Step-by-step technology for manufacturing a solid fuel heater

Now let's figure out how to make a boiler with your own hands. Of course, it will not be possible to make a complex highly efficient model of a solid fuel unit, because this can only be implemented in industrial premises and subject to technological parameters. However, a simple boiler from a pipe with your own hands can be assembled. Such a unit will not only heat the house, but also satisfy the needs for hot water supply.

Tools and materials

To assemble a water boiler with your own hands, prepare everything you need for work in advance:

- a small grinder with a grinding disc and cutting nozzles;

- welding machine;

- protective glasses;

- hammer;

- electric drill and a set of drills for metal work;

- gas keys number 1 and 2;

- screwdrivers;

- a set of cap and open-end wrenches;

- square;

- pliers.

For the manufacture of grates, steel with a thickness of at least 0.7 cm is required, and for all other structures, steel with a thickness of at least 0.5 cm is sufficient.

Materials needed:

- for the manufacture of the frame, a steel corner with shelves 50x50 mm 5 mm thick is prepared;

- if it is decided to make a storage tank, then it needs sheet stainless steel;

- thick-walled steel pipes with a cross section of 3.2-5 cm are needed to assemble the heat exchanger.

Depending on the design of the boiler, other materials may be needed, as well as various devices.

Assembling the heat exchanger and housing

In the process of making a do-it-yourself wood-burning boiler, special attention is paid to the body, because it performs the functions of a combustion chamber and serves as the basis of the entire unit. The firebox is best done with two-layer walls with sand filling between them.

To increase the rigidity of the structure, a metal frame is used. In the front wall of the furnace, using a gas cutter or a grinder, two openings are cut: one for the ash pan, and the second for loading fuel.

After the manufacture of the combustion chamber, the assembly of the heat exchanger begins. The blanks of a straight and semicircular configuration are interconnected by welding to obtain a coil

It is important to achieve compact dimensions and maximum length of the coil to increase the heat exchange area

Design complete set

After the manufacture of all the constituent elements of the unit, the assembly of the boiler begins. It is better to do this immediately at the installation site of the solid fuel heater, since the overall and heavy structure will then be difficult to transport to the boiler room.

Usually the unit is installed on a solid concrete base. Moreover, in the process of manufacturing the foundation for the boiler, embedded parts with anchors are installed, to which the unit is subsequently welded. First, the frame is fixed on the base, and then the filling of the boiler and its lining are installed. In places of welded joints, chamfers are made, and the welds themselves are cleaned of slag and polished.

Grate grates and a heat exchanger are installed in the prepared and fixed body. The last element is connected by welding to the heating circuit of the house. For natural circulation of the coolant, the coil is installed with a slight slope. It is better to entrust the installation of a stainless steel storage tank to specialists with special equipment. The same goes for its manufacture.

After installing all the components, the boiler body must be painted. Two layers of paint coating will reliably protect the unit from corrosion. For work, it is better to use heat-resistant paint, and prime the surface before painting.

At the end of all installation work, a home-made solid fuel boiler must be pressure-tested with a high-pressure water jet.If a leak occurs during the crimping process, then this place must be additionally welded, and then tested with water again. Only after that proceed to commissioning.

A home-made boiler during operation must be periodically cleaned of ash collected in the furnace, and the chimney must also be cleaned. In principle, the whole design boasts durability, reliability and ease of use.

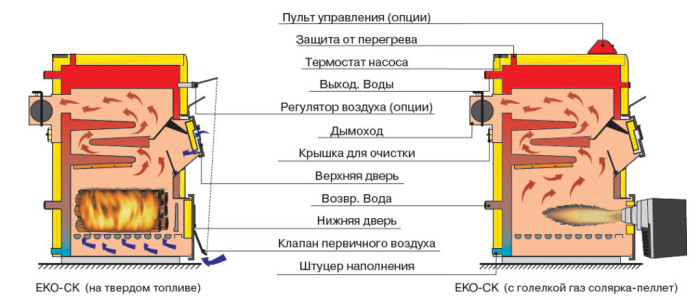

Features of a solid fuel boiler

Homemade heating boilers are an ordinary stove placed in a barrel of water. The unit transfers the heat received in the process of burning firewood to the water. The heated liquid goes through the pipes to the heating devices. However, such simple designs burn a lot of firewood, so their efficiency does not exceed 15%.

