What is an elevator assembly of a heating system

Why do we need an elevator heating unit schemes, principles of operation and installation verification

Reducing heat loss is a major concern when planning district heating. For this, even at the stage of heating the coolant, special conditions are created for its transportation: increased pressure, maximum temperature conditions. But in order for the level of heating to drop to the required level during the distribution of hot water, an elevator heating unit is installed: schemes, principles of operation and checks must strictly comply with the standards. Despite the fact that it is part of the central heating, the average user must know how it works.

Three way valve

If it is necessary to divide the coolant flow between two consumers, a three-way valve is used for heating, which can operate in two modes:

- permanent mode;

- variable hydro.

The ball valve is mainly used for:

- adjusting the temperature of underfloor heating;

- battery temperature control;

- distribution of the coolant in two directions.

There are two types of three-way valves - shut-off and control. In principle, they are almost equivalent, but it is more difficult to smoothly regulate the temperature with shut-off three-way valves.

The device and principle of operation of the heating elevator

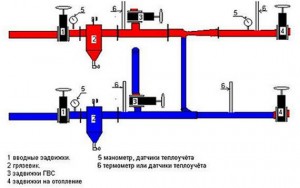

Thermal node scheme

The elevator harness includes:

- mud filters;

- pressure gauges (at the inlet and outlet);

- thermal sensors (thermometers at the elevator inlet, outlet and return line);

- valves (for preventive or emergency work).

The advantages of its use for heating large objects, houses and skyscrapers:

- reliability, due to the simplicity of the design;

- low price of installation and accessories;

- absolute energy independence;

- significant savings in heat carrier consumption up to 30%.

But in the presence of indisputable advantages of using an elevator for heating systems, the disadvantages of using this device should also be noted:

- calculation is done individually for each system;

- you need a mandatory pressure drop in the heating system of the facility;

- if the elevator is unregulated, it is not possible to change the parameters of the heating circuit.

Elevator with automatic adjustment

The elevator regulates the supply and pressure of the coolant, and its pressure drives the flow in the heating circuit.

Features of installation and verification

Installation of the elevator assembly

It should be noted right away that the installation and verification of the operation of the elevator unit and the heating system is the prerogative of representatives of the service company. It is strictly forbidden for residents of the house to do this. However, knowledge of the layout of the elevator units of the central heating system is recommended.

When designing and installing, the characteristics of the incoming coolant are taken into account

The branching of the network in the house, the number of heating devices and the temperature regime of operation are also taken into account. Any automatic elevator assembly for heating consists of two parts

- Adjusting the intensity of the flow of incoming hot water, as well as measuring its technical indicators - temperature and pressure;

- Directly the mixing unit itself.

The main characteristic is the mixing ratio. This is the ratio of the volumes of hot and cold water. This parameter is the result of precise calculations. It cannot be a constant, as it depends on external factors. Installation must be carried out strictly according to the scheme of the elevator unit of the heating system. After that, fine tuning is done. To reduce the error, the maximum load is recommended. Thus, the temperature of the water in the return pipe will be minimal.This is a prerequisite for accurate control of the automatic valve.

After a certain period of time, scheduled checks of the operation of the elevator unit and the heating system as a whole are necessary. The exact procedure depends on the specific scheme. However, you can draw up a general plan, which includes the following mandatory procedures:

- Checking the integrity of pipes, valves and devices, as well as the compliance of their parameters with passport data;

- Adjustment of temperature and pressure sensors;

- Determination of pressure losses during the passage of the coolant through the nozzle;

- Calculation of the offset factor. Even for the most accurate heating scheme of the elevator unit, equipment and pipelines wear out over time. This correction must be taken into account when setting up.

After carrying out these works, the central heating automatic elevator unit must be sealed to prevent outside interference.

Do not use self-made schemes of elevator units for central heating systems. They often do not take into account the most important characteristics, which can not only reduce work efficiency, but also cause an emergency.

The device and operation of the adjustable elevator

1 - body;

2 - diffuser;

3 – mixing chamber;

4 - nozzle;

5 - conical tip;

6 - stock;

7 - stuffing box;

8 - rack;

9 - index belt;

10 - position indicator;

11 - MEP;

12 – handwheel handle;

13 – casing MEP;

14 - threaded plug;

15 - lead screw;

16 - clutch;

17 - nut;

18 - slotted nut;

27 - branch pipe of network water;

28 - return water pipe;

29 - mixed water pipe.

The basis of the regulating elevator is the body 1 with the network water inlet pipe 27 and the return water inlet pipe 28.

