Problems in the mechanism and their elimination

What problems can arise during the operation of the drain mechanism? For example, water may not be drawn into the tank, or the water is now not blocked. The reason for this phenomenon, most likely, lies in the fact that any of the holes is clogged. Another reason for such malfunctions is the failure of one of the two most important parts of the mechanism - the stem or the membrane.

In any case, you will have to disassemble the device and check all the elements. They will also be thoroughly washed and cleaned. But it happens that the cause of malfunctions is a banal low pressure in the water supply system, or its jumps within one day. In this case, the device may simply not work.

If the pressure drops too low, then the water will stop flowing into the tank at all. If the water must come from a suspended structure, then at a pressure below the norm, the water will not even be able to reach the filling chamber. The float will float, but it will not block the water. To cope with this situation, you may even have to increase the water inlet holes by reaming them a couple of millimeters.

In general, the smaller these holes, the greater the pressure should be in the system. This must be taken into account if you are installing a drain mechanism, for example, in the country

If you know for sure that you regularly experience pressure surges during the day, for example, if the water pressure in your house is maintained by pumps that turn off at night, then it is best to pay attention to fittings with a stem valve

That's all, we examined the drain device, as well as the reasons why it can fail. Now it will not be difficult for you to understand everything and troubleshoot.

The time when toilets ceased to be a luxury, after street closets, has long been a thing of the past. However, their installation in apartments required the completion of a latrine with filling and draining systems. After all, without these systems, there can be no talk of any amenities or hygiene, the toilet bowl will simply turn into a stationary pot, which will have to be constantly cleaned and washed by hand. However, this situation is familiar to many, when the cistern device begins to live its own life, incorrectly performing its assigned functions.

It would be useful for a home master to know how common models of sanitary mechanisms of toilet bowls function and are configured, for which we will consider what the majority of our compatriots use today.

First of all, they depend on the type of filling and drainage mechanisms. The functions of draining water are performed by products of lever, push-button and automatic execution.

Lever

Lever models - were the main models installed on the toilets of the last century. In some places they are still in use today. Lever devices are distinguished by their simplicity. The first products worked out the drain only at the moment of pressing, while the shut-off valve was held manually (by the “puller” - a chain or fishing line). Then there were systems using the siphon effect, which themselves control the flow after activation. But both the first models and the subsequent ones are distinguished by an increased unregulated water flow. In addition, such plumbing does not meet the current requirements of aesthetics.

push-button

The flush mechanism for the toilet bowl, made in the push-button version, is installed on most modern plumbing products. The predominant location of the button is top, on the covers of compact systems, and can also be wall-mounted for products installed in building structures. Their advantages, in addition to good aesthetics, are the ability to adjust the parameters of the drain and overflow. Push-button mechanisms also, after activation, keep the shut-off valve in the open state without human intervention.And models with paired buttons allow full or partial discharge of liquid into the toilet.

Automatic

Today, rare and expensive products for draining water that justify themselves when installed in elite products or used in public places. Their work is controlled by touch infrared sensors.

The shut-off valves for the toilet bowl, represented by filling mechanisms, work, as they did many years ago, using the principle of a feeding tap opened and closed by a float. In the classic version, the float transmits force to the faucet valve with side supply through a horizontal rocker.

However, now more often floats are installed that move along a vertical guide, blocking the water supply through a system of levers for both the side connection and the bottom one.

Installation

To install the valve, you do not need to have specific skills. It is enough to follow the step-by-step instructions without violating the sequence. Installation steps:

- Before installing the valve, free up space in the place where the mechanism will be equipped.

- Turn off the water so that it does not interfere with work. Drain excess fluid through the system output system. To do this, there must be separate taps.

- The whole pipe is cut with a cutter to the size of the locking element.

- At the ends of the pipes, threads are cut using special dies. Chips are removed with a metal brush.

- The thread is covered with a sealing thread to create a more reliable connection. Some plumbers use sealant.

- The valve is installed between the pipes, screwed onto the thread. Clamped with a wrench.

