How does an induction heater work?

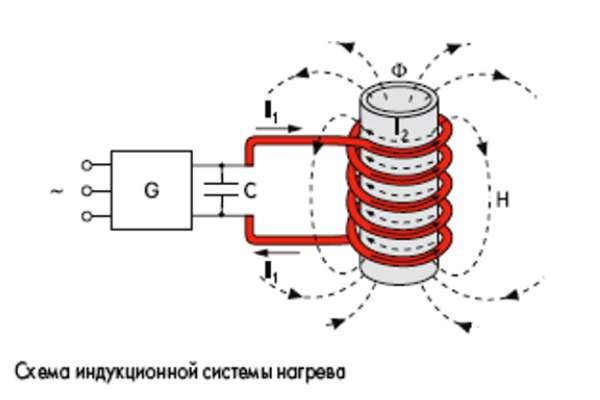

Very simple. We apply operating voltage to the coil. An electromagnetic field is created in the coil. We read carefully - here is the essence of his work:

The electromagnetic field induces Foucault currents or eddy currents in the heating pipe and the metal pipe begins to heat up.

If anyone does not know, the magnetic circuit of the transformer is specially recruited from many thin plates of electrical steel, isolated from each other.

This is done precisely in order to avoid energy losses from heating by eddy currents.

The fact is that the more massive the conductor, the more it will heat up from the Foucault currents, in turn, the force of the eddy currents can be increased by the rate of change in the magnetic flux.

Do you know that a power transformer with a voltage of 110 kV at idle, even without load, generates a thermal power of about 11 kilowatts?

This is mainly due to the effect of eddy currents, which heat the magnetic circuit, on which the primary and secondary windings are dressed.

At the same time, the magnetic circuit is laminated, and if it were solid, then the heat losses would increase many times over!

And the transformer would simply burn out from overheating.

The induction electric boiler works on the same principle and the steel pipe with water passing inside the coil heats up very much, BUT! - due to the circulation of water, the heat has time to be removed from the pipe to the heating system and overheating does not occur.

But can it be more economical compared to electric boilers on heating elements? For what?

Here, let's first think without parsing and comparing these two types of boilers:

Have a house

It doesn't matter what and it doesn't matter where. Even under water, even on Everest

This house has a heat loss of 6 kilowatts.

Through walls, through windows, through the ceiling, etc. - heat is lost, and in order to maintain a constant temperature, these heat losses must be compensated, and for this, naturally, 6 kilowatts of heat is also needed.

And it doesn’t matter where and how this heat is taken, this thermal energy is 6 kilowatts - even burn a fire, even gas, even gasoline, the most important thing is that these necessary kilowatts of heat are released!

Now the most important thing:

to heat such a house, you will need both an induction heater and an electric boiler on heating elements - all the same, the power is also at least 6 kW.

In other words, the boiler simply converts electrical energy into heat.

And how he does it is absolutely not important, because for us the most important thing is that it would be warm in the house. Energy is simply converted from one form to another, from electrical to heat.

And if the boiler allocated heat for 6 kW, then it took at least the same amount of electricity from the network, and given that the efficiency of the boilers is not 100%, then even a little more energy is consumed from the network

Energy is simply transformed from one form to another, from electrical to thermal. And if the boiler allocated heat for 6 kW, then it took at least the same amount of electricity from the network, and given that the efficiency of the boilers is not 100%, then even more energy is consumed from the network.

Then maybe the efficiency of the induction boiler is higher? According to the manufacturers, this value reaches 98%.

The same is true for an electric boiler with heating elements. Their efficiency reaches 99%.

Well, think for yourself - where else can the energy in the heating element go, except how to stand out in heat?

All energy consumed from the heating element network is converted into thermal energy. I took 5 kW - allocated 5 kW of heat.

I took 100 kW - allocated 100 kW of heat. Well, maybe a little less if you take into account the energy loss in the transient resistance at the heating element clamps, but again, this energy loss is released in the form of heat (the clamp is heated) and in the supply cables.

