Characteristic

Ariston gas equipment is produced in two basic versions - floor and wall. In private houses, as a rule, wall models are used.

Depending on the parameters of the model, the unit may have an open and closed combustion chamber.

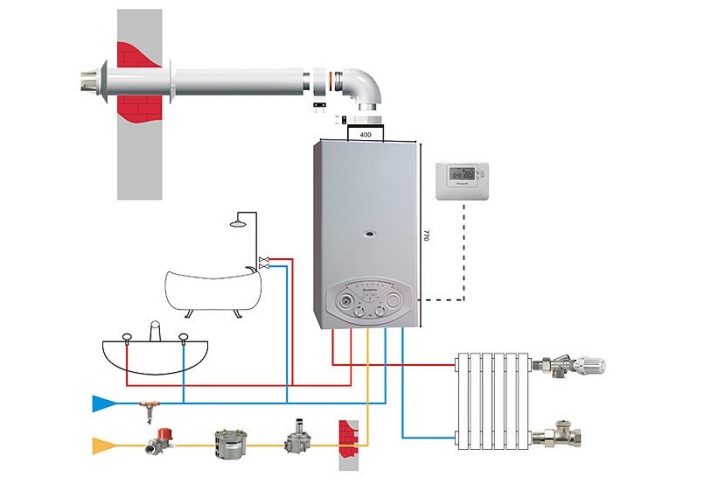

In the first case, combustion products are removed from the boiler in a natural way, in the second case, a forced gas exhaust system works. Typically, closed chamber installations are connected to a coaxial chimney. The coaxial pipeline implies the presence of two structural layers, due to which it is possible to simultaneously remove carbon monoxide and provide fresh air to the furnace.

In addition, the chamber has a built-in fan, which is responsible for the timely removal of burnt gas and hot air. These models are more secure than devices with an open camera.

Floor boilers have a fairly high power

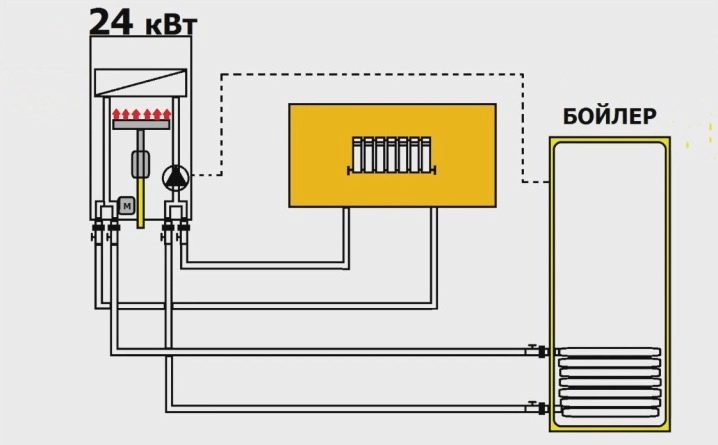

, so they are used for industrial purposes or in residential buildings with a large area. Usually they are designed only to supply heat to batteries and radiators, so if you need to heat water, additional boilers should be purchased.

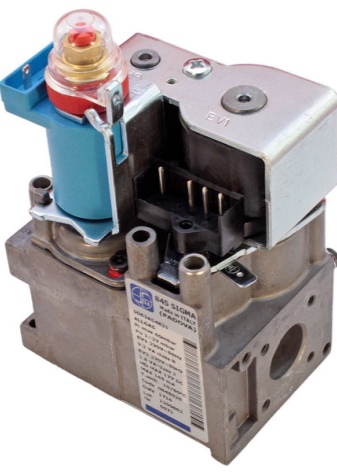

The main element of any boiler equipment is a burner, which is responsible for burning fuel and supplying heat to the heating system. Burners can be conventional and modulating. More modern and technologically advanced are modulation, since they allow you to automatically adjust the power of the device, depending on the results of internal control over the temperature level.

Ariston double-circuit boilers have 2 heat exchangers: the first is necessary to provide hot water, and the second is directly for heating the main coolant. Their manufacture can be carried out in three versions: they are separate, bithermic or with a boiler.

Two autonomous circuits are simultaneously placed in the common boiler body:

- heating - it is responsible for supplying radiators with heated water;

- water - this mechanism is connected to water pipes.