Homemade unit can be made of brick or metal. It is advisable to use brick structures in a spacious country house, but metal heaters can be made from improvised materials. They are the simplest in terms of constructive solutions.

Choice of constructive solution

To make a heating boiler with your own hands, it is not enough just to install a heat exchanger in the furnace. It is necessary to ensure the continuity of fuel combustion, as well as the constant and uniform circulation of the coolant.

When choosing the design of a solid fuel boiler, you can use the following options:

- Devices with lower combustion have a special door for loading a portion of fuel. This door is located in the upper half of the combustion chamber, although the firewood itself burns out in the lower part. Due to this, the upper layers of freshly laid firewood gradually sink to the bottom of the chamber under their own weight. Afterburning of combustion products takes place in the upper part of the furnace compartment. Air currents move through the firebox from the bottom up in a natural or forced manner.

- Units with upper combustion are also called mine. Here, too, the door is located in the upper part of the chamber, and the downward movement of hot air flows is due to the presence of forced draft. The fan drives air from top to bottom, where combustion occurs. In the process of movement, the air additionally dries and heats the firewood.

The easiest way is to make a design with lower combustion on your own, since in this option you can do without the use of a fan and arrange natural draft. More complex designs must meet certain requirements for the assembly quality of all components.

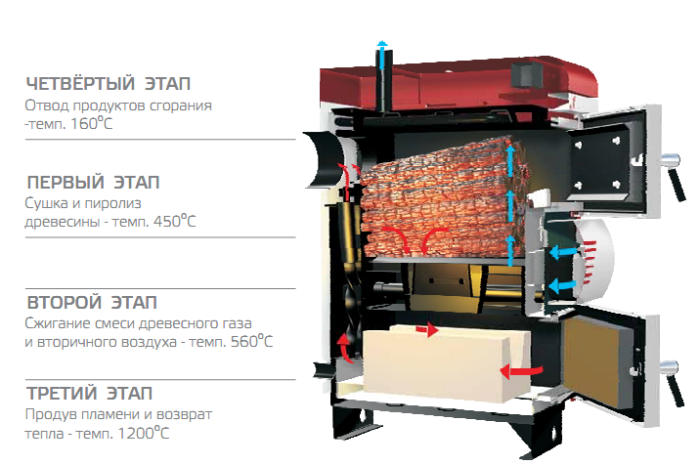

In addition, all solid fuel units come with a normal combustion mode and with access to pyrolysis. In the latter case, solid fuel decomposes into components that burn separately. The second option is more difficult to implement, because you need to install two combustion chambers.

The choice of boiler model depends on the fuel used. Since the combustion temperature of coal is higher than that of firewood, the heat exchanger, grate and appliance body are made of steel with a greater thickness than for a wood-burning boiler. Refractory bricks can be used instead of steel.

Long burning boiler

This boiler for heating a private house has at least two modifications. Of course, each of them can be made by hand.

According to many drawings, the design of the first modification of the long-burning boiler consists of the following elements:

- Ash chamber with a door on which there is a blower.

- Furnace chamber with a door.

- Heat exchanger.

- Branch pipes for the supply and return of the coolant.

- Holes for the release of carbon monoxide. Located at the top of the combustion chamber.

- Draft regulator (includes a temperature sensor in the form of a bimetallic plate or a container filled with wax, as well as a chain mechanism that controls the blower).

- Corps.

- Thermal insulation.

- Skins.

- Legs.

In this long-burning boiler, the ash chamber has the same depth and width as the combustion chamber.It is located under the combustion chamber.

With your own hands, you can make two types of heat exchanger:

vertical pipes that are connected by horizontal pipes

Of course, such a node is placed in the furnace. It is placed with their own hands in the upper part of the chamber. In this case, the movement of the coolant must be opposite to the movement of smoke. In a boiler with such a heat exchanger, they always make an additional body with their own hands. There should be a space of several centimeters between it and the combustion chamber. Due to this, the heat-insulating material will not overheat. which is located around the body.

