How to make adobe and fire bricks

The production of adobe is almost no different from how raw is made. The ratio of clay and sand is selected in the same way, but you need to add more straw, which must first be finely chopped.

For kneading, it is recommended to dig a pit, about 30-50 cm deep. The walls must be made sheer, and the bottom flat. At the bottom, cover everything with a material that is water resistant. For example, a tarpaulin or plastic wrap is suitable. Fill a third of the hole with clean water and pour the composition into it. After that mix thoroughly. You have to be very careful not to slip. As a result, the solution should be liquid and homogeneous. After that, it is allowed to gradually add straw to it and stir constantly. A thick and plastic mass comes out.

After that, a full-bodied brick is molded and it is dried. The technology will be the same as described above. You need to try to calculate the volume of the kneaded mass in such a way that you can use everything at once. If you re-knead the mortar, the bricks will not be very strong.

By the way, such material does not tolerate moisture well, therefore, during the construction of houses, the roof should hang no less than 0.6 m. The openings of windows and doors should be located no closer than 150 cm in relation to the corners.

In addition to raw and adobe, there is a third option - ceramic brick (that is, burnt). In industry, special furnaces are used for this process. They are heated to a temperature of 1200 ° C - this is enough for the clay to turn into ceramics. Of course, such production is not available at home, so you won’t be able to make a large number of such bricks on your site. But if somewhere there is not enough about 40-50 pieces, then it is quite possible to master it yourself.

To do this, prepare an iron barrel. One bottom needs to be cut. Dig a pit, which has a depth of 50-60 cm. Lower the barrel itself there. You just need to put it so that there is a fire under the bottom. it is best to put it on stones, channels, or simply attach iron legs. The barrel should be located in the pit so that its bottom is at a distance of 25 cm from the bottom of the pit. Now the container remains to be filled with bricks. It is necessary to lay them so that there is a small gap. This is required for uniform heating. Then cover with a lid. It will not be able to be lifted until the material has cooled down so that cold air does not get inside. It will take about 20 hours to heat up, so you need to stock up on firewood and peat in advance. Then the barrel should cool down on its own, without forced cooling. You will have to wait approximately 5 hours.

Clay brick is a cheap and environmentally friendly material. Walls, foundations, wells, fireplaces and more are made from it. You can do it yourself, although you will have to spend a lot of time and effort on it. At home, you can get not only raw, but also adobe, ceramic bricks.

clay brick

In the home production of bricks, presses, machines and other specialized equipment for shaping and compacting products are very rarely used. Such practices are possible due to the qualities of the raw materials - natural clay, sand and other fillers (straw, etc.). Natural materials plus new techniques based on methods of making bricks tested for decades, as well as a responsible approach - and artisanal bricks will not let you down. To strengthen and improve the heat-insulating properties, special polymers are added to modern bricks; for good molding, mixtures are plasticized.

Bricks, if simply, denote artificial stones of rectangular shapes.It is this block geometry - a rectangle measuring 250 * 120 * 65 mm that is convenient for masonry. All standard sizes of bricks are accepted in home production, as they have been worked out for centuries, and are guaranteed to provide stability and good bearing capacity of prefabricated structures. In addition, rectangular bricks are more convenient to form, store, carry and store.

One of the highlights in hand-made bricks is high-quality clay. There are many types of clays in nature, and their differences are very significant (and not only in colors - this is a separate extensive topic). Deposits of clays of suitable fat content are not uncommon, and if there is the necessary clay in the area of the site, this is an excellent savings. If not, then clay is also purchased at bases, factories, construction markets, depending on the situation. The radiation background, the purity of the clay, the number and types of inclusions can be investigated both independently and by ordering an analysis in a construction laboratory. But it is always possible and necessary to check the basic qualities of clay, regardless of the source of extraction or purchase. The first test is for fat content (as well as for sandiness), stove-makers are excellent at it, and once potters and sculptors kept the secrets of selecting clay. A clay sample, or rather 2-3 selective portions, is soaked in clean water until it sticks to the hands so that it becomes possible to knead, roll and sculpt a clay ball. A large sample size is not needed, 50-80 mm in diameter is sufficient. In addition to the ball, they roll out the second form - a cake no thicker than 10 mm and about 100 mm in diameter. These samples are laid out in a place protected from direct sun and wind, at normal temperature, and after drying on the third day, the samples are checked for strength.

