Why is the well pump not turning off

From the scheme of operation of a borehole pump, the main reasons for its continuous operation become clear.

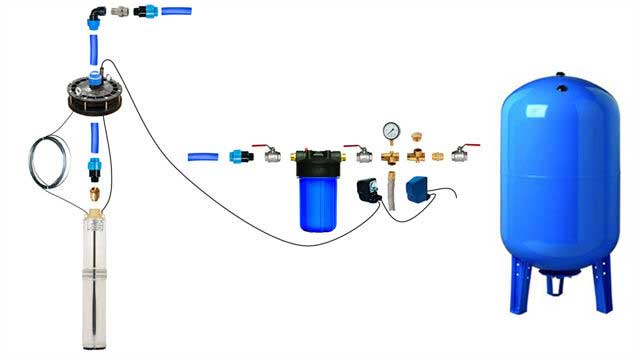

Fig.4 External view of the borehole water supply system

- Pressure switch. If there is excess pressure in the system, it is necessary that the relay turns off - its contacts must open, this may not happen if they are soldered to the contact group during the passage of high current, a malfunction of the mechanical parts of the relay itself. Repair can be done by replacing the faulty relay.

- blockages. The second reason is clogging of the plumbing system. In this case, the pump will be supplied with power through the pressure switch, and a small amount of water will not allow the dry-running protection relay to turn off the water pump from the power source, the repair will require cleaning the water supply.

- A leak. The reason for the decrease in pressure in the water supply, at which the pump does not turn off, is quite often a water leak. This can happen anywhere in the water supply system: at the joints of pipes, at numerous joints after soldering, in a hydraulic tank.

- Voltage fluctuations in the network. Voltage instability quite often leads to malfunctions in the operation of the power supply system, disrupting the work cycle: the pump does not turn on or off.

- Hydraulic tank. When the special valve of the hydraulic tank, designed to bleed air from the system, is depressurized, there will be a constant air leak. This gives a pressure that is unstable, the pump will turn off or work continuously for a long time. Air leakage can also occur in the tank itself due to depressurization of the welds of other or places in its body, in the nipple air pumping device (repair with welding may be required). Sometimes the membrane inside the expansion tank bursts, water fills the entire volume of the tank and the pumping system starts to operate in a pulsed mode.

There are quite a few reasons why the pumps do not turn off and in most cases they can be established using the data of the built-in pressure gauge. If the pressure in the system gives the norm, and the deep pump does not turn off, it is highly likely that the pressure switch will need to be repaired: the cause should be sought in the settings or a breakdown of its mechanical part. With a constantly reduced pressure, water leakage or system clogging is possible; in the event of water pressure drops for the pump with its periodic shutdown or a long time of continuous operation, the malfunction should be sought in the accumulator.

We advise you to read: Water level sensors for pump control

Share with friends:

You might also be interested in reading:

Using the site

oBurenie.ru you automatically agree with

privacy policy

to use any available means of communication such as: comments, chat, feedback form, etc.

1 Prevention and repair of borehole pumps

In order to avoid the risk of being left without water, timely prevention of pumping equipment is needed. It is necessary to carry out preventive inspection of pumps for wells twice a year, which will ensure timely detection of faults and reliable protection against pollution. Scheduled repair of a borehole pump is carried out depending on the characteristics of the operation of the equipment, the characteristics of the terrain and the water supply zone.

With careful monitoring of the cleanliness and general condition of the well, the life of pumping equipment will increase significantly.

It would be more correct if preventive measures are taken at the first sign of contamination: a silty or sandy sediment appeared on the bottom of the dishes, the water pressure decreased; cloudy or blackened water; there was an unpleasant smell.

When using a well, organic matter periodically accumulates in the water. When organic matter decomposes, water may turn black and an unpleasant aftertaste may appear, which is caused by the reaction of hydrogen sulfide release. In this case, periodic cleaning and disinfection of the well will help. Prolonged terms lead to the likelihood that cleaning the well with your own hands will not work and you will have to turn to experienced craftsmen.