As for the water jacket, such a heat exchanger consists of two containers placed one in one. The inner one is the combustion chamber. There is space between the containers. During operation, a boiler made according to the selected drawing is filled with water, which absorbs heat from the hot walls of the combustion chamber.

The second modification of the boiler for heating the house has a similar structure:

- Frame. It is a design of two pipes that are inserted into each other. The space between them is filled with water.

- Ash and loading doors.

- Air distributor. It is a round plate with vertical plates welded from below and a hole made in the center. This distributor supplies air to the firewood through a pipe that is welded to a hole made in it. There is a flap at the top of the tube.

- Top with a hole in the center. An oxygen supply pipe passes through this hole (it is also welded to the air distributor).

- Chimney.

Construction of an option for heating a greenhouse

To increase the yield in the cold season for the greenhouse, it is necessary to foresee supplementary heating. Unlike heating with electricity, the use of home-made heating boilers will be more financially beneficial.

The best option would be to build a furnace in the greenhouse with an outgoing chimney, which can be done with your own hands. Drawings for this can also be easily found on the World Wide Web.

The process of building equipment in a greenhouse consists of the following steps:

- In the vestibule of the greenhouse, it is necessary to lay out a brick oven.

- A chimney is installed along the entire length of the greenhouse at the top of the structure or under the beds.

- The outlet for the pipe must be made on the other side of the greenhouse. Thus, the carbon monoxide will go away, but the heat will remain inside the greenhouse.

Another version of a homemade boiler for a greenhouse is also possible:

- Selection of a barrel of large volume and its coloring from the inside, which will avoid corrosion.

- Making holes in the barrel for the chimney, stove, additional barrel and cream tap.

- Installing the firebox inside the barrel.

- Conclusion from the chimney barrel.

- Installation of an additional expansion tank on the barrel.

- Welding heating for a greenhouse from a profile pipe.

- Laying pipes inside the greenhouse structure.

- Acquisition of a pump for water circulation in the greenhouse system.

A similar option for a greenhouse can work both on wood and on other types of fuel. To control the temperature inside the greenhouse, home-made heating boilers can be equipped with an electronic temperature sensor, and the digital display itself can be placed directly in the house.

Autonomous heating in the form of home-made heating boilers is in demand, both among the owners of private houses and among residents of multi-storey buildings. This allows you to significantly save on the purchase of expensive equipment, as well as control the heating process itself. Homemade heating boilers can run on wood, coal or other types of fuel, which allows the use of such units in various fields.

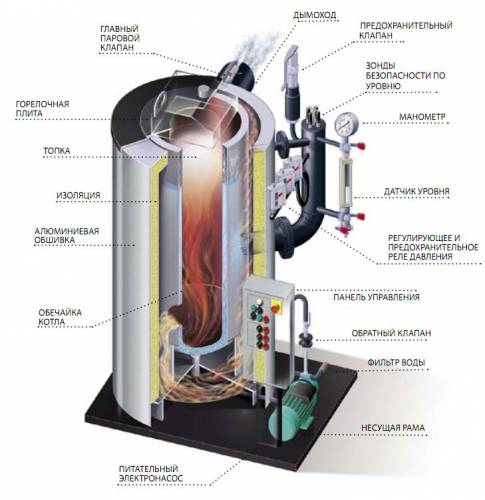

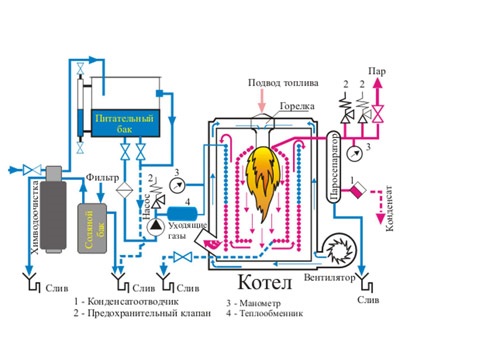

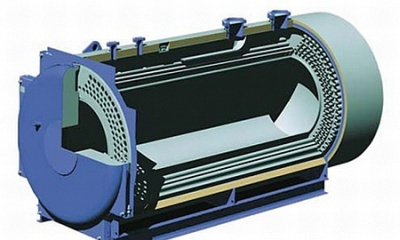

Design features

The design of the boiler in question is based on a kind of drum.Pre-treated water is supplied to this element of equipment through a system of pumps and pipes. Downpipes are located in the lower compartment of the boiler. These elements have different diameters and do not heat up during the operation of the boiler. Through a system of pipes, the liquid from the drum passes to the collectors. The latter are most often placed at the bottom of the boiler.