Next, the valve opens, which held the flow of fluid. It is necessary to check the reliability of the connection at different pressure levels. So you can replace the old valve at home

It is important to monitor the screwing of the locking element onto the thread. Do not allow distortions that can destroy the integrity of the system

If the valve is flanged, additional pipe preparation is required. To do this, they are cut, metal plates with holes for fasteners are welded along the ends. Next, a valve is installed between the pipes. A rubber gasket is fixed between the flanges with waterproof glue. The structure is fixed with bolts and nuts. Optionally, flanges can be welded using a welding machine. The seam must be cleaned with a grinder, covered with an anti-corrosion compound.

Shut-off valves are essential elements of any system that works with gases, liquids. With their help, the power of the liquid or gas supply is changed, the flow is completely blocked. Installation can be carried out by anyone, knowing the step-by-step instructions.

School of TPA. Stop valve. Part 1.

Classification of locking devices

Control valves are available in several classifications. According to the installation method, the following elements are distinguished:

- Coupling - models used in the manufacture of household highways. They are fixed between pipes with threaded connections. Can be attached to products up to 150 mm in diameter. To install the coupling part, you need a wrench.

- Flanged shut-off valve. The part is fixed on the pipeline with bolts, nuts. For this, round or square plates are welded at the ends of the structure, which have mounting holes. The maximum pipe diameter is up to 1000 mm.

If we talk about sealing, then the following elements are distinguished:

- Bellows - designs that have a special corrugated tube.

- Omental models. They have an additional chamber, which has a sealing packing from the inside.

Types of pipeline fittings:

- Gate valves - used in systems with a low level of hydraulic pressure.

- Valves are shut-off valves that are used to shut off or regulate the flow of fluid through a pipeline.

According to the structure, there are two types of valves:

- Corner - the design allows you to fasten pipes running perpendicular to each other.

- Through passage - are installed on vertical or horizontal pipelines.

Most valves are manually actuated. However, there are models with an electric drive that automatically regulates the supply of the working mixture.

Installing drain equipment

As you already understood, the fittings for the tank play a really very important role. must be installed correctly. To do this, you need to go through three stages:

- Install a drain tank on the toilet shelf;

- Connect the installed tank to the water supply system;

- Adjust valve operation.

Installation steps

First of all, a gasket made of rubber should be fixed on the shelf. Often manufacturers offer self-adhesive rubber bands, so they fit better and more securely. Then the tank should be fixed with special bolts, which have tapered rubber gaskets. Moreover, the sharp ends should be directed into the holes. Due to this shape, the gasket better protects against leaks. In principle, it remains to bring the bolts into the holes and complete the installation of the tank with nuts

Here it is very important to carefully tighten so as not to overtighten and thereby damage the ceramic product. It often happened that during installation a person overdid it, as a result of which the newly purchased toilet bowl went to the trash.

Now you should connect the hose to the cold water supply system

Be sure to make sure that the washer-gasket is present in the connection. If it is not, the flow is guaranteed. Turn on the water and check the tightness of the installation. If moisture does not appear on the connection, then you did everything right. The toilet is now ready to be put into operation.

Inlet valve mechanism

The inlet fitting in the tank has its own principle of operation, which should be understood before proceeding with its replacement or repair. Consider the phases that replace each other in the process of moving water to the tank.

So, the first phase is characterized by the fact that the valve is in the open position. At this time, water is drawn into the tank. The membrane, following the direction of the water flow, moves away. This means that water can freely enter the tank.

Initially, water fills only the preliminary compartment. For water to enter the tank itself, a special hole is provided in this compartment. This process is very similar to what happens in devices equipped with valves with a stem, but here there is a membrane that is stretched over the piston. The membrane has a gap through which a plastic rod passes, which also has a gap of 1 mm in diameter. Due to this, some of the water enters the filling compartment. It is formed by the membrane itself and the piston.

If the float is lowered, then a small hole opens in the piston, only about 0.5 mm. Through it, a small part of the water can enter the tank. Thanks to this mechanism of action of the membrane valve, the same pressure is ensured in the preliminary compartment, in the filling compartment and behind it. This is the difference between this design and the one with a stem valve.

