Selection of pipes for the heating system

How to choose steel pipes for the heating system? When choosing, consider the following parameters:

- material used for the production of pipes;

- pipe manufacturing method;

- technical characteristics of pipes.

Selection of pipes depending on the material of manufacture

For the manufacture of steel pipes can be used:

- carbon steel (black);

- stainless steel.

Pipes made of carbon (black) steel (picture above) have the following advantages:

- low coefficient of expansion when exposed to high temperature of the passing liquid;

- non-susceptibility to mechanical influences;

- low cost.

The disadvantage of this type of material is a high level of susceptibility to corrosion. To minimize the formation of corrosive deposits, the pipes are galvanized.

Steel pipes with zinc coating

Stainless steel is less prone to corrosion than carbon steel. Stainless steel is also different:

- resistance to mechanical stress;

- low coefficient of expansion;

- aesthetic appearance, which avoids the need to cover pipes with various decorative elements.

However, the cost of stainless steel pipes is much higher.

Steel pipes made of stainless steel

Selection of pipes depending on the method of manufacture

Pipes for the heating system can be made by one of the following methods:

welding. Welded pipes can have a straight (straight-seam) or spiral (spiral-seam) seam. Straight-seam pipes have a significant drawback - a seam that can be damaged when exposed to temperature and high pressure. Therefore, the heating system with steel pipes is made mainly of spiral pipes;

Welded steel pipe with spiral seam

stretching (rolling). Pipes made in this way do not have a welded seam (seamless tubes), which significantly increases their technical characteristics (resistance to temperature and pressure). However, the cost of seamless pipes is higher than welded pipes, which limits their use (used to create heating systems in harsh climates or high pressure).

Rolled pipes

For the arrangement of heating systems for a private house or city apartment, both straight-seam and spiral-seam pipes can be used, since the pressure in the system does not exceed the design indicators of the pipes obtained after testing.

Selection of diameter and other technical characteristics

The main technical parameter when choosing steel pipes for the construction of a heating system is the diameter.

The diameter of the pipes depends on such indicators as:

- coolant temperature at the inlet to the system;

- coolant temperature at the outlet of the system;

- the amount of heat required to heat the room;

- the speed of movement of the coolant in the system.

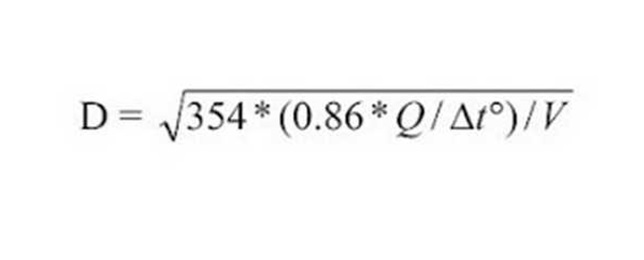

Given all the indicators for the calculation, you can use the mathematical formula:

Calculation of pipe diameter for a heating system

In the presented formula, the following parameters are indicated by letters:

- D - claim diameter;

- Q is the amount of heat (equipment power);

- ∆t° is the temperature difference at the inlet and outlet of the coolant;

- V is the speed of movement.

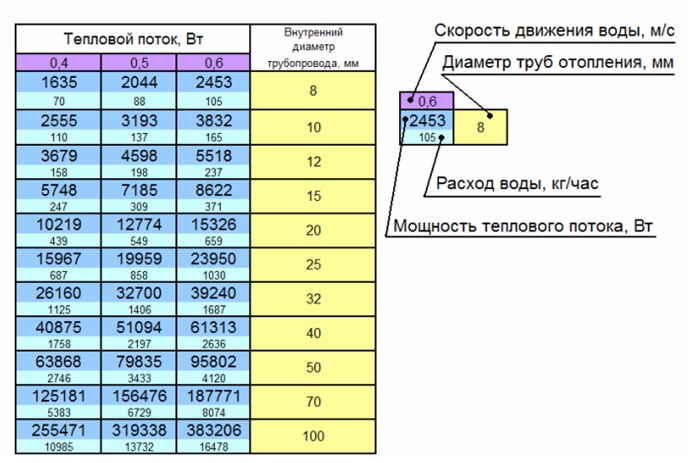

In order not to make complex mathematical calculations, you can use the tables that are developed by specialists based on the specified formula.

Table for determining the diameter

For example, to equip a heating system with a heating equipment power of 2.4 kW, pipes with a diameter of 8–10 mm are required.

