Types of water heating systems

Today, up to 90 percent of the “heated area” of private houses “belongs” to water heating systems. The rest of the territory uses stove, electric, air heating.

Water heating systems

- radiator;

- "warm floor" system;

- baseboard heating.

Water heating radiators are a familiar element of the interior of most houses and apartments. Their "family" is inhabited by: steel, cast iron, bimetallic and aluminum radiators.

Steel radiator in the heating system

The advantage of such devices is proudly excellent heat transfer, and the disadvantage is the increased "demanding" of such radiators to the quality and type of coolant.

Radiator water heating in a private house in a garage or in a country house “on the shoulder” can be done by a person who is more or less adapted to technical work and who wants to learn something new.

For information on what types of water heating radiators should be chosen for a private house, read the article: “Which heating radiators are better?”.

Water system "warm floor"

A water floor can be considered as an addition to a radiator heating system or as an alternative to it.

The advantages of such a system lie in a large heat transfer area - in fact, the entire floor can be conditionally called a large radiator, which also heats the air in the room correctly: the warm zone is below, and the top is cooler.

The location of the temperature zones in the room when using a "warm" floor

This allows you to reduce the operating temperature of the coolant, which for a warm water floor should not exceed 55 ° C, and set the heat output per square meter within the required limits by changing the step of laying the heating pipe. The main inconveniences of such a floor are the relative laboriousness of installation (creating a concrete screed, “nesting” of a pipe in a wooden floor) and the impossibility of making such a system with a completed repair - it is necessary either to raise the floor (more precisely, its level) or deepen. And what if the door frames and doors are already installed, and there is a concrete floor slab below or.

And now heating systems ... plinth!

What is it and what is it eaten with? An “exotic” baseboard heating system is a cross between a radiator heating system and underfloor heating, or rather similar to both.

Skirting heating systems

Heating equipment is installed along the perimeter of the room at the level of the plinth, which allows you to evenly warm up both the walls and the floor, and, accordingly, the air in the room.

Advantages - the absence of bulky radiators in the interior, and the color range of skirting systems allows you to choose them for any style of your home.

Plinth heating system in the interior of the house

Having considered the undeniable advantages and obvious disadvantages of various heating systems, you need to decide on the type of water heating system in your own home. As mentioned above, with completed work on doorways and floors, it may not be practical to make a warm floor, but installing radiators or using baseboard heating systems can be easy and convenient. Construction is in full swing - think about warm water floors as well.

Proper production of wood heating

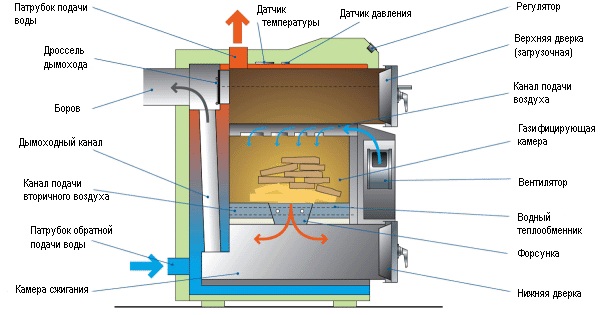

Modern wood fuel heating systems have significant differences from previously used schemes.

The choice of heating device depends on the availability of space for installation and the area of the building

When choosing a wood heating system, you need to pay attention to the following factors:

- Thermal power of the device. It depends on the area of the house, the degree of its thermal insulation and the climatic zone in which it is located.

- The need to allocate space for a boiler or furnace.The device for heating with wood fuel must be installed in a room specially designated for this purpose, which must meet certain requirements. In particular, have stable ventilation.

- Availability of storage space for fuel. Wood must not be stored in a room where a stove or boiler is located. They must be stored separately.

To determine the device that is best suited for heating with wood, you should take into account the parameters of the building and your financial capabilities. As practice shows, the most popular and effective option is to use a double-circuit boiler with a water circuit in a private house.

It will allow not only to warm the building with high quality, but also to always have hot water at hand. But in order to make the final choice in favor of one or another device for heating with wood, you should consider each of them in more detail.