Inside the housing there is a mixing chamber 3 and a nozzle 4, which together with the diffuser 2 form a jet pump.

The action of the jet pump is based on the principle of injection. The flow of network water having a higher pressure and

temperature, enters through the pipe 27 into the receiving chamber and through the nozzle 4 is injected into the mixing chamber 3. In the mixing chamber

network water is mixed with water sucked from the return pipeline through the inlet pipe 28 and fed into the diffuser 2.

In the diffuser, the process of converting kinetic energy into potential energy takes place. From the diffuser through the outlet 29

the mixed water flow enters the supply pipeline of the heating system.

The water temperature of the mixed flow is controlled by changing the ratio between the flows of network water and water from the return pipeline.

The conical tip 5 moves relative to the nozzle 4 with the help of the rod 6, while changing the area of the flow section

nozzles, the mixing ratio of the elevator and, therefore, the ratio between the flows of water coming from the inlets to the outlet.

The main materials used in the manufacture of the elevator

| the name of detail | Material Grade |

|---|---|

| Frame | No. 0-2 - Cast iron SCh20, No. 3-7 - Carbon steel St20 |

| Stuffing box | Carbon steel St20 |

| Tip, stem, nozzle | Stainless steel 40X13 (12X18H10T) |

| pad | Paronite PON-B |

| Gland packing | Fluoroplast F4K20 |

The sealing of the stem during its movement is performed by the gland assembly 7, which is screwed into the housing 1.

In the body 21 of the gland assembly, sealing parts are installed: spring 22, washer 23, fluoroplastic cuffs 24, bushing

25 and fixing nut 26. The use of spring 22 ensures constant compression of cuffs 24 with the required force, which increases the service life

seals.

Before assembling the gland assembly, the cuffs 24 are lubricated with plastic silicone grease, which reduces friction during the movement of the rod, which also increases the service life of the seal.

The main technical characteristics and dimensions of EG703 type elevators are given in the description for the Retel 703 regulator. Read more

Electric linear mechanism (type MEP910) 11 is designed to move the rod 6 with the tip 5 when adjusting the mixing ratio of the elevator.

The current position of the rod with the tip is determined using the position indicator 10. The full stroke of the regulator (RO) of the elevator is limited by position microswitches 35 SQ1, 36 SQ2 MEP.

In case of emergency power off, a manual override is used. To move the RO, the plug 14 is unscrewed and the handle 12 is put on the axis 32 until it stops, and the +24 V power supply circuit is broken, which provides additional security measures.

Values of nominal forces on the rod for elevators:

| Conventional designation of the elevator design | Rated force, N |

|---|---|

| EG703-4-0.04 No. 0… EG703-18-094 No. 7 | 2000 |

The speed of movement of the regulating body at the manufacturer is set to 5 mm / min - for heating systems.

MEP is a gearbox with a built-in stepper motor.

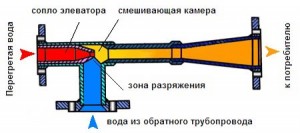

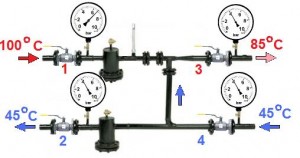

The principle of operation of the elevator unit

The principle of operation of the thermal elevator unit and the water jet elevator. In the previous article, we found out the main purpose of the thermal elevator unit and the features of operation, water-jet or, as they are also called, injection elevators. In short, the main purpose of the elevator is to lower the water temperature and at the same time increase the volume of pumped water in the internal heating system of a residential building.

Now we will analyze how the water jet elevator still works and due to which it increases the pumping of the coolant through the batteries in the apartment.

The coolant enters the house with a temperature corresponding to the temperature schedule of the boiler. The temperature graph is the ratio between the temperature outside and the temperature that the boiler house or CHP should supply to the heating network, and, accordingly, with small losses to your heating point (water, moving through pipes over long distances, cools down a bit). The colder it is outside, the higher the temperature of the boiler room.

For example, with a temperature graph of 130/70:

- at +8 degrees outside, the heating supply pipe should be 42 degrees;

- at 0 degrees 76 degrees;

- at -22 degrees 115 degrees;

If someone is interested in more detailed figures, you can download temperature charts for various heating systems here.

But let's get back to the principle and scheme of operation of our thermal elevator unit.

After passing the inlet valves, mud collectors or mesh-magnetic filters, the water enters directly into the mixing elevator device - the elevator. which consists of a steel body, inside which there is a mixing chamber and a constriction device (nozzle).