Water heating can be done in several ways:

- flowing - this option only works when using hot water: after passing through the burner, it enters the final consumer in a heated form;

- boiler - such a device implies the presence of an additional tank in which water heated to a predetermined temperature accumulates and from there it enters the tap.

According to the location of the circuits, boilers are divided into 2 types.

- Bithermic - in such installations, the water pipe is located inside the heating system. The heating circuit in this case heats up more actively and gives off part of its heat to the water supply.

- Duothermic - include two tubular heat exchangers that evenly transfer heat to both systems. In this case, the energy is used most rationally, however, the heating rate is also significantly reduced. In addition, this principle of operation creates the prerequisites for the appearance of lime deposits, so such devices need regular cleaning.

Depending on the method of combustion, Ariston boilers are conditionally divided into those operating on the principle of turbocharging and natural draft. A turbocharged boiler has a rather high heating rate, however, gas is also consumed in large volumes. The second type of models heats water rather slowly, but fuel consumption is more economical.

How it works

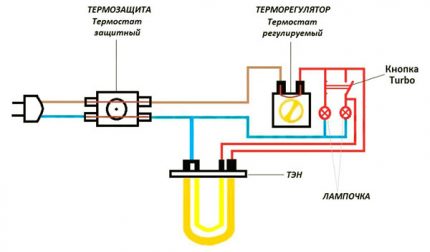

To minimize problems with the device, you should study its device and principles of operation.Usually, in private households, not flow-through, but storage models are used, which allow the use of electricity more efficiently. Such a device consists of a heat exchanger tank, inside of which a heating element is installed - a heating element connected to the power supply.

An important part of the device is the thermostat. This element allows you to maintain a constant temperature of the water inside the tank. Water flows through pipes to the heat exchanger. If its temperature is too low (and it usually happens), then the thermostat gives a signal and turns on the heating element.

Water is heated until it reaches the required temperature. After that, the thermostat works again and turns off the heating element. Hot water is taken from the tank and replaced with cold water, the heating process is repeated over and over again. This is a general diagram of the design and operation of a conventional storage water heater.

Flow models are arranged somewhat differently. They heat not a static volume of water, but a stream. They use more powerful heating elements that start when the water is turned on and stop when it is turned off. To study in more detail the operation and device of a particular model, you need to carefully read the accompanying technical documentation.

The heater tank is a solid stainless steel container, one or two millimeters thick. No matter how resistant this material is to corrosion, nevertheless these processes periodically arise and develop, which leads to the flow of water from the device. One of the most common causes of such breakdowns is electrocorrosion.

To prevent it, you need to regularly, i.e. annually replace the magnesium anode installed inside. This element is specifically designed to prevent electrical corrosion.

Over time, it wears out, and the owners of storage tanks lose sight of the replacement of this important part.

As a result, a tank that has served well for some time suddenly starts to leak. An incorrect state of the magnesium anode may also affect the state of the heating element. From the outside, the storage tank is usually enclosed in a metal or plastic case, and it also has a heat-insulating shell that prevents heat loss.

Damage to the outer shell and insulation is rare, usually due to careless handling of the device. Cracks and chips on the body of the water heater may not disrupt its operation, but this will lead to a deterioration in the properties of the heat insulator, and will negatively affect the operation of the device as a whole

The inlet pipes for cold water and the outlet for hot water usually do not cause any problems if the heater is installed correctly. Typically, a water heater is equipped with two thermostats, one of which is designed to control the water temperature, and the second monitors the state of the first device.

Sometimes a third thermostat is also used, which determines the good condition of the heating element. In any case, a broken thermostat will have to be completely replaced. There are capillary, rod and electronic types of thermostats. Their design is different, but the principle of their work is similar.

The insulating gasket serves not only to seal the connection of the elements of the water heater, it is also necessary as an electrical insulator. This element is recommended to be replaced regularly at every maintenance of the water heater.

The temperature regulator shows to what temperature the water inside the device is heated. If this element breaks, the water heater will still perform its functions, although data on the degree of heating will not be received.

Descriptions of the double-circuit boiler Ariston

One of the most important components in all gas boilers is the burner, in this case it can be modulating or conventional. The first option is more popular than the second.When using it, the entire system will be regulated automatically, without human intervention. In this case, the power of the installed heating equipment depends on the temperature indicators.

