then it does not require special maintenance. If the float is used when working with dirty water and a large amount of solid fractions, then it, like the entire system, must be washed under running clean water. This must be done at least once a month.In this way, you will protect the part from sticking to the pressure pipe or to the pump.

In the event that water gets inside the float, its contacts burn, or the integrity of the cable insulation is broken, all defective elements must be replaced, since they cannot be repaired. If the electronic float itself is completely out of order, then it must be changed in special service centers.

How to connect a float switch to a pump

The float setting can be done in different ways. Before installation, make sure that the current that the pump consumes is less than the maximum allowable current indicated in the system manual.

The easiest way to install a float is the tank mounting method. with cable and a special sinker, which is included with the unit. The float is mounted according to the following algorithm:

- First, the sinker must be put on the cable and the free play of the float must be determined;

- After that, the sinker must be fixed on the cable with a latch;

- Next, you need to fix the cable on the outside of the tank.

After installing the element, you should connect the float switch to the pump. Before you set up the float, you need to carefully study the diagrams that come with the device.

After connecting, you will need to check if the system is working. To do this, start the pump and wait a couple of hours. If the device pumps out water stably, then the installation and connection were performed correctly.

Float switch in action

Before connecting a newly acquired float switch to the pump, it is advisable to make sure that their specifications are compatible. An elementary way to set up the switch for electric pumps is inside the water tank.

Sequential connection diagram of the float switch:

- A special sinker (from the kit) is attached to the float cable.

- On the edge of the tank, the cable is securely fixed.

- The amplitude of the float-switch free play is adjusted to set the highest and lowest level, upon reaching which the float-switch will work.

- The float switch is connected to the pump last.

The main functions performed by the float switch:

- A float connected to a pump that has a tank filling task will cut out when it rises and turn on when it reaches the bottom mark.

- For an automatic station: switching on when the upper liquid level mark is reached and switching off at the lower one (reaching the bottom of the tank).

- Servo operated valves or gate valves: the switch will signal to close when it is in the top position (full capacity) and open the way for water when it reaches the bottom position.

- Control room: monitoring excess and lack of water.

It is possible to bring two pumping devices to one float: the function of the first pump is to fill the tank at the moment of the lower position of the float, the mission of the second one is to pump out water at the moment of the upper position. The scheme is effective only in the case of uninterrupted water supply to the tank. Some connection options for switches to prevent pumps from running dry.

The role of signaling devices in drainage pumps

Drainage pump with float switch is widely used in industry and in everyday life. The scope of its use is cleaning wells, removing dirty liquid, etc. In the drainage pump, the float is endowed with the function of turning the drive on and off automatically. The switch is lowered into the wastewater by means of an elongated cable along with a liquid intake pipe. The vertical type drain pump kit includes a vertical float-switch with the function of pumping liquid from an enclosed space.Such a drainage pump can, for example, drain idle pipelines.

Making a float switch with your own hands

To make the part yourself, you will need to prepare:

- Metal ball;

- 2 buildings;

- 2 small magnets;

- contact plates.

Plates can be made from brass or copper. They should be on different sides of the case so that the ball between them can close the contact. To make the metal strips more springy, they can be put on a file and beat off with a hammer.

The magnets should lift the ball up and hold it at a 65 degree angle. The case itself can be made from any material that does not conduct electricity. Further work looks like this:

- First, wires with a cross section of not more than 2 mm are soldered to the contacts;

- Next, the wires must be insulated and placed in the housing;

- It is also necessary to carefully insulate the inside of the case;

- It will be necessary to fill the float cavity with mounting foam and insulate the outer side of the body;

- After that, at the ends of the case, you need to install the loops and connect the cord.

The manufactured float will last long enough, and you will save a lot of money on the purchase of equipment.

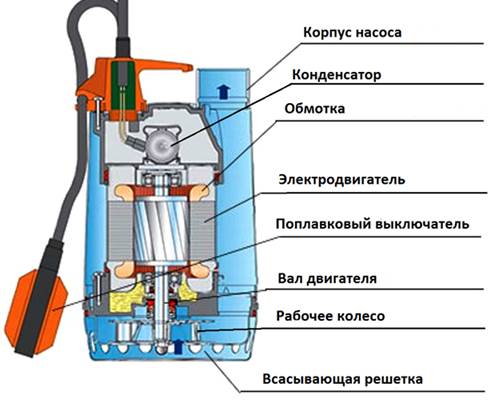

The device and principle of operation of the drainage pump

The device of the drainage pump is quite simple, its main elements are:

Frame

A typical drain has two housings: external and internal. The main unit of the device is located in the inner case - the electric motor, which is cooled by the water flow washing it, following between the cases to the outlet located at the top.

The outer case of the device is equipped with a convenient handle for carrying or hanging in the water column, it also has an outlet pipe (pipe) to which hoses are connected.

The inner case for better cooling is made of metal, the outer material is usually metal (stainless steel) or impact-resistant plastic.

electric motor

In the inner, fully insulated casing of the pump, there is an electric motor consisting of a stator with a winding and a rotor, the shaft of which rotates on the upper and lower bearings. Power is supplied to the electric motor by means of a cable through a hermetic input unit; a capacitor is built in for starting.

For lubrication and cooling of bearings, special chambers are provided in the lower part of the inner housing, filled with technical oil. There are also sealing rings that prevent the penetration of water into the engine.

Working wheel

The impeller in the form of a disk, on which curved blades are placed, is fixed to the motor shaft. The usual material for its manufacture is metal, sometimes it is made of high-strength plastic.

Water intake filter

At the bottom of the pump housing is a stand with legs, on which the pump is usually placed. A little higher is a cover with water intake holes (filter), which excludes the possibility of particles with sizes exceeding its technical characteristics penetrating into the electric pump.

float switch

Almost all designs of drainage systems are equipped with this system. The switches automate the operation of the float drain pump by cutting off the voltage supply to its electric motor when the liquid level drops, and re-applying the supply voltage when the working tank is filled.

The principle of operation of the drainage pump is as follows. When voltage is applied to the electric motor, the impeller starts to rotate. It draws liquid into itself through a hole located in the center of the electric pump body, and the centrifugal force pushes the liquid out through the outlet channel.

Drainers can work in environments with varying degrees of pollution, which is determined by the operating conditions, so before choosing a drainage pump, you should pay attention to the particle size or filter. When choosing the right product, it is better to give preference to devices in a metal case with a metal impeller; for domestic conditions, a capacity of about 10 m is sufficient

cubic/h

We advise you to read: Repair of submersible pumps

You might also be interested in reading:

By using the oBurenie.ru website, you automatically agree to the privacy policy for using any available means of communication such as: comments, chat, feedback form, etc.