Location selection

The construction of a fireplace begins with the choice of a place. In fact, it can be any place, because the hearth can be either built into the wall of the house or freestanding. It is not advisable to place the fireplace opposite the window, as with poorly insulated windows, drafts will constantly occur in the room. The ideal solution for a fireplace device is the corner between two walls or a place at the end of the room.

Construction materials

Before starting work on installing a fireplace, you should acquire the following building materials:

- Clay

- Crushed stone

- Brick

— Cement

- Sand

- rubble stone

Be sure to pay attention to the brick, as the life of the fireplace directly depends on this material. When choosing a brick, it is necessary to inspect it for chips and cracks.

Mortar for laying bricks is prepared from clay, sand and cement

Important! When using refractory bricks, the masonry mortar should be prepared using refractory clay

Work order

The fireplace is built on the foundation, which is laid out first. The foundation must be strong, as it has to hold a rather large weight - about 600 kilograms. The base of the fireplace in terms of area is always less than the foundation somewhere by 10-15 centimeters. In a one-story house, a foundation pit is dug under the foundation of a fireplace with a depth of 60 centimeters, in a two-story house - with a depth of 70-100 centimeters.

In no case should the foundation of the fireplace touch the foundation of the house. The minimum gap between them should be 5 centimeters, which must be filled with sand.

The construction of the fireplace is carried out according to previously created drawings. These documents indicate the exact dimensions of each element and the front brickwork. First, the bricks that form the corners are laid out, and the bricks that form the first row of the chimney

When laying, it is important to ensure that the brick is laid out inside the fireplace with a perfectly smooth side, since the quality of the fireplace will greatly depend on the smoothness indicator

Clay mortar cannot be used to level the internal surfaces of the hearth and chimney. Over time, it will begin to dry out from the fire, and all this will lead to littering of the fireplace and its chimney.

What is a closed fireplace with a built-in firebox with glass

A closed fireplace, unlike an open fireplace, is made on the basis of a metal firebox made of cast iron or high carbon steel, with a door made of transparent heat-resistant ceramics in a metal frame. By their design, closed fireboxes are a complex of advanced technologies, which is based on a combination of proven fireplace systems with the latest developments. This type of firebox involves the installation of a decorating external frame in a different style according to the interior. The frame is made of different materials, mostly heat-resistant. Despite the fact that a fireplace with a closed type of firebox looks like a traditional one, that is, we look at the fire and feel its warmth, it still differs from it in that: gives much more heat;

- significantly saves firewood consumption;

- it is possible to control the combustion process (“faster - slower”);

- safer to operate;

- more convenient and practical to maintain;

- more functional (application in open form is allowed).

Usually, closed-type furnaces of industrial production are used, which are a finished product with its own technical characteristics.

Characteristics of electric fireplaces

In order not to experience disappointment from the purchase, it is necessary not only to take into account the above criteria, but also pay attention to the following characteristics of the electric fireplace

Power

If the main purpose of the acquisition is space heating, then you should look at such a characteristic as power. It is determined by the dimensions and functionality of the device, as well as how productively it heats the room.

Installation method

According to the installation method, electric fireplaces are:

- Wall. There are semi-closed type - they are built into the wall.

- Corner. Devices are mounted in the corner of the room.

- Desktop. The most compact in terms of installation, type of equipment.

- Open. Installed in any desired location.

Decorative Features

Many owners of this device love to admire the flame. In most electric fireplaces, it is difficult to distinguish it from the real one. However, in more expensive models, the flame is more realistic. The most common and budget option is when coals are made from painted transparent plastic. In some models, strips of fabric are used to simulate a flame, which are driven by a built-in fan. In others, the fire is reproduced on a liquid crystal monitor. There are also 3D hearths, where the burning effect is created due to water vapor and the glow of halogen lamps. Models are available with sound effects that mimic the crackling of logs.

Additional features

These include:

- Backlight. Enhances the imitation of a real hearth.

- Shutdown timer. There is no need to monitor and is always near the fireplace, fearing for its possible malfunctions during operation. Now there is a function that turns off the device at a set time.

- Control from the remote control. To start or regulate the fireplace, it is not necessary to approach it.

