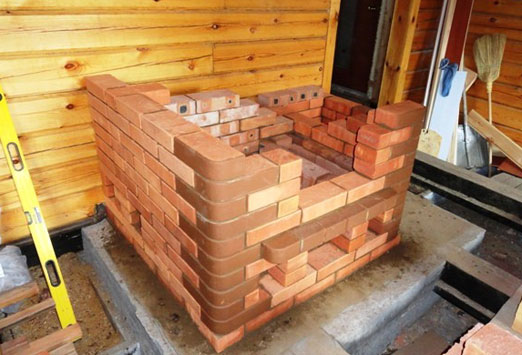

Stove base and fireplace masonry

The necessary material that will be needed in order to fold the fireplace is a ready-made mixture of stove mortar. If you prefer to make your own rather than buy it, then you will need:

- clay, as the main binder when laying a fireplace;

- sand - a substance that is a filler, it should not contain impurities;

- cement is added to the clay-sand mortar, it is especially necessary when working on an external chimney located above the roof. It is recommended to use high quality cement grade 400;

- heat-resistant adhesive used when laying refractory (chamotte) bricks.

Each stacked row is carefully leveled. The firebox is made of refractory bricks. The walls of the fireplace are not tied up with a firebox, since fireclay and red bricks react differently to increased heat. They have a different coefficient of expansion under the influence of high temperatures, so if you tie the firebox to the walls of the fireplace, the stove may simply fall apart. Therefore, there must be an air pocket between the outer walls of the fireplace and the firebox. A fireplace with a firewood burning chamber in the form / is the most efficient. Before you make a fireplace out of the stove, you need to select a sample of the portal and form a portal already when laying the firebox.

Of course, the ideal, or rather, real fireplace is a stove with an open portal, however, some owners prefer to install a glass door on the fireplace, the place for it is left on the second row, and the joints in the masonry are made in the middle of the brick row, but, in no case, not with edge.

Air pockets can be filled with brick chimney; they, like stones in a stove, will keep warm for a long time. A glass-magnesium sheet is installed on top, which can withstand temperatures of a thousand degrees.

On the back of the firebox, on top of the glass-magnesium sheet, three bricks are laid in such a way that there is room on the front side for smoke removal. Immediately behind the front part, on the front side, a metal corner is laid, along which a row screed is carried out, into which the upper oven tapes emanating from the door are already hidden.

The depth of the firebox is related to the height of the portal in a ratio of one to two or two to three. A shallower depth will cause smoke, a larger one will reduce heat transfer. And the fireplace itself should not exceed 1/50 of the volume of the room.

How to convert a stove into a fireplace

You'll need

: simple brick, refractory brick, sand, cement, shelf boards, facing material.

Instruction:

- The easiest way to convert a stove into a fireplace is to install a Finnish glass door instead of a cast iron one. In this case, the heating properties of the stove will remain at the same level, plus the functions of the fireplace will appear. This option can be called the most economical, both financially and in terms of labor intensity. After reinstalling the door, you can also decorate the stove beautifully in folklore style.

- In cases where you plan to radically disassemble the stove and only then make a fireplace at this place, then you will have to do more laborious work.

- First, we dismantle the old furnace to the ground. At the same time, a fireplace podium can be built from old bricks, on which fuel will be burned. During construction, only cement-sand mortar should be used. In the body of the podium we lay a niche for firewood. First, we cover them with three rows of ordinary bricks, after which we put refractory bricks on the edge.

- On the podium we arrange a portal where the combustion process will take place. The portal is determined based on the overall dimensions of the room itself. So for example, in cases with a small room, it should not take up too much space. We also calculate the size of the furnace window.At the same time, it should also be remembered that if its size turns out to be significantly larger than provided, then constant drafts can be obtained, and therefore hypothermia of the room itself. There will be such a fireplace and smoke a lot.

- We calculate the smoke opening of the fireplace. Compared to the opening area of the furnace part, it should be 10-15 times smaller. It is possible that you will even have to narrow the chimney a little.