The collector is connected to the drum by means of a lifting pipeline. Due to the pipeline, heating surfaces are created in the place of combustion of the loaded fuel.

A piping system is connected to the steam generator, operating according to the mechanism of communicating vessels. A mixture of liquid water and water vapor circulates in hot pipes. This mixture has a rather low density, which allows it to freely enter the separator compartment, where the separation of steam and water takes place. The liquid component is sent to the drum of the steam boiler.

The steam passes into the steam pipeline, and then into special heaters, where the pressure rises, as well as the temperature of the steam to the desired parameters. Finally, the steam is sent to a suitable steam turbine.

Making a steam boiler

Features of work and device equipment

A self-made autonomous solid fuel unit is a stove installed in a barrel of water. Burning in the firebox, firewood or coal transfers heat to water, and the coolant enters the heating system, heating the room. A simple device is considered not the most efficient and cost-effective, since the efficiency of a primitive unit is not higher than 10-15%.

They assemble home-made heating boilers made of bricks and metal. The former are distinguished by aesthetic appeal, while the latter are considered easier to manufacture from improvised materials. But in any case, you will need to first draw up a diagram, think over the components of the structure, in order to ultimately get a high-quality heater.

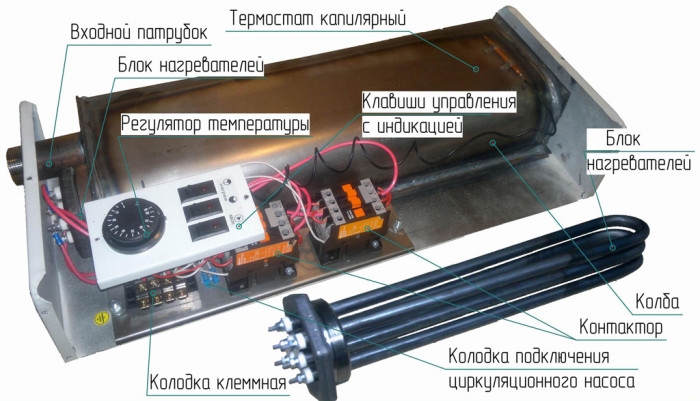

Electric boilers

Electric boilers for heating a private house can have a different design. The easiest option is to install a heating element directly in the heating system. Then there is no need to manufacture a separate boiler.

True, the pipe where the heating element is mounted must have a large diameter. At the same time, it is recommended to make it removable so that it is easier to maintain the heating elements.

Electrode boilers are interesting, when an electric current is passed directly through a liquid to generate heat. Thermal energy is produced as a result of the chaotic movement of ions. The water must contain salt.

It is much more difficult to make an electrode boiler on your own than one working on a heating element: after all, the current has a direct effect on water, which requires serious electrical safety measures to be taken.

The most common threats are an electric arc breakdown of the coolant, which is almost equal to a short circuit, as well as the accumulation of electrolysis gas in the system circuit.

The easiest way to design a solid fuel boiler. When assembling it, heat-resistant grades of steel are used - they are stronger than ordinary steel sheet, which burns out on an open fire and wears out quickly.

However, heat-resistant steel is expensive, and in practice it is rarely used in artisanal boilers. Another option is cast iron: this material tolerates heat well, although it is difficult to work with it. Equipment for the manufacture of a cast-iron furnace is available only at specialized enterprises.

