1. Requirements for ventilation pipes

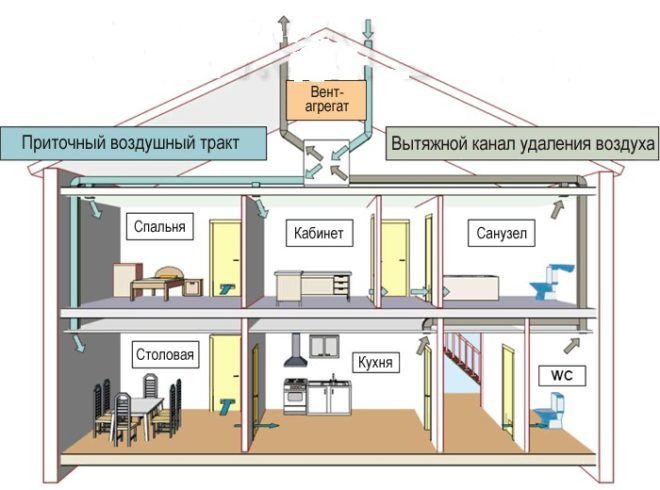

It is good if the arrangement of the ventilation system takes place at the stage of building a house, because in this case the air ducts can be hidden, and they will not violate the aesthetics of the room. Channels are allowed to be laid out with bricks, but this is a long process. Today, mainly special ventilation pipes are used, which simplify and speed up the entire installation process.

Note that most often ventilation ducts in a private house are necessary to remove air. However, if it is necessary to take all air movements under maximum control, forced supply and exhaust ventilation is equipped. This is a complex system, but in this case, pipes will also be needed in order to bring fresh air from the street.

The choice of duct material and its diameter depends on a lot of factors. First of all, this is the type of room and the characteristics of the air to be removed (temperature, chemical composition, etc.). Be that as it may, and whatever option your choice falls on, there are a number of requirements that the duct must meet:

- perfect tightness;

- the ability to ensure the free passage of an air flow of a specific volume and at a given speed;

- safety for human health (non-toxicity) and minimum noise level during the passage of air masses;

- if the pipes are not hidden, then decorative qualities are also important.

Vacuum valve installation rules

The installation of a vacuum valve implies compliance with the following rules:

- the device should be installed at the top of the riser in a heated room. If the air temperature drops below zero, the vacuum valve will not work effectively;

- the device is installed above the drains of plumbing fixtures;

- in the presence of a shower stall, the vacuum valve is installed at a level exceeding a distance of 35 cm from the location of the drain;

- the mounted device should be provided with good access for maintenance and repair work.

What is a sewer vacuum valve for?

Rules for arranging ventilation

- Such a riser must necessarily be displayed on the roof of the building and be at least 1 meter high from the level of the ridge.

- The outlet of the fan system must be located no closer than 4 meters from the nearest window or balcony.

- Its diameter should be the same as the sewer pipe.

- It is forbidden to combine the fan pipe with the general house ventilation system.

- It is not recommended to install a deflector on its head, as it can freeze to block the free exit of air.

The choice of a fan pipe

For organizing "sewer ventilation" in a private house, it is best to choose PVC pipes. Ventilation from sewer pipes has a number of advantages:

- Light weight.

- They are easy to mount.

- PVC pipes have a large number of additional elements. (mounts, turns, corners)

E

For sewerage ventilation of a one-story house, you can use a plastic pipe with a diameter of 50 mm, and if the house consists of more than one floor, then a PVC pipe is needed with a diameter of at least 110 mm.

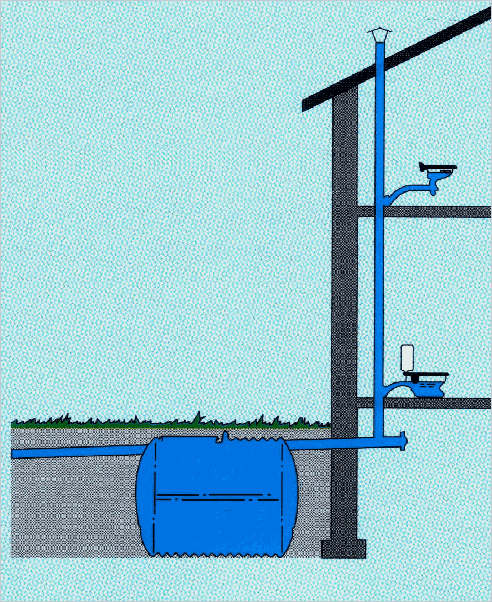

Ventilation of the external type arrangement of the system

When equipping the house with an autonomous sewerage system, it is possible to use external ventilation. There are two possible locations:

- outlet of the hood along the wall panels of the house. In practice, this looks like a drain with the end of the pipe above the roof level.The scheme provides for the withdrawal of the structure from the house and fastening to the wall element by means of clamps;

- installing pipes on a septic tank is a convenient option, since the pipe is located far from the house and completely minimizes the possibility of smell entering the rooms.