- The depth of the firebox of the fireplace is carried out in relation to the height of the portal, as 1 to 2 - 2 to 3. The consequence of a smaller depth may be smoke, and a larger one may reduce heat transfer.

- We block the portal opening of the fireplace with brick lintels, which we arrange according to a special formwork (circle). We start work with laying the heels. We support the circle with the help of temporary supports. After the supporting heels, we install the central brick on the circle and continue laying simultaneously from both sides. The overlap at the curved vaults and the smoke box should be no more than 6 cm.

- Facing can be made in the style and materials that will be included in the overall design of the room. But on the mantelpiece it is best to use processed oak boards.

Today, in country houses, conventional stoves can no longer be found as often as before, as there are more modern heating and cooking systems. Fireplaces come first, which can perform almost the same functions, but their appearance is more decorative. The fireplace can be placed in any room: in bedrooms, living rooms, halls. Such a hearth gives more comfort, gives soft warmth, which quickly heats a house of a small area.

How to make a fireplace durable and comfortable? It should be noted right away that the work differs not only in complexity, but also in significant financial costs. It is required to invite a professional master. You can save a lot if you buy a ready-made metal fireplace that requires only external decorative trim, but this option cannot be called the best.

Sometimes, when buying a country house, it happens that it already has an ordinary Russian stove, which is not used for its intended purpose. In this case, on the basis of this furnace, you can make a fireplace with your own hands. Such an alteration consists in assessing the condition of the furnace, determining the plan of work that may be needed. As a rule, most often it is required to expand the firebox, install a door and a new chimney pipe.

Options for converting a stove into a fireplace

How is a fireplace made from a stove? There are several options here, much depends on the initial state of the structure. The easiest way to make a fireplace out of an old stove is to simply update the firebox, expand it a little to an acceptable size, and then put in a special glass door, which is also called Finnish.

This option is the simplest, there is no need to make changes to the design, it remains the same, but the oven itself must be cleaned. The new door will make the design look like a fireplace as much as possible, and if you also make decorative cladding, for example, using tiles or marble tiles, then the similarity with a fireplace will be maximum.

There are more options on how to make a fireplace from a conventional stove. The most expensive and difficult is the disassembly of the old structure and the assembly of a new one. First, the furnace is dismantled, after which it is required to inspect the base, it may be necessary to add sand again. After that, a roofing material waterproofing layer is laid on the surface, a new masonry is performed according to the selected scheme.

The workflow in this case looks like this:

- The old furnace is dismantled, the base is inspected for damage.

- The brickwork of the podium is being carried out, which is necessary to protect the base from high temperatures when burning firewood.

- According to the prepared scheme, the fireplace is laid, which is no different from the usual one.For this, a special furnace and refractory brick is used. The firebox itself can have different sizes, it is recommended to install a glass door, which will not only increase heat transfer, but also make the use of the fireplace safer. The floor around such a structure must be laid out with a refractory material, such as ceramic or stone tiles. The surface of the fireplace is decorated with various finishing materials. Of the most stylish, tiled tiles should be noted, which are ideal for any interior.

Facing

When the design is completely dry, you can proceed to the decorative design. There are different methods for facing the fireplace, it is necessary that the material is resistant to strong heat.

brick finish

Old brick can be given a fresher, more decorative look if processed correctly.

First, excess cement-clay mixture is removed from the seams and bricks with abrasive paper. It is necessary to process the seams, for example, with a colored mixture, to give them a convex shape.

Bricks must be coated with heat-resistant paint. The finish is a high heat resistant lacquer.

Plastering

A simple finishing option is plaster. To complete the cladding, complex installation work is not needed, such as with tiles.

It is necessary to make the solution more durable, you can use salt, crushed fiberglass. To give the coating a shade, lime paint is added.

Before starting plastering, the fireplace is heated until the outer surface is warm. The plaster is applied in layers, the first layer eliminates minor irregularities, the second - decorating.

stone cover

A spectacular finish can be made with artificial, natural stone. In both cases, environmentally friendly material will be used, the difference in weight, density of raw materials.

Artificial material is much cheaper, you can do it yourself. The natural analogue is better, due to natural properties.

