Material Properties

In addition, the material is durable, non-toxic, chemically inert, and thermally stable.

FUM tape is capable of operating at pressures up to 40 MPa (relevant for antler baths).

The temperature regime is minus 60 - plus 200 degrees.

When heated above 260 degrees, the destruction of the structure of the material begins, and volatile fluoride compounds are released.

Average characteristics of the material:

- thickness 0.04 - 0.2 mm;

- width - 10, 15, 20, 60 millimeters;

- fracture tension 40 – 60 kg/cm2;

- lubricant content 0.3 - 20%;

- 100% elongation before breaking.

Isn't it better to use tow

Tow began to be used by plumbers long before the advent of newer sealing materials. It is with this that the eternal question is connected: linen or fum tape, which is better? And although the first option has been tested by generations of installers, it has a significant disadvantage - you will need skills to work properly with tow. Fum materials do not need special skills.

Each fiber of flax must be separated and straightened. After laying, the threads cannot intersect. Yes, and the amount of tow must be correctly determined, both an excess and a lack of it will lead to the fact that the connection will begin to “tear”. And it’s worth remembering about the layer of sealant, which will have to be applied with a brush on top. In general, it is not for nothing that many have switched to fum!

Each fiber of flax must be separated and straightened. After laying, the threads cannot intersect. Yes, and the amount of tow must be correctly determined, both an excess and a lack of it will lead to the fact that the connection will begin to “tear”. And it’s worth remembering about the layer of sealant, which will have to be applied with a brush on top. In general, it is not for nothing that many have switched to fum!

If you still do not understand how to wind the fum tape, the video instruction will definitely help you figure this out. Happy installations!

Tape FUM1 is used to seal threaded connections. It is made of fluoroplast grade 4D - a synthetic material; a thin elastic white ribbon is obtained as a result of rolling a tourniquet. Most often it is used to seal pipe joints. In this article, we will look at how to wind the fum tape on the thread for a strong connection.

Also, read about alternative types of sealants: tangit-unilok and sanitary tow.

Characteristics of fum tape of three types

- They produce FUM tape in three types - depending on the place of its application. FUM grade 1 tape is a premium grade tape designed to seal threaded joints in systems with aggressive media, such as concentrated alkali or acid. This belt is lubricated with petroleum jelly to improve its performance.

- Grade 2 tape is typically used to seal piping systems that handle strong oxidizing agents such as oxygen and do not contain Vaseline protective lubricant.

- FUM 3 grade is used in general pipeline systems, but it can also be used in systems with potent agents. When using a tape of this brand, you should be aware that this type of tape is less reliable than the previous FUM grades 1 and 2.

To a large extent, the density of the connection depends on the correct winding of the FUM. And how to wind the fum tape on the thread correctly, avoiding leaks?

Correct winding of the fum tape on the thread

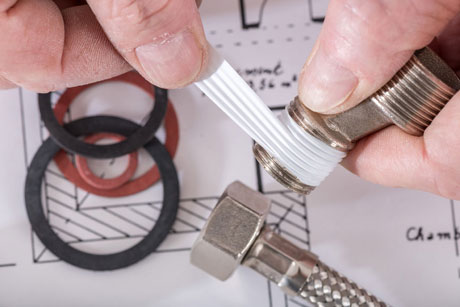

First, clean the threads of dirt and rust before winding the fum tape. Then all parts of the pipeline should be wiped with solvent or gasoline. FUM tape must be wound along the thread with gentle movements.

Each turn of the FUM tape should partially cover the previous one. In order to prevent wrinkles and wrinkles from forming on the tape, so that it is wound evenly, winding should be done with a slight interference.

It should not be forgotten that the more evenly the tape is wound, the more reliable the threaded connection will be. It is not necessary to move the tape roll away from the winding point too much - the best option is when it is close to the thread.

When the tape is wound, you can screw the butt piece to the junction. When screwing, it must go with a certain force - at this moment the FUM tape fills the thread. For clarity, watch the video:

Precautionary measures

- It is not recommended to wind the seal using two or more segments - this will violate the tightness and strength of the connection.

