Tying a gas boiler in the heating system

After the installation of the wall-mounted gas boiler is completed and the heater is placed on the wall, the first step is to connect it to the heating system. Depending on which model is installed single-circuit or double-circuit, there are various strapping schemes. We will consider the connection process using the example of a wall-mounted double-circuit gas boiler.

As you know, a double-circuit boiler, in addition to heating, is capable of producing hot water for household needs. Structurally, this is realized by installing one bithermic or two separate heat exchangers. A double-circuit boiler does not produce very much hot water, but it is enough for 1-2 distribution points (for example, a kitchen faucet and a shower).

A modern hinged gas boiler is very compact and already contains within itself the main elements necessary for the operation of a forced circulation heating system, such as: a circulation pump, an expansion tank, a safety group. In the heating systems of small private country houses, this is more than enough, but if necessary, you can install an additional expansion tank or another pump.

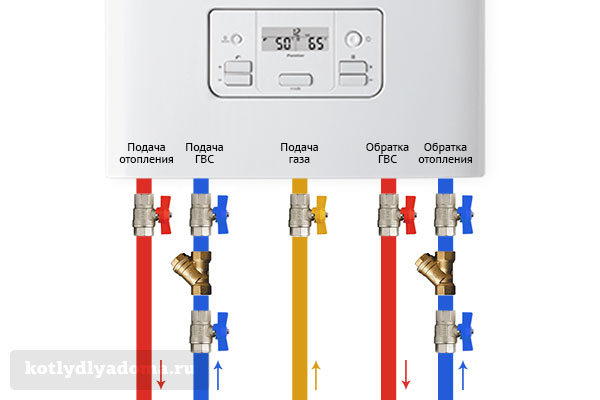

At the bottom of any mounted double-circuit boiler there are 5 nozzles. They are connected to: supply and return lines of the heating system, supply and return of hot water supply, main gas. The gas inlet is usually centrally located and colored yellow. All other lines can be arranged in any order, depending on the model of the gas boiler. Therefore, before starting the strapping, it is required to clarify the purpose of each of them in the instruction manual.

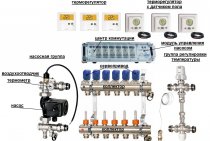

The piping of the wall-mounted gas boiler is carried out with polypropylene or metal pipes. The cross section of heating pipes is usually larger than DHW pipes 3/4 and 1/2 inches, respectively. The heating system is connected to the boiler through the American nuts. Ball valves are installed on each line, for the convenience of dismantling the gas boiler without draining the coolant and for isolating the boiler from the heating system, if necessary. To ensure tightness, all connections must be made using plumbing FUM tape or linen.

Coarse filters must be installed in the heating return line and in the DHW supply line. For the convenience of their washing and cleaning, they are also cut off with shutoff valves. Often, in order to increase the service life of the secondary heat exchanger of a double-circuit boiler, a magnetic fine filter is additionally installed at the DHW supply.

Adjustment of Buderus boilers

All heating units need regular balancing and adjustment of parameters. In most cases, a full range of such work is carried out during the maintenance of boilers. However, there are situations when unscheduled adjustment is required. For example, after an emergency stop, with a decrease in performance, with repeated errors generated by automation, or after a system upgrade.

The specialists of our center are ready to carry out both a one-time adjustment of your heating unit and take it for long-term maintenance. We are authorized to work with the entire Buderus model range, and our masters have all the necessary licenses and certificates.

Boiler adjustment includes such activities as: warming up; check the chimney and safety automation; control and debugging of the ventilation system, fuel supply and power supply. For all types of work we provide an official guarantee.

For more information on all types of services provided by our center, you can call the round-the-clock hotline or come to our office.

__________________________________________________________________________

Connecting the wall-mounted boiler to the mains

Most modern wall-mounted gas boilers are equipped with sophisticated automation. It controls many processes, turning the heating boiler into an autonomous mini-boiler room, the operation of which practically does not require the intervention of the owner. Obviously, the control unit and various sensors require an electrical connection.

Double-circuit wall-mounted boilers are available in two versions: with a familiar socket and with a cable for connecting directly to the machine. In any case, they must be powered from the mains through an individual machine. If you purchased a model with a plug, then an individual socket for a gas boiler should be located next to it, but in no case under it. This is one of the safety requirements so that in the event of a coolant leakage, a short circuit does not occur.

The gas boiler requires mandatory grounding. For these purposes, you can purchase a point grounding kit. It is installed in the basement or next to the house and occupies a small area of about 0.25 m².