The burner is also divided into 2 types:

open;

It is the safest, since it does not involve the entry of combustion products into the room in case of emergency. Also in this case, the owner may not worry about building a chimney. It is necessary to bring a special coaxial pipe to the closed burner; it can always be brought out in any accessible place.

An open-type Ariston boiler, in any case, requires a chimney to bring combustion products outside. Also, do not forget about natural traction. Air will enter the system from the living quarters, so it will have to be constantly ventilated.

The coaxial pipe used in the closed combustion system has the advantage of being made of 2 layers. One is necessary for the removal of combustion products, and the other will ensure that fresh air enters the boiler. Thus, the owner of the equipment does not have to constantly ventilate the room and worry about natural draft. The room will always have enough oxygen.

Technical data of Ariston gas appliances

-

Ariston boilers are used for heating and water heating, that is, they are double-circuit.

Each modification has its own characteristics, but the common type of fuel is gas. -

The gas combustion chamber can be either open type or closed.

In the presence of a chimney, units with an open chamber are used. And in apartments of multi-storey buildings, where there are not always chimneys, equipment with a closed combustion chamber is used. -

Power.

Using this indicator, the gas consumption required to heat the room is calculated. -

Compactness.

Wall appliances are used in small, narrow rooms. Floor-standing units used in production or storage areas are heavier and require more space for installation. -

The presence of a control unit.

This element is indispensable when turning off the water, a sharp decrease in gas. In case of any malfunctions, the unit will immediately turn off the device, which will prevent damage. It can also save fuel consumption.

How to work with the menu

By pressing the “OK” button once, the number 2 will flash on the digital indicator - this will be the first digit of the future three-digit code (Menu group number)

With the plus and minus buttons, you can change this value from group number 2 to any other group. To fix the selected group for further entering the code number, you need to press “OK” again - after that the second digit of the future three-digit code starts flashing (Submenu)

Having selected the submenu, we fix it by pressing the “OK” button again and in a similar way select and fix the third digit (Parameter)

Everything! Now the screen will no longer display the three-digit code itself, but the set value of this parameter, which can be changed by pressing "plus" "minus". After making the necessary changes, do not forget to fix them by clicking "OK".

Please note that after selecting the desired menu, after a few seconds of inactivity, the three-digit code (to remind you where you are) and the parameter corresponding to this menu will be displayed in turn.

The ESC button is used to exit the settings menu and return to the previous step. The exit is carried out step by step, one press is equal to one step back.

Practicing

Now, if you want to practice, to better understand the switching order. For example, enter the menu code 701, this will turn on the forced air removal mode, in fact, turn on the pump in the boiler for 6 minutes.

When this mode is enabled, the symbol “P I -” will light up on the display. You can exit the “Anti-air” mode without waiting 6 minutes if you press ESC.

Then, using ESC, try to go back and switch to mode 300, which means (Set water temperature in the boiler) in the values \u200b\u200byou can see the temperature that you currently have on the DHW regulator.

Ariston boiler menu structure

At first it may seem complicated, but as you figure it out, everything will be simple and clear, so:

Each parameter is identified by a three-digit numeric code. For example 228 (this is just a parameter code that depends on the version of the boiler)

The first digit of the three-digit code means a separate menu group, the boiler has six separate menu groups, each is responsible for its own settings section. Here they are.

2 - Boiler settings

3 - Solar collector and storage boiler

4 - Zone 1 parameters

5 - Zone 2 parameters

7 - Testing and maintenance

8 - Technical parameters.

The second digit of the three-digit code indicates the submenu, and the third is the parameter itself to which access is granted.

For example, code 228 already known to us stands for: 2 - Boiler settings (this is Menu), 2 - Basic boiler settings (Submenu), 8 - Boiler version (Parameter).

Thus, by dialing the three-digit code 228, we get access to the set value of this parameter, which, according to the table, can vary from 0 to 5 and depends on the version of the boiler.

I will provide tables with menu codes and a description of what is regulated by a specific code a little lower, but for now let's figure out how to enter the boiler service menu.

Features of replacing a faulty heating element

If the boiler has stopped heating the water to the desired temperatures, then the heating element should be replaced. To do this, follow the following procedure:

- Switch off the device from the electrical network.

- Stop supplying water to the tank.

