Boiler design

The diesel boiler consists of a control unit, a combustion chamber, a diesel burner, a heat exchanger, a fuel filter and a chimney.

Control block needed for automatic adjustment of the burner and pump. With it, you can control the temperature and adjust it depending on the weather conditions and the preferred microclimate.

In the combustion chamber fuel used for heating is burned. When choosing the appropriate equipment, it is necessary to take into account such an indicator as the resistivity coefficient of the combustion chamber.

Diesel burner needs to be set correctly, since the operation of this element affects the heating of the heating system and how much fuel is needed and whether it can be saved.

In the heat exchanger the coolant heats up. Heating is based on the principle of heat energy exchange in the area between the heat exchanger and the combustion chamber.

Filter is used to prevent debris and dirt from entering the burner, and the reliability of the entire system depends on how correctly the chimney is installed.

It should immediately be noted that a heating system using a diesel type, by definition, cannot be cheap. However, financial costs can be reduced through high-quality insulation of the house, as well as periodic maintenance of installed equipment.

How to choose

During the selection, it is necessary to focus on the following characteristics:

- thermal power;

- mass fuel consumption;

- pump performance, suction power;

- power consumption.

Thermal power is the main parameter by which you have to choose a burner for a heating boiler. It is indicated in kilowatts and displays the amount of heat released during the combustion of fuel.

Diesel burners are produced with certain pre-settings for optimal heat dissipation. However, during setup before commissioning, the actual power can be adjusted over a wide range by adjusting:

- nozzle;

- fuel pump pressure;

- the amount of air supplied.

When choosing, it is important to clarify the entire possible range of burner power changes, which is easy to determine from the table in the technical documentation.

The mass consumption of fuel depends primarily on the settings of the thermal power of the burner and the quality of the device itself. You can specify the flow rate in the same table where the parameters for adjustment are indicated.

The pump capacity determines from what depth the device will be able to supply diesel fuel on its own. If the diesel fuel tank is located at the level of the burner itself, then the suction power may be small.

For buried underground storages, it is especially important to specify the maximum depth from which the pump will be able to lift the fuel, even taking into account its increased viscosity at relatively low temperatures. Power consumption determines the amount of electricity that will be required to operate the fan, igniter and burner control unit

Power consumption determines the amount of electricity that will be required to operate the fan, igniter and burner control unit.

Chimney

The chimney is the main part of the heat generators. Installation of a heating system is not possible without this carbon monoxide combustion chamber. The chimney in the residential complex is internal and external. An external chimney is a pipe-in-pipe installation. Chimneys can be individual - when one chimney is installed on several heat units. With the help of a specialist, a chimney is selected and calculated.Incorrect installation of the chimney can lead to future repairs (if the installation took place without taking into account the shape of the roof, then wind enters the chimney and there is a possibility of extinguishing the flame)

It is important to know that the width of the chimney pipe must be greater than the width of the unit on a diesel engine

Any fuel appliance, gas or diesel, or wood, diesel-gas boiler, chimney must be made of steel. Due to the evaporation of aggressive acids, a chimney made of a different material will need to be repaired very soon. And carbon monoxide gas particles, getting through the cracks into the house, will harm your health. Therefore, the installation of a steel chimney is the most reliable option both from the side of repair tasks and from the side of health.

More recently, chimneys of an unusual configuration have appeared on the market, they are called insulated chimney ventilation systems. Installation is carried out by specialists, because the system is complex, multi-variant and universal. The price of such an insulated chimney is on the same level as the price of a stainless steel chimney. Such chimneys are very resistant to acids, and will not require repair work.

How to make a diesel boiler with your own hands

So, first we will audit the existing equipment and materials. You should definitely have the following on hand:

- Fuel storage tanks

- Metal barrel 200 liters

- Diesel burner

- Fuel supply system

- Automation for the future boiler

- Stop valves, fittings, pipes

- Tools for installation (welding machine, angle grinder, etc.)

- The scheme according to which you will connect the boiler to the fuel supply system

So, let's proceed directly to the process of creating our future "warm" assistant.