The second phase is when water splashes into the tank and at the same time lifts the float up. Together with it, the level of the stem with a rubber seal rises. The seal covers the hole. With further movement of the rod, both the piston and the diaphragm will be pressed against the seat. From this, the filling compartment is sealed.

Due to the fact that the pressure from the water in the filling compartment is added to the pressure of the float, which rises, the membrane is tightly compressed with the seats. And this, in turn, stops the supply of water to the tank.

The third phase is the descent of water.When the water leaves the tank and splashes into the bowl, the pressure of the float on the rod stops. The hole in the piston is no longer closed by the rod, so the pressure in the filling chamber is reduced. It remains only from the water supply network, it is it that acts on the membrane and on the piston, moving them to the side. As a result, the mechanism goes back to the first phase.

Advantages and disadvantages

Check valves have strengths and weaknesses. Advantages:

- In case of breakdowns, any part of the structure can be replaced.

- Reliability of overlapping of the pipeline, high tightness.

- The device opens slowly, and the system does not experience shocks of the working mixture, overloads, pressure surges.

- When working with a part, you do not need to make great efforts.

- Models equipped with an electric drive allow you to set the algorithm for opening, closing the damper in time or depending on pressure changes.

Flaws:

- Complex shape of the flow part.

- High price.

- If the design has glands, it is necessary to carry out additional maintenance of the equipment.

- If the flow part has defects, stagnation occurs that can destroy the structure.

Given the shortcomings, many problems can be avoided during the operation of locking mechanisms.

Assembling drain tanks

In many ways, the further comfortable work of plumbing will depend on how to assemble the tank, and then adjust it. Naturally, each type of equipment has its own installation secrets, which are quite accessible to the home master.

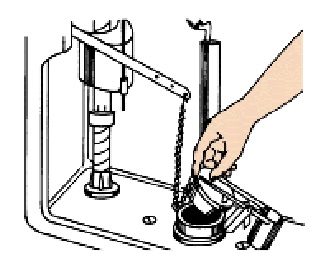

The sequence for completing the tank with the top button (Figure 1) is as follows:

- We fix the outlet valve (5) in the large central drain hole of the storage tank. You can install the mechanism entirely or only its lower part. At this stage, as at all subsequent ones, it is necessary to control the tightness of the gaskets, securely fixing them with threaded elements, in order to obtain tight connections.

- If a model is assembled that includes fittings for a toilet bowl with a bottom connection, then you should also fix the inlet valve (2) with a float (3) in the corresponding hole in the sanitary ware.

- We insert an elastic gasket (6) between the toilet bowl and the drain container. It must be carefully centered, and then tightened with screws (7) both halves of the plumbing into one piece.

- In the model with lateral water supply, we fix the inlet valve.

- We connect the external water supply to the fitting (4).

- We install its upper part (without a button) on the exhaust valve.

- We open the water supply, check the tightness of the interfaces, the operation of the filling and draining mechanisms, and, if necessary, adjust their functionality.

- Now the lid for the toilet bowl is put in its place, into which we fix the button (1).

Tanks with a lever drain today, although not often, are sometimes still used as reliable, time-tested devices. Therefore, questions may arise regarding their installation. Despite the fact that they are made of different materials: plastic, ceramic or cast iron, their assembly is very similar in many ways.

- First of all, inside the tank we fix the lower siphon part of the drain mechanism.

- The lever mechanism and fittings for the toilet bowl with side supply are mounted.

- We hang the storage tank on the wall behind the toilet coaxially with the bowl and attach an external water supply through a flexible connection.

- On a cast-iron structure, we connect the flush pipe through the appropriate threaded fitting, and on a plastic one, we use a compression sleeve with an annular sealing insert.

- We connect the toilet bowl with the flush pipe by means of a rubber cuff, which is fixed on both sides with clamps.

There are lever ceramic compact products installed in the saddle of the toilet bowl.In this case, the assembly of the structure is carried out in the same way as in the push-button model, using coupling screws and an elastic gasket.