- Connect a hose to the drain tap and drain all the water into the sewer.

- Remove the protective box by unscrewing 2 screws.

- Remove the return valve from the pipe.

- Drain the remaining water from the tank.

- Unscrew the nut that secures the flange with a wrench.

- Carefully remove the old heating element without damaging the flange.

- Clean the walls of the container from accumulated dirt. If the walls have a special protective enamel inside, then it is not necessary to remove the scale. You can simply damage the protective film. This layer of scale will protect the walls of the vessel from rust formation.

- The magnesium anode is removed and repaired, if required.

- A new heating element is being installed. You need to do exactly the opposite.

- Verification of work after the final assembly of all parts. The tank must not leak. Otherwise, you need to put new gaskets.

Water heater repair Ariston

Operating instructions for gas boilers Ariston

Before purchasing an Ariston gas boiler, you need to understand that if the buyer does not understand its installation, it is better to contact experienced specialists and entrust all the work to them. After all, even with the most detailed instructions, it is not a fact that the case will end successfully. In this case, there is every chance of damaging the equipment, after which you will have to call repairmen, and this will result in additional costs.

It is very important to keep children away from the equipment. To do this, after, it is necessary to have a conversation with them and explain in an accessible language that nothing can be twisted and put on the unit, only an adult should do this

If the family leaves, for example, on vacation, after the boiler is turned off, it is also necessary to shut off all pipes for the supply of gas and water. Only after that the equipment is disconnected from the network.

If a display is provided on any model, all indicators that it displays must be strictly controlled. It can display malfunctions or deviations from normal operation that occurred during the heating process.

One of the most important points in the instructions for gas equipment is safety. Before connecting the boiler, you need to familiarize yourself with it first.

Pros and cons

Ariston gas boiler plants are popular all over the world, this is due to their exceptional performance characteristics:

- effective built-in protection against power surges in the network - devices can operate in the voltage range from 150 to 260 V;

- the possibility of effective regulation of the water heating rate: in the case when the flow rate does not go beyond 6 l / minute, the temperature can reach up to 37 degrees, in order for the water to heat up faster, you just need to increase the boiler power;

- simultaneous operation in the mode of a water heater and an efficient heater;

- the possibility of automatic shutdown of the gas in case of flame extinction, regardless of its causes;

- automatic shutdown of the heater in the event of a decrease in water pressure in the system to a critical level;

- the presence of two heat exchangers;

- a wide range of models;

- excellent adaptation to use in Russian conditions;

- Italian assembly;

- European quality control system.

However, there are also disadvantages, among them are the following:

- very high cost in comparison with analogues;

- use of components made in China.

Russian users highlight the boilers of this brand as high-quality, reliable and practical. Reviews of the owners of private houses point to such advantages of Ariston as compact dimensions, energy-efficient gas consumption and ease of control of the mechanism. Among the shortcomings, the dependence of its operation on the power supply is distinguished, but this feature applies not only to Ariston - almost no gas equipment works without being connected to an alternating current network.

Tables with three-digit codes, descriptions and set values

The values added in the white fields are the values used in my boiler. If there are no corrections, then I have the same values as those printed in the table. To enlarge, click on the photo of the table.

Do you want to equip your home with individual heating? Already installed and connected gas equipment? Great, then it remains to figure out how to turn on the gas boiler. Do you think it is enough to insert the plug into the socket and select the temperature? No matter how. Before this, it is necessary to bleed the air and fill the system with water. You will find instructions with a sequence of actions in our article.

Weaknesses of the water heater

The Ariston brand is considered one of the most reliable. But, despite this, these boilers have their drawbacks. Very quickly after the purchase of the device and the start of its operation, the scoreboard reflecting the main parameters of the boiler operation fails. However, it is intended for the convenience of the user. A broken panel does not affect the operation of the boiler itself.

Although the manufacturer indicates the frost resistance of the device, the water from it must be completely drained during downtime. Frozen residues may damage the device.

The temperature maximum of the Ariston boiler is 80 degrees. But it is not recommended to use it. The boiler will fail very quickly in this case. It is best to produce heating up to 60 degrees.

If all these shortcomings are taken into account during the operation of the device, then it will last for many years.

Do-it-yourself Ariston water heater repair in the video below:

Some of the existing breakdowns can be easily fixed on your own, because of some, the equipment will have to be transported to a service center.