Defective and new well pumps

Malfunctions of protective systems of pumps

Usually, a properly assembled water supply system and quality pumps have devices that prevent them from idling.

In the event of a malfunction of such protective devices: a dry-running relay for a well and float switches for drainage, a well or fecal pump, the devices can work in the absence of water.

Sometimes the float switch of well or drainage pumps, due to improper installation, does not lower along with a drop in the water level (it falls on a hillock or clings to a protruding object) - this leads to the operation of the electric pump in idling mode and its further failure.

Vibrating pumps, which usually do not have external protective devices connected in the system, working for a long time without water after a drop in its level, can fail if there is no built-in thermal protection.

The pump is out of order

The biggest trouble that can happen with an electric pump is the burnout of the winding, while the device usually cannot be repaired (rewinding the winding with your own hands is difficult, and in a workshop, the cost of work and materials will not be comparable to the price of an electric pump).

With this malfunction, the electric pump will hum, but it will not be able to pump water.

Sometimes the impeller of borehole and well pumps may break, the check valve system (they will not let water through) and the piston ring of vibration models may fail.

Violation of the rules for the operation of submersible pumps, errors in the installation of the plumbing system, a sharp increase in water intake and a decrease in the flow rate of a well or well can lead to a hum of a working electric pump, in which water will not flow to the consumer. In most cases, you can repair electric pumps with your own hands, if you remove the device to the surface to accurately determine the problem area.

The use of various pumps for the organization of water supply of country houses in recent years has become increasingly in demand. However, along with convenience, such equipment brings a lot of trouble. Great difficulties, especially for beginners, are its configuration. Yes, and in the process of work, failures and breakdowns often occur, so it is necessary to have at least the slightest idea about the design of pumps and how to eliminate basic malfunctions. In this article, we will consider how, by one or another sign, to identify the problem and repair the pumping station with our own hands.

As you know, used in household stations (membrane tank) in combination with on-off automatics plays the role of a buffer, as well as a pump control unit. At the moment of switching on, the hydraulic tank takes on the excess load. When a certain pressure level is reached, as the membrane fills, the pump turns off. Gradually, with the flow of water, the pressure in the system begins to decrease, which is fixed by the automation that turns on the pump.

As a rule, at pumping stations, the pressure range is regulated in which the pump is turned on and off. The minimum range can adversely affect the operation of the pump because it will turn on too often.

What should I do if the station stops working after the warranty period has expired? How to find the cause of the malfunction of the pumping station and fix it yourself? Here are the main recommendations on which you can easily repair a pumping station manufactured by Gileks, Marina, Whirlwind, Gardena (GARDENA), Belamos (BELAMOS), ELITECH, Caliber, Karcher (KARCHER), Hammer (HAMMER), DENZEL, ALCO (AL-KO ), Host, Bison, METABO and a number of other manufacturers. The principle of operation of the equipment is the same in all cases. The differences are only in the design features of some elements.

Station malfunctions can be very different:

- The engine is running but there is no water.

- The station often turns on, the water pressure jumps.

- The pump pumps regularly, but the water supply is intermittent.

- The pumping station does not turn off.

- The pump does not turn on at all.

- The motor hums but does not turn.

In some cases, you can fix the problem on your own without the involvement of specialists.

A number of other reasons

There are several more reasons why the pump stops pumping water from the well:

A significant decrease in the water level in the well. The main reason for this phenomenon is improper drilling. Often the water level drops in the summer, during dry periods. To prevent such situations, it is necessary to contact only proven well drilling companies, as well as use the dry running protection system. It will not be superfluous to clean the well with the help of special tools.