If pipes of a smaller diameter are installed in the system, then the amount of heat will not be enough to heat the room.When installing pipes of a larger diameter, noise will occur when the coolant moves.

Selection Criteria

When determining which pipes are best used for heating an apartment or an individual house, they consider the following physical and operational parameters:

Corrosion resistance. Since water or antifreeze with its content flows in the heating circuits, the heating pipes must have a high corrosion resistance.

Strength. The standard pressure in the heating system does not exceed 2 atmospheres, the pipeline must easily withstand this pressure with a margin of 1.5 - 2 times.

Temperature characteristics. The temperature of the carrier in the heating circuit rarely exceeds 70 ° C; for warm floors, the limit value is about 50 ° C. It is clear that the pipeline must withstand temperature parameters with a margin in case of emergency situations - overheating of the coolant due to automation problems, boiler malfunctions.

Thermal conductivity. Heating pipes transport the coolant to the radiators or are themselves heat exchangers, transferring thermal energy to the floor screed

In the first case, their thermal conductivity does not play an important role, and its high degree is even undesirable. When working in underfloor heating circuits, on the contrary, high heat transfer is required, so the thermal conductivity of the pipeline should have the highest rate.

Rice. 2 Elongation of a 100 meter section of pipes when heated by 50 ° C

- Thermal expansion coefficient. It is well known that all materials expand to some extent when heated, this especially affects polymers. If pipes for heating systems are placed on walls or under a bulk screed, this feature of plastics must be taken into account and a material with the lowest linear coefficient should be selected.

- Difficulty of installation. To connect sections of pipelines, different methods are used depending on the materials of the pipes; most technologies require the use of a special expensive tool and skills in working with it.

There are also methods for connecting plastic pipes with removable compression fittings, where the main tool is a regular adjustable wrench. And a little-known novelty in plumbing - a push fitting, you can join two pieces of pipes made of cross-linked polyethylene within a couple of seconds with one click.

Dimensions

When laid, the underfloor heating circuit can be 100 meters or more in length, so it is important that the piping used is of the appropriate size to avoid unwanted joints under the screed. Chemical resistance

The heating pipeline is often placed in walls or screed, antifreezes are passed through it - ethylene glycol, propylene glycol. Therefore, one of the main requirements for the pipeline is resistance to aggressive chemicals.

Rice. 3 The main types of installation of transition fittings on pipes: pressing (for PEX-AL-PEX), PEX compression connection, pressing with a tension sleeve (for PEX), PP soldering, pressing thin-walled stainless steel

Durability. Heating pipes must withstand long-term operation (at least 50 years according to the state standard), while it should be borne in mind that for polymers, the service life to a high extent depends on the temperature parameters of the coolant and line pressure.

Hydraulic characteristics. The inner walls of pipes for heating in an apartment, individual buildings, must have low hydraulic resistance to water flow, that is, be perfectly smooth. This contributes to the high efficiency of the system, reduces operating costs (energy consumption of the circulation pump).

Breathability. The oxygen in the coolant is a strong oxidizer of metals, corrosion destroys heating elements, boiler parts and steel fittings in the system

Therefore, it is important that the pipe sheath does not allow air to pass through, this requirement is irrelevant for metals due to their high density and is important when using polymer pipelines in the heating circuit. Price

The main criterion that is immediately paid attention to when installing heating, it is precisely due to the lower price that plastic products are in the highest demand among the population

Varieties of steel pipes

The metallurgical industry produces only three types of steel pipe products.

Black steel. Pipe products of this type were widely used in the 70s - 90s of the last century in the creation of water supply and heat pipelines. Most often, an electric-welded VGP pipe was used for this purpose, the technical characteristics of which correspond to the requirements of GOST 3262-75.

Welded pipes are often used for the installation of heating mains, such pipes are straight and spiral-seam

Helpful information! Many household craftsmen, when choosing elements of a heating system, take into account, along with the service life of steel heating pipes, also the fact that they are easily welded, and thus facilitate the installation of the system. The main disadvantage of this type of rolled metal products is the susceptibility to corrosion upon contact with water.

For this reason, rust flakes appear in the coolant, and the pipes themselves become overgrown with deposits. The combination of these factors leads to a decrease in the throughput of the heating pipeline. That is why you can buy steel pipes today at a relatively low price, but you will have to change them quite often

The main disadvantage of this type of rolled metal products is their susceptibility to corrosion upon contact with water. For this reason, rust flakes appear in the coolant, and the pipes themselves become overgrown with deposits. The combination of these factors leads to a decrease in the throughput of the heating pipeline. That is why you can buy steel pipes today at a relatively low price, but you will have to change them quite often.

