Divatop micro

Wall mounted gas boiler

Heating and DHW modes (separate heat exchangers)

LCD display with backlight, built-in boiler 3 l

DESIGN FEATURES:

- two heat exchangers: for heating (copper) and hot water (steel)

- the outer surface of the heat exchanger is coated with an aluminum-based anti-corrosion compound

- combustion chamber made of steel with aluminum anti-corrosion coating

- the inner surface of the chamber is insulated with environmentally friendly material

- electric ignition

- digital control system based on two microprocessors: for combustion control and boiler control

- injection burner with AISI304 stainless steel heads

- security system based on ionization electrode

- the process of power modulation of heating and hot water systems is controlled by an electronic board equipped with a microprocessor

- large multifunctional LCD display with backlight for setting system operation parameters

- 3 way valve

- 3-speed heating circulation pump

- bypass circuit (by-pass) in the heating system with automatic parameter setting

- diverter valve

- ECO/Comfort DHW functions

- the ability to operate both on liquefied and natural gas (subject to the use of a special kit)

- anti-blocking of the pump (every 24 hours the boiler is idle for a few seconds turns on the pump)

- frost protection

- the ability to connect a remote control Romeo

- Possibility to connect a room programmer device Oscar

- operation in outdoor temperature compensation mode (when an outdoor thermostat is installed)"

- complete set of accessories: wall template, copper fittings, standard water and gas taps

- easy access to the internal components of the boiler from the front (facilitates the service process)

- easy installation (thanks to the large distance (190 mm) between the wall and the connection fittings)

- Possibility to connect water heaters solar panels (solar systems)

- A chimney must be purchased for models F24, F32 and F37 (see section "Chimneys for wall-mounted boilers with a closed combustion chamber".)

Prices

| Model | Price in rubles | Price in euro | Purchase |

| S24 M | Call! | — | To order |

| S32 M | Call! | — | To order |

| F24 M | Call! | — | To order |

| F32 M | Call! | — | To order |

| F37 M | Call! | — | To order |

Specifications

| Models | S24 M | S32 M | F24 M | F32 M | F37 M |

| Power max, kW | 23,5 | 34,4 | 24 | 34,4 | 34.4 |

| Power min, kW | 8,3 | 11,5 | 8,3 | 11,5 | 11.5 |

| Chimney diameter, mm | 131 | 141 | coaxial | coaxial | coaxial |

| DHW capacity, lit./min | 13,4 | 17,9 | 13,7 | 18,3 | 21,2 |

| Power consumption ~220 V, W | 80 | 90 | 110 | 135 | 165 |

| Overall dimensions height/width/depth, mm | 700/450/340 | 700/450/340 | 700/450/340 | 700/450/340 | 700/450/340 |

| Inlet and outlet of the heating circuit, inch | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 |

| Inlet and outlet of the DHW circuit, inch | 1/2 | 1/2 | 1/2 | 1/2 | 1/2 |

| Gas supply, inch | 1/2 | 1/2 | 1/2 | 1/2 | 1/2 |

| Weight, kg | 28 | 31 | 33 | 35 | 40 |

| Energy efficiency class (EN 92/42 CEE) | Grade 2 | Grade 2 | 3rd grade | 3rd grade | |

| Type of combustion chamber | open | open | closed | closed | |

| Temperature in the DHW circuit (max / min), ° С | 65/40 | 65/40 | 65/40 | 65/40 | |

| Pressure in the DHW circuit (max / min), bar | 9/0,25 | 9/0,25 | 9/0,25 | 9/0,25 | |

| Maximum pressure in the heating circuit, bar | 3 | 3 | 3 | 3 | |

| Nominal pressure of natural gas at the inlet, mbar | 20 | 20 | 20 | 20 | |

| Minimum natural gas pressure, mbar | 1,5 | 1,5 | 1,5 | 1,5 | |

| Ability to work on liquefied gas | Yes | Yes | Yes | Yes |

Boilers from Ferroli

Wall and floor models

Despite a very wide range of installations for heating residential and industrial premises, the lion's share of Ferroli's profit is brought by gas heating boilers - wall and floor. At the same time, it is in the segment of wall-mounted household gas heating boilers that the greatest diversity is observed.

This is due to the fact that compact wall models have a number of advantages in use:

- Firstly, such a boiler can be installed directly in a residential area, since it does not require a separate boiler room.

