How to choose sleeve sizes

When it is necessary to choose the appropriate size of the sleeves and determine the size of the protrusion of the sleeve on the surface of floors or walls, ceilings,

Features of the use of sleeves, depending on their material and material of construction.

The inner surface of the steel sleeve is sharpened from burrs, which can damage pipes made of polymer material, the presence of roughness is dangerous for a pipeline system operating under pressure.

The edges on steel sleeves are flared, that is, they are bent to the outside, removing burrs from the surface.

Sleeves made of polymeric materials have a low level of adhesion with cement mortar. Sleeves in elements made of wood and polymer are hermetically sealed using special technologies.

Ruberoid is not suitable as a material for sleeves, since it contains elements of oil, and this substance can in no case come into contact with polymer pipes. The material from which the sleeve is made must prevent the spread of fire from room to room.

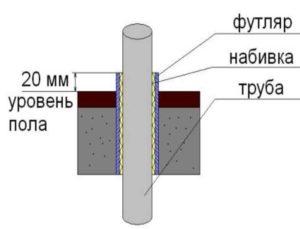

When pipelines cross the foundations of buildings, requirements must be observed that will prevent groundwater from entering the basement. In this case, it is necessary to take into account the process of shrinkage of the sewer system and the foundation. The gap between the sleeves and pipes should be treated with mastic, sealant, while the outer section of the sleeve should be twenty centimeters larger than the same pipe parameter (according to SNiP 478-80).

Sewerage and water pipes, when crossing floors, are also hidden in cases designed for protection. The place between the case and the concrete floor is poured with cement. If the partitions are wooden, then the space is filled with asbestos.

To compensate for changes in the pipe during temperature changes of horizontal copper water pipes, a sliding support is used during their passage through walls and ceilings. During the development of the project, a place is determined for neither. In the place where the pipe exits the wall, tees and elbows are placed to help keep the location of the water pipes of the new room close to the wall surface.

General information

Features of installation of internal sewerage

It is necessary to carry out the installation of the pipeline so that when materials of different strength come into contact, the structures last for many years.

There are general rules for arranging sewer risers through structural slabs.

If metal-plastic pipes pass through the floor structures, then they are placed in special tubular plastic cases of a suitable size.

Factors that determine the use of sleeves

2. Polymer pipes are subject to changes with temperature changes depending on different seasons, time of day. Sleeves protect pipelines when moving inside ceilings.

3. The use of sleeves allows you to dismantle the damaged section of the pipe without destroying the entire sewer. It is not necessary to always put all the elements in the sleeve, this is due to the presence of emergency circumstances. For example, a cold water pipeline made of polymer will have to be completely replaced only after fifty years, when its operational life expires.

4. If you properly seal the gaps formed by a sleeve with pipes that are laid through the walls of buildings, as well as their ceilings, then you can completely get rid of the ingress of smell, insects from neighboring rooms.