Be sure to read: types of heating systems in a wooden house.

Advantages and disadvantages

There are many advantages to heating with wood. The main thing is their low cost. It is lower than the price of gas or electricity. Moreover, even woodworking waste can be used for this type of heating. Moreover, by no means all the settlements of our country are gasified. This is especially true for villages in rural areas. Heating with logs is also great for summer cottages.

An important factor when choosing heating with wood is the environmental friendliness of this fuel and the comfort that it allows you to feel. This is not only warmth, but also a visual pleasure from the sight of burning wood in a fireplace or in a stove equipped with a panoramic transparent screen, which is usually built into the fuel loading door.

Heating with wood also has disadvantages. The first is the lack of automation. After all, the fuel will have to be loaded into the furnace, boiler or fireplace with your own hands, and this takes a lot of time and effort. In this, heating with logs is significantly inferior to gas and electric heating systems. After all, they can be operated practically without human intervention.

In advance, you will need to take care of the availability of a supply of firewood. You can buy them or make your own. In addition, if the area of \u200b\u200bthe house is large, you will have to additionally use radiators, since it is unlikely that it will be possible to achieve good heating with just a fireplace or stove. Especially in winter. It is best to use a boiler with a water circuit.

Despite the fact that firewood is affordable for everyone, you will need to spend money on installing a stove, boiler or fireplace. And this “pleasure” cannot be called cheap. You will also have to mount all the additional equipment that will be required to heat your home with high quality.

Wood burning stove with water circuit

Recently, this type of heating has become increasingly popular in a country house. Its use will significantly save the use of hot water, as well as if you still decide to install the boiler at home with your own hands. he will be able to replace your gas for quite a long time.

It is quite simple to make a water heating system at home with your own hands for absolutely everyone

Does not matter. whether you have a huge private house or a small cottage, a water heating system will definitely suit you

After all, it is quite easy to find materials for it, and it will also not be difficult to figure out the circuit and mount all the necessary equipment.

If you do everything right, carry out the assembly with high quality, then according to all calculations, water boilers will work much more efficiently than gas boilers. Also, with its help, warm air will be distributed throughout the room most evenly.

Heating a house with electricity

Scheme of the device for electric heating of the house.

Heat in a house using electrical energy can be implemented using several options, so anyone can choose the one that suits him. And thanks to flexible prices, now everyone can afford such pleasure.

It is important that consumers who prefer this system have a wide choice of equipment and heating installations.

Electric heaters are of the following types:

- fireplaces;

- "warm floor" system;

- convectors;

- fan heaters;

- infrared heating.

Fan heaters and fireplaces are most often used as temporary or additional heating of a dwelling. And the "warm floor" system is used as a source with which you can get heat constantly. Moreover, this system is mounted not only in the base of the floor, but also in panel walls. And this makes it possible to evenly heat the house without the use of gas and firewood all winter. But such a system can only be installed at the stage of building a house.

Buy or DIY

As a result, your costs will be significant (search for materials, time, worries, damage in case of an unsuccessful experiment), and you will not be able to get sufficient heating. It is advisable to spend money once on solid equipment, and enjoy everyday comfort for many years.

The most expensive are modifications of long burning, all the same, the costs pay off handsomely. The myth that prices are too high can be easily dispelled by starting to use a modern unit in practice.

Do-it-yourself home-made wood-burning boilers and stoves will not give the high power and high user safety that factory products are capable of.

Disadvantages and risks in the operation of homemade boilers:

- short service life;

- the inability to ensure long-term combustion;

- low efficiency;

- overheating of the case (hence - burns with accidental touches).

How much do wood-burning boilers and wood-burning stoves with water heating cost? Focus on the order of prices in the region of 58-65 thousand rubles. at a power of 20-24 kW. The most positive reviews are addressed to such models as Protherm DLO 30, Dakon DOR F 24, Buderus Logano G221 and a number of others. Note that prices are always slightly higher.