Step 1. Inside the barrel, you need to weld 3 supports parallel to the ground. The 1st support will be needed directly for the installation of the boiler itself.

The 2nd support will be needed to mount the boiler door, so it must be done approximately at the height of the blower door from the ground.

The 3rd support is placed at a distance of 20 cm from the top of the barrel.

Step 2. We make the bottom of our boiler. Its role is played by a steel sheet with a thickness of at least 4 mm. The diameter, as you understand, must match the diameter of the barrel of our future boiler.

Step 3. Starting to make grates. In the classic version, a grate is a cast-iron grate that serves to remove ash from the combustion chamber, as well as for free air circulation in the furnace. In our performance, the grate will be a circle of steel (take the sheet as thick as possible so that it burns out more slowly over time) with slots.

Step 4. Making the lid of the boiler. By analogy with the bottom, for the cover we use a steel sheet with a thickness of 5 mm or more. And, accordingly, we cut out a circle of the desired diameter from it.

Next, we need to make another hole in the center of this cover - it will be needed for additional fixation of the pipe that will pass through the boiler.

Do not forget! Supports for partitions - those same 3 pieces, you need to mount strictly one above the other!

Step 5. We make a hole for the oven door. To do this, you need to make a hole in the bottom of the barrel and install the doors.

Step 6. We proceed to the construction of the boiler furnace, which will have to be done through the wall of the boiler. A mandatory element is a partition that separates the furnace compartment from the ash compartment.

How diesel burners work

The principle of operation of such an element is based on the combustion process, which is also clear from its name. However, the device can only work when the fuel is combined with oxygen. In fact, the operation of a diesel boiler burner is simple, but there are some features:

1). The presence of a nozzle - this gives a uniform distribution of liquid fuel before entering it into the combustion chamber. This principle is one of the main for the normal functioning of the element.Thanks to him, a finely dispersed atomization of the energy carrier is obtained, after which the reaction of the fuel with oxygen occurs faster. This makes it possible to regulate the combustion process.

2). The operation of the burner requires careful filtering of the diesel fuel before the combustion process.

3). Equally important is the presence of a fan in the design of the device. With its help, the necessary pressure is created and the normal operation of the unit.

4). And, of course, a separate boiler room. After all, when working, burners for diesel heating boilers create a lot of noise, so it is recommended to place this kind of equipment in a separate room - the boiler room. If this is not possible for some reason, then you can use a noise-absorbing casing, which should be put on the burner.

But how does the whole process take place?

with the help of a pump, fuel enters the device. By the way, the burner takes only the amount of fuel that is needed, and the rest goes back to the tank. After that, the filtration and heating of the energy carrier to a certain temperature takes place. Then it enters the nozzle, where it is sprayed. Next, the process of oxygen entering the combustion chamber is carried out. A vortex is created inside with the help of special blades, which allows you to control the torch. Electrodes are located in front of the nozzle, with the help of which the process of fuel ignition takes place. This is how the boiler starts!

Important! After purchase and installation, adjust the diesel burner. How to do this, read our article about Installation and configuration of diesel burners!

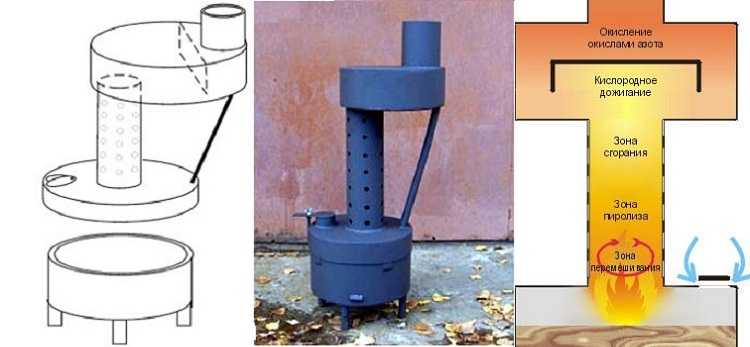

pyrolysis option

This design is so popular that it is also produced in industrial enterprises. In this case, the oil in the reservoir is ignited. When heated, it evaporates, the vapors rise up into the combustion chamber (pipe with holes), where, mixing with oxygen, they continue to burn. In the afterburner chamber (expansion on the pipe) there is a complete and final oxidation (combustion) of all fuel components.