But what about the clamps, that the cable cross-section is the same in terms of parameters for both the vortex induction electric boiler and the heating element.

Vortex induction heater

A vortex induction heater (VIN) is a kind of induction cooker. It consists of a coil, a magnetic circuit and a heat exchanger.An alternating current flowing through the coil forms an alternating magnetic field. If a conductive material is placed in this field, it will heat up. The main advantage of VIN is that the inductor temperature does not exceed 140°C. In addition, the alternating magnetic field counteracts the formation of scale. In contrast to the vortex heat generator, the principle of operation of the VHP fits into the laws of physics. The efficiency of a vortex induction heater is close to 100%, which gives it the right to be used in heating systems and other liquid heating systems. However, what do sellers of vortex induction heaters promise us? And here miracles begin. They promise savings of up to 50% compared to conventional heating elements. That is, either the efficiency of the heating element is 50%, or the efficiency of the VIN is 200%. Let's try to figure it out. Your humble servant was not too lazy and called several companies selling vortex induction heaters. The most important question that was asked is what advantage will I get by paying a lot of money for this device? Here are the responses I received:

- We have a lot of sales and everyone is happy

Fantastic reliability and durability

Save up to 50% compared to heating elements

No noise

Well, one can argue with the first and second statements. As for the noise - the heating elements do not make noise either. And, here, with the economy - it's interesting. It turns out (according to the sellers), the formation of scale on the heating element reduces its efficiency. Accordingly, the efficiency of VIN is due to the constant efficiency compared to heating elements. But let me, how does scale reduce the efficiency of heating elements? Consider the law of conservation of energy. Let's say we brought 1 kW of electric power to the heating element. Accordingly, we must receive 1 kW of thermal energy. If we get less heat, then the remaining energy must be released in some other form. Something I don’t remember that the heating elements in the water glowed or emitted, say, electromagnetic waves. Undoubtedly, scale reduces the heat transfer of the heating element, but this does not affect its efficiency in any way. With a decrease in heat transfer, the temperature of the heating element itself rises, and, consequently, its electrical resistance increases. With an increase in electrical resistance, the power consumed by this heating element decreases. In fact, the change in temperature and power consumption is so small that the average user won't even notice it. Will the kettle boil in a minute or in a minute and 5 seconds - does it matter? At the same time, the amount of electricity required to heat the kettle with water will remain unchanged. However, VIN sellers are trying to turn the situation on its head and talk about a decrease in efficiency.

Thus, VIN can be an alternative to heating elements, but it will not give any savings in savings. There are no miracles. And as for "fantastic reliability", for the money that VIN costs, you can buy several electric boilers and arrange a reservation. Reliability will be several times higher.

The main types of induction boilers

Before you buy an induction electric heating boiler for your home, you need to choose which type is the most suitable.

There are two varieties on sale - SAV induction boilers and vortex boilers (VIN), which have characteristic differences.

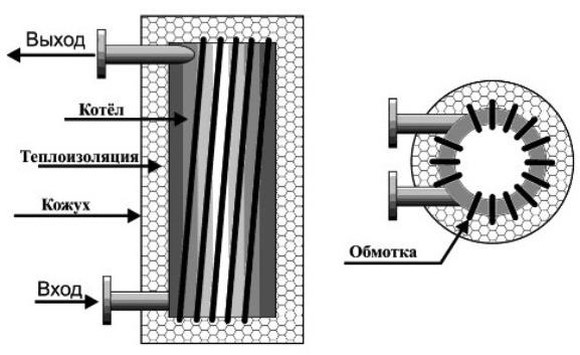

Induction heating boilers SAV

Boilers of this type do not require the use of an inverter. Mains voltage of 50 hertz is applied to the winding (inductor). The secondary winding in the form of a system of metal pipes of the heat exchanger is very quickly heated by Foucault currents. The heated coolant moves in the circuit forcibly with the help of a circulation pump. Boilers are produced for voltages of 220V and 380V. A 2.5 kW boiler heats a room up to 30 m2, and you can buy an induction electric heating boiler complete with a control and automation unit for a price of about 30 thousand rubles.