- Imitation of the smell of smoke. The operation of some models equipped with special flavors is accompanied by the smell of smoldering logs.

In addition, models of electrical devices are equipped with elements for humidifying and purifying air, background lighting, thermostats, several heating power modes, brightness and flame height adjustment.

Types of fireplaces for the home

Today you can choose a fireplace of any design, they all differ not only in appearance and fuel used, but also in their functionality. Four main groups can be distinguished:

- open;

- cumulative;

- convection and fireplaces that have the function of heating water.

An open stove performs mainly only decorative functions. There is no way to control the combustion process, and its products enter the room. Most of the energy received is lost, that is, it will not work to establish an additional source of air heating in this case.

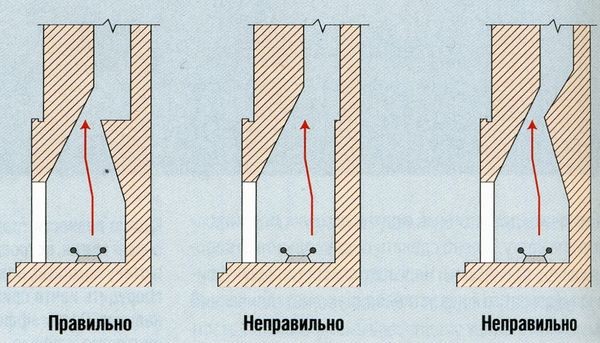

Schemes of the gas threshold of the fireplace.

Convection produces a large amount of heat, it allows you to quite effectively heat even a roomy room. Air enters the furnace through the lower part, where there is a special cartridge, and exits heated through the upper holes in the grate. Such a stove is used to warm the whole house with the help of special air channels that are bred in the thickness of the walls.

The cumulative fireplace is a combination of a long-term heating effect and the presented fire. Usually these are tiled stoves with short channels. Similar structures are made of fireclay bricks, the energy produced in the furnace is accumulated in a special cumulative mass, after which it is gradually released to the room. The flame is bright even when fully loaded with wood, the glass in the firebox remains clean for a long time, cleaning the firebox itself is not often required, the fuel burns out almost completely.

When asked how to choose a fireplace that could serve as a heating system, you need to pay attention to stoves with the possibility of heating water. Here, part of the energy that is generated during the combustion of fuel is transferred to a container with water, from where the coolant enters the general heating system

The heat itself in this case is transferred using a layered buffer tank or through a special plate heat exchanger.

What models should you pay attention to?

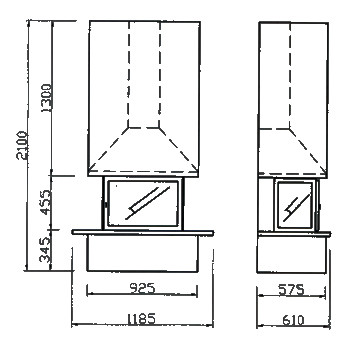

Drawing of a three-sided fireplace.

A stove for a home can differ in the type of radiation, here one-, two-, three-, four-sided designs stand out. The simplest design has only one heat radiating side. The heat transfer here is the largest, since there are three sides that reflect heat towards the fourth, that is, an open portal. This type is used most often. Bilateral fireplaces have a more interesting appearance, but they have a number of disadvantages, among which it should be noted: the volume of air that enters the room must be increased, it is necessary to organize a large protected area around the fireplace.

Three-sided fireplaces are distinguished by their original appearance, attractiveness, such models have low heat transfer, the fireplace needs excellent protection. The same can be noted about four-sided ovens, which are used only for decorative purposes.

Fireplace selection

The fireplace plays an important role in the living room, it keeps the house warm and cozy. In accordance with the style of the interior of the living room, you also need to choose a facing for the fireplace.

There are many different materials from which the lining of the fireplace is made. The most common materials are marble, stone and wood.

Without any doubt, we can say that the fireplace is the heart of the living room. Now in the construction market there is a huge variety of facings for the fireplace.

This gives us a great opportunity to turn the fireplace into a decorative element that will fit perfectly into the interior of the living room.

It is very important to choose the right fireplace cladding, since a fireplace from even the simplest and most inexpressive living room can create a very hospitable and cozy living room.

