Types of contours

To stabilize the jumps of the pressure gauge needle, special compensating tanks are placed in the circuit. The pressure in the heating expansion tank forces the working fluid back into the pipe. They are of two kinds. Design differences allow them to be used in systems of different types:

with coolant access to air;

In open circuits, the circulation of the working fluid occurs due to gravity. What pressure in the expansion tank of an open-type heating system is not of key importance, its volume is more important. These systems are designed in such a way that an expansion tank is located at its highest point. This is a vessel of certain dimensions made of metal or plastic. It is leaky and the coolant in it is in contact with air. An open-type tank may be without a lid, but it is still better when it is. Thanks to her, garbage or insects, if any, will not get into it;

without access of the working fluid to air;

The pressure in the expansion tank of a closed-type heating system is higher than that of a conventional one. In closed circuits, water is pumped by an electric pump, which is the root cause of the pressure. Without a pump, circulation is not possible. Schemes of such systems involve the installation of a sealed expansion tank. It can be set at any point of the contour, except for segments:

- after the electric pump;

- after the heater.

Its location in space also matters. Air bubbles are pushed up by the coolant. They can't get into the tank. Since this will affect what pressure will be in the expansion tank of the sealed heating system.

The network often starts talking about what pressure should be in the expansion tank of the heating system. To find out the last, an ordinary layman will have to shovel a decent amount of information, since the answers of the participants often contradict. Let's try to put everything on the shelves and start with the design.

Navien boiler error 10

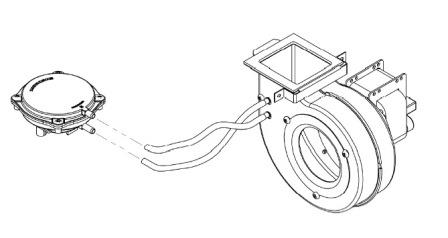

This error is related to the smoke exhaust system of the gas boiler. The products of combustion must be removed; for this, a fan is provided in the boilers. To control the operation of the fan and determine the presence of an acceptable draft for the operation of the boiler, a differential relay is used, which is connected to the turbine with two plastic tubes. When the fan is running, a vacuum is created, the relay closes, and the boiler functions normally.

Causes errors 10 may be a clogged chimney, back draft or incorrect connection of the air pressure control sensor to the fan. For the latter case, it is necessary to check that the yellow tube is connected to the bottom of the fan, and the transparent tube to the top, and the tubes themselves are not damaged, deformed or condensed inside.

Increased resistance in the chimney can occur due to direct gusts of wind or clogging of the chimney (bird nest or cobwebs, frost in winter). That's right, the place for the chimney to take into account the direction of the winds of a particular region at the design stage and the chimney should not be led to the leeward side of the house.

We stopped at the most common failures in the operation of Navien boilers, but in fact there are significantly more error codes. Ways to check and troubleshoot is the topic of a separate article. For convenience, here is a summary table of codes with a brief description:

| Fault number | Brief description of the problem |

|---|---|

| 02 | Low water pressure in the heating system or breakdown of the flow sensor |

| 03 | No signal from ionization electrode |

| 04 | Incorrect signal from the flame sensor or short circuit. Make sure that the ionization electrode is not in contact with the boiler or burner body, diagnose the control board. |

| 05 | Damage to the heating temperature sensor. Measure the electrical resistance of the sensor and compliance with the temperature table, make sure that the connection between the sensor and the control board is reliable. |

| 06 | Short circuit of the heating water temperature sensor circuit. Ring or replace the sensor. |

| 07 | Damage to the DHW temperature sensor. Check the dependence of resistance on temperature on the sensor, make sure that the sensor is connected to the control unit. |

| 08 | Short circuit of the DHW temperature sensor. Ring or replace the sensor. |

| 09 | Fan failure. Measure the resistance of the fan winding (reference value approx. 23 ohms). Make sure that there is 220 V voltage at the fan terminals. There may be a malfunction of the control board circuit (Navien board diagnostics is required) |

| 10 | Malfunction of the combustion products removal system |

| 13 | Short circuit of the CO flow sensor. Sticking of the sensor, or malfunction of the control unit. |

| 15 | Control board internal error (diagnosis and repair required) |

| 16 | Boiler overheating. Signal from the emergency thermostat. The causes of overheating may be insufficient circulation of the coolant (see error 02), clogging of the heat exchanger or a malfunction of the thermostat itself. Operation occurs at 98 degrees, shutdown of the accident when it cools down to 83 degrees. |

| 27 | Open or short circuit in the air pressure sensor circuit |

Differences between Navien Ace and Navien Delux

Navien Delux is a modified model that replaced Navien Ace. Navien Delux Coaxial is a series of boilers with two heat exchangers with a power of 10 to 30 kW with a closed combustion chamber and forced smoke extraction using a turbine. The manufacturer notes the following features of Navien Delux:

-

Frost protection system. Unlike boilers from other manufacturers, in addition to automatically turning on the burner when the temperature drops below 6 degrees, at temperatures below 10 degrees the boiler ensures continuous movement of the coolant by activating the circulation pump.