Superheated water exits the nozzle into the mixing chamber at high speed. As a result, a vacuum is created in the chamber behind the jet, due to which water is sucked in or injected from the return pipeline. By changing the diameter of the hole in the nozzle, it is possible, within certain limits, to regulate the flow of water and, accordingly, the temperature of the water at the outlet of the elevator.

The elevator of the thermal unit works simultaneously as a circulation pump and as a mixer. However, it does not consume electricity. but uses the pressure drop in front of the elevator or, as they say, the available pressure in the heating network.

For efficient operation of the elevator, it is necessary that the available pressure in the heating network correlates to the resistance of the heating system no worse than 7 to 1. If the resistance of the heating system of a standard five-story building is 1 m or it is 0.1 kgf / cm2, then for the normal operation of the elevator unit, the available pressure in the heating system to the ITP is at least 7 m or 0.7 kgf / cm2.

For example, if in the supply pipeline 5 kgf / cm2, then in the reverse it is not more than 4.3 kgf / cm2.

Please note that at the elevator outlet, the pressure in the supply pipeline is not much higher than the pressure in the return pipeline, and this is normal, it is quite difficult to notice 0.1 kgf / cm2 on pressure gauges, the quality of modern pressure gauges is unfortunately at a very low level, but this is already a topic for a separate article. But if you have a pressure difference after the elevator more than 0.3 kgf / cm2, you should be wary, or your heating system is heavily clogged with dirt, or during a major overhaul, you have greatly underestimated the diameters of the distribution pipes

The above does not apply to circuits with Danfoss type thermostats on batteries and risers, only mixing circuits using control valves and mixing pumps work with them. By the way, the use of these regulators is also in most cases very controversial, since most domestic boiler houses use precisely high-quality regulation according to the temperature schedule. In general, the mass introduction of Danfoss automatic regulators became possible only thanks to a good marketing campaign. After all, “overheating” is a very rare phenomenon in our country, usually we all receive less heat.

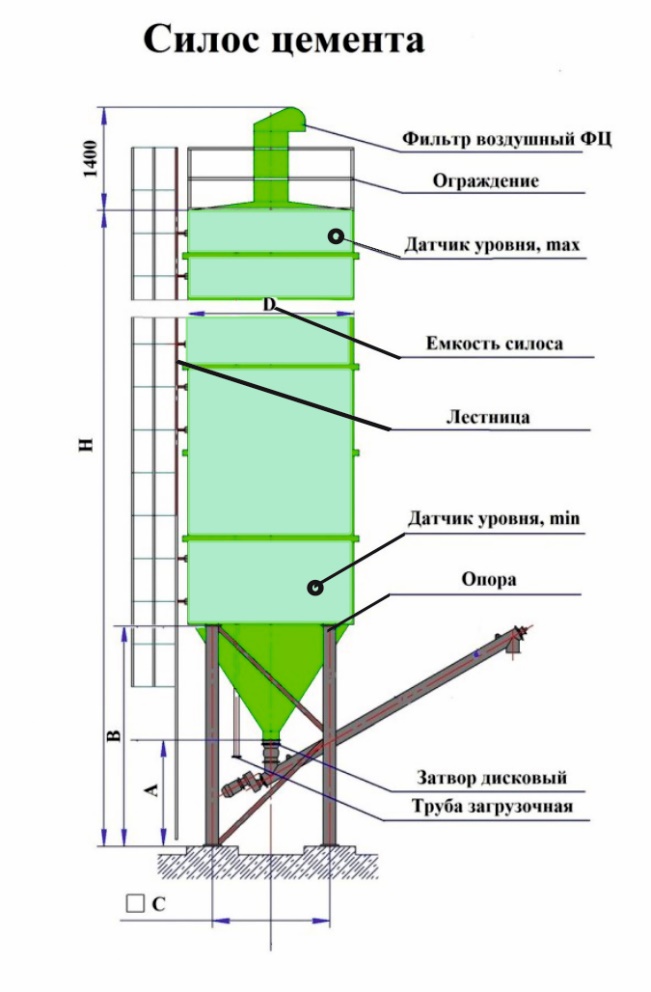

We study a typical drawing of a cement silo

The drawing of a cement silo shows the placement of the main structural elements.

The silo is installed vertically. The cement is supplied to storage through the loading pipeline with a pump. Loading of cement can be carried out inside or outside the silo. An air filter and a maintenance hatch are installed in the upper part of the silo. A gallery with pipelines, filters and switches is placed along the roof. The cone of the lower part has a special hole for supplying cement with a gate valve. The metal supports of the large-capacity silos rise above the railroad tracks, where the scales are installed. Then loaded into wagons or road transport.