One of the most important stages in the construction of a private house is the choice of heating. To create a heating system, first of all, you need to decide on a boiler. At the moment, a huge range of domestic and foreign manufacturers is presented on the market. Therefore, in order to buy a boiler that will best fit into your home, you need to correctly navigate the huge variety of products.

Since the price of heating is growing every year, people have seriously begun to think about the possibility of using alternative methods of heating.

Economical wood-burning boilers for heating a private house today have taken a leading position in the market for heating appliances, because such boilers produce a large amount of heat with minimal use of wood.

Wood is not the only fuel.

An economical long-burning boiler has many advantages:

- High level of efficiency;

- Complete independence of the boiler from external communications;

- Inexpensive fuel (when compared with gas);

- Possibility to choose fuel.

Assembly process

The process of creating a boiler includes several stages. In the manufacture of each element, it is worth considering the special operating conditions of the manufactured product.

Air supply device

We cut off a segment from a thick-walled pipe with a diameter of 100 mm, the length of which will be equal to the height of the furnace. Weld a bolt to the bottom. From the steel sheet we cut out a circle of the same diameter as the pipe or larger. We drill a hole in the circle, sufficient for the passage of a bolt welded to the pipe. We connect the circle and the air pipe by screwing the nut onto the bolt.

As a result, we will get an air supply pipe, the lower part of which can be closed with a freely moving metal circle. During operation, this will allow you to regulate the intensity of burning firewood and, consequently, the temperature in the room.

Using a grinder and a metal disc, we make vertical cuts in the pipe with a thickness of approximately 10 mm. Through them, air will flow into the combustion chamber.

Housing (furnace)

The case requires a cylinder with a sealed bottom with a diameter of 400 mm and a length of 1000 mm. The dimensions may be different, depending on the available free space, but sufficient for laying firewood. You can use a ready-made barrel or weld the bottom to a steel thick-walled cylinder.

Sometimes heating boilers are made from gas cylinders for a longer service life.

In the upper part of the body we form a hole for the removal of gases. Its diameter must be at least 100 mm. We weld a pipe to the hole through which exhaust gases will be removed.

The length of the pipe is selected depending on the design considerations.

We connect the case and the air supply device

In the bottom of the case, we cut a hole with a diameter equal to the diameter of the air supply pipe. We insert the pipe into the body so that the blower goes beyond the bottom.

The air supply pipe should end a few centimeters before the start of the chimney.

Heat dissipating disc

From a metal sheet with a thickness of 10 mm, we cut out a circle, the size of which is slightly smaller than the diameter of the body. We weld to it a handle made of reinforcement or steel wire.

This will greatly simplify the subsequent operation of the boiler.

convection hood

We make a cylinder from sheet steel or cut off a piece of pipe, the diameter of which is several centimeters larger than the outer diameter of the furnace (body). You can use a pipe with a diameter of 500 mm. We connect together the convection casing and the firebox.

This can be done using metal jumpers welded to the inner surface of the casing and the outer surface of the furnace, if the gap is large enough. With a smaller gap, you can weld the casing to the furnace around the entire perimeter.

From a steel sheet we cut out a circle of the same diameter as the firebox or a little more. We weld handles to it using electrodes, wire or other improvised means.

Considering that during the operation of the boiler, the handles can become very hot, it is worth providing special protection from a material with low thermal conductivity.

To ensure long burning, we weld the legs to the bottom. Their height must be sufficient to raise the wood-burning boiler at least 25 cm above the floor. To do this, you can use a different rental (channel, corner).

Congratulations, you have made a wood-burning boiler with your own hands. You can start heating your home. To do this, it is enough to load firewood and set it on fire by opening the lid and the heat-dissipating disk.