-

Variable speed fan. In Navien Delux boilers, a turbine is installed with an adjustable speed of rotation of the blades, depending on the readings of a special air pressure sensor. Thus, the optimal ratio of the gas-air mixture is ensured and the productivity of the boiler is increased.

-

The heat exchanger is made of stainless steel. Due to the use of a variable speed fan and increased combustion efficiency, it became possible to replace the copper heat exchanger with a stainless steel heat exchanger, which certainly has a significantly longer service life.

-

Also noted is the protection of boilers from the influence of mains voltage fluctuations by a special protective chip and the ability to operate at low (up to 4 mbar) pressure of main gas and water. In other words, the manufacturer tried to make a product that is maximally adapted to the worst operating conditions.

What are the advantages of Navien Ace boilers

Navien Ace is a double-circuit version of a wall-mounted boiler. It is equipped with an open combustion chamber with a natural release of combustion products. The instructions for their operation speak eloquently about the advantages of Navien boilers - they work even under conditions in which competitors' equipment fails.

…

Did you know? To increase the service life of Navien boilers, they are made of stainless steel, since stainless steel has a fairly high thermal conductivity.

Among the main advantages of Navien Ace boilers, it should be noted:

- universality;

- simplicity of control commands;

- compactness;

- high-quality anti-corrosion material was used in the production;

- fully electronic, Russified control system;

- compliance with high European standards (quality, comfort, safety);

- reliability and resistance to various conditions (voltage surges up to 30%);

- the ability to work in a frankly emergency situation (low pressure of gas and liquid heat carrier, low-quality gas, unstable pressure in the water supply system);

- economical fuel consumption;

- environmental friendliness (mostly carbon dioxide is emitted);

- acceptable price.

Important! In the event of power surges in the electrical network, the SMPS function is activated in the unit, and the boiler continues to operate smoothly.

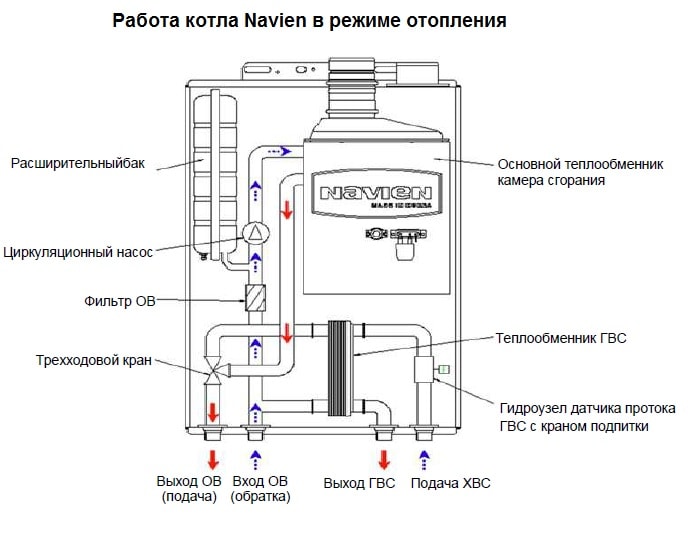

The principle of operation of the Navien boiler

The principles of operation of modern gas boilers are almost the same for all manufacturers, the differences are only in the configuration of the equipment and the internal arrangement of the actuators. The scheme of water movement in the boiler is shown in the figures. The Navien boiler works either to maintain the desired temperature in the CO, when the heated water from the first heat exchanger is pumped by the circulation pump in a large circle, or in the DHW preparation mode. The DHW mode is a priority, which means that if it is necessary to heat the water, a special three-way valve switches the circulation to the DHW plate heat exchanger, while the coolant flow through the heating circuit is blocked. The signal to switch the boiler to the DHW preparation mode comes from a flow sensor located on the hydraulic unit with a make-up tap.

The most common malfunctions and elimination of problems in the operation of the boiler

With its functionality and provision with electronics, there are certain disadvantages and malfunctions that can be encountered during the operation of the Navien Ace boiler.