- Secondly, if earlier the power required for heating could be provided only by large-sized installations, today, due to the use of modern technologies, even a small boiler can heat up to 300 square meters of living space.

- Ease of installation is another argument in favor of choosing small models mounted on the load-bearing wall of the room. Of course, it’s not worth installing the boiler with your own hands, since this requires a special permit - but the installation cost directly depends on its complexity!

The price also plays an important role. Although Ferroli products cannot be attributed to the cheapest price segment, you can still choose a very affordable option among mounted models.

Application and equipment

Ferroli boilers can be used in the following areas:

- Firstly, for heating private houses and cottages. As we pointed out above, the power quite allows.

- Secondly, the compact dimensions make it possible to use these installations even in apartment buildings for organizing individual heating.

For the effective implementation of these functions, Ferroli units are equipped with the following equipment:

- An open or closed type combustion chamber (respectively, they are marked C or F).

- Bithermic heat exchange tank made of copper alloy.

- Automatic control system for the operation of the burner on the meringue of the microprocessor unit.

- Protection against freezing, overheating or the formation of internal scale.

Also included in the basic package is a unit responsible for modulating the flame and an ionization system for controlling the intensity of combustion. Thanks to this, Ferroli boilers are completely protected from possible gas leaks.

The appearance of the boilers, as well as the location of the main elements, are shown in the photo. The instruction included with each product clearly demonstrates the process of connecting the boiler to the network, as well as the sequence of adjusting its main functions. The installation of Ferroli gas heating boilers should be carried out only by specialists, and no amateur performance!

Main series

DIVAtop

The list of models of heating equipment put on the market by Ferroli is very wide. Therefore, within the framework of this article, we will consider only the most significant series from the entire product range.

The DIVAtop series is one of the first to be introduced to the Russian market. The basis of this series is high-performance double-circuit boilers for domestic use.

- DIVAtop devices are characterized by a stylish housing design, which allows them to be installed directly in residential areas.

- The key design feature of the DIVAtop range is the 3-way valve equipped with a separate servomotor.

- For efficient heat transfer, the heat exchanger for the hot water system, which has a lamellar design, is responsible.

DOMIcompact

Units from the DOMIcompact series are focused not so much on heating (although they perform this function quite efficiently), but on the fastest way to get hot water. At the same time, the heat exchanger of a special design installed in the boiler does not overheat, and scale is practically not formed in it.

- The DOMIcompact boiler can be controlled both with conventional adjustment knobs and with the help of a liquid crystal display. A built-in chimney can be used to remove combustion products.

- The DOMIcompact-B modification includes a more modern heat exchanger.Using the energy of steam condensation allows you to increase the power of the boiler, while reducing fuel consumption.

- Also, this modification significantly reduced the percentage of emissions of harmful gases into the atmosphere.

Ecocept

The Econcept series represents the embodiment of the ecological paradigm. Distinctive features of the Econcept series boilers are:

- Heat exchanger-condenser made of high-strength aluminum.

- Cermet burner with continuous modulation, equipped for the use of different types of gaseous fuels.

- Microprocessor-based boiler control system, adapted for the installation of a weather-compensated control system.

- Plate heat exchanger, providing the fastest possible heating of water in the hot water circuit.

At the same time, the Econcept series is characterized by a minimum amount of atmospheric emissions, as well as very impressive safety and fault tolerance indicators.

CONTACT OUR SPECIALISTS

List of works on service maintenance and repair of FERROLI boiler equipment1. Check, inspection and cleaning of dust, soot and deposits (if necessary) of the boiler furnace

2. Inspection of the chimney for tightness, cleanliness, as well as for the required allowable diameter and height

3. Checking the presence and correctness of the air flow into the boiler room4. Checking and cleaning electrodes, burner diffuser, injector nozzle5. Checking and cleaning suction line filters, pump and nozzle6. Photoresistor cleaning

7. Cleaning of high-voltage wires and electronic boards from dust8. Checking the solenoid valve (valve and filter)9. Cleaning the ionization electrode and pilot burner with jet10. Checking the tightness of all pipelines, devices (including the fuel line and gas line to the boiler)11. Checking the tightness of the burner connection to the boiler12. Checking the pressure of the coolant in the heating system (visually)13. Checking the supply voltage and electrical protection, as well as the correct phasing and the presence of equipment grounding14. Checking the performance of circulation pumps15. Checking the operation of automation: - operation of the thermostat - operation of the thermostat