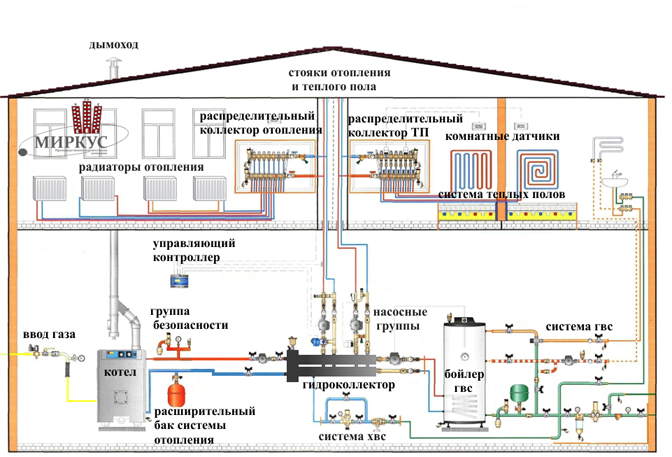

On water circulation

A home-made solid fuel boiler for water heating with a classic layout has a combustion chamber with grate - horizontally mounted steel strips of metal that replace the all-metal bottom. Fuel is laid over the grate, and the ash remaining after its combustion falls between them into the chamber below. A chimney channel is attached to the latter, designed to remove smoke.Every time before the start of the next furnace, the ashes from this chamber must be raked out.

Next to the combustion chamber - usually on the side of the chimney - there is a container for heating water, connected to the pipeline circuit of a private house: chilled water enters the lower part of the container, which rises as it heats up. The air flow into the combustion chamber is forced by a fan. The boiler is equipped with two doors: the upper one is designed for loading fuel, the lower one is for cleaning the chamber under the grate. Also, this chamber is necessary for air circulation.

On the principle of pyrolysis

Pyrolysis boilers have a different design. They have an additional upper chamber, where the gases released during the combustion of firewood enter. There, the gases burn out, producing additional heat.

A home-made pyrolysis boiler has a higher efficiency compared to a traditional type device.

For heating a country house consisting of several rooms, an apparatus with a heating element is suitable, consisting of a pipe with a diameter of 21.9 cm and a length of about 50 cm. Such a device will be economical, because kilowatts of energy will not be wasted. In addition, the device is very compact.

If the heating element is supposed to be installed in a separate housing, then it is better to make a boiler with small dimensions. If the boiler is used for heating running water, this rule does not apply. After all, then you need to have a supply of liquid, and this requires a larger reservoir.

The boiler does not need a dedicated power line to operate, it can be connected to a household network along with other electrical appliances. Unlike electrode equipment, a heating boiler with a heating element is safe, because the coolant is isolated from those parts of the device that are energized. If you equip the unit with a regulator, then it will be possible to adjust the water heating temperature with high accuracy - this is the main advantage of an electric boiler over a solid fuel one.

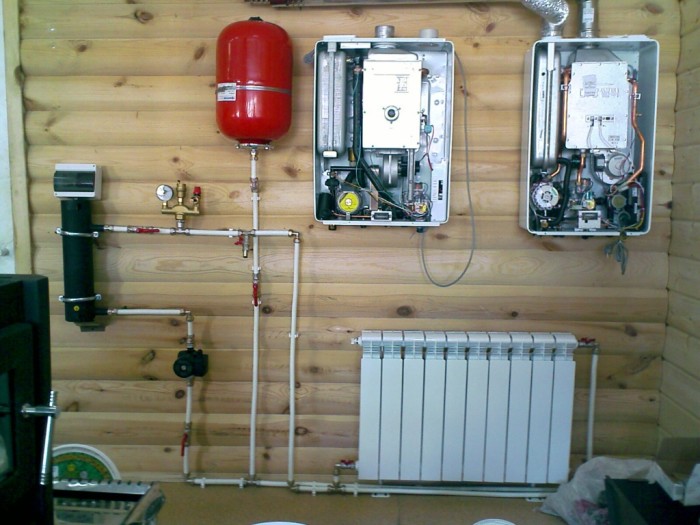

The popularity of steam heating

This type of creating warmth and comfort in the house with the help of steam has been and remains quite popular in our country. Steam heating of a private house is not only affordable, simple, but also effective. The main feature of this system is the use of water vapor as a heat carrier. At the same time, both a steam apparatus purchased through a distribution network and a home-made steam apparatus can serve as a source of heat.