Customer preferences may differ in choosing a fireplace, however, fireplace mantels made in both traditional and modern styles will always create a warm and calm atmosphere in any living room.

With the help of a huge variety of additional accessories for facing the fireplace, there is a unique opportunity to create a beautiful composition that will fit perfectly into the interior of the living room. It can be all kinds of protective screens, mantelpieces, fireplace grates.

How best to install a fireplace in a wooden house

Installing a fireplace in a wooden house entails increased fire safety requirements, which require foresight, knowledge of the operation and operation of the fireplace system. The basis for the fireplace can be a separate foundation, or a concrete floor. The design of a separate foundation must be carried out not only for the installation of the leaning wall, but also for the body of the fireplace itself, and potentially for the chimney. In the event that, for various reasons, a separate foundation for a fireplace is undesirable, then it is possible to consider the option of making the foundation in the form of a monolithic platform of concrete supported by the strip foundation of the building. The fireplace cannot even be leaned directly against the wooden wall itself, although the design of the fireplace is designed for thermal insulation of the fireplace wall with a basalt heat insulator. It is necessary to additionally install a protective wall made of fireproof materials: gypsum or gas silicate blocks, bricks.

The shape and size of the leaning wall depend not only on the type of fireplace to be installed, but also on the chimney arrangement. The fireplace wall can be part and support of the chimney, which is made in the form of a brick shaft. But a light pipe assembled from elements called “thermos” or “sandwich” can be supported both on the supporting components of the ceiling and on the leaning wall.In the first case, measures should be taken to ensure the elasticity of the connection between the chimney and the fireplace insert, which can ensure its tightness in case of potential shrinkage of the walls and seasonal movements of wooden floors. Similar requirements should be provided for when performing the upper part of the arch of the fireplace and the place where it mates with the ceiling. Also, the ventilation grilles of the internal cavity of a closed fireplace should not be located closer than forty centimeters from the ceiling. When equipping a fireplace in a wooden house, you need to be especially attentive to the upper part of the fireplace vault, as well as the device for passing the chimney through a combustible ceiling. It is best to entrust the assembly of the fireplace to professionals with extensive installation experience. The master will conduct not only an audit of the building, but also draw up instructions, drawings and prepare a place for installation.

Types of electric fireplaces

The operation of an electric fireplace is based on the action of a tubular electric heater, which can be of an open or closed type. The design of this decorative and heating element of the interior is a hearth or firebox and a portal - that is, a frame. The last element of the fireplace can be metal, made of stone, ceramics, wood, plastic, etc. The firebox can be built-in - a cassette controlled by a remote control or replaceable. According to the location of the fireplaces are:

- Floor. Differ in the simplest design and mobility. They can be placed anywhere in the apartment and can be easily removed if necessary.

- Mounted. They differ in aesthetic appeal, but have low heat transfer.

According to mobility, fireplaces are divided into built-in or portable. The latter have a compact body and are equipped with a roller for movement. Built-in are placed against the wall and consist of a frame, an electrical unit that imitates logs and a flame.

There are also mini-fireplaces that can be placed on tables or built into pieces of furniture, as well as large-format appliances that are distinguished by their sophisticated look and large heating area. Choose the first option, which is optimal for owners of small premises, and the second for large houses and apartments.

How to build an outdoor fireplace with your own hands

A living room with a cozy burning fireplace can only be afforded by owners of country cottages or private houses built within the city. In modern high-rise buildings, installing a fireplace is a rather difficult task, and most often not at all feasible. However, if the desire to have a fireplace in the living room is very great, there is one fairly simple solution - you can create a high-quality imitation of such a piece of furniture. The process of making a false fireplace from drywall with your own hands is not as complicated as it might seem at first glance. Thanks to modern materials and strict adherence to instructions, even the most daring design decision can be realized.

Plasterboard for self-manufacturing of decorative fireplaces

A decorative plasterboard fireplace, made by hand, will become a worthy element of the living room interior design, complementing the room's decor with originality and giving it a classic nobility.

Drywall is the most common choice for decorative fireplaces due to its affordability, malleability, and ease of use. From it you can create the most incredible designs, without limiting the flight of fancy.