Natural raw materials are characterized by increased resistance to any changes in temperature, humidity, mechanical damage, unlike artificially created material.

The cladding is complex, it is difficult to attach natural raw materials to a conventional solution. It is recommended to consult with a bricklayer.

Tiled surface

Not all tile models are suitable for decorating the outside of stoves, fireplace devices: clinker, porcelain stoneware, terracotta, majolica.

Clinker tiles are widely used due to their stability. There are many colors, imitation of natural stone. Models are produced with the addition of stone chips, which enhances performance.

For tiles, you will need glue that will not dry out under the influence of high temperatures.

It is not very difficult to make a fireplace from scratch, or to remake an old stove, the main thing is to work out a scheme and prepare materials. You can not replace the material with a similar one, the structure will be very hot.

Step-by-step algorithm for reworking the furnace:

The procedure for arranging a fireplace stove with your own hands

The following materials will be required for fireplaces and stoves of this design solution:

- solid and refractory bricks;

- steel strips;

- clay mortar;

- oven;

- cooking panel;

- steel doors.

Further, the installation of a fireplace stove with your own hands is carried out in the following sequence:

- The 1st and 2nd rows of bricks serve to level the structure under construction, since as a result of pouring the foundation, irregularities still form on its surface. After completing the second row, the building level should show an absolutely flat surface, otherwise the life of the structure will be short.

- On different sides of the fireplace stove, one blower and two cleaning windows are formed.

- A steel door is mounted on each window. A steel strip is additionally placed above the blower door.On the front side of the structure, a fireplace compartment is equipped, preferably with a side so that combustion products do not fall out of it.

- The doors are covered with bricks, and a portal is opened from the side of the fireplace.

- A grate is placed above the blower. The long narrow compartment is covered with a steel strip.

- The side channels are divided by bricks in half. Open the furnace window.

- Install the firebox door.

- The firebox door is covered with a steel strip and covered with bricks.

- The fireplace is also covered with a strip of steel.

- The channel above the firebox is connected to the nearest well. On the front side, the fireplace is covered with bricks and forms a smoke intake.

- The hob is placed above the firebox. The remaining space above the passage and the well is covered with steel strips.

- The channel above the fireplace is narrowed and the brewing compartment is formed.

- The 14th and 15th rows are performed similarly to the 13th.

- An exhaust hood is installed between the nearest well and the cooking chamber.

- A cleaning metal door is mounted in the hood.

- The rear well, located above the hood, is divided in half. The one that will go outside is covered with a summer damper. The well above the hearth acquires the size of 1 brick. Steel strips cover the cooking chamber over the entire area.

- The cooking chamber is covered.

- The 20th row is similar to the previous one.

- The 2nd rear channel is expanded to the maximum size and a cleaning window is removed from it. A damper is installed above the well with a fireplace.

- Install a cleaning door.

- A metal oven is placed in the cavity. A vertical smoke well remains on the far side.

- On one side of the oven, smoke is drained into the central pipe.

- Actions are repeated.

- They make a transition from the cavity to the pipe, since the oven has ended.

- The cavity and well are covered with steel strips.

- On top of the strips, the area is covered with bricks. In the last unused well, a winter valve is mounted.

- All wells are connected to the chimney by using horizontal passages. Install a cleaning door.

- The 30th and 31st rows are similar.

- The area is covered. Install a common damper.

- 33rd row and beyond - the structure is narrowed - it goes into a pipe.

Today, in country houses, conventional stoves can no longer be found as often as before, as there are more modern heating and cooking systems. Fireplaces come first, which can perform almost the same functions, but their appearance is more decorative. The fireplace can be placed in any room: in bedrooms, living rooms, halls. Such a hearth gives more comfort, gives soft warmth, which quickly heats a house of a small area.

How to make a fireplace durable and comfortable? It should be noted right away that the work differs not only in complexity, but also in significant financial costs. It is required to invite a professional master. You can save a lot if you buy a ready-made metal fireplace that requires only external decorative trim, but this option cannot be called the best.