This unit is used to produce hot water vapor at a pressure greater than atmospheric pressure. It is formed using thermal energy that is released when fuel is burned in a special chamber.

To create this system on your own, you do not need any fundamental knowledge. But, nevertheless, it is necessary to have an idea about some of the nuances.

- Steam unit

- Stoyakov

- pipelines

- Radiators

Such a set of components is typical for an individual heating system. It generates heat in a steam boiler, assembled and installed with its own hands, which is able to function on almost any fuel.

Such heating can be made single-circuit or double-circuit. In the first option, only space heating will occur, the second method also involves the preparation of hot water.

The piping system consists of horizontal and vertical elements. The wiring can be lower or upper - it depends on the characteristics of the building.

Of course, before you create such a heating system in your home, you need to carefully analyze all its pros and cons.

The main advantages are:

- Inexpensive installation and compact dimensions

- Quick warm up

- Possibility of heating large areas and volumes of premises

- economy

- High heat transfer with no heat loss

- The impossibility of freezing the system

- The impossibility of changing the temperature of the air in the house

- Aggressive impact on pipes

As you can see, such heating has more pluses than minuses. A self-made installation of the system further complements the list of the best qualities.

How a typical steam heating boiler works

Heat is generated in the combustion chamber. In the future, it enters the heating surface. There are 2 types of heating surfaces: convective and radiative.

The principle of operation of the steam boiler

The composition of convective surfaces includes the following elements:

- air heaters;

- economizers;

- heat exchange devices.

The listed additional equipment is necessary to increase the efficiency of the boiler, rationalize fuel consumption and reduce heat losses.

It is important that the water used to operate the boiler is exceptionally pure - impurities are not allowed. Therefore, before being fed into the boiler, the liquid must be cleaned of gases and various kinds of impurities, eventually becoming nutritious.

The purified liquid is sent to the economizer. A special pump helps her with this. In the economizer, the liquid heat carrier is heated under the influence of gases. Next, the liquid passes into the upper compartment of the drum compartment. Here the boiler water is mixed with the feed liquid.

A certain amount of water passes from the upper compartment of the drum compartment to its lower compartment. The movement of water occurs through the boiling tubes.

At the top of the steam boiler, the gases have a lower temperature, which gradually increases as they approach the lower compartment of the unit.

Water is heated and together with a mixture of steam and water is sent to the upper chamber of the drum.

The second part of the liquid from the upper drum compartment goes to redistribution. Boiler water is heated. The resulting steam bubbles go to the upper compartment of the drum compartment.

In the upper chamber of the drum due to the separator there is an almost complete separation of the mixture of liquid and vapor. As a result, saturated steam is created, which contributes to an additional increase in the efficiency of the boiler. It is this saturated steam that is used by the end user.

In order to increase the efficiency of the boilers, their work is organized in such a way that the level of “lower” and “higher” water fluctuates in the upper chamber of the drum compartment. Between the mentioned liquid levels there is a reserve supply of water designed to maintain the operation of the heating unit in the event of a cessation of the flow of liquid into the system.

The allowable “higher” liquid level in the drum compartment is determined with the expectation that no water enters the superheater.

The maximum allowable "lower" liquid level in the drum is calculated so as to prevent overheating of the upper compartment of the drum, as well as the boiling beam

It is important that the water enters the downpipes in a stable volume.

To further increase the efficiency, the design is equipped with an air heater.

The fluid in the system can circulate forcibly and naturally. Natural motion is based on the difference in the density of the liquid and the resulting vapor. The mixture of water and steam in the riser tubes has a lower density than that in the downcomer tubes. However, the pressure value and temperature value remain the same throughout the tube. As a result, steam, which by its nature is a gas, rushes upward.

Forced circulation is provided by special pumping equipment.