Shutoff valve repair

If the problem is in the shut-off valve, then the drain tanks are repaired as follows. As you know, the shut-off valve is responsible for adjusting the volume of water in the tank. If the dosage of the water supply is violated, then either the membrane is to blame, or the holes through which the water passes are clogged.

Troubleshooting this problem is quite simple. It is necessary to unscrew the protective cap and remove the membrane, clean all the insides in the most thorough way. Then we put the membrane and the cap in its original place and check the operation of the toilet bowl. In general, if we talk about a float, then the membrane is its most vulnerable point. Therefore, in the event of a breakdown, it is better to replace it with a new one by putting an additional copy, usually supplied with the toilet bowl, or buy it at any specialized outlet. You can watch the video instruction for repairing toilet bowls in our article.

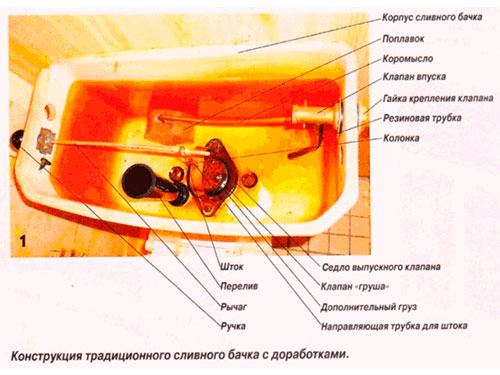

Tank device diagram

Toilet elements

Outwardly, they can be different, which makes it seem that there is a difference in the design itself. However, the basic elements are almost always identical.

Drain tank. The water supply can be carried out from below and from the side. This container has two openings, one of which is always closed with a plug. To drain the water, you must press the button on top, although some models have a side drain system. As a rule, the volume of the tank is from 8 to 10 liters.

Bay system. In fact, we are talking about a toilet valve that performs two tasks - it allows water to pass when the tank is empty, or it shuts off water when the tank is full.

When choosing a toilet, pay special attention to the shut-off valve. If earlier pistons were most common, now they are practically non-existent.

Most of the systems are equipped with a diaphragm valve.

Drain system. She's a drain valve. When the button is pressed, the container is emptied by opening the drain hole. When all the water comes out, the drain is blocked.

Bowl. In fact, they differ from each other in the device of the sewer outlet. It can be oblique or straight.

Modern Diaphragm Valves

Membrane float valve provides a quick set of water. Depending on how high-quality fittings are selected, this process can be noisy or almost silent. Unlike older models, it overlaps very quickly.

The value of such pressure should be in the range of 0.05-0.1 MPa. Moreover, in order for such a valve not to fail quickly, the water in the system must be clean. It is clear that both of these conditions are rather difficult to achieve in some places, for example, in villages or summer cottages.

Another aspect that should not be overlooked if you are considering a membrane-type cistern shut-off valve in your toilet as an option is the quality of all shaped and shut-off elements. If the material for its manufacture was not of very high quality or defects were made during the production, then there can be no question of long-term operation of the product. This valve will need to be replaced frequently. Even repairs here, most likely, will be powerless. It is not possible to make a new membrane on your own.

Types of drain devices

There are two main groups of toilet flush mechanisms, which are distinguished depending on the actuation:

- exhaust,

- Pressure.

The first is also called stock. This name is due to the fact that to bring such a device into action, it is necessary to lift the stem up using the handle, and then the drain hole will open. Almost all new models of toilet bowls are deprived of such a system. Most manufacturers have used it before.

As for the second type of drain mechanism, it is also called push-button, and it has two subgroups:

- Single-mode flush - such a device has only one button or key that must be pressed so that the water from the tank splashes into the toilet.

- Dual-mode drain - this device has a button of two halves, or two buttons. One half drives the mechanism so that only half of the water from the tank splashes out, and the second serves to release all the water at once. It is also called a device with two buttons.

There is a third type, these are tanks with a stop function. They have one key, but water can be released in different ways. To adjust this, you need to press the button more than once. For example, if you press it once, water will begin to splash out of the tank, and if you press it again at this time, the release will stop, the valve will close it.