Most often, users are faced with a problem when the unit stops working, and the electronics signal a critical error. This situation can be caused by various factors, including the sensitivity of the sensors. The most common mistakes:

Smoke removal. Fault code "10" indicates problems with the removal of combustion products. Possible causes: turbine malfunction, pressure sensor tubes are not connected correctly, the chimney is clogged, the nozzle is too long.

If none of these causes are identified, and the Navien Ace boiler continues to signal an error, then normal gusts of wind may be the cause. You can solve this problem by redoing the chimney. As a quick response option, you can open the boiler body and disconnect the air supply hose. However, this measure is temporary. For frequent errors on the Navien gas boiler, see this video:

Important! The manufacturer recommends installing boilers with the chimney exit on the leeward side.

- Flame sensor failure. Fault code "03" may indicate poor gas quality. The problem can only be solved by elimination. First of all, the cleanliness of the gas supply nozzles is checked. If they are in order, you need to choose the optimal position of the controller electrode (it must be in the hot phase of the flame).

- Equipment overheating. Fault code "01". A possible cause is a blockage in the heating system, a malfunction of the circulation pump, or a decrease in flow. Ways to solve the problem: check the system and filter for the presence of air, check the health of the pump and the resistance of the coil for a short circuit, check the impeller in the circulation pump.

- The Navien gas boiler is working, there is heating, but no hot water. Error code "02". There is a jump in water temperature on the remote control (it rises sharply to a maximum and instantly drops). Perhaps there is a blockage in the hot water system. The reasons may be: lack of pressure in the water supply system, airiness of the system, the circulation pump cannot gain momentum, the distribution valve is closed, or the flow controller does not work.To eliminate this malfunction, first of all, it is necessary to adjust the pressure, bleed the air in the system, check the resistance of the pump coil and the impeller for damage, open the boiler distribution valve, disassemble the regulator housing and clean the box.

In addition, when hot water is turned on, the Navien boiler may hum or make an incomprehensible noise. At the same time, there is no error information on the display and the pressure is normal. As a rule, this is due to clogging of the heat exchanger. To fix the problem, you can clean the heat exchanger or replace it.

Did you know? It is best to choose boilers that are equipped with smooth adjustment - this will allow you to change performance depending on the air temperature.

Navien Ace gas boilers are distinguished by high quality and reliability in operation. However, the duration and features of operation depend on how correctly you were able to install and configure the Navien Ace boiler, as well as on the quality of the fuel used.

Location of expansion tanks

By location in the system, several options for expansion tanks are distinguished.

- Built-in closed - all modern boiler models are already equipped with expansion tanks. Their volume directly depends on the dimensions and performance of the boiler. The greater the expected load on the tank, the larger the displacement of its expander.

- External open - usually used in conditions of natural gravitational circulation of fluid in the system. It is an open container installed at the top point. The fluid displaced from the pipes rises up along with the air, and goes back into the system under the influence of natural atmospheric pressure and gravitational force.

How to install

Installing an expansion tank is not particularly difficult, that is, it is not at all necessary to have any skills and craftsmanship. The installation process also does not take much time. Installation is easy and fast. But, nevertheless, you should follow the instructions, and carefully follow each step.

- First, turn off the heating system, that is, turn off the boiler. Then you should take the tank and use a conventional car pump to pump it with air. To do this, dismantle the special plug, which is located on the top of the device. This is the first stage of preparatory work.

- Then it is necessary to drain all the water from the heating mains. To do this, open the tap and wait until all the liquid has released the pipes and radiators.

- Now you can install the tank. In general, the tank can be mounted anywhere, but it is advisable to install it near the boiler on the pipe through which water enters the boiler. For installation use special tees. It is also recommended to use a check valve. It is needed in order to, if necessary, block the inlet of the coolant into the tank.

- Now open the tap and fill the system with coolant. Then turn on the boiler.

That's all! If the tank is installed in accordance with all points of the instructions, then it will function correctly.

When the temperature of the coolant rises, excess liquid will flow into the tank, and when the temperature returns to normal, the liquid will again return to the pipes.

If the tank is chosen incorrectly, then its capacity may not be enough for the amount of coolant that expands when heated. If this happens, then the pressure will increase, as a result of which the liquid is automatically discharged from the system, and the boiler will stop working. After turning off the boiler, it can be turned on again. If there are no residents in the house for a long time, and there is no one to turn on the system, then due to frost, it will simply cease to function. The boiler will have to be replaced.

Based on the foregoing, we can conclude that the expansion tank is one of the most important elements of any heating.

It plays the role of a kind of fuse, where part of the coolant will flow in case of its thermal expansion. If there is no such tank in the system, then with an increase in the temperature of the liquid, constant emergency shutdowns will occur.