Sometimes, when buying a country house, it happens that it already has an ordinary Russian stove, which is not used for its intended purpose. In this case, on the basis of this furnace, you can make a fireplace with your own hands. Such an alteration consists in assessing the condition of the furnace, determining the plan of work that may be needed. As a rule, most often it is required to expand the firebox, install a door and a new chimney pipe.

Installing a foundation for a fireplace

To make a foundation for a furnace, it is necessary to prepare the following tools and building materials:

- roulette;

- shovel and crowbar;

- burner;

- Bulgarian;

- welding machine;

- ruberoid;

- sand;

- 10 mm reinforcing rod;

- mortar of concrete grade M300.

The dimensions of the future foundation are marked on the floor with chalk - 110x100 centimeters. These parameters are larger than a standard furnace, due to the presence of a viewing window (portal).The depth of the hole to be dug should be 35 centimeters. Its bottom is leveled with a sand cushion 5 centimeters thick. The walls are also made as smooth as possible using a shovel.

Where can you see the Russian stove

We will answer all your questions step by step. In our country, far from civilization, a huge part of the population lives. In the 1990s, there was a tendency for the villages to die out. Young people left their parents' homes and went to the city in search of a better life. Many buildings were simply abandoned.

Most village houses were equipped with stove heating. In order to dismantle the stove, it is necessary to re-lay the floor covering and seal the hole in the roof for the chimney. Not everyone had the desire and opportunity for this, so the symbols of warmth in the house and comfort, sung in Russian fairy tales, stand to this day.

Massive brick building

Gasification made it possible to install a burner in the stove and give the structure a second life. But the modern approach to refurbishment implies that there will be a conversion into a functional, stylish fireplace.

Rework Options

The simplest way to remake is the method of expanding the structure. Its peculiarity lies in the fact that the old stove will have to be cleaned well, and the equipment itself should be made more modern - to change the outdated finishing material to a new one.

The biggest difficulties arise with the redevelopment of the furnace of the old furnace. Experts advise using cast iron plates or fire-resistant bricks to cover the firebox.

Remodeling the oven completely is the most difficult task. Work begins with the complete dismantling of the entire structure. Then the foundation is considered. If its quality meets modern requirements, then it can not be dismantled. The old and cracked foundation will have to be redone.

It is worth noting that the complete dismantling of the building must also be carried out correctly:

- The superstructure is completely dismantled from ceiling to floor;

- Whole and good bricks are set aside (they can be used in the process of building a new structure);

- The dismantling of the old furnace should not be accompanied by severe destruction of nearby walls and interior items;

- Keep a close eye on the old firebox. In the process of dismantling, try not to damage its doors or chambers. Damaged equipment will have to be thrown away and new ones made.

How is a stove different from a fireplace?

Now let's dive into the realities of the upcoming work and note their laboriousness and complexity of implementation in technical and theoretical terms. To understand how to make a fireplace from a stove, you need to determine all the types of work required. Only a real pro can do this, so the involvement of a master will most likely become a prerequisite. But for the sake of information, we will explain how to conduct a reconstruction analysis.

A stove is no different from a fireplace. Both devices work by burning fuel and both participate in space heating. But still, one of them is called a stove, and the other is called a fireplace.

- The functions of the furnace are not designed to provide an opportunity to observe the flame, therefore, all technological nuances are aimed at high-quality and efficient use of heat. The firebox door is made of metal and hides the combustion process from the eyes of the observer.

- The gases formed after combustion have a high temperature. You don’t really want to give such energy to nature, so the chimney in the furnace body is made in the form of a labyrinth. When moving, the heated gases give off their heat to the bricks of the stove.

- The firebox of the Russian stove is somewhat smaller than, according to calculations, should be at the fireplace, which is for such a room.

Ready-to-use brick building

Otherwise, the differences relate only to external elements, which can also be used in a redesigned design.

Step by step instructions for conversion

You need to draw up a scheme, which is better to order from the master. The specialist will carry out calculations to avoid errors, alterations. It will immediately be established what materials, tools are needed for work.

You will need a fire-resistant brick for the furnace, heat-resistant blocks. The material can be found in a hardware store, on the market, or you can order delivery through a reliable company.