Galvanized steel. The zinc coating layer, as mentioned above, is designed to counteract the phenomenon of corrosion and increase the service life of black steel pipe products. Galvanizing does not completely cope with the task, but only slows down the corrosion of the base metal.

According to experts, galvanization is the most stable and durable material, the technical characteristics of which make it possible to create centralized heating with its unpredictable pressure surges and temperature schedule. In autonomous heating systems that allow operational control of operating parameters, cheaper pipes made of metal-plastic and polypropylene can be installed.

Galvanized elements of the heating pipeline have only two serious drawbacks:

- the weld breaks the zinc layer inside the pipe, creating a vulnerable spot for corrosion. This inevitably leads to a decrease in the service life of the heating system. And mounting on a thread will take a lot of time and effort.

- the cost of galvanized products is much higher than the price of heating pipes made of black steel, metal-plastic or plastic.

Pipes for heating should be chosen galvanized or stainless, they are resistant to corrosion and last longer than usual

Stainless steel. Theoretically, the use of seamless or welded stainless steel pipes makes risers, as well as eyeliners, almost eternal. But this solution is not popular due to the complexity of processing corrosion-resistant steels and their high cost.

Against this background, the use of a corrugated stainless steel pipe seems to be much more profitable.

- during installation, you can get by with a pair of gas wrenches and an inexpensive pipe cutter;

- recommended working pressure at +100˚С is. Such an indicator is not available to any plastic;

- pipes can take on any complex configuration and are easily bent by hand.

Note! If your family has small children, they will inevitably use the radiator leads as a crossbar or support, which will cause deformation of these elements of the heating pipeline. And stainless steel, in fact, like any metal, loses strength with repeated bending and may even break.

Criteria for choosing metal pipes for heating

When building a house and laying a heating system with your own hands, the main question arises - which metal pipes are better? As you know, the metals used for communications are classified as:

- black;

- color;

- alloys.

The first category includes rolled steel, galvanized iron and cast iron. Non-ferrous metals do not rust, but oxidize, these are:

- bronze;

- copper;

- aluminum, etc.

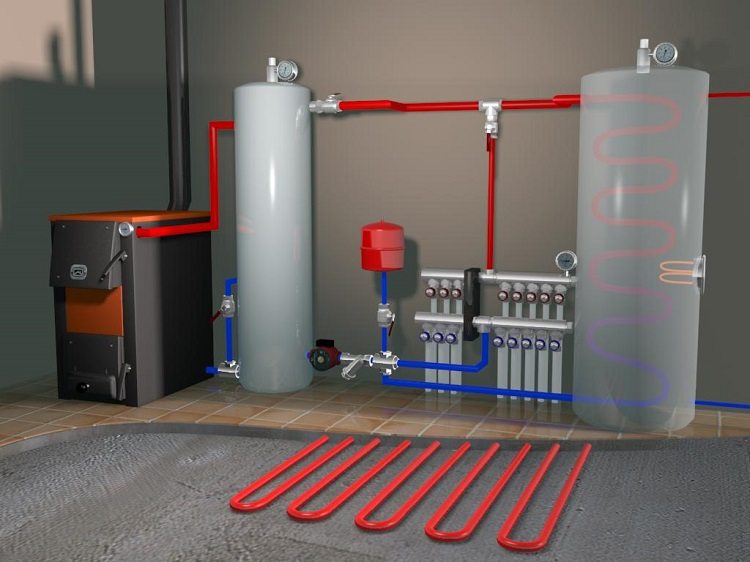

The type and layout of the heating system is one of the decisive factors when choosing pipes for the network

Main selection criteria:

- type of heating system (gravity or forced);

- maximum load (the conditions of the northern regions differ in the heating period of the southern latitudes);

- the possibility of replacing sections of the pipeline with the greatest load;

- installation method (hidden or closed, inside the walls);

- the general configuration of the system, including the number of storeys of a private house;

- design and maximum pressure inside;

- type of coolant;

- do-it-yourself transportation and installation possibilities;

- total length and budgetary framework for installation;

- maximum possible temperature in the system.

Longitudinal pipe welding methods

Pipe products manufactured by the method of bending a sheet (strip) of steel into a circle and connecting its joints are welded using several different technologies.