The clay cake and the ball cracked - a good sign that speaks of the fat content of the clay. In this case, the recipe must include fine-grained sand, river or quarry, without dust impurities. If cracks do not appear on the sample ball, then they test the strength in a simple way - the balls are thrown effortlessly onto concrete, asphalt, paving stones or any hard surface from a height of about one meter. If clay koloboks do not break at the same time, the clay is excellent, almost ideal for home-made brick molding. Clay is tested for plasticity and fat content both by used and individual tests.

If the dried kolobok samples did not crack at all, the original clay is most likely not oily enough. Dry clays often look great immediately after drying - smooth, even, but they are not suitable for brick. Finished products will be fragile and will not withstand even weak blows. Dry clays, however, are suitable and quite in demand, they are diluted with fatty compounds, and special professional additives are also widely used (for the rheology of the mixture, to increase impact strength, for plastic, etc.). The selection of the composition is experimental, and requires intuition and skill. To determine the solution formulation, a number of test samples are made from the available components (which are always individual, like any natural raw material). Knead and soak the clay to a creamy density, add fine river sand and fatty clays (most often purchased, with accurate characteristics). Preliminary calculations - for one part of very oily clay 4-5 parts of sand by weight; on clay of medium fat content - 1-2 parts of sand. The exact composition is selected without haste, and must be adjusted for each new batch of raw materials. In the future, all the time spent on empiricism will pay off handsomely.

Homemade brick fillers - sawdust, straw, needles, etc., are in demand today more than ever. The effects of natural additives are an increase in the insulating qualities of bricks, sufficient for the use of adobe in hydro- and heat-insulating protective walls, including those below zero, in the foundations and foundations of buildings.

About the composition, characteristics of clays and the selection of clay for bricks - in the article Composition of clay.

About the manufacture of fired and raw bricks - in the article Brick from clay.

The benefits of cosmetic clay for oily skin

We are all well aware that on oily skin the first signs of aging appear later than on other types of epidermis. However, the owners of such skin do not consider themselves happy, because they face a huge amount of trouble while caring for it. This is a constant shine against the background of hypersecretion of the sebaceous glands, because of which you constantly have to monitor makeup, these are inflammatory processes that provoke acne, and enlarged pores. In addition to the daily basic care (cleansing, toning, matting, nourishing and moisturizing), additional use of matting and cleansing agents is required. Cosmetic clay is a highly effective remedy that is used in the form of face masks. Clay masks perfectly mattify and dry oily skin, cleanse while exfoliating dead epidermal cells, tighten pores, control sebum production, reducing the risk of pimples and acne, and also supply useful trace elements.

There are quite a few types of cosmetic clay, but green, white and blue clay are considered the most useful and effective for oily skin. Click here for white clay mask reviews.

Proportions and mixing of the solution

In addition to cleaning before kneading, the clay for laying the oven must be prepared. The material is laid out in a metal-lined box or barrel, filled with water so that the liquid covers it entirely. If there are large lumps, they must be broken into smaller fragments in advance. Everything is mixed well and left for a couple of days. Clay is aged for at least five days with constant addition of water. After that, the solution must be mixed again and poured through a sieve into another container.

The clay composition should be of a pasty consistency, without impurities. If, after 48 hours, small lumps come across in the mass, it must be mixed again, all seals broken and kept for another day.

After preparation, you can begin to prepare the solution. If clay is mixed with sand, the latter is poured into the prepared container, then plastic material is laid out, and a sandy layer is again poured over it. A shovel is used to mix the components. If moisture appears at the top, add a little sand. If the composition is too dry, topping up with water is required. The solution can be considered ready if it begins to slowly move out of the shovel and becomes homogeneous.

If the base is medium fat, you can not add the sand component. Step-by-step instructions for breeding clay without sand for the stove with your own hands:

- The material is laid out on a wooden platform in layers, each layer is wetted.

- Upon reaching a height of 30–35 cm, the mass is mixed. For this purpose, you need to slap on the upper layer with the back of the shovel.

- The kneading continues until a homogeneous substance is formed.

You can check whether the masonry clay for the oven is correctly prepared as follows: apply a thin layer on the red brick, put another block on top and leave for an hour or two. If, when the upper brick is raised, the lower one does not fall off, you can use the composition for the construction of the stove. Clay seizes for a long time, you can immediately knead the required volume of the binder composition. It will take approximately 20 liters to lay out a 50-brick sauna stove, and 15–20 percent more to build a Russian stove.