Induction boilers VIN (vortex)

These are induction boilers of a new generation; an inverter is required for their operation - a frequency converter of the electrical network. This technical solution made it possible to make the device compact and lighter than SAV type boilers. The heat exchanger is made of ferromagnetic material, and the magnetic circuit and the secondary winding are not only the heat exchanger, but also the boiler body.

A VIN-type boiler with a power of 3 kW can provide heat for 40 m2.

The kit includes an automation unit, a pump and a circulation pump, so the highest price for an electric induction heating boiler is about 38 thousand rubles.

The principle of operation of the inverter boiler

Traditional electrical equipment works on the principle of transferring energy directly to the coolant through heating elements. At the same time, if the device has heating elements in the configuration, then, therefore, it is necessary to prepare a place for heating water.

Heating elements are also highly susceptible to corrosion, so they must be protected from irreversible processes.

Inverter equipment works on the basis of electromagnetic induction. The generation of the current itself occurs due to the alternating magnetic field. For this purpose, it is necessary to convert the direct network current into alternating current. The inverter copes with this task perfectly, the operation of which is possible both from the network and from batteries.

There are two types of circuits in an inverter boiler:

- Magnetic, allowing you to generate a magnetic field of an alternating type.

- Heat exchanger, which contributes to the heating of the coolant.

With an appropriate supply of alternating electricity, the coil begins to form a magnetic field. This contributes to the heating of the liquid in the system and its further transfer through the pipes.

Scheme of the induction heating system

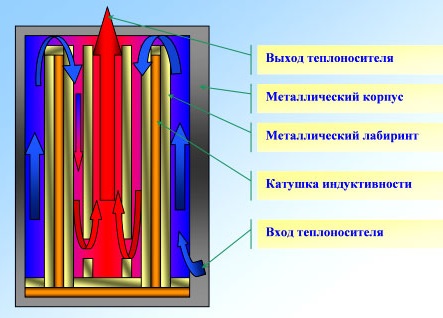

VIN type water heaters

The heart of the unit is a coil, consisting of a large number of turns of insulated wire, and placed vertically in a cylindrical body in the form of a vessel. A metal rod is inserted inside the coil. The housing is hermetically sealed from above and below by welded covers, terminals for connecting to the electrical network are brought out. A cold coolant enters the vessel through the lower branch pipe, which fills the entire space inside the vessel. The water heated to the required temperature goes into the heating system through the upper pipe.

Heat carrier heating scheme

Due to its design, when connected to the network, the heat generator constantly operates at full capacity, since it is not rational to supply the heating installation with additional voltage regulation devices. It is much easier to use cyclic heating and use automatic shutdown / on with a water temperature sensor. It is only necessary to set the required temperature on the display of the remote electronic unit and it will heat the coolant to this temperature, turning off the hot water induction element when it is reached. After the time has elapsed and the water has cooled down by a few degrees, the automation will turn on the heating again, this cycle will be repeated constantly.

Since the winding of the heat generator provides for a single-phase connection with a supply voltage of 220 V, induction-type heating units are not produced with high power. The reason is that the current in the circuit is too high (over 50 amperes), it will require laying cables of a large cross section, which in itself is very expensive. To increase the power, it is enough to put three water heating installations in a cascade and apply a three-phase connection with a supply voltage of 380 V. Connect a separate phase to each cascade device, the photo shows a similar example of induction heating.

