Purpose and principle of operation

Any heating system is under pressure. There is a safe range of values that every properly configured and functioning heating system must fall within during the heating and cooling cycles. For low-rise country houses, this is usually 1-2 bars. At higher values, heaters, such as the universal solid fuel boiler "Wirbel" EKO, may fail.

In the event of an emergency, such as overheating of a hot water boiler, the pressure in the system begins to rise. This is due to the fact that the coolant is heated above the permissible temperature. As you know, the liquid expands when heated, and since there is no reserve for emergency expansion in a closed heating system, the pressure of the coolant increases. As a result, this can lead to rupture of pipes, breakage of the boiler or other elements.

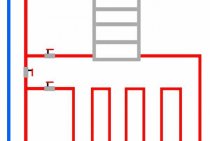

In order to control the pressure and reset it in the event of an accident to safe values, the boiler safety group is used. Let's look at how it works and what blocks it consists of:

Automatic air vent

Air in the heating system is highly undesirable. Its presence in the coolant leads to the appearance of such an unpleasant phenomenon as cavitation. It contributes to premature failure of various elements and noise during operation. However, air inevitably gets inside during the pouring stage, mixing with the coolant. Also, at high temperatures of the coolant, steam bubbles naturally form in it. In order to reduce airiness, an air vent is needed.

pressure gauge

With it, the owner can exercise visual control over the pressure in the system. Often, for ease of control, additional scales are applied to it, indicating the boundaries of the working pressure and its minimum and maximum values.

Safety valve

It discharges the coolant, thereby reducing the pressure in the system. Usually, valves with a threshold value of 3 bar are installed on the safety group, which corresponds to the maximum allowable operating pressure of modern heating devices, such as the Start automatic pellet boiler. The direction of the coolant ejection is usually indicated on the body with an arrow. It is necessary to periodically check the operability of the valve by forcibly opening it with a special handle. If he is out of work for a long time, various deposits can clog his mechanisms and at the right time he will not work.

All three devices are usually mounted on a common steel or cast console with a common connecting hole with a diameter of 1 inch. To insulate a hot surface, many manufacturers cover metal parts with a protective casing made of polyurethane.

How to make a safety block for heating with your own hands

If you separately purchase a safety valve, a pressure gauge and an air vent, connect them using tees, adapters, you can assemble a security group with your own hands.

In the case of purchasing all components separately and self-assembly of safety automation, the price will be significantly lower than if you buy a ready-made boiler safety unit:

- safety valve - 6 at. e.;

- manometer - 10 at. e.;

- automatic air vent - 5 c.u. e.;

- brass cross DN 15 as a collector - 2.2 c.u. e.

When choosing components, it is necessary to take into account the following recommendations:

- Do not buy the cheapest safety valves.Chinese models, as a rule, after the first operation, they begin to leak or do not relieve pressure at all.

- Chinese pressure gauges, most often, lie very much. If during the filling of the system the device underestimates the readings, then after heating an accident may occur, since the pressure in the network may jump to a critical value.

- The safety valve must be selected based on the operating pressure of the boiler, which is indicated in the technical data sheet.

- Purchase only a straight type air vent, as the angular one creates increased resistance to the outgoing air.

- The crosspiece must be made of high quality thick-walled brass. When choosing, you just need to weigh the more expensive and cheaper model in the palm of your hand, and the difference will be immediately noticeable.

The body of the security group can also be made independently from scraps of polypropylene pipes and fittings, this will cost much cheaper than the factory-made model, where there is a lot of brass.

It must also be remembered that a safety group made of polypropylene must be installed only in low-temperature heating systems (for example, underfloor heating, but in no case radiators). The reason is that when the coolant reaches 95 degrees, polypropylene begins to break down, and as a result, a rather unpleasant situation may arise.

Installation of a homemade security group is quite easy. The air bleeder is screwed into the upper outlet of the cross, and into the side ones - a safety valve and a pressure gauge as it will be convenient. The finished element must be cut into the line next to the boiler.

In the event that there is a desire to make the solid fuel heating boiler as safe as possible, it is necessary to pay attention to the thermal discharge valves. Their principle of operation is as follows: in case of overheating of the coolant, it is discharged from the boiler water jacket and a mixture of cold tap water is started.

Conclusion: the purchase and installation of a safety group for a closed heating system is not a mandatory requirement for all boilers. Most of the wall-mounted gas boilers are already equipped with this automation from the factory, which is indicated in their operating instructions.

However, some manufacturers of solid fuel boilers also complete their products with parts for the safety group, but you will have to work on installing them yourself.

What is the heating block made of?

The safety group includes the following devices that are installed on the case:

- safety valve;

- automatic air vent;

- manometer.

Thus, the security group performs three main functions, let's consider each of them in more detail.

The safety valve serves to save the heating system from too high pressure. This valve can only withstand a certain level of pressure, as soon as the pressure in the system becomes higher, the valve works and dumps the excess.

The problem of compensation of excess pressure in the heating system must be solved by an expansion tank. But sometimes there are situations when the expansion tank for some reason does not work. To prevent such misunderstandings, a safety valve is installed, thanks to which excess water is discharged from the heating system with an expansion tank. In order to prevent water from dripping onto the floor, it is necessary to attach a tube to the thread on the side, which is discharged into the sewer.

Safety valves are made for a variety of pressures, you need to purchase based on the pressure your boiler is working with. For a private house, you will need a valve designed for 3 atmospheres.

The main task of the air blower is maintenance.Inside it there is a chamber, which is equipped with a float, which in turn is mechanically connected to a valve that opens in the absence of water.

The main function of this device is to remove air during the filling of the boiler and the system with coolant, as well as during operation. Also, as an additional function, one can name the release of the first steam, which appears when the boiler overheats.

Because of the air vent, the entire safety group is mounted on top of the boiler, this is due to the fact that the air vent must be located at the highest point, since this is where air bubbles tend to go.

Manometer - this device is necessary for monitoring the pressure in the heating system. As in the case of safety valves, pressure gauges are designed for different pressures. It is necessary to choose such a device so that its use is as convenient as possible: in order to determine the readings, you just need to look at the device, and no calculations are required.

All safety blocks work in the same way, but it is necessary to choose based on the pressure parameters for which the pressure gauge and safety valve are designed.

Rating of popular models

Among the companies producing safety fittings for boiler rooms, two manufacturers are especially popular. Let's take a look at their products:

Security group "Watts"

Watts manufactures a wide range of heating system elements, including KSG safety groups for heating boilers. The line includes models on a steel, cast brass or cast iron console, standard and compact. Some blocks are equipped with protective heat-insulating casings.

All models of the Watts KSG series have a 3 bar safety valve. Connection to the heating system is made through a 1 inch female threaded hole. The model range is designed to work with hot water boilers with a capacity of 50 to 200 kW. Prices for the Watts KSG models range from 2,000 to 6,000 rubles.

Valtec Security Group

The Valtec company is also a manufacturer of protective fittings for heating systems that is in demand among consumers. It manufactures safety groups for both boilers (VT 460) and expansion tanks (VT 495) mounted on hollow wall brackets.

The Valtec VT 460 safety group is made in a compact brass case and is designed for boilers, boilers and hot water systems. The model is designed to work with household heating devices with a power of up to 44 kW and a maximum pressure of 3 bar, such as the wood-burning heating boiler "Motor Sich". On average, such a device can be bought for 1700 rubles.

As you can see, the prices for safety fittings are far from low, so many people make them with their own hands. This process is not at all complicated, so it is quite possible to assemble a security group yourself at home.