Do-it-yourself boiler for working out: pyrolysis method

For normal operation of the furnace, air is supplied to the container where the oil is located and primary combustion takes place through a special hole with a damper. The position of this damper regulates the intensity of combustion and the temperature in the room. Air must flow freely into the upper combustion chamber. Therefore, a vertical pipe with two tanks is made with a large number of holes.

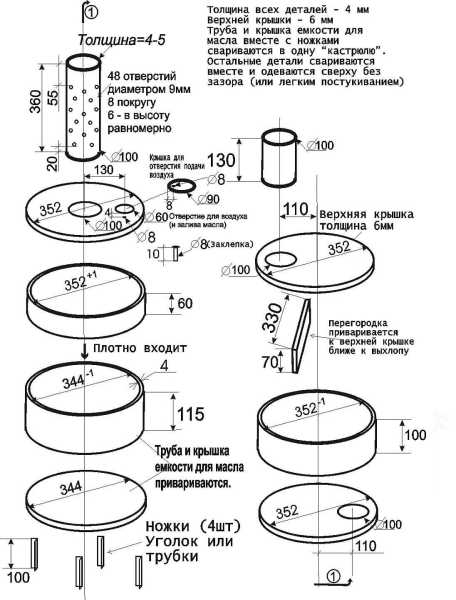

Waste oil boiler. Dimensional drawing

Such an oven requires strict adherence to the recommended dimensions, compliance with the indicated proportions. If you require a larger unit, increase all parts proportionately.

Installation requires a straight chimney. Its height to the “crown” is at least 4 meters. Since the stove is not very heavy, either a metal chimney or a sandwich would be ideal.

Why can't the proportions be broken? The thing is that the optimum temperature at which all hydrocarbons are burned, and only carbon dioxide, nitrogen and water vapor remain at the outlet is 600 o C. If the furnace produces a temperature of more than 900 o C or less than 400 o C, in the exhaust heavy organic matter will be present. They have a very bad effect on the human body. Therefore, it is advisable to strictly adhere to the given proportions: this way you guarantee the safety of both yourself and those around you.

Everyone loves this oven. There is only one drawback: a small tank. Adding fuel while the stove is running is dangerous, and waiting until it burns out is not always possible. Simply increasing the size of the tank will not work: a large amount of oil will not warm up to the desired temperature and will not evaporate. There is one refinement that will allow you to extend the burning without any problems.All that is needed is to make an additional reservoir nearby, which is connected to the main one according to the principle of communicating vessels.

Stove tank - a way to extend the burning at one gas station

Another refinement allows you to remove heat from the upper circuit to heat water. Having welded metal pipes into the upper part of the furnace, you get a working furnace with heated water. The photo shows one of the options for such a heat exchanger.

The top of this boiler can be used to heat water

The disadvantage of such a boiler is that it burns out the oxygen in the room very quickly, so a good ventilation system is needed. In addition, the furnace body is heated to a red glow, the temperature is very high, which requires careful compliance with fire safety standards.

Be sure to take care of a fireproof base on which the stove is installed and protect nearby walls from excessive heating with a metal screen. under which to lay a layer of heat insulator. So that no one accidentally touches the stove, it is also desirable protective fencing.

It’s probably impossible to use home-made boilers for working out at home: you won’t leave them unattended even for a minute. In addition, they are unsightly in appearance. But heating a garage, greenhouse or other similar technical room is realistic.

Diesel generators diagnostics, repair

The generator may not work due to poor fuel or a minor breakdown. Sometimes you need to contact a service center, but most often you can repair a diesel burner for a boiler yourself. To repair the burner, you need to have some knowledge, since the repair of diesel boilers is diesel and electric.

When repairing a diesel burner for a boiler, all safety rules must be followed. Repair of diesel boilers is best done with goggles.