Principle of operation

The design of the flanged valve can be direct-flow, straight-through or angle. In straight-through valves, the direction of the fluid is maintained, but the spindle is inclined to the axis of the passage, and not perpendicular. The design of direct flow valves is designed to reduce hydraulic resistance, as well as to straighten working environment flow.

Globe valves have inlet and outlet fluid in the same direction, but inside the main cylinder, it makes two 90-degree turns. With the help of such valves, the movement of liquids, which have high temperature indicators and pressure, is blocked. Excessive loads for straight flanged valves are not dangerous, since the valves help to maintain tightness. But inside such structures, high hydraulic resistance often occurs, which leads to the fact that stagnant zones appear in the cylinder.

float adjustment

If we want the drain fittings for the toilet bowl to work for a long time and properly, then we need to know how the water in the tank is adjusted. This action is performed using a float. Its improper regulation leads to the fact that the water in the toilet rises to its edges, although according to the rules it should recede from the side openings of the tank by 3-4 cm, or in the absence of such, the water must slightly close the drain mechanism. Therefore, in order to reduce the amount of water in the tank, you need to lower the float with a screw or an adjusting rail. Otherwise, it must be raised.

Selection principles and prices

Prices for parts vary depending on their size, the material from which they are made, the presence of an electric drive, weight, type of sealing elements, type of fastening to pipes. Average price depending on the material:

- Cast iron - 250 rubles.

- Steel - 550 rubles.

- Brass - 750 rubles.

When choosing a device, you need to consider some features:

- Brass - are resistant to rust, withstand frequent temperature changes, high pressure. The disadvantage is the high price.

- Steel is a popular material for the manufacture of locking mechanisms. Withstands heavy loads, sudden temperature changes. During manufacture, the alloy is saturated with alloying additives, which change its characteristics.

- Cast iron - low price, prevalence, good casting qualities made models from this material attractive to buyers. The main disadvantages are low resistance to rust formation, low strength index.

On packages with parts, it is indicated for which working environments they are intended, what pressure they can withstand. From this it is necessary to build on, choosing a through valve.

Features of choice

Possible malfunctions during the operation of the drain tank

-

Water is not supplied to the tank or its supply is not blocked

. The culprits for this are either a water supply valve or a float.Floats are made either in the form of a hollow cylinder or an inverted glass. In the first case, the damaged float cannot be repaired, and the problem is eliminated only by replacing the float or the entire valve. With a float in the form of an inverted glass, only one trouble can occur - it is overgrown with dirt and various deposits, which is why it starts to work poorly. In this case, it should simply be cleaned. - If the float is ok, but water does not stop flowing into the tank

- the cause is a worn valve membrane. Usually a spare membrane comes with another float. If not available, it can be purchased separately. The protective cap is removed from the valve, after which the old membrane is removed and replaced with a new one. It is also useful to clean the small hole in the valve through which water enters the tank. If it is clogged, then, accordingly, tank stops filling

or this process is extremely slow.

As you can see, there is nothing complicated in the device of the toilet cistern, so if necessary, everyone can easily install or repair it.

Fittings for toilet bowls are an important element! Prices, reinforcement mounting schemes and photos are presented below

In most cases, when a person chooses a new toilet for his home, the focus is on external aspects, aesthetics. But he forgets about more important things

For example, about such a thing as fittings for the toilet, which plays a very significant role in the operation of the entire system. Remember that the drain mechanism should be remembered not only when there is noise or a leak. Timely periodic prevention and adjustment will allow you to forget for a long time what a non-working toilet is. To begin with, we recommend that you familiarize yourself with the device and the main components of the toilet bowls. Note that in most cases the choice falls on compact toilets. In them, drain tanks are mounted on the shelf of the bowl. They are inexpensive and fairly easy to maintain.

- 1

Toilet elements -

2

Installing drain equipment2.1

Installation steps -

3

Possible problems and solutions- 3.1

Need to reduce the amount of flushing water - 3.2

There was a leak in the tank - 3.3

Drain is getting weak - 3.4

Changing the big pad - 3.5

float not working - 3.6

Replacing any element

- 3.1

Setting up sanitary cistern toilets

The end of the assembly of plumbing does not mean the end of all work on its installation. Often, the fittings of the toilet cistern will have to be adjusted, after which the functions of filling, overflowing and draining must be performed flawlessly. Also, sometimes it is necessary to adjust the mechanisms during their long-term operation or replacement.