For masonry, you will need dry cement mortar, clay, a construction mixer, a drill nozzle.

Under the solution you need a large container, clean water. The mixture is applied with a trowel.

In order for the fireplace to turn out to be even, it is necessary to constantly monitor the installation using a building level, usually a plumb line.

The first fireplace row is placed on the waterproofing with markings applied, applying the solution down. After laying out, according to the rules of order, you need to put the second tier with a shift of half, a third, a quarter of a brick. To make the rows even, the blocks must be cut evenly with a grinder.

The ordering of the brickwork involves the location of the bricks of each next row above the junction of the blocks of the previous tier.

Clay in the solution prevents the destruction of the structure, a mixture of sand and cement does not tolerate such loads. In combination with clay, it is possible to achieve a heat-resistant effect.

To form a furnace recess, you will need a dense sheet of refractory metal, on which subsequent rows will be laid.

A frame is immediately installed under the future door, which is fixed with fire-resistant wire.

What to look for when remodeling the oven

When altering the furnace, it is imperative to perform the following preparatory steps:

- Checking, assessing the state of the design of the furnace and chimney. This is done without fail, since further safety of use depends on the quality. There should be good cross at the chimney, since the fireplace simply will not work without draft. The cross section must be no less than the size of one brick. Otherwise, the thrust will be very small, completely insufficient. Usually the chimney is immediately dismantled, after which a new one is installed in its place.

- The furnace has a small firebox, this is not enough for a fireplace. This means that during the reconstruction, the size of the furnace must be increased to the required size. You can install a glass door that will cover the firebox, ensuring the safety of using the structure. But this door is not mandatory, it is not necessary to specially mount it.

- It is required to carefully examine the body of the structure. If it is intact, there are no cracks, signs of deformation, numerous falling out bricks on it, then it is not necessary to disassemble it. It is better to decorate the surface of the case after all the work, giving it great attractiveness.

Alteration

Before drafting a future fireplace, check the condition of the chimney. The smoke extraction system bears most of the responsibility for safety.

Check the condition of the stove, foundation. If violations are found, it will be necessary to redo it from scratch, especially if the foundation has been damaged.

It is easier to convert the structure into a decorative device.

The chimney pipe must meet the basic requirements. For example, the height of the pipe used can be at least 7 m. The cross section of the material is 13 - 25 cm, the depth of the furnace is from 0.5 m.

The furnace compartment is laid out with refractory, fireclay bricks, which will not deteriorate from direct contact with fire.

During masonry, channels are created that allow air to pass along the door, which will prevent the accumulation of soot.

After completing all the rough work, you can proceed to the fine finish.

An example of converting a stove into a fireplace structure with a heat shield:

Rebuilding the stove into a fireplace

The very first step that needs to be done before installing a new fireplace is to prepare a future drawing. All dimensions must fit under the old foundation.

The conversion of the stove into a fireplace takes place in several stages:

- The foundation of the furnace is reinforced with waterproofing. Roofing material is used as a waterproofing material. Several layers of material are laid on a clay-cement mortar.

- The next step is to install the base under the fireplace. You can build a new foundation or put a furnace if it is in excellent condition.

- The furnace is made according to new drawings, since the furnace furnace hole is not suitable for a fireplace. To create a base for a firebox around the circumference, the structure is lined with brickwork.

- The furnace itself is being built. The walls must be made vertical. It is advisable to check the clarity of the lines of the future side walls of the furnace using a building level.

- Correct calculations are also important at the stage of building a chimney. It is laid out with brickwork. Every few rows, you need to remove excess mortar from the inside of the chimney, as soot may remain on them later. Because of this, the chimney will have to be cleaned frequently.

The air duct can be made not only from bricks. You can consider the option of a sandwich pipe, the streamlined shape and smooth walls of which do not prevent smoke from escaping from the fireplace.

Conversion Instructions

Converting the stove into a fireplace is not required so often, usually such work is planned when the stove is already in the house, but it is used extremely rarely. Having spent not so much time and money, you can make a beautiful and stylish fireplace from such a stove, which will not only heat the house, but also become a real decoration for any interior. Furnaces are not so difficult to convert into a decorative design.