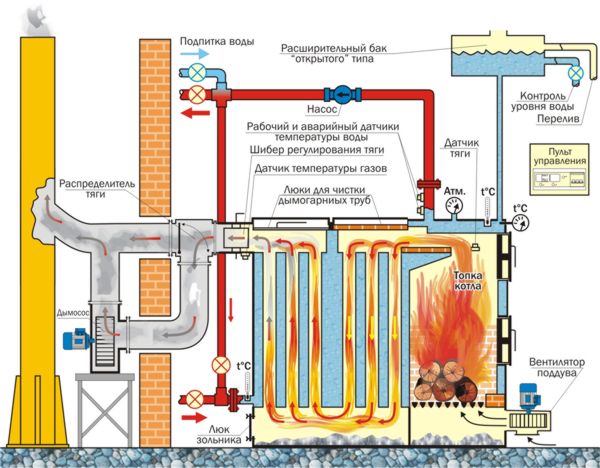

Rules for organizing a boiler room for wood-burning heat supply

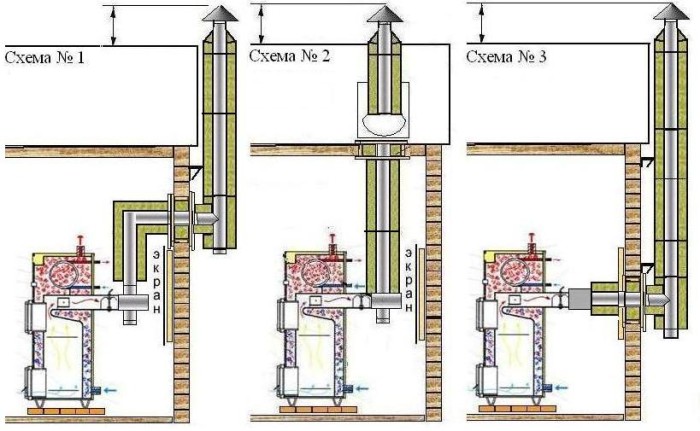

Scheme of a boiler room in a private house

The professional organization of wood-burning heating of a private house independently implies the arrangement of a boiler room. This should be a separate room in which the boiler and the means of regulating its operation are located.

If wood-fired heat supply to the cottage is done according to the gravity scheme, the boiler should be located at the lowest point in the system. There are no such requirements for forced heat supply.You should also prepare the room in which the heating equipment will be installed. It must meet the following requirements:

- Ceiling height - at least 2.5 m;

- Usable area - from 6 m². At the same time, its minimum volume should be 15 m³;

- Forced ventilation. The air exchange rate is three times the volume during the operation of a wood-burning boiler for heating the house;

- Chimney parameters. The minimum height is 4 m. The diameter depends on the connected boiler nozzle, but not less than 100 mm;

- For carrying out preventive and repair work, it is necessary to provide free access to all sides of the wood-burning heating boiler for a summer residence;

- Lighting should be combined - natural and artificial.

An important point is to ensure fire safety. For this, it is necessary to use only non-combustible materials for finishing the room. If electric elements are used in heating a private house with a wood-burning boiler, a power line should be provided. Installation of the ground loop is carried out only at the request of the manufacturer.

One of the problems in the operation of a wood heating stove is the likelihood of back draft. To minimize this effect, it is recommended to install a special design on the chimney.

Wood heating schemes at home

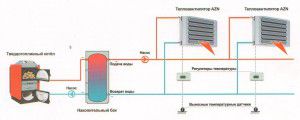

Boiler connection diagram with heat accumulator

The key point in the design of wood heating is the choice of scheme. It depends on it - whether a wood-burning heating boiler will be installed with your own hands or whether a stove or a fireplace will perform its functions. To determine the optimal option, it is necessary to take into account all possible factors.

First of all, the area of \u200b\u200bthe building and the number of rooms are taken into account. Most often, wood-burning heating stoves for summer cottages are installed if there are a maximum of two rooms. In this case, it is not necessary to make a water heating system.

Consider the main factors influencing the choice of type of heating:

- Water. It consists of a boiler (stove, fireplace) connected to the pipeline. The transfer of thermal energy occurs due to installed radiators. The best option for a house with an area of 80 m²;

- Furnace. Wood burning stoves are used to heat the air in the room. They are characterized by low efficiency, small heating area. However, their arrangement requires the least effort. The exception is fireclay brick constructions. This type is used to heat houses with an area of less than 60 m²;

- Fireplace. Analogue to furnace heat supply. The difference will be pumped in the size of the combustion chamber - it is much larger near the fireplace. In addition, heating a private house with a wood-burning boiler sometimes implies the presence of a hob in the design.