Diagnostics for the repair of diesel boilers:

- Repair of diesel boilers is required if the burner does not ignite. Repair (repair of diesel boilers) must be done immediately - check the filter, clean the filter if necessary. If you do not hear a spark, then the repair of diesel boilers must begin with the analysis of the burner. It is necessary to remove the nozzle holder cover and turn off the fuel to the burner. Then it is worth disassembling the fuel filter and turning on the burner - a spark should appear. When repairing diesel boilers, you need to be sure that the fuel from the tank does not enter the burner. Another cause of problems with the burner, due to which repair of fuel units is needed, can be too strong air supply.

- The burner lights up but quickly shuts off. The reason for the repair of diesel boilers may be a contaminated LED. In this case, the repair of a diesel boiler must begin with the fact that the LED must be pulled out and wiped. The problem may also lie in the filter, due to which the burner goes out. But if the automation unit is broken, then it will not be possible to repair the burner and nozzle on its own.

- The burner sometimes goes out. In this case, you need to thoroughly wipe the filter or replace the nozzle. Repair of diesel boilers will help the use of high-quality diesel fuel tanks.

- The burner constantly smokes. The reason is bad fuel, which needs to be replaced, either make it combined, or use diesel. You also need to look at the nozzle. The nozzle should be changed if you have not changed the nozzle for a long time.

Source kotlomaniya.ru

The company "Thermoservice" offers the services of its qualified specialists in cleaning the nozzles of heating systems. This type of work can be carried out both as part of the comprehensive maintenance of gas boilers, and provided as a separate service. In the first case, our specialists will also clean the boiler and a number of other service works.

Cleaning the boiler nozzles is one of the mandatory measures when servicing boilers, which can significantly extend the life of the entire heating system. In addition, it avoids the need to overhaul existing equipment.

One of the most popular and most effective methods for cleaning the nozzles of heating systems today is ultrasonic cleaning. However, it is recommended to use it only in the most difficult situations.

In cases where only a general cleaning of the boiler nozzles is required, it is recommended to use a chemical method. It is less expensive, although it has its drawbacks - for example, it uses a significant amount of toxic solutions that require further disposal.

Source www.termoservice.ru

Diagnostics and elimination of malfunctions of a diesel torch. (10+)

Diesel burner - Faults, diagnostics, repair

The inoperability of the burner may be caused by low-quality fuel or a breakdown. It is sometimes easy to find out and eliminate the cause, and sometimes you need to contact a service center.

Burner repair involves contact with mains voltage electricity and work with flammable liquids. Make sure you are qualified for this. Familiarize yourself and observe safety precautions.

Turning on the disassembled burner, understand how you will turn off quickly. Create conditions so that the shutdown does not require a lot of time.

Be prepared for accidental ignition. Wear glasses, get a fire extinguisher, learn how to use it.

Requirements for installing a diesel boiler

- The boiler must be installed only in a separate room with an area of at least 8 sq.m. and the maximum ceiling height is not more than 2.5 m.

- The room must have a good ventilation system, since diesel fuel or diesel fuel have a persistent unpleasant odor, which can be fatal to humans at high concentrations in the air. If you want to place a lot of heating devices in it, then take care of strengthening the foundation of the room.

- Access to the boiler must be unproblematic for maintenance purposes. The distance from the walls of the boiler to the walls of the room must be at least 40-50 cm.

- Separately about the ventilation system. It is calculated as follows: for each kilowatt of the boiler, 8 cubic cm should be supplied. fresh air. Do not forget also that the entrance to the ventilation should be located under the ceiling, and the chimney hole - in the wall.

- The chimney must be airtight and impervious to gas. To comply with this condition, it is necessary to cover it with a dense layer of plaster or lay an asbestos-cement pipe inside.

A few important rules that must be observed during installation work

During the installation of equipment that involves the use of liquid fuels, several general rules must be observed, as well as the requirements specified by the manufacturer of the equipment being installed.