- operation of the indicating thermomanometer - burner blocking system (switching off the electric power and fuel)

- thermomanometer operation

- operation of safety automation and fittings (safety valves)

- performance of the thermocouple (when using boilers with piezo ignition)16. Adjustment of correct burner setting (air, diffuser gap, fuel pressure, etc.)17. Measurements of boiler operation parameters: (if necessary) - measurement of fuel pressure at the burner inlet

- measurement of fuel pressure at the outlet of the gas valve and at the burner block - measurement of gas pressure in the line - measurement of flue gas temperature - measurement of CO, CO2 content - measurement of vacuum in the flue duct - measurement of soot content in flue gases (Baccarat indicator - soot)

-Checking the operation of the minimum gas pressure controller18. Checking the starting and working gas pressure19. Checking the air pressure in the expansion tank of the heating system20. Checking the air pressure in the expansion tank of the hot water system21. Boiler safety group check22. Checking the ground contact23. Checking sensors and boiler automation

24. Air release (if necessary), as well as pumping the heating system to the required parameters

25. Measurement of the required voltage and the presence of a stabilizer (uninterruptible power supply) at the heating boiler

26. Consultation of the personnel at the facility (boiler room) on programming parameters, entering programs, logical control of the boiler or cascade, entering additional parameters, as well as advice on eliminating installation defects (modernization of the boiler room)

27. Filling out the required accounting documents with customizable options, etc.

Our company has the necessary warehouse stock of the main spare parts and components for the equipment we service! CALL FOR ALL QUESTIONS!!! 8 (903) 725-92-17 Or order online. Breakdown of spare parts depending on boiler model>>>>>

Ferroli boiler service, spare parts for FERROLI boilers, accessories for Ferroli boilers!!! Departure, guarantee, original spare parts. You will find everything here 8-903-725-92-17!!! (CALL!!!)

How to setup

Many boilers from Ferroli are equipped with or supplemented with automatic controls, which makes the use of the product easier. The owner of the house himself will be able to configure the operation of the equipment through the panel.

Do-it-yourself gas valve setting is done as follows:

- a pressure gauge is installed in a special socket to control the pressure level at the outlet of the valve;

- for a few seconds you need to connect the test mode;

- the "eco/comfort" button is pressed;

- “q02” signal will appear on the screen;

- if the pressure level differs from the initial parameters, then by pressing the “-” or “+” buttons, you can reduce or increase the “q02” parameters by the required number of units;

- then the "heating" button is pressed;

- “q01” will appear on the screen;

- to return to the test mode, the "eco/comfort" button is pressed;

- it remains to double-check all the settings and adjust them;

- you need to turn off the pressure gauge and exit the test mode.

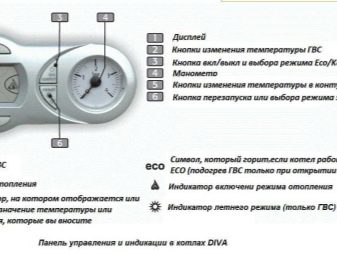

2 control panels

panel

1

8

5

11

12

14

3

fig. 1 - control panel

Key of panel fig. one

1

DHW temperature setting decrease button

2

DHW temperature setting increase button

3

Heating system temperature setting decrease button

4

Heating system temperature setting increase button

5

display

6

"Sliding Temperature" Menu - Summer/Winter mode selection - Reset button

7

Unit On/Off - Economy/Comfort mode selection button

8

DHW symbol

9

DHW mode

10

summer mode

11

multifunction

12

Eco (Economy) mode

13

heating

14

heating symbol

15

Burner lit and actual power level (flashing during combustion fault function)

16

Service Tool connection

17

water gauge

2

EN

2

9

10

15

7

eco

2

comfort

1

reset

4

13

16

6

cod. 3541P560 - Rev. 00 – 06/2018

indication during operation

heating

A heating demand (generated by the Room Thermostat or Remote Timer Control) is in-

dicated by flashing of the hot air above the radiator on the display.

The display (detail 11 - fig. 1) shows the actual heating delivery temperature and, during

heating standby time, the message "d2".

domestic hot water (DHW)

A DHW demand (generated by drawing domestic hot water) is indicated by flashing of

the hot water under the tap on the display.

The display (detail 11 - fig. 1) shows the actual DHW outlet temperature and, during

DHW standby time, the message "d1".

Comfort

A Comfort demand (reinstatement of temperature inside the boiler) is indicated by flash-

ing of the water under the tap on the display. The display (detail 11 - fig. 1) shows the

actual temperature of the water in the boiler.