Furnace welding

The steel strip (strip) entering the rolling mill to be rounded is preheated in a tunnel furnace to a temperature of about 1300 °C. Approaching the rolling rollers, the side nozzles additionally heat the pipe edges with hot air to a temperature of about 1400 °C. Similar nozzles are installed in the area of the rolls of the forming mill and heat the edges of the strip to 1400 ° C before directly bending the sheet into a circle with the contact of the extreme edges.

After joining the edges, heated to a high temperature under pressure with rollers, a strong seam is formed, obtained by the method of mutual diffusion of molten metals. Next, the pipe is once again pulled through the furnace with forming rolls to give it the correct geometric shape. The technology refers to the types of steel processing by hot deformation.

Rice. 5 Scheme of furnace and electric arc welding in a flux environment

Electric welding

Electric welding is more often than other methods used when welding round pipes, it allows you to get a high-quality seam on thin walls. Tubular products used for pipelines of the oil and gas industry are manufactured using arc welding with flux. To carry out welding work in the forming rolling mill, a round tube shell is formed, if the diameter of the product is too large, the circle is assembled from two sheets, which are formed under a press until a semicircular shape is obtained.

Automatic electric welding is carried out simultaneously from both sides until a uniformly welded longitudinal seam is obtained, a wire is used as an electrode. After removing the giant, ultrasonic testing and hydrotesting, the pipe is ready for use.

Rice. 6 Electric welding in inert gases - principle

Electric welding in a shielding gas environment

The disadvantage of welding in air is the harmful effect of oxygen on the joint, as a result, air bubbles form in the seam strip, its chemical composition changes due to the carbidization of alloying elements, and scale appears on the surface.

To get rid of these harmful factors arising from the effect of environmental oxygen on the metal, allows the use of inert shielding gases in the field of welding: carbon dioxide, argon and helium. During operation, neutral gases, being heavier than air, displace it from the working area, excluding the contact of the molten weld pool with atmospheric oxygen. Refractory products made of tungsten are used as electrodes.

Welding in an inert gas environment is more often used to connect parts made of stainless or high-alloy steel, the seams are distinguished by material uniformity, the same thickness, high surface quality, and provide excellent tightness and joint strength.

Tubular products obtained by electric welding belong to the group of cold-formed ones.

Rice. 7 HDTV welding schemes

High frequency (induction) welding

The modern high-speed pressure welding method (by pressing the melted edges together with physical force), in which the edges of the workpiece are heated by high-frequency high-frequency currents until softened, is widely used in pipe production. The current density is maximum in the surface layer of the product and decreases sharply when immersed in the depth of the workpiece (surface effect), due to which only a thin layer of the outer shell with a depth of 0.1 - 0.15 mm is strongly heated.

The joined edges are heated by an inductor located in the immediate vicinity of their edges; it generates induction currents along the edges of the workpiece using two electrodes sliding along the tubular sheath.

In induction welding, the joined pipe edges of the workpiece have the shape of the letter Y, HDTV is brought to the edges by means of an inductor or a rotary roller so that it passes through the point of their convergence. The distance from the current-carrying contacts to the junction varies from 25 to 300 mm.

There are several technologies for induction welding, for the connection of pipe edges made of ferrous and non-ferrous metals, the technique of welding under pressure with flashing is more often used. The heating rate with this technology is 15·104 °C/s, precipitation is 2000 mm/s, the technology ensures high quality of the welding joint.

Rice. 8 Physical parameters of metals of heat-treated and hot-reduced straight-seam pipes of classes A and B (GOST 10705-80)

The principle of using and installing heating with steel pipes

The use of steel pipes is advisable when large diameters and mechanical strength are required. It is rather problematic to lay pipes due to the difficulty of giving them the required geometry. In addition, pipe insulation is recommended due to their significant thermal conductivity.

In the presence of a floor boiler with natural circulation, the use of "black" steel will be optimal. This raw material in the plumbing system is rapidly rusting. But, in an autonomous heating system, with long circulation of the coolant, rapid oxygen evaporation, the service life of black pipes can last about 50 years.

When using wall-mounted boilers equipped with a copper heat exchanger and forced circulation (pump), the use of steel pipes becomes impractical. This is due to the unaesthetic nature of such a system, corrosive clogging of the thinnest heat exchanger and installation high cost. Therefore, it is advisable to dismantle steel pipes with copper or plastic raw materials.

To assemble steel pipes, it is necessary to have a device for cutting pipes and threads, an adjustable and gas wrench, a hacksaw, welding, and an airtight tape to seal all joints. When buying non-galvanized pipes, they must be painted with asphalt varnish. In the presence of factory galvanization, it is not necessary to additionally process the pipes.Preferring open pipe laying, you need to take care of the mounting clamps. Attachment points can be located at a distance of:

- 2.5 meters if the inner diameter of labor is up to 20 millimeters;

- approximately 3 meters diameter value from 25 millimeters and above;

- 4 meters with an internal diametrical value of 40 millimeters.