So, in order for all heating to work in uninterrupted mode, and bring warmth and comfort to the house, the tank must be selected correctly, because it is the right expansion tank that contributes to the correct operation of the entire heating system.

Pros and cons

Closed expansion tanks have a number of advantages over open ones:

- Closed analogues do not have to be installed in the attic, it can be installed near the boiler itself. And open ones must be installed at the highest point of the system.

- In closed tanks, water does not have access to contact with air, which means that oxygen will not dissolve in water and interfere with the movement of the coolant.

- Most people have converted the attics of their homes into living quarters, so using enclosed tanks is a space saver as they can be installed anywhere.

The disadvantages of closed tanks are as follows:

- High price.

- It is required to pump air into the device from time to time.

Design and principle of operation

tank scheme

The pressure in the hermetic expansion tank of the closed type is created due to its design. It consists of two chambers separated by a rubber membrane. In one of the chambers there is a coolant, it is connected to a common circuit, and in the other, sealed - air. Its quantity is regulated depending on the characteristics of the heating system. For this, a nipple is provided in the air compartment, to which a conventional machine pump fits. There is no air-to-coolant connection. In order for the coolant from the circuit to enter the expansion tank for closed-type heating and vice versa, the pressure must be correctly adjusted. This is a prerequisite to compensate for the expansion of the liquid when heated. Increasing in volume, it acts with greater force on the walls of the pipes. Slowly, excess coolant is forced into the tank. After the temperature of the working fluid decreases and it decreases in volume, the air in the gas chamber will force it back into the circuit.

Calculating pressure in two ways

- design. At this stage, a decision is made about which rooms will be heated and which not, diagrams are drawn and the volume of the system in liters is calculated;

- boiler selection. Based on the volume of the system and the area of heated premises, a heater is selected. For 15 liters of coolant, one kilowatt of heater power is required;

- determination of the required volume of the expansion tank.

Now consider several different methods for calculating the pressure in the expansion tank of a sealed heating system.

Option number 1.

For this we need the following quantities:

- system volume (OS);

- tank volume (OB);

- the maximum allowable value of the pressure gauge scale for this system (DM);

- water expansion - 5%.

By the time you have to do the calculations, you already know how many liters the system holds. The required volume of the tank is calculated by dividing the capacity of the circuit in liters by ten. Although this is an approximate calculation, it is very working.

The volume of the tank in a closed system may be more than necessary, but less - in any way. An error will result in the replacement or installation of an additional one.

Air vent

Option number 2.

It's good that we live in a world of fierce competition. To ensure that the client is satisfied with the purchase and does not have any problems with operation, boiler manufacturers indicate in the product passport the required pressure of the heating expansion tank. If for some reason this cannot be found out, then this value can be calculated, knowing what the readings of the pressure gauge should be in the operating mode of the system.

The latter with one hundred percent probability can be found in the technical documentation or on the boiler. Then, 0.2-0.3 atmospheres should be subtracted from the working pressure. What is it for? If the pressure in the tank is greater than the operating pressure in the system, then the coolant will not be squeezed into the tank. He simply will not be able to do this as an even greater force acts on him from the side of the tank. And if there is not enough air in the tank, then there will be difficulties with the return of the coolant to the system.

Navien boiler error 03

In gas boilers, the presence of a flame on the burner is checked by a special sensor - an ionization electrode. The logic of the unit is to continuously check for the presence of a flame after opening the gas valve. Symptoms of the appearance of error 03 on Navien boilers can be divided into two groups:

-

unsuccessful ignition attempts (flame does not appear)

-

ignition occurs, but the flame goes out

In the case when ignition does not occur, you need to check:

-

gas pressure at the inlet and outlet of the gas valve (can only be carried out by a qualified specialist using special equipment - a differential pressure gauge)

-

the condition of the ignition electrodes (gap compliance with the manufacturer's standard, contamination of the electrodes). The norm of the distance between the electrodes is 3.5-4.5 mm.

-

the integrity of the insulation of the electrode power wire (visually, you can make sure that the spark breakdown occurs precisely on the body of the gas burner, and not anywhere else)

-

correct setting of the boiler power on the DIP switch (valid if there is a problem during the first start-up of the boiler or after replacing the electronic board)

-

presence of voltage on the ignition transformer

Error 03 on the Navien boiler it will also appear in case of unstable combustion (intermittent flame) or if the control unit cannot determine the presence of a flame. In this case, it is necessary to make sure that the connection of the ionization electrode to the control board is reliable, check the boiler grounding and the absence of contamination on the electrode. Instability of combustion can be caused by an increase in the fan speed, so you need to make sure that the yellow hose from the turbine to the APS sensor is securely connected and not damaged.