Fault

In case of a fault (see cap. 4.4) the display shows the fault code (detail 11 - fig. 1) and

during safety pause times the messages "d3", "d4" and "d5".

2.3 Lighting and shutdown

Connection to the power supply

•

During the first 5 seconds the display will also show the card software release.

•

Open the gas cock ahead of the boiler.

•

The boiler is now ready to function automatically whenever domestic hot water is

drawn or in case of a heating demand (generated by Room Thermostat or Remote

temperature control).

Turning the boiler off and on

Press the on/off button (detail 7 - fig. 1) for 5 seconds.

When the boiler is turned off, the circuit board is still powered. domestic hot water and

heating are disabled. The frost protection system remains activated. To relight the boiler,

press the on/off button (detail 7 fig. 1) again for 5 seconds.

17

The boiler will be immediately ready to work whenever domestic hot water is drawn or in

case of a heating demand (generated by the Room Thermostat or the Remote Timer

control).

B

The frost protection system does not work when the power and/or gas to the

unit are turned off. To avoid damage caused by freezing during long shutdowns

3

in winter, it is advisable to drain all water from the boiler, the DHW circuit and

the heating system water; or drain just the DHW circuit and add a suitable an-

tifreeze to the heating system, as prescribed in sec. 3.3.

4

2.4 Adjustments

Summer/Winter Switchover

Press the summer/winter button (detail 6 - fig. 1) for 2 seconds.

The display activates the Summer symbol (detail 10 - fig. 1): the boiler will only deliver

domestic hot water. The antifreeze system remains activated.

To deactivate the Summer mode, press the summer/winter button (detail 6 - fig. 1)

again for 2 seconds.

Heating temperature adjustment

Use the heating buttons (details 3 and 4 - fig. 1) to adjust the temperature from a min. of

30°C to a max. of 80°C; in any case, it is advisable not to operate the boiler below 45°C.

DIVAtech D F

fig. 2 - Turning the boiler off

fig. 3

fig. 4

Usage Tips

In order for the boilers to break down less often, the user needs to take good care of the equipment casing by wiping it with a rag and soapy water. Once a year, a complete inspection of the product should be carried out. Experts advise to check the combustion process from time to time

It is extremely important to monitor the set parameters of Ferroli boilers

It is virtually impossible to find negative reviews about the equipment of this manufacturer.

All users note excellent performance, thoughtful design of devices and low gas consumption, almost silent operation of products, which is extremely important when installing them in residential buildings where boilers with heating and hot water are needed

But still, you can find certain nuances when using gas appliances from Ferroli. In reviews, the possibility of leakage in the heat exchange system is often noted. This is a common problem that can in no way be related to the quality of the company's products. Such phenomena appear due to improper use of the product and due to the use of hard water. For this reason, it is better to immediately choose models that are able to work with both gas and water.

An overview of the Ferroli Domiproject 24F gas boiler model, see the video below.

FAULTS AND REPAIRS

REPAIR OF THE GAS COLUMN

SPARE PARTS FOR BOILERS

4 Troubleshooting

Diagnostics

The boiler is equipped with an advanced self-diagnosis system. In case of a boiler fault,

the display will flash together with the fault symbol (detail 11 - fig. 1) indicating the fault

code.

There are faults that cause permanent shutdown (marked with the letter "A"): to restore

operation, press the RESET button (detail 6 - fig. 1) for 1 second or RESET on the op-

rational remote timer control if installed; if the boiler fails to start, it is necessary to eliminate

the fault.

Faults marked with the letter "F" cause temporary shutdowns that are automatically reset

as soon as the value returns within the boiler’s normal working range.

List of faults

table. 2

Fault

Fault

possible cause

code

no gas

Ignition/detection electrode fault

A01

No burner ignition

Faulty gas valve

Gas valve wiring disconnected

Ignition power too low

Electrode fault

Flame present signal with

A02

burner off

Card fault

Heating sensor damaged

Overtemperature protection

A03

action activation

No water circulation in the system Check the circulating pump

Air in the system

Fume thermostat contact open

Fume thermostat activated

(after activation of the fume

Wiring disconnected

F04

thermostat, boiler operation

Flue obstructed or not correctly

is prevented for 20 minutes)