Heating with induction boilers

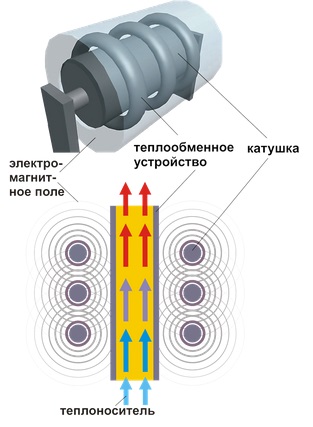

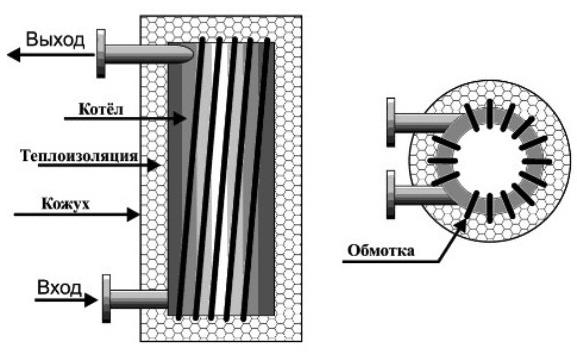

Design features of Sibtechnomash type heaters Using the same effect of electromagnetic induction, another company develops and manufactures water heaters of a slightly different design that deserves attention. The fact is that the electric field created by a multi-turn coil has a spatial form and spreads from it in all directions. If in the VIN units the coolant passes inside the coil, then the Sibtekhnomash induction boiler device provides for a spiral heat exchanger located outside the winding, as shown in the figure.

The winding creates an alternating electric field around itself, eddy currents heat the coils of the heat exchanger pipe in which water moves. Coils with coils are assembled in a cascade of 3 pieces and attached to a common frame. Each of them is connected to a separate phase, the supply voltage is 380 V. The Sibtekhnomash design has several advantages:

- induction heaters have a separate collapsible design;

- in the zone of action of the electric field there is an increased area of the heating surface and a larger amount of water due to the spiral circuit, which increases the heating rate;

- heat exchanger piping is available for flushing and maintenance.

An example of connecting an induction boiler

Despite the differences in the design of the heat generator, its efficiency is 98%, as in heaters of the VIN type, this efficiency value is declared by the manufacturer himself. The durability of the units in both cases is determined by the performance of the coils, or rather, the service life of the winding and electrical insulation, this indicator is set by manufacturers within 30 years.

Positive and negative sides of the inverter boiler

There are a number of advantages that inverter installations have, including:

- increase in operational parameters as a result of the absence of heating elements;

- small inertia during heating, thus, in the presence of a centrifugal pump, the coolant will heat up faster;

- the operation of the system is not affected by the chemical composition of the coolant;

- the ability to install the device anywhere.

Like other heating systems, the inverter boiler has several disadvantages:

- rather high cost of inverter equipment compared to similar devices operating on heating elements;

- has an impressive size and weight, and therefore requires strengthening the base on which the boiler will be located;

- the device needs an electronic control system for subsequent power adjustment.

Despite minor shortcomings, nevertheless, inverter boilers are very popular among consumers and the demand for them is constantly increasing.

Inverter equipment device

Myths about induction boilers

One of the most popular myths is created by sales representatives selling induction electric boilers. The bottom line is that these boilers are allegedly 20-30% more efficient than other heating electrical installations, especially heating elements. This information is not true, since all heat generators that convert electricity into heat operate with an efficiency of at least 96% in accordance with the physical law of conservation of energy. The only undeniable fact is that the heating elements heat up the coolant a little longer due to their multilayer structure. The tungsten coil first heats the quartz sand, then the tube material, and then the water. At the same time, energy is not lost anywhere, and the efficiency of the heating element unit is 98%, as well as the vortex one.

Example of a heating system

Another myth says that the induction electric boiler does not require maintenance at all, since the alternating magnetic field prevents deposits from settling on the heating elements.This question depends on the quality of the water and scale on the core of the coil appears in the same way as in heating elements, if the coolant is not desalinated. Therefore, at least once every 2 years, the heat generator itself and the heating system must undergo a flushing procedure.