- The tape located on the thread should not be partially unwound, since when it is applied again, the connection will lose its reliability. In case of unsuccessful winding, the material should be removed completely and the process repeated.

- If too much stress is created when connecting the elements, which can lead to breakage, it will not work to loosen the tape. In this case, it is also necessary to reapply the sealant, removing the old segment.

FUM tape is a material with sufficient reliability when sealing threaded connections. Its correct use will ensure the tightness of any pipeline, even for a person who does not have much experience in plumbing work.

Fum tape winding sequence

For those who want to learn how to wind the fum tape correctly, there is a certain algorithm of actions, the implementation of which will ensure a reliable connection:

- First of all, you need to choose the desired width and thickness of the tape. For example, if the parts of the water supply system have significant wear, then the tape must be selected with a greater thickness, up to 0.2 mm.

- Next, it is necessary to thoroughly clean the joined parts so that there are no residues from previous tapes, tow, paint, rust residues, etc.

- Then you should carefully wind the tape on a part with a smaller diameter, that is, on the one that will be screwed in (or on which the second element of the threaded connection will be screwed).

- It is necessary to wind the tape strictly clockwise, since according to our standards, almost all threaded connections (in general, everything in plumbing) have a right-hand thread. This is done so that when the joining parts are twisted, the fum tape does not fold, but, as it were, continues to wind along with the part. Understanding how to wind the fum tape correctly is quite simple. If desired, this can be learned in 30 minutes.

Using these basic rules, you can easily understand how to properly wind fum tape with threaded water connections

It is worth paying special attention to the fact that the twisting force must be selected carefully. This is especially true for plumbing parts made of bronze and other soft metals and alloys.

The main thing - do not overtighten! The final result depends on how to wind the fum tape correctly. The main parameter here is the skill of the repairman, but for beginners, it is enough to simply tighten without much effort. After starting the water, it is necessary to check the connection and, if necessary, tighten. If the water is still leaking, and it is risky to pull it further, then it is necessary to turn off the water, unwind the connection and add a couple of turns of the tape.

Tow what is it and how to work with it

Before the advent of fum tape on the market, sanitary tow, which is a flax fiber, was used to seal threaded pipe joints. Optimum results were achieved by smearing the tow layer wound on the thread with a small amount of oil paint. Such a connection after a few years was difficult to disassemble.

Now sanitary flax in the form of long silky threads is used along with new sealing materials. Only now a layer of sealing paste is applied over the winding, which ensures a reliable and durable connection. The paste protects the flax from rotting and, if necessary, facilitates dismantling.

Flax fibers are long, thin, strong, tightly fit into the grooves of the thread and do not deform when screwing

How to wind tow on a thread

To prevent flax from slipping along the thread, notches are provided on it.

Impregnation of flax with a special paste, coupled with proper winding, is a guarantee that the connection will last a long time

For winding, a small strand of flax is separated. The length and thickness of the "strand" is determined visually depending on the diameter of the pipe. The winding is done as tightly as possible, the threads are guided along the thread, the free end of the tow is fixed with a finger, and after a couple of turns it is brought into the guide strand. The tightness of the connection is ensured by the optimal layer thickness. Calculating the density is quite difficult: you need experience, a certain “plumbing” eye.

Correct use

Knowing some of the features will help in creating an airtight connection (look at this page for a video of alternative heating of a private house with your own hands).

In turn, this will save you from the troubles associated with the occurrence of sudden leaks in the pipeline.

You must perform the following sequence of actions:

- the threaded connection is cleaned of debris and rust;

- parts included in the connection are degreased with gasoline or solvent;

- the material is wound on the external thread in a clockwise direction. Be sure to give the tape a slight tension, in which the PTFE fits snugly against the thread;

- the end of the tape is displayed in such a way as not to interfere with the wound element.

FUM tape is wound in several layers to create a tighter connection.

The number of turns depends on the diameter of the pipes (for plumbing in the apartment).