Cold or insufficiently hot water flows from the boiler

The cause of a malfunction of this nature can be a breakdown of the heater, thermostat and a large layer of scale on these devices. Before determining the cause of the malfunction of the 80-liter Ariston water heater and doing your own repairs, you should turn off the power supply and drain the water.

Then, using a 13 wrench, a Phillips screwdriver, remove the protective box and unscrew the bolts on the mounting plate

Carefully remove the flange on which the heating element and thermostat are attached. Now you need to descale these 2 devices

The thermostat should be unscrewed by cleaning the attachment points to the flange from sediment, then carefully, using a screwdriver, release the thermostat from scale. You can check the performance by using a tester, the absence of a signal on its contacts indicates a malfunction and the need for replacement, since the thermostat cannot be repaired

You can also check the heating element for operability using a tester by connecting the ends of the tester to the contacts of the heating element. If there is voltage, the heating element is working, but it needs to be cleaned

The heating element can be cleaned with a screwdriver, carefully removing pieces of deposits

Then you need to prepare a solution of citric acid - 100 g per 1 liter of water and immerse the heating element in the solution. The effect of the solution on the device will be indicated by air bubbles that appear as a result of the reaction. If such an action is not enough for complete purification, you can put a vessel with a solution and a heating element on a slow fire.

After cleaning the heating element, it is necessary to descale the tank

Be careful not to damage the inner surface of the tank. If it is possible to remove the heater from the wall, cleaning can be done with a solution of citric acid, pouring it into the tank

After the manipulations, assemble all the parts in the order in which they were disassembled and carefully insert and secure the flange. Make sure that during assembly there are no distortions of parts, do not overtighten the bolts, change the gasket between the body of your storage boiler and the flange, since the flange gasket was also exposed to salts

Filling the heating system with water

Starting a gas boiler begins with filling the heating system with water. Everything is simple here - modern double-circuit boilers do not require the installation of a special system feed unit. It is already built into the boiler and is equipped with a special faucet, which, as a rule, is located at the bottom of the boiler in close proximity to the cold water connection pipe. Open the make-up tap and slowly fill the system with water.

Starting the boiler - how to fill the system with water

A very important point in the operation of any boiler equipment is fluid pressure. To control this parameter of the heating system, almost all boilers are equipped with a pressure gauge. In the process of filling the systems with water, it is necessary to monitor the pressure and after it reaches 1.5-2 atm, the filling of the system will need to be stopped. In principle, the indicator of the working pressure of the boiler, depending on the manufacturer and model, may vary - therefore, see the exact figure for the working pressure in the instructions for the boiler.

Do-it-yourself first start-up of a gas boiler

Peculiarities

Italian-made gas boilers Ariston are presented in a wide variety of models, however, regardless of the modification, the equipment of this brand is focused on the installation of heating systems on an area of \u200b\u200bno more than 500 m2. Some types of boilers work only for heating, while others are used not only to supply heat to the house, but also for hot water supply.

Speaking about the indispensable options for gas boilers of this manufacturer, the following characteristics can be distinguished.

- The presence of a multilingual menu - this allows users to choose a familiar language for them to effectively control the operation of the boiler.

- The "auto" function - makes it possible to adjust the required power parameters offline based on monitoring the actual temperature indicators in the room, as well as inside the boiler.

- Heat and noise insulation - ensures silent operation of the equipment, and in addition, helps to keep the coolant at a given temperature for a long time even after stopping work.

- The warranty for all its equipment, for standard boilers it is 2 years, and for condensing models it is longer - for 3 years.

- Ease and ease of use - the menu is thought out very well, thanks to which even beginners who have not yet dealt with gas installations can effectively manage the boiler.

- Safety system that prevents breakdowns caused by power outages.

- Built-in electrified elements that maintain the unit's performance and performance even in conditions of reduced water or fuel pressure.

A characteristic feature of all Ariston models is a well-thought-out and deeply technological protection system, which ensures long-term and uninterrupted operation of the gas installation.

It includes:

- mechanisms for feeding the boiler with water;

- built-in system of timely pumping of accumulated air;

- blocking the circulation pump;

- anti-freeze protection mechanism.