Scheme of transferring a steam boiler to a hot water mode

Assembly of the unit

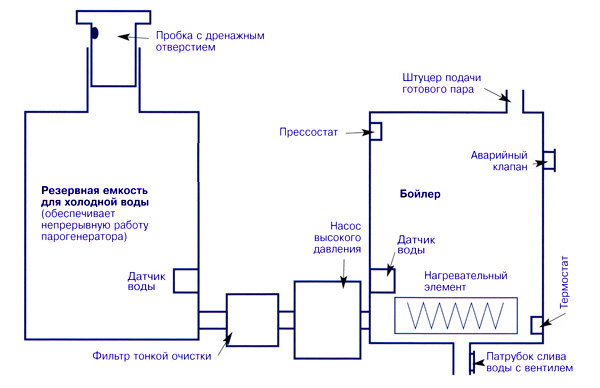

The work on self-manufacturing of the boiler is carried out in a few simple steps. Follow each step of the instructions in sequence, focusing in parallel on the drawings and diagrams.

First step.Determine the optimal dimensions of the future steam boiler. The size of the equipment directly affects its performance. Specify this point on an individual basis, taking into account the specifics of your specific situation.

At the same stage, prepare all the necessary drawings. If you wish, you can order their compilation by a professional or use ready-made drawings from open sources.

Second step. Prepare the necessary materials. Previously, a list of required elements was given. First of all, buy pipes with a diameter of 32 mm and 12 mm. Sheet stainless steel must have thickness about 2-3 mm.

Third step. Prepare the boiler body. The best option is to weld the case yourself from sheet metal. Choose the dimensions of the case individually, according to your needs.

Fourth step. Make the base of the boiler. It was previously said that the design of steam boilers is based on a system of communicating pipes. First of all, prepare a piece of pipe about 11 cm long with a wall thickness of about 3 mm.

Cut a pipe with a diameter of 11 cm into 12 elements - they will act as smoke pipes. Cut a pipe of a larger diameter into flame tubes.

Choose the length of the pipes in accordance with your schemes.

Fifth step. Make the required number of bulkheads and walls of the steam boiler. To do this, use stainless steel sheet.

Sixth step. Prepare holes in the walls of the unit for placement of flame and smoke tubes. Attach the mentioned elements in a flared form to the base of the boiler. The welding machine will help you with this. At this stage, also be guided by the available drawings and diagrams.

Seventh step. Attach the safety valve and steam manifold to the unit body. Through the valve in the future, you will release the residual steam.

Eighth step. Insulate the boiler with asbestos sheet.

Steam generator connection diagram

Thus, having understood the main provisions of the instructions, you can independently assemble a simple steam generator and include it in the heating system of your own home. At each stage of the work, be guided by the drawings you have, because. it is impossible to understand the assembly order of the unit from textual recommendations alone.

What are manual boilers for?

Do-it-yourself boilers are cheaper than their factory counterparts, but do not exceed them in terms of efficiency. The principle of operation of the equipment is based on the fact that the burning fuel releases heat, which already enters the heat exchanger and heats the circulating water. In this, homemade products are no different from factory ones.

The main disadvantage of boilers assembled according to individual drawings is the lack of a guarantee. In the case of factory-made equipment, the owner can be sure that the equipment will work, and if not, it can be returned or replaced. Only the one who assembled and installed it in his house is responsible for the quality of the work of a home-made boiler. In the event of a breakdown, you will have to repair the equipment at your own expense.

For heating with a self-made boiler, it is recommended to use only safe types of fuel - firewood, coal, pellets, electricity. Home-made gas and diesel boilers are very dangerous - they should not be installed in residential premises.

Moreover, the competent authorities will not allow the insertion of self-assembled equipment into the gas pipe circuit, and if a violation is found, they will require the owner to be brought to administrative responsibility.

Despite the disadvantages, a hand-assembled boiler has an undeniable advantage - the performance characteristics of the equipment can be made such that they exactly match the needs of the owners of the house.

Conditions for safe operation of the boiler

The boiler must be not only efficient, but also safe.The key to reliable and efficient operation of a steam heating boiler is to maintain a predetermined level of heating of metal elements.

In view of this, the coolant must circulate all the time inside the heated tubes with simultaneous cooling of the heating surfaces.

It is important that the coolant stably removes heat from the material of the pipes heated under the influence of flue gases. If the heat removal is insufficient, the metal will simply overheat, become less durable, and the efficiency and safety of the equipment will decrease.