sized

F05

Card parameter fault

Wrong card parameter setting

Low pressure in the gas system

No flame after the ignition

A06

phase

Burner minimum pressure setting Check the pressures

F07

Card parameter fault

Wrong card parameter setting

Wiring disconnected

A09

Gas valve fault

Faulty gas valve

Sensor damaged

F10

Delivery sensor 1 fault

Wiring shorted

Wiring disconnected

Sensor damaged

F11

DHW sensor fault

Wiring shorted

Wiring disconnected

Sensor damaged

F14

Delivery sensor 2 fault

Wiring shorted

Wiring disconnected

Wiring disconnected

A16

Gas valve fault

Faulty gas valve

F20

Card parameter fault

Wrong card parameter setting

A21

Card parameter fault

Wrong card parameter setting

A23

Card parameter fault

Wrong card parameter setting

A24

Card parameter fault

Wrong card parameter setting

F34

Supply voltage under 180V. Electrical mains trouble

F35

Faulty mains frequency

Electrical mains trouble

pressure too low

Incorrect system water

F37

Water pressure switch damaged

pressure

or not connected

Probe damaged or wiring shorted

F39

External probe fault

Probe disconnected after activate-

ing the sliding temperature

Delivery sensor or DHW sensor

A41

Sensor positioning

detached from the pipe

F42

Heating sensor fault

Sensor damaged

32

EN

Cure

Check the regular gas flow to the

boiler and that the air has been elimi-

nated from the pipes

Check the wiring of the electrode and

that it is correctly positioned and free

of any deposits

Check the gas valve and replace it if

necessary

Check the wiring

Adjust the ignition power

Check the ionisation electrode wiring

Check the card

Check the correct positioning and

operation of the heating sensor

Vent system

Check the thermostat

Check the wiring

Check the flue

Check the card parameter and modify

it if necessary

Check the gas pressure

Check the card parameter and modify

it if necessary

Check the wiring

Check the gas valve and replace it if

necessary

Check the wiring or replace the sen-

sor

Check the wiring or replace the sen-

sor

Check the wiring or replace the sen-

sor

Check the wiring

Check the gas valve and replace it if

necessary

Check the card parameter and modify

it if necessary

Check the card parameter and modify

it if necessary

Check the card parameter and modify

it if necessary

Check the card parameter and modify

it if necessary

Check the electrical system

Check the electrical system

Fill the system

Check the sensor

Check the wiring or replace the sen-

sor

Reconnect the external sensor or dis-

able the sliding temperature

Check the correct positioning and

operation of the sensors

Replace the sensor

cod. 3540Z443 - Rev. 01 – 02/2015

DIVAtech C 24 D

Fault

Fault

possible cause

code

No system H

F43

Exchange protection trips.

Air in the system

Modulating Operator wiring dis-

connected

F50

Gas valve fault

Faulty gas valve

Cure

O circulation

Check the circulating pump

2

Vent system

Check the wiring

Check the gas valve and replace it if

necessary

Accessories

For any category of its products, the company also produces various kits. Wall-mounted models with two circuits can be supplemented with a smoke extraction kit or a device that allows the structure to operate on liquefied gas. The floor-mounted boiler can be equipped with boilers, temperature controllers, hot water priority systems, turbo nozzles and control devices.

Condensing type products are often complemented by sensors that take into account the temperature outside, control boards with multiple circuits, hydraulic arrows, as well as whole sets to ensure the uninterrupted operation of boilers.

Most requested models:

- "Domina N" with a bithermic compact thermal device. The status of the unit can be visually observed using the indicator with LEDs. "Domina N" is a unit that has a hot water function, it guarantees excellent heating and has electric ignition. Advantages of "Domina N" - increased efficiency, light weight and oversized parameters, electrical control system, which contributes to a very high performance of the device, self-diagnosis function. The product will be able to work both on liquefied gas and on conventional fuel.

- Model "Diva" has another steel heat exchanger, which can be used to heat domestic water. A fairly large LCD screen is installed on the control panel, there are also buttons for setting parameters, various service settings, and most importantly, diagnostic buttons. "Diva" are produced with open and closed combustion chambers. "Diva" is very convenient for maintenance, has an efficiency of almost 93%, it has a digital control of the product, which helps to increase the efficiency of the unit.