The common parameters of all Ariston models are small dimensions and the ability to supply hot water. The basic package includes: a double-type heat exchanger, a burner control module, a carbon monoxide control system, a mechanism for maintaining a normal microclimate in the room, a device responsible for controlling water freezing inside the heating system.

Characteristics of Ariston boiler models

A distinctive feature of Ariston boilers is their high quality. After all, the name of the company is translated from Greek as “the best”.

Its products are especially popular among middle-income consumers. Gas boilers of this brand are purchased for space heating up to 500 sq.m. The company's products are universal. The transition to liquefied fuel is carried out only by replacing the burner.

Practical in use are double-circuit wall-mounted gas appliances. It is represented by three lines, each with its own modifications.

For all modifications of boilers, the common is:

- small size.

- hot water supply, in the absence of its centralized supply.

Different modifications differ in structure, the common thing is their low cost and high-quality performance of parts.

Basic equipment of units from Ariston:

- double .

- electronic control module .

- carbon monoxide control.

- support of the microclimate in the building or in a separate apartment.

- control of water freezing inside the system.

Let us consider in more detail the existing types of Ariston equipment.

Ariston Genus

-

Are issued with the double heat exchanger.

All modifications are double-circuit and are mounted on the wall. -

This model is considered the most functional of all Ariston devices.

It has an LCD display, a control panel with buttons. Ariston Genus can be configured to work offline for a whole week. -

The display shows basic information about the status of the device and a list of possible errors.

The burner is modulating, that is, fully controlled by electronics. This function increases the comfort of using this model of gas appliance, due to the minimum control by the consumer.

The Ariston Genus line includes Evo and more expensive Premium models.

The Evo model is a two-circuit gas appliance with a burner of both types: open and closed.

Genus Premium condensing boilers. They are used for heating residential buildings and commercial buildings. Power range from 24 kW to 35 kW.

Ariston Clas

- Small size device.

-

This is a boiler with two circuits and a graceful appearance.

The reduced dimensions did not impair its functionality in any way. -

Expansion tank for 8 liters.

Hot water is heated fairly quickly

Existing modification:

-

Evo is available in open and closed combustion chambers.

Power with an open burner - 24 kW, with a closed - 24 - 28 kW. -

Premium Evo condensing type appliance.

Has advanced comfort and freezing functions - Premium simple condensing unit.

Ariston Egis

-

Installed mainly

in rooms up to 200 sq.m. -

The most common Ariston gas appliance model in our country.

It heats water with a stainless steel heat exchanger, and a copper heat exchanger is used for heating. -

The compact device, differs in profitability and can be used under complicated weather conditions.

For example, at sharp sub-zero temperatures. -

The device is equipped with a modulating gas burner

, which allows for electronic control over the operation of the boiler.

This model is adapted to work in harsh climatic conditions. Normally withstands changes in gas pressure. The device is equipped with a collector into which condensate flows. This ensures operation at temperatures below 50 degrees.

Distinctive abilities

According to reviews of Ariston gas wall-mounted double-circuit boilers, they have 4 distinctive features that are useful for their owners:

- All models of this company are equipped with automatic protection systems.

- The presence of a water pump, which is necessary for the constant circulation of water through the pipes.

- Possibility to choose a model with an expansion tank. With its help, automatic pressure control will occur inside the heating system.

- Ariston equips its equipment with various types of ignition. It can be automatic, which will greatly facilitate the life of the owner of a particular boiler. Otherwise, each time the unit is started, a person will need to press a special button.

Service menu of the boiler

For all manipulations with switching modes, only 4 buttons are involved - Plus, Minus, Ok / Menu, ESC.

It is important to understand that not all menu items of the boiler will be available to you, some of them will become available only when additional devices are connected to the boiler, such as external sensors or a solar collector. And most of the menu items are available only by the service code, I'll tell you about it below, but for now, "let's practice on cats"

And most of the menu items are available only by the service code, I'll tell you about it below, but for now, "let's practice on cats"

Our kitties will be values that are open to free access. But first, read how to work with the menu.

Model instruction manual

You can also choose the Ariston boiler as heating equipment, the instruction manual is supplied with the kit and must be studied by you before using the equipment. In it, the manufacturer discloses security issues

For example, it is important to exclude the leakage of liquid gas, as this may pose a danger to human life. If this still happens, then the heating system must be turned off.

The room should be checked by closing all doors that lead to living rooms. The use of electrical switches is prohibited.