Preparation for work

First you need to decide where the decorative fireplace will be installed, make an example of a sketch and calculate the amount of material needed.

They have an artificial fireplace, as a rule, near the side wall of the room, but so that it does not clutter up the passage.

In the process of developing a sketch, it is necessary to think through everything to the smallest detail: details, dimensions and fastenings.If there are difficulties here, you can find DIY decorative plasterboard fireplace designs on the Internet. When choosing or drawing up drawings, you need to soberly assess your capabilities: will it be possible to complete the task on your own.

To make a fake fireplace yourself, you will need:

* profile;

* drywall;

* jigsaw;

* screwdriver;

* scissors for metal;

* materials for decor.

Making a frame for a decorative fireplace.

The work is divided into three main stages:

1. Profile marking according to the drawing.

2. Cutting drywall.

3. The connection of the resulting pieces into one design.

After making sure that there are no errors in the drawings, you can transfer the desired dimensions to the profile. Next, using a hacksaw or scissors for metal, cut the blanks.

If you plan to create an arch, then you need to make several transverse cuts on one side and bend it into any desired shape.

The elements are assembled into one frame using self-tapping screws and a screwdriver. To make the structure stable and not warp in the future, it is desirable to have transverse jumpers.

If the sketch turns out to be a heavy and bulky fireplace, or, conversely, too narrow, you should attach it to the walls and floor.

Sheathing and finishing the fireplace with drywall

Upon completion of the installation of the frame, you can form a draft version of the fireplace. To begin with, it is necessary to cut out the details from the material according to the sketch and try them on the fireplace, adjusting them, if necessary, to the desired dimensions. This can be done with a regular sharp knife.

Details are attached to the profile with black hardened self-tapping screws. Hats should be deepened a little, and then puttied. So the product will look more aesthetically pleasing.

After the structure is assembled, it is necessary to process all joints and fasteners. The corners should be reinforced using paint mesh. The surface of the hearth is desirable to level with putty.

Then only the design of the hearth will remain.

You can decorate the product using artificial stone, tiles or stucco, fireplaces with imitation of brickwork and the mirror surface of the back wall of the hearth look very advantageous.

How best to prepare a place for a fireplace in an already built house

A specialist will help to prepare the place for the fireplace correctly, who will not only arrive at the place where the fireplace is assembled, but also study the design features of the house, prepare all the necessary drawings and give the necessary recommendations for the implementation and preparation of work, as well as orient on the choice of the type of fireplace. And preparation for installation and the installation itself can be done on its own. To install a fireplace, you need a floor (base) on which the fireplace is installed, as well as a special wall against which the fireplace leans (with the exception of "central", special types of fireplaces) and a chimney of the desired and suitable location and size. You can make a comprehensive preparation of the site, highlighting a solid and large base, a chimney "with a margin" and a large wall, but it is best to prepare for a specific type of fireplace, taking into account its weight, geometry, characteristics of the firebox and the style of lining in the calculation.

If the floor in the room is strong, reliable and made of tiles (stone) over a concrete floor, then, most likely, no additional preparation is required. If in the room instead of stone, parquet or board was planned as a floor covering, then it is better to make the area in front of the fireplace from floor tiles, since the parquet in the pre-chimney zone will be damaged by coals, and over time it will dry out and form cracks. A fireplace, which is installed on a wooden floor, when wooden beams serve as a power base, poses a threat not so much by the magnitude and size of the additional load, but by the risk of cracks and leaks associated with the mutual relative mobility of the fireplace leaning wall and the floor. It is better to replace the wooden floor under the fireplace itself with a harder one, which guarantees a minimum displacement regarding the fireplace wall.

If a leaning wall is planned for the selected type of fireplace, then it must be made of a strong fireproof material: concrete, brick, etc.Accurate recommendations on its shape and design can only be made when the model of the fireplace is determined. So a successful preparation for classic portals can be considered a device in the wall of leaning a niche. A plastered wall made of brick, the width of which is greater than the height of the fireplace, is a universal preparation.

A correctly selected and well-made chimney is ninety percent of success in a good work of a fireplace without smoke.