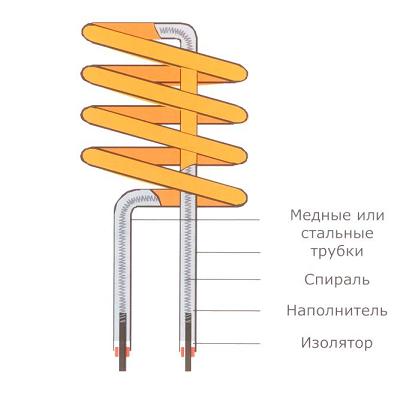

Heat exchanger in furnace

As you can see, the choice of option directly depends on the area of \u200b\u200bthe house. It should be borne in mind that the wood heating scheme can be upgraded. It is enough to install a heat exchanger in the furnace to make it possible to make a full-fledged water heat supply.

But the most common option is to install a wood-burning boiler for home heating. It is much more practical and easier to operate than a fireplace or stove.

For the normal operation of wood-burning heating of a country house, it is necessary to think over the chimney system in advance. The optimal diameter of the pipe and its height are taken into account.

Do-it-yourself water heating of a summer house

In order to highlight the entire list of nuances and the completeness of the problem, let's take the worst possible option - from the resources there is only water. Then the choice will definitely fall on a solid fuel boiler (if with your own hands, then a stove with hydropiping). How to make a hydropipe with your own hands - you will need steel pipes with a diameter of up to 1.75 inches, which must be welded to the firebox of a steel furnace.Bring the bottom of these tubes into one pipe and do the same from above, after which the system itself can be pulled to both ends. If we are dealing with a Russian stove, then the pipes can be placed inside the firebox in the form of a coil or under the stove for cooking.

Since there is no electricity, there is no need to talk about the circulation pump. The natural circulation is calculated as follows:

the entire path of the main pipe (from the end of the hydropipe to its beginning) must be compared with the distance between the points of connection to the main pipe system - in this case, a coefficient is obtained indicating the possible level of the pipe slope, measured in mm per meter of length (the slope from 1 to 5 mm per meter of pipe length).

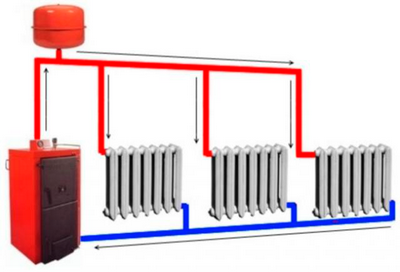

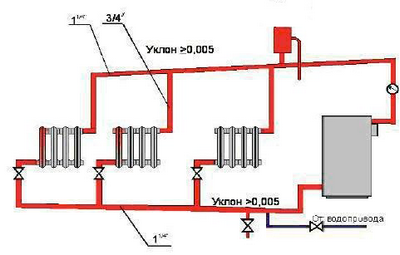

Scheme of water heating of a summer residence

In principle, the number of heating radiators can be any (in the sense that there is no clear regulation either on the number of batteries themselves or on the number of sections in them). An important condition for the inclusion of water heating radiators in the system is their level sequence and correct installation. The connection should be made in series at the level at which the main heating pipe runs, and the batteries are installed and attached to the walls according to two fundamental principles:

- all batteries of one heating system must be fixed at the same level (in some cases, like ours, a slight discrepancy is allowed, but only within 10-15 mm);

- each individual radiator should not have an ideal level along the upper edge, but hang on a bevel towards the Mayevsky tap at the same angle as the main pipe of the heating system.

In order for the natural circulation of the coolant in the system to work, and efficiently, it is necessary to introduce an expansion tank into the system, which will create pressure in the system and force the water to pass forward, and not to stagnate. The volume of the tank under standard conditions is considered sufficient at a ratio of 0.1 to the volume of the entire system. But with an increase in the number of heating radiators, the volume of the system increases and, accordingly, the volume of the expander increases.