Contrary to the assurances of the sellers, the water heater cannot be placed in any room. There are two reasons: the danger of electric shock and the presence of an electromagnetic field around the device. It is better to place it in a technical room with limited access (boiler room).

Heating installations using eddy currents for heating really have many advantages, especially among them they are attracted by the heating rate, compactness and durability. How much these advantages justify the high cost of the product - each homeowner will have to decide individually.

Induction water heater

Induction water heaters have a housing and an original electric inductor (transformer) inside it, and its secondary winding is the metal pipe itself with water, in the form of a short-circuited coil.

As a result of the flow of significant electrical currents in it, from the electrical voltage inductively induced in it, this pipe is intensively heated and heats up the water in it with its heat.

In a nutshell, how does an induction heater work?

this is a step-down transformer that is installed in a pipe

At first I decided that if the word “induction” is present in the name, then heating occurs with high-frequency currents such as in a microwave, it turned out that it was not.

There is no high frequency at all, powered by a 220/380 volt power frequency 50 Hertz.

The technology is actually very simple - there is an ordinary coil in a shielded pipe - this is, as it were, the primary winding of a transformer, if we draw an analogy with a transformer.

The role of the secondary winding, and at the same time the magnetic circuit, is performed by a metal heating pipe!

Advantages and disadvantages

The real advantages that induction boilers have for heating a house or an industrial building are as follows:

- High, as with all water heating installations, the efficiency of work, which is in the range of 97-98%.

- Durability due to no moving parts and simple design.

- Small dimensions that allow you to place heating equipment in a room of any size.

- High heating rate of the coolant and no inertia when it is turned off.

- Comfort during operation, an induction electric boiler does not require the constant attention of the owner of the house, and the frequency of its maintenance depends entirely on the quality of the water used in the system.

Vortex heaters are supplied with automatic control kits, which makes it possible to link heat generators with other climate systems in the home.

Sectional heater

This equipment also has disadvantages. The main one is the high cost, especially for heat generators of the Sibtekhnomash type. If it is quite acceptable to use these units for industrial purposes, then induction heating of a private house may turn out to be unreasonably expensive.

The experience of practical use of vortex heaters by homeowners and maintenance personnel of service companies is not very extensive yet, but at the moment there are no significant complaints about the equipment.

Feedback Electric induction boiler Alternative energy VIN-40 Heats well, with big shortcomings.

I decided to somehow change the usual electric boiler. It is necessary to heat 400 square meters. Connoisseurs advised me to take an induction boiler, as it is innovative equipment and even saves my budget a lot. I got it. Immediately about the budget.It costs twice as much as an electric boiler with heating elements. Well, I think I’ll save on electricity when the boiler is operating in winter. During the sale, the sellers convinced that there were no heating elements in the boiler and there was no need to worry about replacing elements such as heating elements. I have a question about how the coolant heats up without a heating element. The heating element turned out to be an induction coil. And if, when a heater burns out in a conventional electric boiler, you can replace the heater or turn off and leave the rest of the heaters, then replacing the induction coil is problematic and expensive! There are very few collapsible elements in the purchased boiler, which leads to difficulties in replacing failed elements and difficulties in disassembly. But in fact, it cannot be disassembled without cutting. Another minus of the boiler is its huge weight. VIN - 40 weighs about 250 kg., Oh, how problematic it is to hang it on the wall, if only through anchor bolts in the hay. A control cabinet is sold with the boiler, where all the electronics are hidden. With my own eyes I observe constant blinking of the light when the boiler is turned on. And yet, powerful electrical contactors with their pops and clicks really make me jump every time in surprise. It is quite noisy during operation, which made me install it in a separate room. Pluses of the VIN-40 boiler: 1. The working temperature is easily adjusted, press the button three times.2. There is a setting for the temperature difference between switching on and off the boiler.3. Easily mounted in the heating system.4. Connections for mounting on the boiler are threaded.5. Safety - no open electrical places. Efficiency 98%, when I had a boiler with heating elements, its power was constantly falling due to scale and deposits on these very heating elements. But now I think it was all fixable. With all the minuses, it WARMS EXCELLENT! Don't save on electricity!