- The Divatop Micro boiler with two circuits can be called a completely new development. The product includes a large number of innovations that qualitatively began to influence the reliable operation of devices and their high efficiency. 2 copper heat exchangers were installed for water heating and heating system. The product has 3 way inverter valves. The device can maintain the temperature you need for a long time without third-party intervention. A convenient self-diagnosis system will ensure the safety of the unit. The Divatop Micro design has a separate connection to the Oscar element, which is installed in the room, so that it is possible to air-condition the rooms and control their heating at the same time.

- The wall-mounted steel unit "Domitech C32" has a high-quality anti-corrosion coating. The device will work without problems on both natural and liquefied gas. The product is used for heating homes and providing domestic hot water. It can be controlled using a digital system with two microprocessors. One will help control the boiler, the second will control combustion. Electric ignition will simplify the start of the unit.

- The device "Divatop 60 C 24" is produced for high-quality heating and fast water heating. These boilers with two circuits have a backlit LCD display, where you can get acquainted with all the performance characteristics of the product. To get heated water, you can use a 60 liter boiler. The company has provided fuel economy, so this model is very popular among consumers.

- Model "Pegasus" - a boiler with a cast iron heat exchanger, which is installed on the floor. These units are focused only on heating the home, for this reason the power in them reaches a maximum of 150 kW. The Pegasus boiler is ignited using an electrical system without a special igniter.

- "Ferroli DomiTech" is a wall-mounted appliance with two circuits, with a built-in instant water heating function. The operation of the product is controlled by a digital control system. The device includes a copper heat exchanger. It is considered the most effective and can successfully work for ten years.

- The product "Atlas D" is a floor-standing device that is produced for heating spaces with parameters up to 900 m2. These are 3-way cast iron boilers that can function with a burner that can be changed. They are used not only for space heating, but also for water heating. There is an LCD screen and an anti-freeze protection system.

Peculiarities

To choose the right heating boiler from Ferroli, you can identify some of the main characteristics of its products.

You can divide the devices manufactured by the company into a number of categories:

- By location - designs from Ferroli are of 2 types. These are either floor or mounted products. Floor mounted ones are produced for large rooms, mounted ones are excellent for heating oversized spaces.

- According to the number of circuits, a double-circuit wall-mounted unit, as well as a floor-standing device, is perfectly suitable for heating the coolant itself and heating the liquid for domestic purposes.

- According to the principle of operation - devices with atmospheric-type flame burners are produced at a low price and maximum ease of maintenance, as they will work according to a simplified scheme. In units of a condensing type that have closed chambers, the air goes by force. Thus, they increase efficiency and reduce gas consumption. To use appliances with closed chambers of the furnace, electricity is indispensable.

- According to the material from which the heat exchanger is made. Steel appliances provide increased heat transfer. A cast iron boiler will have a low efficiency, but will last much longer.

Given the competition, the company's specialists offer more effective and popular solutions. As a result, Ferroli's gas-fired designs guarantee the right level of performance with little fuel consumption.

Ferroli differs from other companies producing boilers by a product control system using innovative microprocessors, and it is they who will control the level of flame burning in these devices. Also, the company's engineers invented a unique copper heat exchanger with compact parameters, which is coated with a special aluminum composition against corrosion.

Stylish design, simple maintenance and operation, ease of setup - all this is present in Ferroli products, for which customers appreciate them.

Wall-mounted boilers are the most popular type of heating products, which are represented by such interesting models as "Diva" and "Divatop Domina". Due to its affordable cost and simple structure, the popular Arena model is in the greatest demand. This is a wall-mounted double-circuit type design, where there are also 2 heat exchangers. The combustion chamber here can be either open or closed. In the model, you can find parts from well-known companies (Siemens and Wilo).

Floor products represent the Pegasus and Atlas series in various models. Usually these are weighty devices, so they are mounted on the floor. The Pegasus model consists of a cast iron thermal device, a Honeywell valve, a reliable burner, a signal subspecies contact, and also includes connectors for high-quality connection of pumps and a small thermostat. For ease of use, ignition from the mains was provided and the possibility of connecting a boiler. The device has a built-in smoke removal control, an ionization sensor, a bimetallic indicator for monitoring overheating.These products have many options - a separate control unit, thermostat activation elements and turbo nozzles.

Condensing units from Ferroli can be found in the "Econcept" series, as well as "Energy" or "Bluehelix". These are designs with a single circuit, among them you can choose products with high power (the Econcept series, for example, will have the highest power - up to 300 kW). The characteristic features of condensing appliances include weather-dependent automation and a large LCD screen. In addition, an aluminum heat exchanger and a ceramic burner were built into the Econcept.