Push button cistern adjustment

What should be paid attention to in the process of setting up modern "push-button" plumbing?

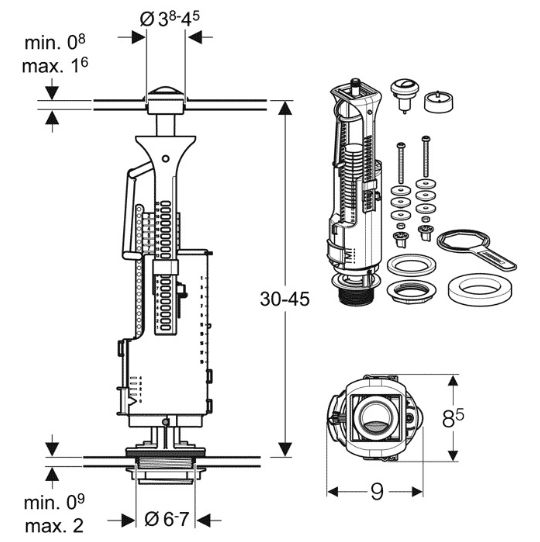

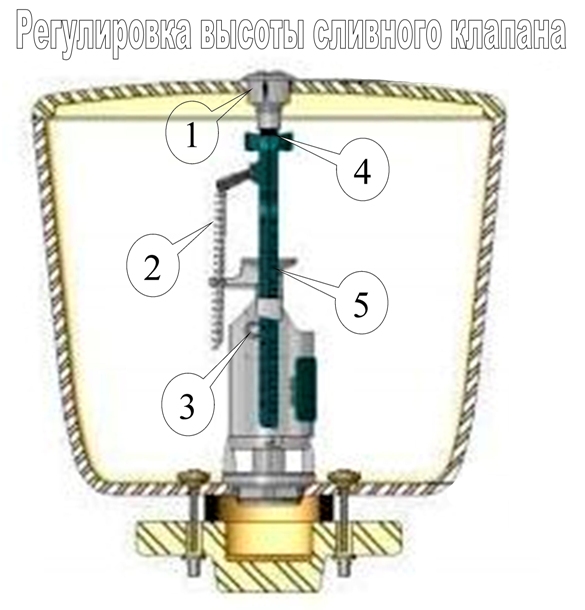

- The flush valve height is set (Figure 2). Its design must correspond to the dimensions of the storage container under the cover, taking into account the button (1). Disconnect the rod (2) from the latch of the overflow tube. Release the rack clamps (3) on both sides. Move the racks (5) in the required direction vertically, guided by the scale printed on them. Fasten the clips and tie rod in the new position.

- The height of fixation of the overflow tube is adjustable. There are two requirements for this parameter: the surface of the water in the toilet bowl must be 15-20 mm below the edge of the overflow, but at the same time, the fully pressed button should not touch the top of the tube. To do this: Set the gap between the edge of the overflow and the top (4) of the rack (5), (Figure 2). To perform this operation, you will have to release the rod (2) and the clamping ring or the clamp on the tube. Lower or raise it to the required height. Fix overflow and traction.

- The functionality of the filling fittings is configured in accordance with the requirements of the previous paragraph regarding the filling volume. In order for the inlet valve to provide the optimum water level in the drain tank, the position of its float must be set. If you need to set an early cutoff of the supply, then the float is lowered lower or fixed higher if the volume of liquid is insufficient. Changing its position is carried out by rearranging the rod similar to the rod on the drain valve.