Important guidelines include the following:

- diesel boilers cannot be installed in garages with a small area and city apartments, since the boiler itself takes up a lot of space, requires a fuel tank and has a high noise level;

- diesel equipment must be installed in separate rooms, the ceilings of which are at a height at least two and a half meters;

- from the surface of the boiler to the wall opposite, there must be a distance exceeding one meter;

- the walls of the boiler room must be concrete or brick, covered with plaster or tiles;

- in the boiler room it is necessary to install doors of the third class of fire protection;

- no more than nine hundred liters of fuel should be stored in the fuel tank, which leads to the need to equip a room separate from the boiler room for the tanks.

Features of using a diesel boiler

The main guarantee of the correct stable and efficient operation of a liquid fuel boiler is the proper quality of the fuel. However, when confronted with reality, it comes to the understanding that high-quality fuel is either very expensive or difficult to obtain. Therefore, you have to use what is available, and many owners of diesel boilers even use fuel, to put it mildly, not of the highest quality. This is where a series of problems associated with this begins, the most important of which is clogging of the fuel filter. Cleaning it will not be difficult, but in this case you will have to do it regularly.

Another problem, more significant, is the clogging of the burner nozzles. If this happens, then you will leave more than one kilometer of nerves when heating the house in such conditions. To begin with, clogged nozzles threaten not only a significant decrease in the efficiency of home heating, but also increased fuel consumption. Simply put, you will be cold, but you will spend a crazy amount of diesel fuel to maintain such a cold in the house. Plus, with high speed, the boiler heat exchanger will begin to be covered with soot from the inside. And he, in turn, will further reduce the efficiency of the boiler.

How to clean the nozzles and restore the original power of the boiler? On your own, you are unlikely to be able to do this, since the process is very complex and requires skills. Therefore, to carry out this procedure, you will need to call the service personnel.

It’s also impossible to clean off soot just like that - for this you will have to disassemble almost the entire boiler.

Advantages of diesel boilers

The main advantage of diesel boilers is that their installation in the house does not require any permits from special authorities. The owner himself can easily install the unit or ask a specialist about it if he himself has never encountered such work before. For normal operation of the boiler, you only need a regular electrical outlet.

Another significant advantage is the clean operation of this type of heating system. A diesel-fueled boiler will heat the room, but dirt and burning will not form. You will have to clean the installation very rarely, it will not take much time and effort.

Despite the fact that the diesel boiler runs on gasoline, its smell will not be felt in the room during heating. Therefore, the installation can be safely used to heat children's rooms and bedrooms. It is also perfectly acceptable to use a diesel boiler to heat rooms with people suffering from diseases of the respiratory system.

Fully automated operation of this type of boiler makes it possible to forget about the constant regulation and maintenance of the unit. It is enough to turn on the unit once, after which it will automatically turn off on its own and, if necessary, turn on.

The consumption of diesel fuel in boilers of this type is relatively economical. According to preliminary calculations, 1 kg of diesel fuel per 10 kW of heat is quite enough. This suggests that even for heating a huge room with an area of about 150 m², 35 kg of diesel fuel per day will be more than enough. For this reason, it is advisable to purchase diesel boilers even for large private houses.

And another important plus is the ability not to change this heating installation to another when conducting gas into the house. If necessary, it will be enough to simply replace the electric burner with a gas one, then the work will be more economical.

Requirements for a diesel boiler house in the house

Installing a diesel boiler in a house is a complex technical process that requires qualified assistance.When connecting, take into account the current regulatory requirements and fire safety regulations. Adjustment and maintenance are carried out using special computer software.

The organization of heating in a private house with a diesel boiler is carried out subject to the following conditions:

- The room for the boiler is chosen from technical rooms with sufficient area, lighting, ventilation.

- The placement of diesel boilers in residential country houses is carried out on a non-combustible base. Wall and floor decoration is carried out using non-combustible building materials: ceramic tiles, plaster.

- Automation - maintaining the temperature in the house is carried out automatically. Human participation in the operation of the heat generator is reduced to a minimum. Be sure to install safety automatics that turn off the operation of the boiler in the event of an emergency.