A centrifugal pump can pump out water faster than the well can refill. It is necessary to choose the right pump based on your personal needs. At the same time, it is better to buy a device with a power slightly higher than necessary, because guests may arrive, or you will need to water the garden with plenty of water. Do not forget to save it as reasonable as possible - do not open all the taps in the house at once and do not pour water in vain.

Weak pressure. Another problem that arises if you choose the wrong pump. For example, the depth of the well is about 50 meters. And the device is designed for a shaft length of about 30 meters. Of course, he will not be able to raise water to the surface with the necessary pressure.

Power outages can adversely affect the operation of all appliances, including the water pump. In this case, it is recommended to buy a voltage stabilizer, or connect the pump to the generator.

Disconnection of the pipeline. With this option, you can hear the "gurgling" of water. You need to check the water supply system and fix the problem.

Clogged pipes or system filters. Often occurs during the first, trial run of the pump and water well. At this time, sand or clay particles may enter the hoses or pipes. The main reason is incorrect or insufficiently high-quality assembly of the system

It is important to observe accuracy and accuracy during installation. To eliminate this problem, the pump can be washed in a container of water, after disconnecting the pipeline and check valve.

If the sound of a running engine is clearly audible and all possible causes of problems have been checked, but there is still no water in the house, we recommend that you pull out the pump and take it to a repair center.

The consequences of flooding are eliminated with the help of special equipment called drainage pumps. In everyday life, such devices are no less necessary. This is understood by the owners of personal plots with artificial reservoirs.

With the help of pumps, liquid with foreign inclusions is pumped

It doesn't matter if it's clay lumps or solid particles, the equipment will handle it. Well, if this device is in the country

Some types of repair work

Some do-it-yourself pumping station repair steps are intuitive. For example, it is not difficult to clean a check valve or filter, but it can be difficult to replace a membrane or a pear in a hydraulic accumulator without preparation.

Replacing the "pear" of the accumulator

The first sign that the membrane is damaged is the frequent and short-term switching on of the pumping station, and the water is supplied in fits and starts: sometimes strong pressure, sometimes weak. To make sure that the diaphragm is the problem, remove the plug on the nipple. If not air comes out of it, but water, then the membrane has torn.

To start the repair, disconnect the system from the power supply, relieve pressure - open the taps and wait for the water to drain. After that, it can be turned off.

- Loosen the flange at the bottom of the tank. We are waiting for the water to drain.

- We unscrew all the bolts, remove the flange.

- If the tank is from 100 liters or more, unscrew the membrane holder nut at the top of the tank.

- We take out the membrane through the hole in the bottom of the container.

- We wash the tank - it usually has a lot of rusty sediment.

- The new membrane must be exactly the same as the damaged one. We insert a fitting into it, with which the upper part is attached to the body (we twist it).

- We install the membrane in the accumulator tank.

- If there is, install the membrane holder nut at the top. With a large tank size, you can’t reach it with your hand. You can tie the holder to the rope and so install the part in place by screwing the nut.

- We tighten the neck and press it with a flange, install the bolts, successively twisting them several turns.

- We connect to the system and check the work.

Replacement of the pumping station membrane is completed. It's a simple matter, but you need to know the nuances.

Continuous water supply to the house depends on the stability of the hydraulic equipment. Failure can have various causes, both structural and operational. Many of them can be eliminated on their own, therefore, when the pumping station does not pump water, it is worthwhile to carry out timely diagnostics of the main components.

The principle of operation and the device of the station

Each water station, regardless of the pump used (submersible or surface), consists of a certain number of working units, which allows you to pump water with high quality

Each water station, regardless of the pump used (submersible or surface), consists of a certain number of working units, which allows you to pump water with high quality. It is necessary to know them in order to quickly identify the possible causes of equipment malfunction and understand why the automation does not turn off.

So, the pumping station consists of:

- The pump of the selected model. which pumps fluid from a source.

- Hydraulic accumulator. which provides both a supply of water in the required volume and its transportation through pipes under constant pressure.