In general, the required volume of the expander is calculated as:

- 0.5 liters for each section of the battery (cast iron or aluminum) or. if we talk about steel pipe registers, then 0.5 liters per meter of register pipe length;

- Naturally, you need to add at least 25-40% to this value, so that it is definitely enough.

The expansion tank, as the driving base of the natural circulation heating system, cuts into the supply pipe at the highest point - immediately behind the boiler. The upper part of the tank has an opening through which the atmosphere communicates with the coolant to remove air from the system and equalize the pressure and volume of the coolant at different times of the year. This prevents the possibility of airing the heating system in the country house, assembled with your own hands.

The main advantage of private housing construction is that complete independence from public communal goods can be achieved here. At the same time, they should still be, but much better than those that utilities can offer. The most important thing, probably, is that in your house the heating season can begin when the homeowner wishes and, accordingly, end when he wants it.

It is important, of course, and how it will pass

The heating system cannot be purchased from a store and installed at home. More precisely, of course, all its components in a store or on the market are just sold, but buying them in one set will not work. In order to make the heating system of a frequent house with your own hands, you first need to know:

- How will the house be heated?

- What is the appropriate energy carrier to use in the system.

Designing a heating system is one of the most important in the communications of a private house

After that, it will be necessary to carry out a lot of calculations to determine the number of heating radiators, as well as pipes. All this should correspond to each other in many ways.

In general, first you need to decide which boiler can heat the house.

ordinary boiler

First, let's look at how to make a simple wood-burning boiler with your own hands. The model consists of two cylinders placed inside each other. The first is used as a firebox. With a horizontal arrangement, it can be lined with refractory bricks from the inside.

The second acts as a convection carrier or is used to heat the coolant. Firewood is loaded directly into the firebox.

improvised materials

To reduce the amount of welding work, you can use a thick-walled pipe or barrel. It is also possible to use other improvised materials.

A rectangular firebox welded from a thick sheet can be easily placed inside a cylindrical container.

Design features

The wood-fired boiler is provided with a blower for the influx of fresh air and a chimney for exhaust gases. The blower is located at the bottom of the pipe and allows the bottom row of firewood to smolder, generating additional heat. Firewood is loaded into home-made boilers through the top. For this, a special hatch is being prepared.

In order for each pile of firewood to burn as long as possible, a special load is often provided, made in the form of a disk with blades and a hole having a diameter of 20 mm. When the load is pressed, the burning fuel is compressed. At the same time, the volume of incoming air is significantly reduced, since it can only pass through the existing opening.

Connection method

Such a boiler can be connected to the heating system in two ways:

- ramming pipes with water directly into the barrel. Circulating between the pipes, it will heat up, so that when it enters the heating system, it heats the radiators;

- cutting the chimney into the tank with the coolant. Exhaust hot gases will enter the tank, gradually heating the coolant.

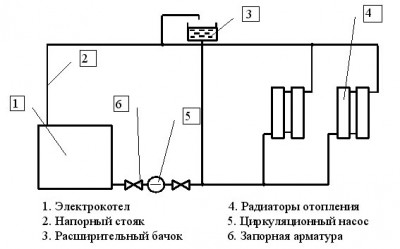

Use of electric boilers

Scheme of installing an electric boiler in the heating system.

In order to heat all housing with electricity, a boiler is installed that heats water to a certain temperature, and then it circulates through the heating system through a coolant. Many believe that the installation and use of such boilers is an uneconomical option for a private mansion.

In this case, gas, compared to electricity, is much more practical, but this is if there is access to the gas main. Although the installation of gas equipment and maintenance of gas boilers pay off for a very long time.

The main advantages of using electric boilers:

- convenience in the operation of equipment;

- fast heating of the house;

- temperature control;

- installation of equipment at any time of the year.

The principle of operation of an electric boiler is practically the same as a gas heating system. The difference lies in the fact that the heating of water occurs through heating elements, and not gas. At the same time, heat throughout the living space occurs in the same way as with gas heating, that is, in the pipeline using a coolant.