Boiler automation is very sensitive to the quality of the supply voltage. With an insufficient level or imperfect shape of the sinusoid at the input, the devices quickly fail. To prevent frequent breakdowns and extend the life of the unit, it is required to connect voltage stabilizers for gas boilers. To avoid stopping the heating equipment in the event of power outages, you should additionally purchase an uninterruptible power supply.

Adatvdelmi belltsok

Határozza meg Ön a cookie-beállításokat.

Ezeket a beállításokat bármikor modosíthatja. Ez azonban azt eredményezheti, hogy egyes funkciók nem fognak rendelkezésére állni. A cookie-k törléséről böngészője súgójában talál tájékoztatást.

Tudjon meg tobbet az általunk használt cookie-król.

Icon forward-right

Módosítsa a cookie-beállításokat a csúszkával:

ic_switch

Required

ic_check

Increasing the convenience of work

ic_statistics

Statistical

ic_refresh

Targeting

123

This site may

- Necessary: Necessary: remembering your cookie settings

- Required: Required: session cookies

- Necessary: Necessary: remembering your cookie settings

- Required: Required: session cookies

- Necessary: Necessary: remembering your cookie settings

- Required: Required: session cookies

- Statistical: Statistical: optimize data quality for our statistical analysis

- Statistical: Statistical: anonymization of statistical data

- Necessary: Necessary: remembering your cookie settings

- Required: Required: session cookies

- Statistical: Statistical: optimize data quality for our statistical analysis

- Statistical: Statistical: anonymization of statistical data

- Targeting: Targeting: a selection of information and advertising based on your preferences or based on previously viewed content on our web pages. (Currently no targeting/corresponding cookies are not used).

Actions not allowed

- Statistical: Statistical: optimize data quality for our statistical analysis

- Statistical: Statistical: anonymization of statistical data

- Targeting: Targeting: a selection of information and advertising based on your preferences or based on previously viewed content on our web pages. (Currently no targeting/corresponding cookies are not used).

- Statistical: Statistical: optimize data quality for our statistical analysis

- Statistical: Statistical: anonymization of statistical data

- Targeting: Targeting: a selection of information and advertising based on your preferences or based on previously viewed content on our web pages. (Currently no targeting/corresponding cookies are not used).

This site may

- Necessary: Necessary: remembering your cookie settings

- Required: Required: session cookies

- Necessary: Necessary: remembering your cookie settings

- Required: Required: session cookies

- Necessary: Necessary: remembering your cookie settings

- Required: Required: session cookies

- Statistical: Statistical: optimize data quality for our statistical analysis

- Statistical: Statistical: anonymization of statistical data

- Necessary: Necessary: remembering your cookie settings

- Required: Required: session cookies

- Statistical: Statistical: optimize data quality for our statistical analysis

- Statistical: Statistical: anonymization of statistical data

- Targeting: Targeting: a selection of information and advertising based on your preferences or based on previously viewed content on our web pages. (Currently no targeting/corresponding cookies are not used).

Actions not allowed

- Statistical: Statistical: optimize data quality for our statistical analysis

- Statistical: Statistical: anonymization of statistical data

- Targeting: Targeting: a selection of information and advertising based on your preferences or based on previously viewed content on our web pages. (Currently no targeting/corresponding cookies are not used).

- Statistical: Statistical: optimize data quality for our statistical analysis

- Statistical: Statistical: anonymization of statistical data

- Targeting: Targeting: a selection of information and advertising based on your preferences or based on previously viewed content on our web pages. (Currently no targeting/corresponding cookies are not used).

Save and Close

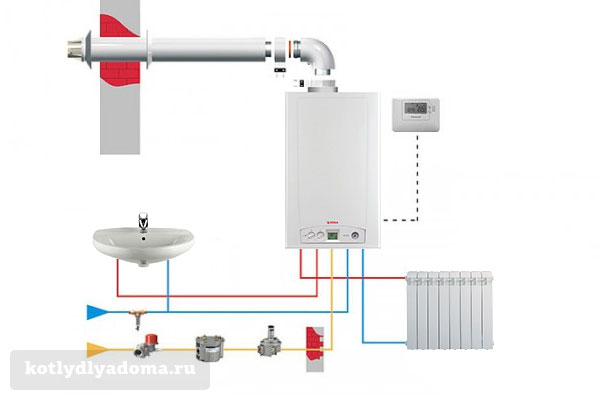

Choosing a chimney for a gas boiler

Any wall-mounted gas boiler needs a chimney. Depending on the model, this can be either a traditional chimney or a small horizontal chimney that can be led outside right through the wall of the house.

In double-circuit boilers with an open combustion chamber, the combustion process occurs with the help of air from the room in which the heater is installed. Typically, such models are installed in specially equipped boiler rooms. To remove combustion products, they are connected to traditional chimneys for gas boilers made of ceramic or stainless steel.