If during the checks it was not possible to normalize the operation of the boiler, it is likely that the boiler board will need to be diagnosed, repaired or replaced. We recommend watching a video in which one of the users imitates error 03 on the Navien boiler:

The most popular models of wall-mounted boilers Navien Ace

The most reliable Navien boilers, the operation of which can only be found positive reviews, are distinguished by an optimal price-quality ratio. They are divided into two categories:

- Ace ATMO. Traditional boiler with an open combustion chamber. Equipped with atmospheric removal of combustion products.

- Ace TURBO. An improved boiler equipped with a turbocharged burner and a special SMPS control system that regulates the process of gas combustion.

Important! Navien Ace gas boilers can operate both in automatic and manual modes, which allows you to more accurately set the parameters of the boiler and eliminate errors in operation as much as possible.

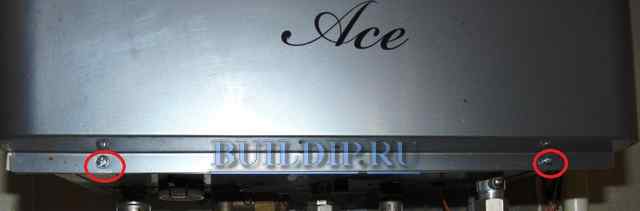

Changing the expander of the Navien boiler

Before you start repairing the Navien gas boiler, turn off all the taps. Water supply, taps for heating, gas tap. Be sure to disconnect the gas boiler from electricity.

To repair, the front cover must be removed. Using a Phillips screwdriver, unscrew the two screws on the bottom of the NAVIEN boiler.

Then remove the two latches on top.

Removing the front cover of the Navien gas boiler.

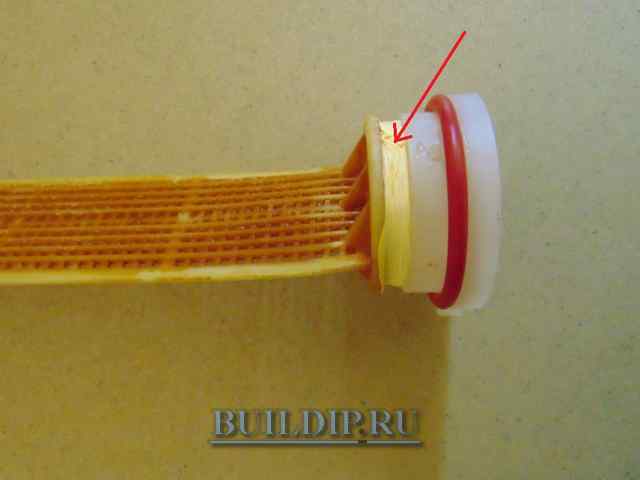

The front cover can be removed. Relieve pressure using the relief valve. Now drain the water from the expander. To do this, remove the drain plug and water filter from below.

Drain plug and boiler water filter.

To remove the plug, turn it counterclockwise half a turn and pull it down. Don't forget to put a container to drain the water. To remove the filter, pull out the metal bracket and pull the filter down. We are waiting for some time for all the water from the expansion tank to drain. This may take up to half an hour.

Unscrew the pressure gauge to make it easier to access the tank.

Boiler manometer.

Now disconnect the expansion tank from the system. To do this, remove the rubber hose located below.

We remove the expansion tank of the Navien wall-mounted gas boiler.

Use pliers to remove the clamp. Now unscrew the three screws that secure the expander to the case.

And carefully remove it.

Expander removed.

We take a new tank, first check the pressure in it, if necessary, pump it up with a car pump.

We check the integrity of the new expansion tank of the Navien boiler.

And set it in place.

New Navien gas boiler expander installed.

Now we connect a hose to it. If the new expansion tank of the wall-mounted boiler is the same, then you are in luck. And if the fitting is shifted to the side, then be sure to check if the hose is pinched. In our case, the old tank had a hole in the front, and the new one in the center. I had to shorten the hose by 1 centimeter in order to avoid bending.

Now you need to replace the filter and drain plug. We fill the system with water by opening the taps. Feed the boiler up to the required pressure using the valve at the bottom of the boiler. If water is leaking from the filter or drain, it is advisable to replace the rubber gaskets. If they are not at hand, then you can wind the FUM tape under them.

Filter seal.

Now we put on the lid and turn on the boiler. After a while, the air will automatically vent and the Navien wall-mounted gas boiler will work normally.