When using products with a diameter of 15 - 25 millimeters, three full turns of the seal will suffice. As the size increases, more layers of PTFE are wound.

To the touch, the FUM tape is slippery and can cause inconvenience during operation. The wound seal cannot be reused.

How to wind correctly and how many turns of FUM tape to make on the thread, see the video.

Tape FUM1 is used to seal threaded connections. It is made of fluoroplast grade 4D - a synthetic material; a thin elastic white ribbon is obtained as a result of rolling a tourniquet. Most often it is used to seal pipe joints. In this article, we will look at how to wind the fum tape on the thread for a strong connection.

Also, read about alternative types of sealants: tangit-unilok and sanitary tow.

Characteristics of fum tape of three types

- They produce FUM tape in three types - depending on the place of its application. FUM grade 1 tape is a premium grade tape designed to seal threaded joints in systems with aggressive media, such as concentrated alkali or acid. This belt is lubricated with petroleum jelly to improve its performance.

- Grade 2 tape is typically used to seal piping systems that handle strong oxidizing agents such as oxygen and do not contain Vaseline protective lubricant.

- FUM 3 grade is used in general pipeline systems, but it can also be used in systems with potent agents. When using a tape of this brand, you should be aware that this type of tape is less reliable than the previous FUM grades 1 and 2.

To a large extent, the density of the connection depends on the correct winding of the FUM. And how to wind the fum tape on the thread correctly, avoiding leaks?

Correct winding of the fum tape on the thread

First, clean the threads of dirt and rust before winding the fum tape. Then all parts of the pipeline should be wiped with solvent or gasoline. FUM tape must be wound along the thread with gentle movements.

Each turn of the FUM tape should partially cover the previous one. In order to prevent wrinkles and wrinkles from forming on the tape, so that it is wound evenly, winding should be done with a slight interference.

It should not be forgotten that the more evenly the tape is wound, the more reliable the threaded connection will be. It is not necessary to move the tape roll away from the winding point too much - the best option is when it is close to the thread.

When the tape is wound, you can screw the butt piece to the junction. When screwing, it must go with a certain force - at this moment the FUM tape fills the thread. For clarity, watch the video:

Things to remember

After the connection is tight, you should not unwind the tape back. If it was incorrectly applied, it is necessary to completely peel off the product and rewind it.

If it worked out tape tension too high

, it must be removed from the thread and wound a new layer.

Fum tape is an excellent material that is used to seal various joints. In order for the product to provide an excellent result, it is necessary to choose the right variety, as well as learn how to wind the tape in accordance with all requirements.

When performing installation work, it is often necessary to seal the joints

This is important when laying water or gas distribution systems. In the past, flax fibers were usually used for this purpose.

Now, fluoroplastic fum tape is increasingly used as a sealing and sealing material. Below we will consider the technical characteristics of the fum tape, indications for use, features of its proper use.

Despite the unfamiliar name, many of us know the fum tape very well, and most people actively use it in everyday life, calling it silicone tape. Let us consider in more detail what it is, where and when the fum tape is used and how to use it correctly.

In fact, this product is made from fluoroplastic (fluoroplast-4), which has excellent sealing and heat-resistant characteristics. The tape is produced in the form of white or transparent strips wound into rolls. The width of the tape is 1-1.6 cm. Some types of tape may additionally have a lubricant or an adhesive layer.

The scope of fum tape is quite diverse. With its help, they achieve sealing of almost any detachable connections: threaded, nipple, flanged. It is used in many engineering systems, the working pressure in which does not exceed 9.8 MPa. In everyday life, it is used for the installation of metal, plastic and metal-plastic plumbing systems, when connecting plumbing fixtures, installation. Fum tape also provides sealing of country irrigation systems.