How to dilute clay for kiln putty:

- The dry base is ground and soaked.

- Sand is added with lime or cement. The proportions of medium-fat clay with sand and lime are 1:2:1.When including cement powder, it is necessary to proceed from the amount of the sand component in a ratio of 1: 3.

- To make the plaster layer stronger, you can add asbestos, fiberglass, hemp or straw in a ratio of 1: 2: 0.1 (clay / sand / additives).

When additional ingredients are included in the clay solution, they are first mixed with each other, and only then with pre-soaked clay.

Variety of clay bricks

Brick is one of the universal building materials, which has been widely used for the construction of structures for any purpose and architectural complexity for centuries.

Production line at a brick factory

The reliability and durability of this material has been tested for centuries. It should be noted that there were no special changes in the geometric parameters and brick production technology. It is still a ceramic product made of clay and has gone through certain stages of production.

Depending on the purpose for which the brick will be used in the future, it is divided into several types: construction, facing and special purposes. Of course, the pricing policy is also different.

So, building brick, the most demanded of all types of this category. It is widely used in the process of building any property: houses, cottages, brick fences. However, often the resulting surface needs additional processing - cladding. In ordinary bricks, color heterogeneity, a certain degree of roughness, small corner chips, and the like are allowed. But the facing brick is produced according to strict technology, all kinds of inclusions and cracks, and heterogeneity of shade are categorically not allowed. The presence of all of the above indicates the marriage of the finished product.

Brick pressing process in a factory

At the same time, if domestic manufacturers allow minor deviations in the production process, then foreign ones strictly adhere to the recipe. In no case are any deviations in geometric parameters allowed.

Modern technologies and advanced equipment allow brick manufacturers to produce quite a variety of products, which makes it possible for masons to build various buildings according to unique projects. The use of rounded bricks with non-standard geometric parameters allows you to lay out not only original drawings on the wall, but also build independent structures.

A special brick has a specific area of application, for example, the use in the process of laying a structure around a stove or fireplace, where direct contact with an open fire is expected. Refractory fireclay bricks or high-alumina bricks can be safely attributed to this type, which is distinguished by its special endurance to various environmental influences.

But silicate blocks are recommended to be used in cases where constant contact with moisture is not provided. It is quite dense and durable, which makes it possible to erect walls of varying complexity with its subsequent cladding with other building materials. The masonry technique of this block is practically no different from the classic one.

White

It appears as a white powder with a yellowish milky or creamy tint.

Kaolin produces the following effects:

- absorbs sebum;

- dries;

- cleanses pores;

- mattifies;

- additionally - tones, nourishes, smoothes.

Soap for morning cleansing

- clay (hereinafter we mean the drug in powder form) - 100 g;

- soda, boric acid pharmacy (powder) - each ingredient 1 tsp.

The funds are mixed, transferred to a dry bowl. In the morning, take a pinch of the mixture, add water, stir to form a slurry. Moisturize and lather the face with clay, leave for 2 minutes. Then they wash, use a tonic, then a moisturizing cream for oily skin. This normalizes the secretion of fat, cleanses the pores, and reduces inflammation.

Clay mask for oily skin for nutrition and whitening

To prepare the mask take:

- kaolin - 2 tbsp. l.;

- egg white - 1 pc.;

- water - 3 tbsp. l.;

- lemon juice - 0.5 tsp;

- honey - 1 tsp

Protein is whipped into foam, clay is diluted with water, then all components are mixed. The mask is smeared on the face and kept for a quarter of an hour.

Mask for inflammation, shine

The composition includes:

- white clay - 2 tbsp. l.;

- aloe juice - 1 tbsp. l. (or 1 ampoule of extract);

- water - 1 tbsp. l.

A paste of mixed ingredients is applied to the face, left for 15 minutes.

Expert answers

Elina Linberg:

clay-sand mortar when laying the stove is very dependent on the quality of local clay and sand. proportions are easy to figure out. you take a lump of solution and flatten it on the wall. if it cracks when it dries, it means a lot of clay. if it crumbles easily, then sand :))))

Victor Spirin:

The consistency should be like medium sour cream. I lifted it with a shovel, tilted it, and the solution flows down, but not quickly and does not fall off.