External sewer ventilation in a private house is equipped in the absence of a sewer riser, which happens in small buildings or seasonal residences. The use of this method involves the arrangement of a vacuum valve to improve the ventilation system.

Non-standard solutions for the arrangement of the ventilation system

If a building with a sewer system is built, and it is difficult to change them physically or materially, several alternative ventilation options can be used. They do not contradict the basic building codes, they are quite effective. The device of the presented schemes is possible in the presence of a septic tank or other treatment facilities. If they are present on the site, you can try to install the hood in several ways.

Examples of alternative ventilation arrangements

Installation on the wall of the building. The presented option is considered to be advantageous, since the ventilation duct will not outwardly differ from a conventional drain

It will not spoil the appearance of the building, which is important for many owners. When installing, the pipe is brought out above the roof level

Its diameter is 110 mm. It is also recommended to mount the exhaust pipe away from windows in order to prevent the spread of an unpleasant odor.

Fence installation. Installation of ventilation is no different from installation on the wall of a building. It is recommended to take into account that the hood is removed from the building for a considerable distance. When installing it, one should take into account the placement of the main and additional buildings on their own and neighboring sites.

Septic tank ventilation. The treatment plant should be located at a distance of 5-20 m from the building (depending on the requirements of regulatory documentation). This will prevent the entry of an unpleasant odor into the living quarters. Installation of a septic tank ventilation pipe can be carried out at the final stage of construction. Installation is not difficult to perform.

The choice of the variant of the sewer system exhaust device is carried out on the basis of its initial parameters, the needs of the residents. A fan pipe, a vacuum valve are the best solutions that most private property owners prefer. The presented alternatives are not always successful, but acceptable.

Video: Ventilation of a private house

A selection of questions

- Mikhail, Lipetsk — What discs for metal cutting should be used?

- Ivan, Moscow — What is the GOST of metal-rolled sheet steel?

- Maksim, Tver — What are the best racks for storing rolled metal products?

- Vladimir, Novosibirsk — What does ultrasonic processing of metals mean without the use of abrasive substances?

- Valery, Moscow — How to forge a knife from a bearing with your own hands?

- Stanislav, Voronezh — What equipment is used for the production of galvanized steel air ducts?

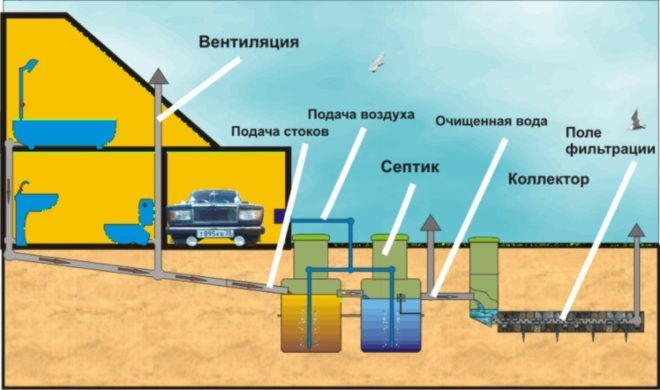

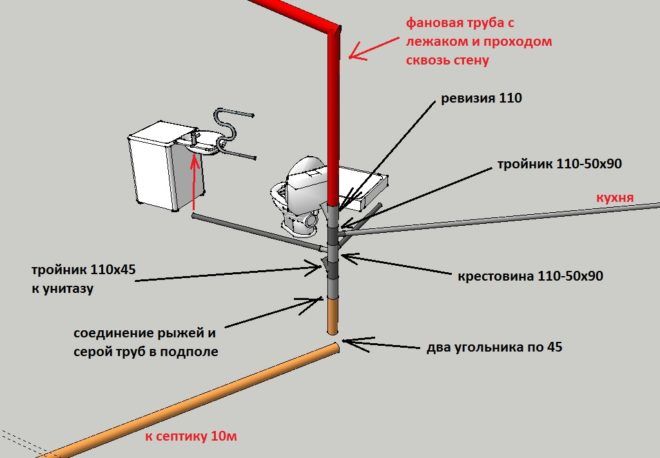

Installation of a fan pipe

Effective ventilation of the riser of the sewer system is formed using a fan pipe. It is a kind of continuation of it. The principle of operation of the fan pipe is quite simple. Warm air inside the sewer riser rises to the outside. A kind of traction is formed in the system. It helps draw air out of the room. Therefore, unpleasant odors can leave the sewer system. As a result, the comfort of the owners will not be disturbed.