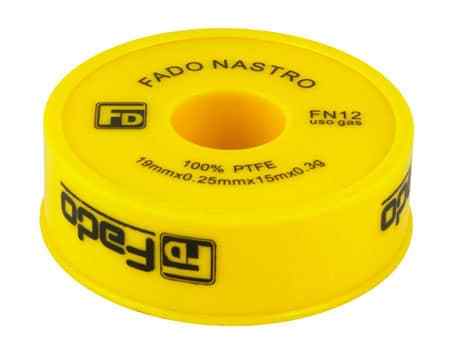

Fum plumbing tape has its own symbol, which reflects its brand, roll length, width and thickness. For example, a designation such as: "FUM 12m x 12mm x 0.1mm" can be deciphered as follows: "Tape 12 m long, 12 mm wide, 0.1 mm thick."

What is better linen or fum tape for water

A professional plumber always has on hand different types of seals:

- fum tape;

- flax and sanitary paste;

- threads (type "Tangit");

- anaerobic sealant.

Masters know that all seals, when properly installed, perform their task 100%.But for this you need to know how to use, what and under what circumstances to apply. The abundance of modern sealing materials has displaced flax from its leading position. But not all masters agree with this.

The fact is that in the past decades, flax was used in conjunction with red lead or oil paint. Today - with Unipak sealing sanitary paste. Its main task is to prevent drying and decay of flax. Connections made with these materials can be adjusted (shifted along the axis) by 45° without loss of tightness.

Flax Benefits:

- inexpensive price;

- suitable for sealing threads of any diameter;

- the connection will be of high quality regardless of whether the base surface was wet or dirty.

The disadvantage is that any connection made with flax subsequently requires twisting and tightening. Another “minus” of flax is that it is not very convenient to work with it: the fibers delaminate, cling to clothes and the tools and materials used.

If we compare flax and fum tape, then the latter loses in that it does not allow you to adjust the connections without losing tightness. That is, if you need to slightly turn an already tightened fitting, leaks may form in this place.

Comparison of PTFE and flax

Along with synthetics, sanitary flax fiber is still used (which is better than FUM tape or linen).

The material is produced from the waste of flax processing industries. Tow is used together with silicone sealant or oil paint to isolate threaded connections.

The use of natural material is a proven method that guarantees 100% tightness.

The refusal of plumbers from flax is associated with difficulties in use (how to install a tulip sink in the bathroom is written here).

In order to qualitatively seal the connection with sanitary flax, you must have certain skills.

This is not required by synthetic PTFE. It can be used without any preparation.

Before winding, the tow fibers are uniformly separated.

Then an adhesive-sealant is applied to the tow (which one is needed for polypropylene, read in this article).

Incorrect or insufficient application of flax will result in a poor connection and leakage.

Excess material leads to an excessively tight connection, excess material is cut off with metal coils.

This leads to an increase in voltage in the connected parts.

The result will be the complete or partial destruction of parts.

Determining the right amount of flax comes with experience.

Working with cast iron threaded fittings and steel products of large diameters does not require professional skills.

It is most effective to use FUM-tape for water when connecting metal-plastic or polymer pipes.

FUM tape will not provide guaranteed tightness when working with old metal pipes. In this case, tow with silicone sealant is used.

Anaerobic sealant gels santekhgel

Another modern material for sealing pipe threads is santekhgel. Reliable sealing occurs due to the polymeric component of the gel. After curing, santekhgel does not shrink or expand, is resistant to temperature changes (from -60 to +150) and pressure surges, has proven itself well in various environments: water, natural and liquefied gas, heating antifreeze.

How to seal a plumbing connection: flax, fum tape, anaerobic sealant - a specialist decides

Santehgel is produced in three types:

- In green tubes - facilitated dismantling.

- In blue - medium dismantling.

- In red (Stop Master Gel) - dismantling with heating.

Installation using santekhgel is simple: shake the tube and apply the gel in a thick layer around the entire circumference of the thread, distribute it evenly (with a brush, a special spatula), assemble the structure. Excess gel is removed with a cloth. Gel polymerization occurs in 15-20 minutes.