Sheva:

There is a special Masonry Mix For Stoves and Fireplaces from Prospectors (Designed for laying fireplaces and stoves in interior spaces, withstands temperatures up to 1000 C. It is used for laying all types of refractory bricks.)

yuri antonov:

In order to determine whether the mortar is good or not for laying the furnace, it is necessary to first prepare the mortar correctly and then lay several bricks on the mortar. After two or three days, you should carefully examine the seams in the masonry. At the same time, there should be no cracks in the seams and the masonry itself should be strong, that is, the mortar should adhere firmly to the bricks. through a fine sieve. Next, combine the measured part of the clay with an accurately measured amount of sand and mix well. The composition of the solution depends on the fat content of the clay: usually 2 to 4 parts of sand are taken for 1 part of clay. Water is added as much as necessary to obtain a solution of the desired consistency. At the same time, a clay mortar with a ratio of 1: 2 or 1: 4 is used only for above-ground masonry of buildings or furnaces that will be operated in a dry environment with relative humidity inside the room up to 60%.

If this is necessary, the strength of the clay solution can be increased by adding table salt to it in an amount of 100-150 g per bucket of solution. Also, the strength of the clay mortar can be increased with Portland cement in the amount of 0.5-1 kg per bucket of clay mortar by first dissolving it in water or mixing it in dry form. Another not unimportant factor in the manufacture of clay mortar is the use of sand with different grain sizes. In other words, it would not be bad to mix sand with larger particles with sand that has smaller particles of grains, in proportions of 2 x 1. That is, one bucket of fine fraction is added to two buckets of sand with large grains. Such a solution is stronger and more balanced. More details here: stroivagon /pechi/rastvor-dlya-kladki-pechi

Sergei Kireev:

Soak the clay for 2-3 days, then add a little sand, mixing well! You need to check the mixture like this: squeeze it into a fist and unclench it and count to three at the expense of 3, should the lump fall off the palm, if this happened? the mixture is ready! This is an old but very good way of cooking! Good luck !!!

Julia Tray:

more clay than sand!!!

Draftsman:

depends on the fat content of the clay. sifted sand through a sieve no larger than 1.5 mm.the mixed solution is plastic, if it is possible to add a merkel, soak it beforehand for a day, pour 7-8 parts of fatty clay with hot water and knead. if there is a drill with a nozzle, and so by hand. it took me about 1 hour for 6-8 buckets of mortar. open special literature in more detail, and more by skill

ANDREY Fomin:

I would advise you to buy a ready-made oven mixture, it already contains both clay and sand and special additives so that the solution does not crack. at one time they shifted the stove to me, so the master immediately said that it was better to buy a ready-made mixture. only for example, we (Pskov region) have 2 types, cheaper and more expensive, but here it’s up to you to decide which one to take.

kpacota.at/:

for kiln masonry, it is necessary to mix 9 parts of (pre-soaked) fireclay clay, one part of washed river sand (without clay filler) and one part of cement grade 400, this solution is an ideal composition that meets all requirements The question arises: why wash clay from sand if we do we mix it with clay? Because in that sand there is a different clay and, accordingly, a different filler

Igor Iskandarov:

And sand and clay are different everywhere, you need to ask the local stove-makers.

Scope of brick clay

Clay solid brick has been known for many centuries, but still remains a very popular material in construction. Brick clay is used to create not only ceramic bricks, but also clinker ones. Such natural material is also used for other purposes. For example, this is the production of panels for ventilation facades, slotted blocks, facing tiles, tiles and other things. In addition, ceramic-type fillers for concrete are also made, which are distinguished by their lightness. For example, these are expanded clay and agloporite, which are obtained by firing (it should only be short in time) clay granules in rotary kilns.

Brick clay is used as an additive during the production of pozzolanic and clay-lime type cements. If the mass contains a large amount of ferrous oxides, and it has a bright shade, then it is used as part of mineral paints. Brick clay can be used as a binder in plaster and masonry mortars, and it can be used either alone or mixed with cement.

Clay bricks also receive them from such a material. You can make them yourself. And in appearance, they will not be inferior to the factory ones, and the strength indicator will be much higher, so this material is perfect for building a furnace or even a whole house. Brick clay is also used for masonry. But if this is not a stove, but external walls, then it is best to use a mortar with cement.

If the masonry is built of unbaked bricks, and even made on a clay mortar, then it is best to additionally veneer such a wall with tiles or bricks. You can cover it with a polymer cement type plaster, or you can simply use siding or clapboard (before that, the wall must be covered with a roll-type waterproofing material). Clay-based coating is only great for areas where hot and dry climatic conditions prevail. Due to the constant dampness, the clay can become sour.