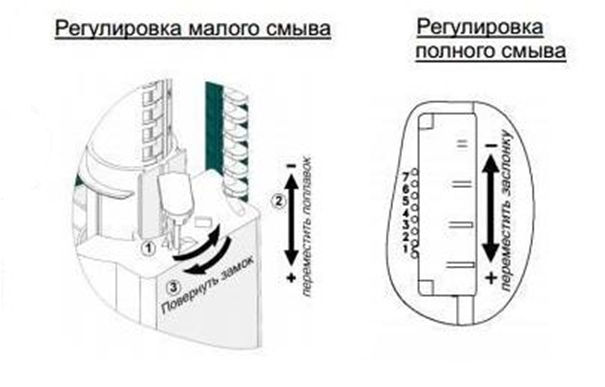

Two-level drain adjustment

In modern push-button toilet sets, it is not uncommon to have a two-level water discharge. Such models require small and full drain settings.

The discharge of the entire volume of liquid is regulated by a damper, increasing this parameter by moving it down and, decreasing it, by moving it up. Partial discharge of water is set by a small flush float, which, after opening the lock, we move it up or down, respectively increasing or decreasing the flow rate.

You can learn more about adjusting the two-button trigger mechanism from the video:

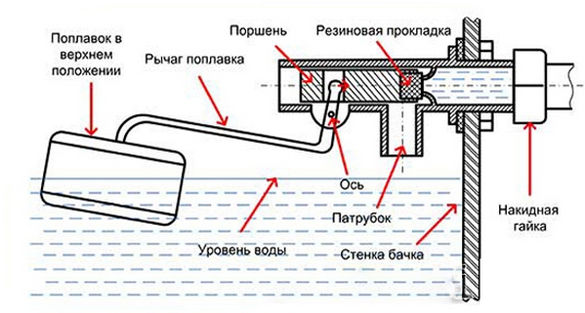

Adjusting older models

In conclusion, it is worth mentioning the adjustment of "classic" systems with a lateral water supply. The old-style toilet cistern device only involves setting the inlet valve.

His work depends on the position of the float, which is lowered or raised. To this end, if the rocker is brass (steel), then it is simply bent into the desired position, and if it is plastic, then the geometry of the lever changes after loosening and then tightening the mounting screw.

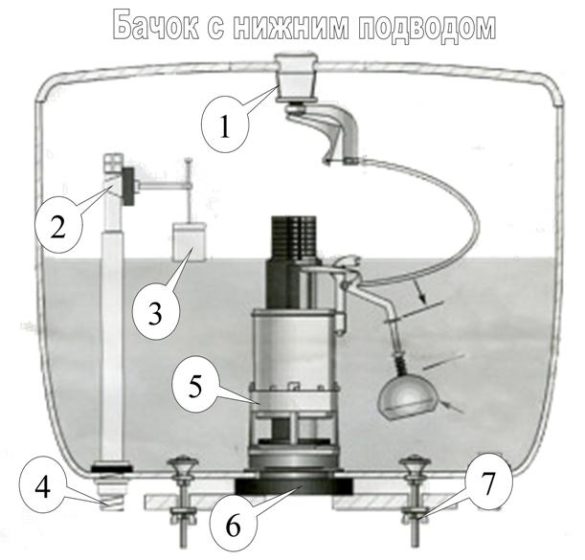

Features of the mechanism for supplying water to the drain tank

All drain tanks have only two main structural elements - a water supply mechanism and a drain mechanism. The water collection system can be made in two versions:

- with side feed;

- with bottom feed.

The first are float valves designed for tanks, the water to which is supplied to the upper side. These models are produced mainly by domestic firms, they are simple and low cost, but they create a lot of noise in the process of collecting water.