When constructing a sewer riser using a vent pipe, the following rules should be followed:

- the fan pipe rises above the roof level by 500 mm (more is allowed);

- the diameter of the exhaust system must correspond to the diameter of the sewer riser;

- if there are 2-3 sewer risers, they can be connected at the top point and exit through a single fan pipe;

- it is strictly forbidden to combine a sewer hood with a stove or building ventilation;

- it is not advisable to install a fan pipeline near windows, balconies. This will lead to the spread of an unpleasant odor inside the building. The fan pipe moves away from the windows at a distance of 4 m;

- in the presence of a multi-pitched roof, it is forbidden to bring the ventilation pipeline under the slopes. It can break under the weight of the snow cover;

- it is not recommended to install a deflector on the upper cut of the hood. There is a possibility of condensation. The resulting liquid freezes in winter at sub-zero temperatures, which will significantly reduce the efficiency of the hood;

- the fan pipe is made from materials used for the production of sewer risers. Cast iron quickly breaks down under the influence of the environment. Its use is not allowed.

4. Corrugated ventilation pipes

Ventilation pipes can be divided into two large groups:

- hard;

- corrugated.

The former keep the shape given to them at the factory, the latter, due to the presence of numerous ribs, can take virtually any shape. Naturally, the installation process is greatly facilitated, because there is no need to use all kinds of connecting elements, but not everything is so simple.

The main advantages of corrugated ventilation pipes include:

- flexibility and elasticity. The product can be bent at any angle, give it the desired shape, and this is an invaluable quality when it comes to installing ventilation in difficult areas;

- strength;

- ease of installation;

- there is no need to use tees, adapters and other auxiliary elements.

It does not make sense to build the entire ventilation system only from corrugated pipes. Of these, only those parts of the air ducts are equipped, where, when using rigid pipes, too many turns and connections would have to be made. Everyone knows that the more bends, the worse the air will pass, but a smooth bend in terms of aerodynamics is much better than turning at an angle, so a corrugated pipe is chosen from two evils.

Why is the corrugation used only on short complex segments? Because it has a lot of cons:

- the ribbed surface impairs the airflow performance, slowing it down and reducing the ventilation efficiency. If in short sections this is not particularly noticeable, then in long sections the effect will be impressive;

- the appearance of vibrations and noise with a stable strong air flow;

- mounting difficulties.

The fact that the corrugation is not used in long sections is also confirmed by manufacturers who do not produce connecting elements for this type of pipe.

Corrugated pipes can be:

- aluminum, more precisely, made of multilayer aluminum foil, they are slightly heavier than plastic, more prone to condensation, but tolerate higher temperatures;

- plastic pipe is made on the basis of polymers, which are reinforced with aluminum. Such products are lighter, less noisy, but will not withstand high temperatures.

Use of vacuum valves

In general, a vacuum valve is not used in the design of ventilation of the sewer system, but some craftsmen, due to lack of money or laziness, or because of the impossibility of arranging this building, do not install a vent pipe on the sewer riser, but use it. And, most importantly, it works.

The principle of operation of the valve is surprisingly simple: at the moment a vacuum is created, it opens slightly, allowing air to enter the sewer.As a result, the created negative pressure is balanced by atmospheric pressure, and there is no outflow of water from the hydraulic seals. After equalizing the pressure in the sewer, it closes, blocking the way for the stench.

Disadvantages of Vacuum Valves

In addition, the valve can freeze, get dirty, it is not immune from jamming and rotting, etc., so it cannot be called a complete replacement for the ventilation of the sewer system.

Why ventilation is needed

According to modern building codes, sewer ventilation in a private house is mandatory if the building has more than 1 floor. The hood is installed when the system contains risers with a diameter of more than 50 mm.

If ventilation is not provided, when a large volume of liquid is drained, the lumen of the pipeline is blocked, which leads to the formation of a vacuum. As a result, water is sucked out of the siphons. This element of the sewer system is a kind of valve that blocks the movement of an unpleasant odor outward. In the absence of water, the siphon is not able to perform its intended function.

Unpleasant sewer odors appear when the sewer system is designed and installed to meet building codes. If the drainage in the building is small, and there is no complete blockage of the sewer pipe, the water from the siphons may evaporate. This happens when you do not use a plumbing fixture for 3-5 days. Modern siphons have a small volume, which reduces their cost, but worsens their efficiency.

When arranging the ventilation system, the installation of a fan pipe or a vacuum valve is chosen. The first way is more efficient. Installing vacuum valves will not always give the desired result.