Properties of brick clay

There are several types of clay bricks:

- Raw. This material is unfired.

- Red clay brick, unfired and with straw. He is known as Saman.

- Burnt red brick. This is done to obtain a ceramic material.

Not every clay is suitable for the production of ceramic stones. The one that is used in this case is called brick. There are several suitable varieties of material that differ in composition and parameters.

Clay suitable for the production of ordinary bricks must have the following properties:

- connectivity indicator - not less than 3 kgf / cm2. This indicates the compressive strength of the material;

- tensile strength - not less than 0.8 kg/cm2;

- flexibility;

- lightness;

- the ability to swell, that is, the initial volume should increase by at least 4%.

- the ability to form a viscous composition;

- stickiness;

- the ability to retain the given shape after the firing process;

- fire resistance index - not less than 1.1 thousand ° C;

- sintering index - from 1 thousand ° C.

When choosing a material for the production of ordinary clay bricks, it is also necessary to pay attention to its composition. The main component is kaolinite

In addition, there must be other ingredients:

- montmorillonite (a mineral that can swell a lot);

- hydromica (silicate-type minerals);

- iron oxides, which affect the shade of clay;

- quartz.

As for the fractions of the material, there are 3 main categories. The first includes clay particles, in which the dispersion index is not less than 0.005 mm. The second group includes particles of dust type, which have fractions in the range of 0.05-0.065 mm. The third category is sand particles, in which fractions should be from 0.05 to 2 mm.

The ratio of such particles can be any, but if you need a material for making bricks, then only the product is suitable for which the clay particle modulus is at least 0.11. This amount is the percentage of clay compounds to the total amount of dust and sand. If the clay itself is less than dust, then such material is called loam. If there is more sand in the composition, then such a product is called sandy loam.

How to get raw

To get raw, you need to prepare in advance clay (non-greasy and oily), sand (river sand is best; it must be clean), cement (it will be needed to sprinkle the molds). For adobe, you will need more straw. You will need self-tapping screws or nails, plywood, boards (their thickness should be about 2.5 cm) and water. Of the tools - a hacksaw, a shovel, a sieve, a hammer, a trowel and a container for kneading.

First you need to make molds for bricks. It is necessary to take into account the dimensions of the clay brick that will be needed in the construction of the planned facility. They can be anything. As a rule, the height is 65 mm, the width is 120 mm and the length is 250 mm. But it must be borne in mind that during drying, the product decreases by about 15% in volume.

First you need to cut out the side walls of the mold from the board with a hacksaw. The bottom and lid will be made of plywood. Fix the parts with self-tapping screws. The lid must remain removable. This form is great if you need a solid brick. If it is necessary that a void remains inside the product, then bars in the form of a rectangle or cylinder can be nailed to the bottom. This option is not only more economical, but also more reliable: adhesion to the mortar during masonry will be much better. In advance, you need to prepare several forms or one, but there should be a lot of cells in it. The latter option will speed up the production process.

Now you can start forming bricks. You need to take a small piece of clay and add water, kneading with your hands, like dough in the kitchen. As soon as the mass begins to stick to your hands, you need to stop adding water. After that, pour out the saucer and a small ball and leave to dry in the shade for several days. If, over time, cracks appear in them, this means that oily clay is used. Then you should add a small amount of sand to the composition and experiment again with a new ball and saucer. If the ball is thrown on the ground and it crumbles, this will mean that the clay is thin and more fat must be added.

When molding, the walls are moistened with water. Additionally, you can crush them with a small amount of cement. After that, fill the form with dough and shake. The mass must fill all the empty spaces. Remove excess with a trowel.Press on the lid. Now leave the mass for a while so that it freezes. Then remove the lid and turn the mold over. Finished bricks can only be dried. This will take 1-2 weeks. To check if everything is done as it should, one brick needs to be broken. Throughout the thickness it should have the same color.

Methods for removing impurities

From the natural clay stored for oven laying, the first step is to remove impurities. For this, different methods are used.

Dry punching

You can wipe the clay through a sieve in a dry or soaked form.

You can wipe the clay through a sieve in a dry or soaked form.

The most primitive way. With your hands, select everything that is superfluous - grass, pebbles, garbage, crush large clods. After that, the plastic material must be rubbed through a metal sieve with cells of about 3 mm.