Wall-mounted boilers with a closed combustion chamber (turbocharged) use outside air in their work. It is fed into the device through one of the channels of the coaxial chimney. The second channel is used to vent flue gases into the atmosphere. The coaxial chimney is very easy to install and you can connect a gas boiler to it with your own hands.

The main stages of setting up Buderus boilers

-

Checking and adjusting automation.

This includes not only diagnostics of the operation of the control system, but also various sensors, including those for weather-dependent operation. -

Burner setting.

Our masters will not only carry out all the necessary work, but also check the correct selection of the burner for your type of boiler. With the help of special equipment, specialists will adjust the supply of air and fuel for optimal combustion. -

Hydraulic balancing.

Proper operation of the pressure transducers, pump, valves and accessories will ensure maximum efficiency and safety.

Commissioning of boilers by qualified specialists will ensure the correct and safe operation of the entire heating system.The complex of works includes pressure testing when the heat unit is delivered in separate sections; filling the heating system; tightness control; checking the location of the flue gas guide plates (not for all models); turning on the burner and control system; flue gas temperature control; checking the flue gas exhaust system; operation control in all modes.

Connecting a wall-mounted boiler Buderus

The peculiarity of wall-mounted boilers is that it is, as they say, a boiler room in miniature. Inside one housing are enclosed both the boiler itself and the DHW circuit, sometimes together with a small storage tank, and the circulation pump and, of course, the control automation. Sometimes an expansion tank of a small volume is also placed inside. Naturally, all these nodes are combined and connected to each other already at the factory. But nevertheless, the boiler itself still needs to be correctly and reliably connected to the gas, chimney and pipes of the heating and hot water circuits. All connection operations are described in the installation instructions, and theoretically can be performed independently if you have the necessary skill. But do not forget that during the initial connection and commissioning, you will still need to have an agreement with a certified installation company in your hands.

When replacing a wall-mounted boiler, which at first glance is quite simple, it is also worth remembering that the boiler is high-risk equipment, and its poor-quality connection can lead not only to failure, but also to much more unfortunate consequences.

Any questions on connecting gas boilers are best left to professionals. There is an unimaginable number of subtleties, which, by the way, are well known to our specialists both in theoretical and practical terms, and if you do not want to face unforeseen heating accidents, we recommend that you contact the Thermal Company for solving connection problems.

The efficiency and safety of the operation of a gas boiler largely depends on its proper connection to the heating system. This process, also called strapping, consists of several stages. Due to the fact that gas is a very dangerous fuel, some work must be carried out by certified gas service employees, but much can be done by yourself.

Connecting a wall-mounted gas boiler is a set of works that includes: piping in the heating system, connection to the gas and electrical networks, installation of the chimney. In this article we will try to talk about each of the stages.

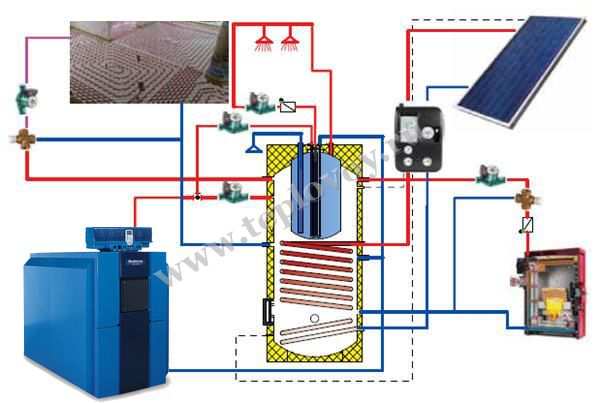

Buderus boiler connection diagrams

There are standard classic schemes illustrated in the installation instructions for Buderus boilers of a particular series. However, in practice, almost always, the schemes undergo changes to optimize the wiring, fit the geometry of the furnace room and the relative position of the individual nodes of the heating system.

The heating systems of country houses, although similar to each other, are only in general terms. In reality, how diverse are the areas and layouts of buildings, their heating systems are just as different. Departure from standard schemes can also be caused by:

- connection of the pool heating heat exchanger,

- placement of a volumetric buffer tank to which you plan to connect alternative heat sources: solar collectors, solid fuel boilers or a fireplace insert with a water circuit.

Complications of the circuit cannot be avoided when implementing the Buderus cascade boiler connection scheme, when the system is designed to use several gas boilers working together or alternately. A modern approach to the construction of such systems is the use of special units - hydraulic arrows, which ensure the equalization of temperatures and pressure of the coolant in several circuits connected to it.