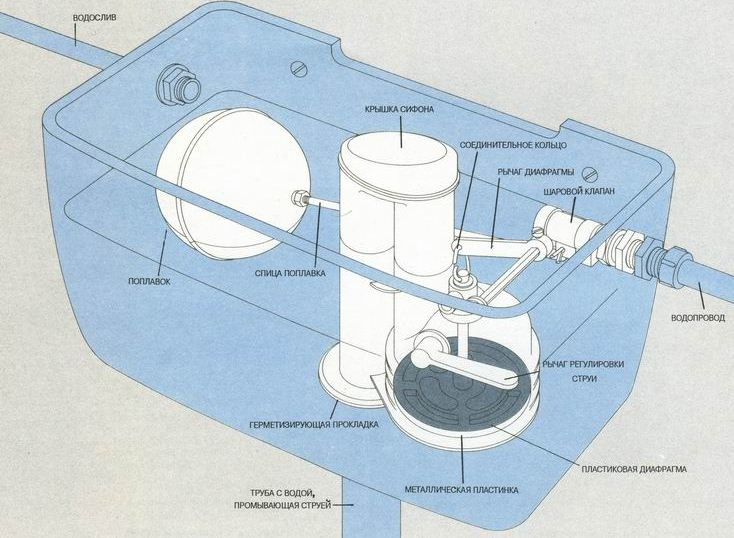

Scheme of the device of the toilet cistern

Such a valve includes two main parts - a body with a membrane in it, which closes and opens the water supply to the tank, as well as a float connected to the body by means of a lever. Thus, lowering and rising along with the water level in the tank, the float sets in motion the lever, which in turn acts on the stem with the membrane fixed on it, opening and blocking the access of water to the tank through the valve.

The mechanism with the bottom water supply is a little more expensive, but it also works much quieter. This system is somewhat more complex, in which the float moves along a special vertical rod, although the principle of operation itself has not changed. The mechanism for shutting off the water supply is actuated by means of a special rod connected to the float, which is also a water level limiter in the tank.

Other cistern problems

In addition to the problems considered and methods for their elimination, there are several more breakdowns that can be fixed by hand. If the connection fixing the tank with the toilet is broken, then you need to disconnect these two nodes from each other, remove the gaskets and replace them with new ones. At the same time, do not forget about the seals of the screws connecting the tank to the toilet.

Another problem that you may encounter is a broken mechanical toilet assembly. This problem is more serious, and its solution may be as follows. Either you replace the part of the mechanism noticed in the breakdown, or you have to come to terms with the fact that replacing the armature is the only correct way out.

Float Valve Types

Float valves are used for the inlet and outlet of water. They have their own varieties, such as:

- Croydon valve;

- Piston valve;

- Membrane valve.

The first one has a shell, a lever axle on a float, a saddle and a piston. The lever moves the piston perpendicularly. Typically, these valves are equipped with old drain tanks, which are no longer used anywhere.

The piston-type cistern inlet valve device has a lever axle. It is fixed in a forked cotter pin. When the lever is moved in a horizontal direction, it drives a piston, which touches the seat from time to time, which helps to regulate the flow of water into the tank.

The piston has a seal at the end. When it comes into contact with the seat, the seal shuts off the flow of water. This type of valve is quite common.

The third type of valve has a membrane in its design instead of a gasket. It can be made of silicone or rubber. As the piston moves, the membrane also moves. Thus, it can block the incoming water flow at the right time. This type of valve is the newest and most modern. They are equipped with all the latest models of drain tanks. Therefore, further we will consider its mechanism and design in more detail.

Float

Breakage of floats is of two types. In the first case, the supply of water ceases to the tank, and in the second, its supply does not completely overlap. To blame for this, there may be problems in two parts of the toilet - a float or a shut-off valve. If the problem is in the float itself, then the problem can be solved quite quickly.

By design, the float can be of several types: hollow inside or in the form of an inverted glass. The hollow float is more problematic. If water gets into it, it ceases to function and cannot be repaired. In this case, buy a new one. The second option is more preferable and is easily repaired. To do this, you just need to rinse it, as it is most likely contaminated.

Drain mechanism

What is a check valve

A shut-off valve is an element of any system that works with liquids. It is designed to block or open the flow of fluid. If an accident occurs on the line, the workers shut off the valves to fix the breakdown. Before buying a part, you need to find out its device and principle of operation. It consists of several elements:

- Handles for rotation.

- A housing that has at least two nozzles. One incoming, one outgoing.

- Spindle that transmits force when the handle is rotated.

- Spool - a locking device that closes the fluid supply channel.

The principle of operation of the part is that after turning the handle, the spindle begins to move down the thread. It gradually closes the hole through which water, oil, fuel, acids enter.