The method can be made a little less time consuming if the clay is dried. To do this, clay clods are laid out on a wooden sheet and dried in the sun. In winter, this is done in the cold, laying under a canopy so that it does not fill up with snow. With a small amount of material, they are placed indoors, on a heated stove or on a heating radiator. The drying rate depends on the size of the clods: the smaller they are, the faster they dry.

Pour the dried clay into a box with thick walls and crush with a rammer. Clay dust after grinding is sifted through a sieve with small cells to remove various inclusions from it: pebbles, chips, and other debris.

Soaking and soaking

“Dry punching” is a rather laborious task, therefore it is more expedient to soak the clay after manual cleaning for 2–3 days.

- Lay the material in a large basin in layers of 12-15 cm, with abundant wetting.

- Pour water in an approximate ratio of one to four with clay.

- When the mass softens, mix with a concrete mixer or using other means.

- Wipe through a wire rack with 2-2.5 mm mesh.

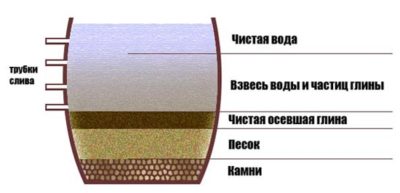

There is also an older method of elutriation:

- In a wooden container, several holes are drilled vertically with a small distance between them.

- Each of them, before filling the tub with a liquid clay mass, is drowned out with a wooden cork.

- Grains of sand and various small stones precipitate first due to their greater weight.

- After that, after settling, clay particles settle to the bottom.

- The top layer of water gradually becomes lighter, but you need to wait until the liquid becomes transparent. As soon as the boundary of the clarified moisture falls slightly below the first hole from above, the plug is removed. The settled water flows out of the container.

- After the appearance of the next level of settled liquid, the next plug is pulled out.

This process is repeated until all clarified water is completely drained. To speed up the precipitation after loading the solution into the tub, you will need to add bitter Epsom salts - about one pinch per bucket. If there is no wooden barrel at hand, it will be successfully replaced by a metal container of suitable height and volume. The principle of operation is the same with one difference - short sections of tubes are first soldered into the holes, plugs are installed in them.

When all the settled liquid is drained, the liquid clay is transferred to a wide box and left in the sun to evaporate excess moisture. After the dried material ceases to be fluid, periodically stir it with a shovel. As soon as the mass becomes similar in texture to thick dough and stops sticking to the palms, it is covered with polyethylene or oilcloth and stored until the start of furnace work.

We make bricks with our own hands

I would like to emphasize that the manufacture of bricks is possible not only at industrial enterprises (the technology for making bricks is described in this article), but also at home.To do this, it is necessary to have the raw material itself and a certain base of knowledge and skills for holding such events.

Manual selection of material for home-made bricks

The first step is to determine the quality of the raw material. To do this, dry clay must be mixed with water until such a consistency that the mixture begins to stick to the hands. Next, two small products are formed: a ball and a cake. Within 3 days, the clay molding dries under a canopy, after which it is carefully studied. There should be no cracks on the cake, and a ball thrown from a height will not break. Such raw materials are quite suitable for further use in the brick production process at home. It is best to purchase oily clay from a trusted supplier.

Next, you need to make a mold for the production of bricks. To do this, you will need boards that are knocked together. You can prepare a form of standard sizes, or individual. It is worth noting that the boards must be smooth without any defects. In the formed cells, previously moistened with water, the resulting clay mass is placed. Surplus is removed. In order to avoid the appearance of voids in the mass, it is necessary to place the molds on a special vibrating table, due to which a denser shrinkage of the raw material is carried out. It is best to make small molds so that you can lift them up. Each mold is closed with a lid. The pressed clay should stand a little in the form, after which the finished product should be carefully pulled out. Here is a raw brick and ready. However, it must go through the drying stage for another 1-2 weeks. To do this, semi-finished products are placed under a canopy, away from a source of moisture. It is best to place the blanks on a pallet.

Before firing the material

From ready-made clay bricks, you can build a structure for any purpose. However, it should be remembered that the roof should protrude at least 60 cm from the wall. In addition, door and window openings must be located at least 1.5 meters from the corner.

Roofing must be made of wood, and the walls themselves must be additionally lined with other building materials, which will serve as a kind of protection from various natural influences.