- Ventilation in the boiler room is provided through channels with natural and forced supply and air exhaust. The cross section of the ventilation duct is calculated based on triple air exchange for an hour.

- Diesel fuel storage is installed in a separate building. In the boiler room, it is allowed to store a reserve tank, with a maximum capacity of not more than 3-5 m³.

The correct installation of a diesel boiler in a residential private house is based on an understanding of work processes. The burner device creates strong noise interference, therefore, soundproof measures are carried out in the boiler room.

Additionally, a UPS and a stabilizer are installed to ensure the system's performance, even during power surges or power outages.

Advantages and disadvantages of domestic diesel fuel boilers

Reviews of diesel heating boilers for private houses and cottages indicate the same problem. A domestic consumer, if he reads the instruction manual, adjusts the operation of the boiler to his needs, violating the manufacturer's recommendations, which is the main cause of malfunctions.

The performance of boiler equipment depends on proper operation, from precisely set settings to the need for regular maintenance. If you properly heat the house with a diesel boiler, there are high rates of efficiency and heat transfer. Any violations lead to excessive fuel consumption.

The disadvantages of heaters are:

- Noisiness of boilers - as a rule, noise is not heard if the passage to the boiler room is closed by a door. It is not recommended to install a diesel boiler in the kitchen or any room adjacent to living rooms.

- Maintenance cost - you will need to regularly clean the heat exchanger and chimney from accumulated soot. When switching to another type of liquid fuel, as well as before the start of the heating season, it is necessary to adjust the burner. The best solution that allows you to save money is the conclusion of a contract for ongoing maintenance.

The advantages of boilers are considered to be low installation costs, quick commissioning, no need for permits and approvals.

The most economical boiler is one that is installed and operated in accordance with the manufacturer's recommendations. After installation and connection, a representative of the company will instruct on the use of the heat generator.

Operating experience shows that following the recommendations is the best way to extend the life of the boiler, ensure maximum heat transfer and comfortable heating of residential premises.

Calculation of power and temperature of a warm water floor

How to store solar

Perhaps this is the very first question that confronts the owners of a diesel boiler. And it's true: the storage of liquid fuels is subject to special requirements to ensure your safety.

There are 2 types of storage tanks for diesel fuel:

- open-mounted - are plastic barrels made of polyethylene or PVC. Their kit must necessarily include a system for taking fuel from the tank, a sealed cover and a float to determine the level of liquid in the tank.

When can they be used? For fuel storage in small country houses, if the planned volume of diesel fuel does not exceed 1000 liters.

Tank for storage of large volume of fuel

- closed installation - most often made of galvanized iron, however, it has recently been possible to use chemically resistant plastic. They are installed in a pre-dug pit, which should be at a distance of at least 5 meters from the foundation of the house. In this case, the system must be equipped with a pump to supply fuel from the depth.

When can they be used? They are indispensable if you are going to store a large amount of diesel fuel (up to 20,000 liters).

Such systems must be equipped not only with level sensors, but also with fuel leakage sensors. Diesel fuel for filling the barrel is delivered by a special service for the sale of fuels and lubricants.

Diesel burners for boilers their functions

A diesel burner is one of the main parts of the heating unit; without it, the boiler simply will not work. This is a special device with which the process of burning fuel takes place. Its purpose is to prepare the fuel, i. mix it with oxygen. Only then can the mixture be used in the combustion chamber. As a rule, such equipment runs on diesel fuel or fuel oil, rarely on oil.

This equipment has the following advantages:

- Large range power;

- Economical fuel consumption;

- High efficiency rates;

- Ability to automate the device.

Compared to gas "brothers", diesel ones have one drawback - this is the high price of diesel fuel. But here a cheaper option is also possible - the use of used oil for its operation.

Heating with droppers

If a drip oven is used for heating, its power is needed at least 15-16 kW. This cannot be achieved only by increasing the frequency of the drops: due to the increased heat release, the drops will evaporate even in the supply tube. The stove (now a self-made liquid fuel boiler) will switch to popping combustion, and then go out. Therefore, in a heating boiler for diesel fuel and working out, the dropper tube is brought to a flame bowl in a shirt cooled by an air stream.