In the worst case, the pipes will simply break.

Check the operation of the boiler regularly. Correct all problems as soon as they are discovered. Even the slightest defect can quickly lead to a significant reduction in the efficiency of the unit and a deterioration in the safety of the system. The water will come out of the drum, steam will enter the drop tubes, the drum and tubes will get too hot and an accident will occur.

Also, you, as the owner, must ensure that all structural elements and equipment used are of exceptionally high quality.

Ways to reduce gas consumption

To figure out how to make a gas boiler more economical, you should analyze not only the characteristics and condition of the unit, but also consider the conditions of the heated area. In addition, so that the gas device does not increase fuel consumption, it is necessary to clean its components from soot and burning in time, and heat exchangers from scale.

Gas boiler power

The first thing to pay attention to is whether the power of the installed unit corresponds to the heated area. It is bad if there is not enough productivity or it is available with a significant excess

If the power of the unit is not enough to heat a given room, it will constantly work at the limit of its capabilities, while consuming a lot of fuel. This mode of operation will shorten the life of key components of the boiler. In addition, with a lack of power, the unit will not be able to provide high-quality heating of housing. You can correct the situation by cardinal methods - reduce the number of heated rooms or install an additional gas appliance.

The situation when the power of the unit is more than 20% higher than the optimal one for a given room is also undesirable. Otherwise, the gas boiler will turn on and off too often - this is called "clocking". It turns out that the unit heats the coolant too quickly to the set temperature, after which it immediately turns off. In this mode, part of the radiators will remain unheated, and equipment wear and gas consumption will be high. In this case, the unit should be switched to a lower operating mode.

…

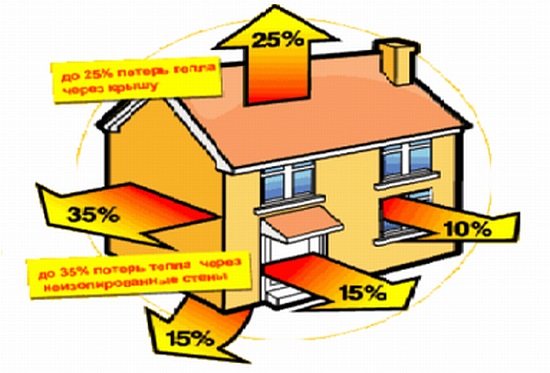

House insulation

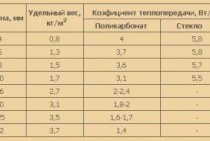

The degree of insulation of a house or apartment is essential in saving gas. If the building is not insulated, and the doors and windows are blown through, a significant part of the heat will go outside. The material of the walls of the house also matters. For example, wood and blocks conduct heat faster than double brickwork.

Good insulation of the ceiling, floor and walls will save a lot of fuel. It is advisable to replace old frames with energy-efficient double-glazed windows, and wooden doors with a more hermetic modern analogue. A well-insulated building will save up to 30% of gas.

…

Particular attention should be paid to the insulation of the attic and basement, since a lot of heat also escapes through them. Note! To increase the energy efficiency of the house, you can install reflective aluminum foil screens between the battery and the wall, they will return part of the heat to the room

Note! To increase the energy efficiency of the house, you can install reflective aluminum foil screens between the battery and the wall, they will return part of the heat to the room

Installation of modern automation

Save fuel help thermostats that automatically maintain a given level of heat. On sale there are many different options for any wallet. On these devices, the desired temperature in the room is set, and it is maintained using sensors. If the temperature in the room drops by at least a quarter of a degree, the sensor will signal the gas boiler to turn on. After reaching the desired temperature, the unit will turn off. This mode of operation will save up to 20% of fuel.

The disadvantage of the thermostat is that it allows you to maintain a given level of heating in only one room. But there are new models of thermoregulation, which are equipped with outdoor temperature sensors. When it gets warmer outside, a signal is given to reduce the flame of the burner.

One of the most profitable heating options is the "warm floor" system. The coolant in it usually has a temperature of 30-45°C. To maintain the heating of the coolant at this level, the system does not require a lot of fuel.