If you smell gas, the gas leak can cause an explosion. Under these conditions, smoking is prohibited.

It is important to exclude the possibility of sparks and open flames. Open windows and turn off the gas supply immediately.

The heating system must be turned off. No people should be allowed into the danger zone.

The Ariston boiler, the operating instructions of which you must read if you have purchased such equipment, is installed taking into account the manufacturer's recommendations. After reviewing them, you can find out that the installation of the device is carried out on a vertical flat surface. For ease of maintenance, minimum clearances should be ensured. Special ventilation in the room where the device is installed is not required.

When connecting gas, make sure that the connections are tight.Wiring must be connected in such a way as to facilitate the electrical isolation of the equipment. Before supplying water, flush the system without disconnecting the device. In order to remove contaminants and prevent damage to the heat exchanger, it is worth making sure that there are no contaminants, as they can cause build-up and corrosion.

Correct instrument maintenance

The fact that there are problems in the operation of the device may be indicated by some changes in the mode of its operation. For instance:

- increasing the time for heating water to a predetermined temperature;

- the appearance of unusual sounds accompanying the operation of the device;

- the appearance of foreign impurities in tap water, a change in its color, smell or taste.

If at least one of these signs is observed, the water heater should be cleaned immediately. To do this, you will have to perform the following operations:

- Disconnect the device from the power supply.

- Remove protective cover.

- Disconnect electrical wires.

- Shut off cold water supply.

- Use a hose to remove excess water from the tank.

- Unscrew the bolts that hold the heating element.

- Remove the heating element and clean it from scale.

- Clean the inside of the drive from dirt and scale particles.

- Rinse the device thoroughly.

- Check the condition of the magnesium anode.

- If necessary, replace this element immediately.

- Wait until the tank is completely dry.

- Install the heater in place.

- Reassemble the device.

- Check the security of all fasteners.

- Connect the water heater to the power supply.

- Check for grounding.

The heating element should be removed carefully from the tank, the bolts may be too stubborn, sometimes the heating element is difficult to remove due to too much scale. The heating element is cleaned by mechanical or chemical means, as well as the removal of contaminants from the tank. If a large amount of scale is found inside the device, you should consider revising the operating mode of the water heater.

This phenomenon is often observed when the device has been operating at maximum power for a long time. It is recommended to set the maximum heating temperature no higher than 60 degrees in order to increase the life of the device and reduce the number of breakdowns. If the body of the heating device is energized, the heating element may have been deformed and ruptured, or there may be a breakdown in the control system.

Conclusion

The Ariston double-circuit boiler, one of which was discussed above, will allow not only to arrange a heating system, but also to use hot water. Modern equipment is equipped with many features that will make living in the house comfortable. You can also choose boilers from the manufacturer "Ariston". They are offered for sale in a wide range.

Autonomous heating systems are experiencing a rebirth today. This is due to the fact that not so long ago a boom in individual construction began in the country. It is quite difficult to connect a country house to central communications. If this is done, then coziness and comfort in such a dwelling will depend on a number of unreliable factors, including the condition of the pipes, the operation of the boiler room, etc. This includes centralized power transmission.

If you also decide to follow the experience of the majority and choose a gas boiler for heating a suburban building, then it is certainly recommended that you familiarize yourself with the operating recommendations, from which, among other things, you can learn how a gas boiler works, how to turn on this equipment, and also how to avoid its premature breakdowns. For example, in order to prevent foreign bodies from entering the system, a hard filter should be installed at the inlets of running water, gas, as well as a heating circuit

It is also important to take care that the system has a voltage stabilizer, which is located at the input to this. This will protect the control board from power surges.

If you wondered how to turn on the Baxi floor-standing gas boiler, you must follow a certain technology. In the first step, you must open the gas cock, usually located under the equipment itself.

It is important to make sure that the system has the right pressure, only then can power be supplied to the device. Then you should press the "Start" button and set the device to the "Winter" or "Summer" mode

The panel has special buttons with which you can set the desired temperature values in the boiler and hot water circuits. This will turn on the main burner. If you have purchased a gas boiler, how to turn it on, you need to ask before unpacking the goods. After you have carried out all the above actions, you need to make sure that the boiler is working, this will be indicated by a special symbol of a burning flame on the display.