But that's not all. Due to the same greater heat release, the evaporation of fuel and the combustion of vapors will be more intense. Part of the fuel vapor will be immediately thrown aside, will not burn and will accumulate in the volume of the boiler, which can lead to an explosion. Therefore, a swirler is installed at the outlet of the fuel line, and the design of the deflector will be different than in a drip potbelly stove.

Scheme of a heating system with a drip boiler on diesel fuel

Air supply up to approx. 12 kW thermoconvection non-volatile: the intake air is first heated in the air jacket of the chimney, and then cools somewhat in the aluminum corrugated hose, which provides the necessary "suction". For high power, airflow from a fan is required approx. 60 W, for example, blowing the VAZ-2109 radiator.

Drawings of drip boilers on diesel fuel for water and air heating

A significant drawback of the described system is that in order to avoid the burner going out and the accumulation of explosive vapors in it, the water in the boiler jacket must flow countercurrent to the natural thermosiphon circulation, i.e. top down. Therefore, the system requires a circulation pump with non-volatile (thermomechanical) automatic emergency shutdown of the boiler in case of power failure. All this makes this system very complex and at the same time unreliable.

It is possible to build a drip boiler for a water heating system with natural thermosiphon circulation, but in this case its design becomes more complicated and it becomes necessary to force air into the fuel line cooling jacket. If you want to be heated without fail with diesel fuel or there is simply nothing more, then the drawings of a drip heating boiler with natural circulation of the coolant in a water jacket, see the following. rice.

Drawings of a drip boiler on diesel fuel for a water heating system with thermosiphon circulation

Also an option

There is another way to start a wood-coal stove on kerosene and diesel fuel: put an ejection burner into the furnace. It is possible if there is a source of compressed air - a boost of 1.5-2 ati is needed. Provided that the fuel tank is located below the burner (this is absolutely necessary!) This method is as safe as possible: there is no pressurization - the burner goes out. The assembly drawing of the spray head of the ejection burner for gasoline, kerosene and diesel fuel is given in fig. Air is supplied to the annular gap (highlighted in color); the missing dimensions can be taken proportionally, because scale drawing.

Spray head drawing for liquid fuel ejection burner

Conclusion

So we talked about what diesel heating boilers are. Fuel consumption, consumer reviews, as well as some of the technical specifications discussed in this article will help you make the right choice. In any case, you should take care in advance about where you will take fuel for the boiler. If there are machine-building plants nearby, where oil is used as a lubricant, and a large amount of mining is simply poured out, then it is possible to agree on very favorable terms for both parties.

Most models have a fairly high efficiency, about 95%. This suggests that almost all of the combustible fuel will go into heat in the house. But diesel boilers also have their drawbacks. The main one is that the quality of fuel is not always high. During the fuel supply to the burner, the filter quickly becomes clogged, and it has to be changed.

Unlike natural gas, a diesel or oil leak is not fatal, which is no doubt very important. But here the joints can leak, so you need to constantly watch them and, if necessary, tighten the nut

Contrary to all stereotypes: a girl with a rare genetic disorder conquers the fashion world This girl's name is Melanie Gaidos, and she broke into the fashion world quickly, shocking, inspiring and destroying stupid stereotypes.

Unforgivable Movie Mistakes You Probably Never Noticed There are probably very few people who don't like watching movies. However, even in the best cinema there are errors that the viewer can notice.

Never do this in a church! If you're not sure if you're doing the right thing in church or not, then you're probably not doing the right thing. Here is a list of the terrible ones.

20 photos of cats taken at the right moment Cats are amazing creatures, and perhaps everyone knows about it. They are also incredibly photogenic and always know how to be at the right time in the rules.

11 Weird Signs That You're Good in Bed Do you also want to believe that you're giving your romantic partner pleasure in bed? At least you don't want to blush and apologize.

7 Body Parts You Shouldn't Touch Think of your body as a temple: you can use it, but there are some sacred places that you shouldn't touch. Display research.