- Pressure switch. This part controls the pressure levels in the system when water is drawn into the hydraulic tank and its outflow from the latter. In this case, the pressure switch sends a signal to the pump to turn on and off.

- Pressure gauge. which allows you to monitor the pressure in the system from the outside.

- Check valve. preventing the flow of water from the pump back into the well or well.

Important: it is necessary to assemble the pumping station strictly in a certain order to ensure its reliable operation. Incorrect installation of even one part can disable the entire installation.

Finding a reason

To troubleshoot a water pump, it is important to first find out the cause of the breakdown. But first of all, it is necessary to determine those conditions without which the normal operation of the device is impossible:

- The amount of water that the pump will lift up. Reducing its level can affect the pressure.

- The power supply parameters must comply with the technical characteristics of the pump. In other words, it is necessary to correctly select the power of the device in accordance with the depth of the well and the calculated water flow.

- Pump serviceability.

- Taps, filters, valves, pipes and other elements of the device must also be in good condition. Failure of at least one component of the system will lead to malfunctions.

Often, tap water in a private house is needed not only for domestic consumption, but also on the street (for watering the garden, washing the car). Therefore, the cause of the malfunction should be sought in three directions - in the hydraulic system, indoors and outdoors. How to determine the cause? Let's use the elimination method.

First, disconnect the supply hose located in the caisson. If at the same time water flowed, then the problem is either indoors or in the pipes on the street.

If there is no liquid, then the reason may be hiding in the well itself or in the details of the pump.Sometimes this situation also happens - the device is buzzing, but there is no water. Then the most likely reasons are:

- Incorrect installation or some parts of the pump that are not quite suitable.

- A decrease in water in the well, as well as surges in the electrical network, can also be the culprit in water supply problems.

- Phase failure during operation of the electric motor.

Borehole pump connection diagram

To determine why the pump does not turn off, consider its typical connection diagram. This will help identify the node or unit in which to look for the cause of the malfunction.

Rice. 1 Scheme for connecting a borehole pump for supplying water to a house

The main components of the connection scheme for a borehole pump for water supply in the house are the following nodes.

Dry running protective relay

The relay monitors the pressure in the plumbing system - as soon as it becomes less than a certain value, the membrane inside stops pressing the contacts and they open. Submersible pumps are disconnected from power when the pressure in the water supply decreases from 0.1 to 0.6 atm. (can be adjusted). This situation occurs when there is no water in the system or its very small amount (clogging of the filter, lowering the water level).

Hydraulic accumulator (expansion tank)

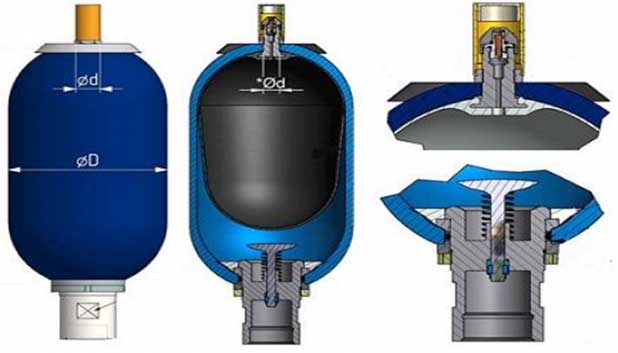

Fig. 2 Appearance and arrangement of the accumulator

The most important part of any water supply system, makes it possible to maintain a constant pressure in it. The device is assembled as a tank with a rubber membrane inside, during normal operation the tank is filled with water and the membrane is stretched. With a short-term loss of water, pressure drops, the membrane contracts and pushes the liquid out of the storage tank into the system, maintaining a constant pressure in it. If there was no storage tank, then for any short-term pressure changes, the pressure switch would trip, this would give impulse switching on and off of the power source, forcing the pump to turn off or turn on, respectively, leading to its premature failure.