Often such stoves are in kitchens, in central rooms, they do not take up much space, but their appearance is not always aesthetic. Therefore, you can safely take on the alteration and use the fireplace as an additional source for heating the room.

To convert the stove into a comfortable and beautiful fireplace, you need to prepare the following tools and materials:

- furnace and refractory brick, its volume depends on how much the furnace will have to be redone;

- building level;

- Bulgarian;

- cement;

- clay masonry mortar;

- finished chimney pipe (if the old one has to be completely removed);

- Master OK;

- putty knife;

- tiles for facing;

- glass door for the fireplace.

Before you start converting the stove into a fireplace, you need to consider that the fireplace is heated differently. Only special wood briquettes or dry firewood are suitable. Therefore, it is recommended to immediately take care of the fact that there is always a certain supply of fuel.

It is necessary to prepare all the indicated materials and tools, draw up an individual drawing of the future fireplace. Its appearance depends on the original furnace. Be sure to inspect the furnace, find out how well the body is made, what condition the foundation is in. If everything is in perfect order, then you should not disassemble the already standing structure, the work is carried out on the material that is. Between the common foundation of the floor of the house and the base for the stove there should be a gap of 25 cm, it is completely covered with sand.

At the firebox, the depth should be 50 cm, the body inside the furnace must be lined with refractory bricks.

If all conditions correspond to the required, then it is necessary to proceed to the inspection of the chimney, as it may have to be rebuilt. For fireplaces, the requirements for chimneys differ from those for stoves, the height should be from 7 m, the cross section should be at least 13 * 25 cm. Special channels are required that will control airflow along the doors inside the structure. This will prevent soot from permanently settling on the door glass. A variant of the converted furnace design can be seen in the figure. IMAGE 1.

No matter how strange it may sound, but quite often the question arises of how to convert a stove into a fireplace. There are several facts that require further clarification.Where did the oven come from in the 21st century? Why does it need to be redone? Is this possible, because the stove and fireplace are different devices?

Home

Preparation of building material

Of course, you can convert the stove into a fireplace, leaving the old bricks. To do this, it is enough to replace the furnace door of the fireplace, but this will not be a fireplace that will bring to the house the comfort and warmth that is expected from it and, therefore, we will consider the option when the old stove will have to be completely dismantled. The fireplace will have to be folded on the foundation of the stove. It is necessary to purchase all the material at once, exactly how much, how much is needed to build a fireplace, and since a non-professional builds a stove, even with a small order.

In order to lay a fireplace, you have to buy

- a little more than 500 bricks of the M-150 brand;

- for laying a fireplace insert, 55 pieces of fireclay, refractory bricks are needed;

- you can buy 6 bags of a special mixture of furnace mortar.

There is an opportunity to save money - this is to prepare a clay solution, but the preparation process will take a lot of time and require a lot of labor.

- you also need to buy a fireplace door;

- chimney sandwich panels;

- eight 50 mm metal corners;

- chimney flue.

- in order to fix the oven fittings, you will need a construction oven tape.

The cost of all the material will be about 10,000 rubles.

Features of the rework procedure

This process will require much less financial investment compared to the complete elimination of the stove and the installation of a new expensive fireplace.

. As a result of this work, you can significantly improve the appearance of any room, as well as choose a design that will ideally fit into the existing interior.

The very first steps that can be done by hand are those that involve the preparation of building materials and tools. You can use the old bricks of the stove during work, and here it is usually replaced by a standard fireplace. This solution is not considered optimal, since the stove still does not look like a fireplace. Therefore, it is best to almost completely dismantle the furnace structure, in place of which a full-fledged fireplace is being built. It is quite difficult to do such work with your own hands, but it is possible if you follow the instructions exactly.

To remake the structures, it is necessary to purchase bricks and masonry mix, as well as a special fireplace door and some other special items that will be used in the process. These include:

- sandwich panels designed to decorate the chimney;

- metal corners;

- view for the chimney;

- oven tape.