Tape fum what is it

Fluoroplastic sealing material, or fum tape for short, is a polytetrafluoroethylene film used to seal pipe joints. It is made by rolling a fluoroplastic bundle to the required thickness. The sealant is produced in the form of a tape of a certain size, wound on a reel (similar to electrical tape). Used in the installation of systems under pressure: water supply, gas supply, central heating. The material performs the function of a deformable filler and at the same time a thread lubricant, which improves the sealing of joints.

Types of fum tape:

- fum-1 - designed for sealing pipelines working with aggressive media. Contains lubricant - purified vaseline oil;

- fum-2 - used in systems in contact with strong oxidizing agents, therefore it is not impregnated with lubricant;

- fum-3 - used in systems working with clean media. Contains no lubricant.

The fum plumbing tape also differs in size: the thickness ranges from 0.075 to 0.25 mm; width starts from 10 mm; length from 1000 mm.

They produce a special gas fum tape of yellow color with a thickness of 0.15-0.25 mm. For gas pipes operating under low pressure, the use of ordinary plumbing tape is allowed.

Special gas fum tape is denser than ordinary plumbing

Technical characteristics and properties of the fum tape

Main properties of PTFE:

- Low coefficient of friction. Fluorine-containing plastic polymers (PTFE) have a very low coefficient of friction - they are slippery, which makes it easier to connect fittings. They act as a kind of gasket for pipe threads, improving fit and seal.

- Thermal resistance. PTFE has an extremely high melting point for plastic - 327 degrees. They are designed for use at temperatures up to 260 degrees (when heated above, toxic fluoride compounds are released). PTFE are excellent dielectrics (electrical insulators), which is an added bonus.

- plasticity and strength. Resistant to mechanical stress. They work at a constant pressure up to 10 MPa, withstand drops up to 41 MPa. The average service life is 13 years. Prolonged exposure to light slightly degrades the properties.

- Chemical and biological inertness. They are highly resistant to acids and alkalis. There is no solvent for PTFE yet. The polymers are, as it were, evenly sheathed with fluorine atoms, which makes the material inert with respect to almost all chemicals. Decomposition is possible only under extreme conditions created in special laboratories. Not subject to decay.

The malleability of PTFE allows plumbing tape to stretch and fit snugly around threads

What is better tow or fum tape

Each material has its own advantages and disadvantages. Plumbing linen is used for sealing steel pipe connections (especially rusty and / or large diameter).

Benefits of tow:

- the possibility of adjusting the connection: it is permissible to turn back by 45 degrees;

- reliable tightness: it absorbs moisture well;

- resistance to mechanical stress;

- easy dismantling of the connection.

The disadvantage is the tendency to rot / decay, since tow is a natural material.

It is preferable to use plumbing tape on pipes of small diameter, plastic pipes, in case of using thin-walled fittings. It is easier to work with fum tape, it takes less time to install.

To the question: “Which is better - fum tape or plumbing linen” there is no definite answer. It all depends on the specific plumbing work.For example, it is more convenient to connect a kitchen faucet with a flexible hose using fum tape, and it is better to seal the fitting on a water pipe with tow.

A better seal is achieved by winding a small amount of flax, followed by fixing with several turns of tape.

Fum tape winding technology

We offer step by step instructions:

- Thoroughly clean the surface of the thread on which the winding is to be performed. Remove traces of dirt, debris, and rust deposits.

- Wipe all elements with gasoline or thinner. Proceed to the next step after the surfaces are completely dry.

- The tape should be wound from the end of the thread, moving towards its beginning. The direction of movement is clockwise if the thread is right, for the left, on the contrary, you need to move against.

- When winding the tape, you need to keep it slightly taut. This will provide sufficient density, reliable sealing of threaded connections.

But do not overdo it with the tension of the tape, so as not to cause it to break.

The sealing material is applied in several layers. The number of turns depends on such factors as the diameter of the pipe, the condition of the thread, the quality of the fum tape itself.

For a pipe with a diameter of up to 20 mm, 3-4 turns will be enough, over 20 mm - up to 4-8 layers should be applied

.

It is not advisable to leave the end of the fum tape on the last turn of the thread; bring it out so that it does not interfere with the subsequent winding of the connecting element.