Pressure switch

Rice. 3 Pressure switch

The relay is the main element in the borehole water supply system, which provides automatic control of water intake. In case of insufficient pressure in the water supply, the relay contacts are closed, the electric pump is supplied with voltage, and water is drawn. When the use of water is suspended, the accumulator is filled and the pressure in the water supply rises - the membrane inside the relay presses on the contacts and they open, forcing the pump to turn off. Single-chamber low pressure switches are used to work in water intake systems using pumps with a power of up to 3 kW., Their response threshold is 1.2 - 1.6 atm., Adjustable with two clamping screws (one determines the upper limit, the second determines the response range).

Additional elements of the water supply system

head. A very convenient device, installed on top of the pipe if the pump is working in a well. A pipe with a pump and a suspension system is passed through it, it protects the well from foreign objects. If the well was drilled at the bottom of the well, the head can be used for rod pump installation systems at a given depth.

Pressure gauge. It is built into all water supply systems using borehole pumps, it allows not only to monitor the pressure, but also serves to set the threshold for the operation of protective relays.

Check valve. The membrane, which is installed immediately at the outlet of the submersible pump before connecting to the water supply, prevents the reverse flow of fluid from the system into the well.

Filter. Flow-through fine filter with replaceable cartridges when using domestic water, the filter is an indispensable element

Additionally, the downhole pump connection system may consist of elements responsible for the safety of the pump motor: float or electronic water level sensors, flow sensors that respond to the speed of water movement in the pipes.

Possible malfunctions of the water pump pump.

- Deterioration of the water pump drive belt;

- Damage to the impeller of the water pump;

- Deterioration of the bearing of the water pump;

- Coolant leak.

How to determine the malfunction of the water pump?

In order to determine the malfunction of the water pump, it is necessary to follow the recommendations for diagnosing the water pump.

Overheating of the engine is one of the symptoms of a bad water pump. Engine overheating can occur if the water pump impeller is damaged, the drive belt is worn, and coolant leaks from the cooling system. The normal temperature of the engine is 90 degrees Celsius, so you need to follow the arrow of the coolant temperature indicator.

One of the main signs of a water pump malfunction is increased pump noise and excessive smell of lubricant and coolant.

Bearing wear can be one of the causes of increased noise and malfunction of the water pump, so it is necessary to measure the play of the water pump bearing.

Inspect the cooling system for coolant leaks

Pay attention to whether there are coolant leaks under the car after a long parking.. “According to the technical recommendations of car manufacturers, the engine water pump must be replaced every 90 thousand km

mileage".

“According to the technical recommendations of car manufacturers, the engine water pump must be replaced every 90 thousand km. mileage".

Water pump leaks.

Water pump coolant leaks cause grease to be washed out from under the bearing, causing subsequent destruction.

Noisy water pump?

The noise of the water pump indicates its imminent failure

Pay due attention to this, since the condition of the car engine depends on the operation of the water pump. When the engine overheats, its wear increases significantly, so there is no need to delay the repair of the water pump.

Why is the water pump noisy?

- Worn water pump bearing;

- Improper installation of the impeller.

Why do water pumps fail?

- Water pump failure can occur due to long-term engine load, vehicle operation in mountainous areas, in traffic jams and difficult climatic conditions.

- Water pump failures can occur due to the use of low-quality coolant and contamination of the cooling system.

After you have determined the malfunction of the water pump, you can repair the water pump - water pump repair technology.

Causes of failures in the operation of the pumping station

Sometimes it happens that the pumping station "gets sick" with the so-called turretless. The disease is based on the continuous operation of the device without the required shutdown cycles, when the device pumps water without stopping. Therefore, in this material we will find out what to do if the pumping station does not turn off and why this happens.

Important: a water station operating in a continuous mode (pumping and pumping water) will definitely soon lead to the combustion of the pump itself. Therefore, it is necessary to detect the causes of such equipment failure as soon as possible and put the entire water supply system in order.