Cement silo design features

Cement storages with a radius of up to 6.0 m are installed according to the project in 1 row, with a radius of more than 6.0 m - in 2 rows. This design practice takes into account the stability of structures. Silos are calculated according to SP 20.13330.

The project takes into account the loads:

- temporary long-term (the weight of cement, its friction against the walls of structures, the weight of pneumatic transport, filters, etc.);

- short-term

- monolithic metal silos are designed taking into account the same groups of loads;

- in addition, steel silos are tested for stability, taking into account temperature fluctuations,

- supports are calculated as racks clamped into the foundation.

For silo cylinders, in addition to the section of the KM project (metal structures), a section of the KMD project (metal detailing structures) and a KZh section (reinforced concrete structures) for foundations are developed.

To start the development of a foundation project, data from geological and hydrogeological surveys are required; information about the presence of underground and surface communications. The type of foundation is determined by the design calculation. More often, a concrete monolithic slab with reinforcement is performed. On rocky soils, free-standing strip or prefabricated foundations are designed. The foundation on piles is designed if the soils have a draft.

Structural solutions of the project must be linked with engineering solutions, the design of access roads and auxiliary facilities on the site. A well-executed project complies with urban planning and environmental regulations.

The project passes the necessary approvals, then a contract for architectural supervision is concluded between the customer and the designer, and construction can begin.

Elevator with adjustable nozzle.

Now it remains for us to figure out how easier it is to regulate the temperature at the outlet of the elevator. and is it possible to save heat with the help of an elevator.

Saving heat with a water jet elevator is possible, for example, by lowering the temperature in rooms at night. or during the day when most of us are at work. Although this issue is also controversial, we lowered the temperature, the building has cooled down, therefore, in order to warm it up again, the heat consumption against the norm must be increased. There is only one benefit, at a cool temperature of 18-19 degrees one sleeps better. our body feels more comfortable.

water jet elevator with adjustable nozzle

In principle, all control elevators are made in the same way. Their device is clearly visible in the figure. By clicking on the picture. You can see an animated image of the operation of the WARS control mechanism of a water jet elevator.

And finally, a brief comment - the use of water-jet elevators with an adjustable nozzle is especially effective in public and industrial buildings, where it saves up to 20-25% of heating costs, lowering the temperature in heated rooms at night and, especially, on weekends.

What else to read on the topic:

- Elevator unit with a heat meter scheme

- Passport of the heat energy metering unit sample

- What is an elevator? Elevator heating unit –…

Distribution devices

The elevator assembly with all its piping can be represented as a pressure circulation pump, which, under a certain pressure, supplies the coolant to the heating system.

If the facility has several floors and consumers, then the most correct solution is to distribute the total heat carrier flow to each consumer.

What is an elevator

In simple terms, the elevator is a special device related to heating equipment and performing the function of an injection or water jet pump. No more, no less.

Its main task is to increase the pressure inside the heating system. That is, to increase the pumping of the coolant through the network, which will lead to an increase in its volume. To make it clearer, let's take a simple example. 5-6 cubic meters of water are taken from the supply water supply as a coolant, and 12-13 cubic meters enter the system where the apartments of the house are located.

How is this possible? And due to what is the increase in the volume of the coolant? This phenomenon is based on some laws of physics. Let's start with the fact that if an elevator is installed in the heating system, then this system is connected to central heating networks, through which hot water moves under pressure from a large boiler room or CHP.

So the temperature of the water inside the pipeline, especially in extreme cold, reaches +150 C. But how can this be? After all, the boiling point of water is +100 C. This is where one of the laws of physics comes into play. At this temperature, water boils if it is in an open container where there is no pressure. But in the pipeline, water moves under pressure, which is created by the operation of the supply pumps. Therefore, she does not boil.

Go ahead. Temperature +150 C is considered very high. It is impossible to supply such hot water to the apartment heating system, because:

- Firstly, cast iron does not like large temperature changes. And if cast-iron radiators are installed in the apartments, they can fail. Well, if they just let it flow.But they can break, because under the influence of high temperatures, cast iron becomes brittle, like glass.

- Secondly, at such a temperature of metal heating elements it will not be difficult to get burned.

- Thirdly, plastic pipes are now often used to tie heating devices. And the maximum that they can withstand is a temperature of +90 C (besides, with such figures, manufacturers guarantee 1 year of operation). So they just melt.

Therefore, the coolant must be cooled. This is where the elevator is needed.