Vortex induction heater VIN

It turns out that this mysterious VIN heater is very simple and can be easily assembled right at home. Let's briefly consider the principle of operation.

The operation of such heaters is based on the heating of conductive materials by Foucault currents, which are induced by a high-frequency magnetic field. The resulting thermal energy is taken by the coolant (water, oil, etc.) and used, for example, to heat the room.

As you can see, nothing complicated. And now let's see how I managed to put all this into practice.

In order not to create unnecessary difficulties, I decided to use a ready-made high-frequency welding inverter with a welding current of 15A (I had a sample with the ability to smoothly adjust the current). You can take, of course, and more powerful. It all depends on the required power of the heater. Since I was just conducting an experiment, I took the high-frequency inverter that was available.

As a material that will be heated in a high-frequency field, I decided to use pieces of thick steel wire. I was able to get a wire rod with a diameter of 7 mm and bit it into pieces of about 5 cm. If you do everything for centuries and for yourself, then you can get stainless steel scraps, although if the heating circuit is always full, then this is not necessary. Even ordinary iron will not rust.

As a section of the pipeline where the water will be heated, I decided to use a thick plastic pipe. The inner diameter should be chosen slightly less than the length of our wire scraps. We fasten an adapter on one side of the pipe for connection with the rest of the heating system, lay a metal mesh on the bottom (so that the pieces of wire rod do not fall further) and fill our wire inside. Then, in the same way, we close the free end of the pipe with the second adapter. It is necessary to pour so many wire scraps so that they occupy all the free space there.

Now let's make the induction coil itself: for this, we simply wrap the middle of our plastic pipe with wire rod scraps with copper enameled wire turn to turn (PEV or similar). For my inverter, 80-90 turns of wire with a diameter of 1.5 mm will be enough.

That's all. It remains only to turn our device into a break in the heating circuit, fill the whole thing with water, connect a welding inverter to the winding and turn on the pump (to ensure forced circulation of water in the system). Of course, it is highly not recommended to turn on the inverter without water, since in this case our plastic pipe is guaranteed to melt from the heated pieces of wire inside.

Thus, in a matter of hours, from improvised materials, I was able to assemble an operating vortex-induction heater. By the way, it is very economical - if you believe what they say, its efficiency reaches as much as 98-99%!

You can not stop at this and, in order to further increase the efficiency, organize the cooling of our inverter with the same coolant from the heating circuit. True, this only makes sense if the inverter circuit itself is located outside the heated room.

You can also organize automatic temperature control. To do this, you just need to get a thermostat and turn it into a break in the power line of the inverter, and place the thermostat sensor in a controlled area.

I did all this a long time ago, but I am writing about it only now (at the urgent request of one comrade), so there will be no photo report. To be honest, I only assembled the heater itself, did not turn it on anywhere, did not try to heat anything with it. No, I didn't have a pump. I just poured water inside and turned on the device. The water quickly heated up to boiling point. So, as you can see, the described technique for making VIN is really working and there is nothing complicated in it.

The device and principle of operation of the induction boiler

The induction boiler consists of the main elements:

- Corps;

- induction coil;

- core.

The principle of operation of induction units is extremely simple: passing through the coil, an electric current generates a strong electromagnetic field. In accordance with the Joule-Lenz law, under the influence of electromagnetic waves, the tubular core is intensely heated, giving off thermal energy to the coolant circulating inside it.

The performance of such systems is evidenced by the fact that, since the 1930s, the principle of electromagnetic heating has been successfully applied in metal-smelting furnaces.