For bending steel pipes, it is advisable to use a hydraulic pipe bender, which is a small-sized, convenient and easily transportable device that saves energy. If there is no such tool, then it is possible to purchase ready-made steel fittings of the required shape, which ensure the connection of straight sections in a pipeline bend. To date, the choice of fittings is a simple task, as manufacturers offer a sufficient range of them.

Which pipes to choose for the organization of the heating system

The choice of pipes for heating a private house is a responsible process, during which one should take into account the area of \u200b\u200bthe room, whether it is heated or not, what power the boiler has, etc. To create a high-quality system, it is better to use polypropylene pipes. They are inexpensive, have high tightness and are easy to install. Installation takes a little time, unlike calculations and preparatory work. In order for the system to work for a long time and not need preventive maintenance, it is better to choose reinforced pipes and stainless steel taps.

Metal-plastic pipes are a good, but more expensive option. For installation, it is enough to have a wrench. The main disadvantage of the products is the low service life of the connections. Such pipes should only be used for heated rooms. If the budget allows, it is better to purchase stainless steel pipes. They are more expensive, but will last at least 100 years.

Heating pipe diameter

Another important stage in the organization of the system is the choice of the diameter of the pipes for heating a private house. Products are presented in different diameters.

To choose the right one, you should study the system diagram and contact the specialists. The approximate diameter can be calculated independently, taking into account the area of \u200b\u200bthe room and the speed of the coolant.

There is a misconception that installing pipes with a large diameter is the key to the efficient operation of the system. In fact, due to massive pipes, the pressure in the system decreases or disappears. As a result, water is not able to get into all radiators. Pipes with a smaller diameter have a higher water flow rate. The optimum value is between 0.2 and 1.5 m/s. If the speed is too high, water seething is heard in the coolant.

To select a suitable diameter, a calculation of the thermal power is made. For example, for a room with ceilings up to 3 meters high, 100 watts of energy is needed for every square meter. For a room of 20 square meters, 2000 watts will be needed. If you add 20% of the stock, you get 2400 watts. Thermal power is provided by the presence of 1-2 radiators installed under the windows. According to the table, pipes with diameters of 8-10 mm are suitable for this room. These are approximate calculations, but they will help to calculate the budget when renovating a house.

Arrangement of heating is an important stage that is performed immediately after the construction of the house. It is worth taking a responsible approach to the choice of pipes, as they are the main elements of the system. They must be strong, durable, resistant to temperature and pressure surges. When choosing products, it is worth considering a lot of nuances. This is the area of \u200b\u200bthe room, whether it is heated or not, the way communications are laid. It is not worth saving on the organization of the heating system. High-quality materials will last up to 100 years, while maintaining performance. You should choose products from trusted manufacturers, since even the slightest violation of manufacturing technology significantly impairs performance.

Pros and cons of steel pipes

The technical characteristics of steel pipes for heating depend on the technological features of their production. Products can be welded or seamless. The former are sewn together from a metal sheet, while the latter are formed on sophisticated equipment.

The main advantages of a steel pipe for heating include:

- high thermal conductivity. This moment is very important for the organization of heating systems in residential buildings. The metal surface transfers heat to the air space of the room, thus partially fulfilling the function of a heating device;

- small thermal expansion. This property predetermines the absence of the need to use thick-walled products;

- high gas tightness. The value of this characteristic reaches, practically, one hundred percent mark. It is unrealistic to create a full-fledged closed heating circuit without fulfilling this condition;

- strength. Due to this property, high-pressure lines are created only on the basis of metal pipes;

- availability. The relatively low cost of steel plays an important role in creating budget options for heat supply.

There are many types of steel pipes, and each of them has its own advantages and disadvantages.

Among the shortcomings, experts highlight:

- susceptibility to corrosion. Metal poorly resists the effects of an aggressive environment and oxidative processes. But galvanizing steel pipes can increase their service life by 10 ... 15 years, that is, practically 2 times;

- big mass. Significant physical effort will be required to lay the pipeline;

- rigidity. It is possible to bend the pipe only by thermal action. When forming a line for connecting steel pipes, curly elements are required.

- electrical conductivity. This property of the metal is of particular importance when arranging a heating system based on an electric boiler.