Classification of heating systems

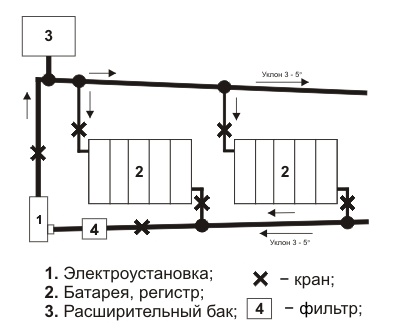

To properly fill the water heating system. you need to know what type it is. There is a classification of systems according to the method of piping: from the top, from the bottom, horizontal, vertical or combined. According to the method of connecting devices with the help of pipes, the systems are: single-pipe and two-pipe.

Also in the system, water can circulate naturally or forcibly (if a pump is used). According to the scale of action, local and central heating systems are distinguished. In the direction of water movement in the pipes - dead-end and associated. All these types in everyday life are used in a mixed manner.

Water or coolant choose the optimal system filling

Antifreeze for heating system

The optimal composition of the liquid should be determined by the parameters of the heating system. Often the heating system is filled with water, as it has a number of significant advantages. The determinant is the affordable cost - they often take plain tap water. However, this is fundamentally wrong. A large number of metal elements and alkali will contribute to the formation of build-up on the inner walls of pipes and radiators. This leads to a decrease in the passage diameter, an increase in hydraulic losses in certain sections of the pipeline.

But how to properly fill a closed heating system with water in order to avoid such troubles? Experts recommend using distilled water. It is maximally purified from impurities, which affects for the better its physical and operational properties.

Energy intensity. Water accumulates heat well in order to subsequently transfer it to the room;

Minimum viscosity index

This is important for closed heating systems with forced circulation and affects the power of the centrifugal pump;

When the pressure in the pipes increases, the boiling point shifts upwards. Those

in fact, the process of transition from liquid to gaseous state occurs at a temperature of 110°C. This makes it possible to use high-temperature heating modes.

But if there is a possibility of exposure to negative temperatures, then water, as a liquid for filling heating systems, is unacceptable. In this case, antifreezes should be used, in which the crystallization threshold is much lower than 0 ° C. The best option is solutions of propylene glycol or glycerin with special additives. They belong to the class of harmless substances and are used in the food industry. Solutions based on ethylene glycol have the best technical qualities. Until recently, they filled closed heating systems. However, they are extremely harmful to humans. Therefore, despite all their positive qualities, the use of ethylene glycol-based antifreezes is not recommended.

But what can fill the heating system - water or antifreeze? If there is no possibility of exposure to low temperatures, water is the best choice. Otherwise, it is recommended to use solutions of a special coolant.

Automotive antifreeze must not be poured into the heating system. This will not only lead to a breakdown of the boiler and failure of the radiators, but it will also be dangerous to health.

The main types of coolants

Heating system.

Heating system.

The principle of operation of the heating system is that the coolant moves from the heat source to the end point through the pipes, heating them. The type of heat carrier used depends on the type and device of the heating equipment, which can be liquids and gases.

The most popular liquid coolants:

- Water is the most accessible and cheapest resource.According to statistics, about 70% of heating systems use water, which has a high density and heat capacity. In addition, this type of coolant has gained such popularity due to its properties, such as low viscosity, high heat transfer coefficient, as well as easy temperature control. The main disadvantage is the ability to freeze at zero temperature. If water freezes in the heating system, this will lead to rupture of pipes and failure of all equipment.

- Antifreeze - this type of coolant is not as widespread as water, and its use is 5%. It is used for heating office buildings and residential buildings, where the heating system does not allow the use of water due to the increased risk of corrosion. The main advantage of antifreeze is freezing at frosts of 60 - 70 degrees.

The following gases are used as a heat carrier:

- Water vapor is mainly used in industrial buildings, since its use is prohibited in residential and public buildings. Water vapor maintains the temperature of heating devices at 100 degrees, according to sanitary standards, this figure should not exceed 80 degrees.

- Flue gases are toxic, therefore, recently they are used only for heating water and in order to save electricity to obtain a heat source.

- Air - is characterized by low heat capacity, therefore, its movement through the heating system requires large energy costs. It is most cost-effective to use air as a heat carrier, provided that it performs two functions simultaneously: heating and ventilation.

At present, organic liquids are introduced as a coolant, which have excellent freezing levels and low viscosity. However, they have not yet received wide distribution, due to the high cost and scarcity.

Heating system pressing

Heating system pressing

Before filling the heating system with coolant, it is necessary to check the tightness of all joints and connections. For this, pressing is performed - the creation of excess pressure in the pipes, i.e. artificially creates a situation of destabilization of the system.

This can be done in two ways - by blowing air or coolant. This must be done even before the heating system of the double-circuit boiler is filled. This procedure can be carried out using a mechanical (electric) pump or by connecting the water supply. The latter option is not recommended, as it will be very difficult to control the process. The order of execution is as follows:

- Preliminary visual check of joints and connecting nodes;

- Connecting the mechanism to the inlet pipe of the system;

- Creation of excess pressure, the value of which should exceed the norm by 1.5 times.

Be sure to check the condition of the heating elements. In the event of a leak, the process stops immediately and can only start when the defect has been eliminated.

The process of starting an open gravity heating system

In modern homes, open heating systems are rarely arranged; such technologies have long been considered a relic of the past. But they still exist, so you should consider how they need to be filled with water. In any such heating system, there is an expansion tank at its highest point, it is designed to accumulate water after its volume has increased in the system with increased pressure during temperature rise. The tank is an open reservoir with or without a lid. Through the tank, the system is filled with water. Large volumes of liquid, of course, will be quite problematic to fill in small containers, moreover, to the highest point.

It would be most rational to use a conventional domestic vibration pump. To do this, prepare a capacious container, fill it with water. Pre-prepared hoses are attached to the pump with clamps. Such a pump has a submersible type of structure. The hose through which the water will be drawn must be lowered into the prepared water tank. The hose from which the water will be released is immersed in the expansion tank. Turn on the pump, the pressure in the system should be from one and a half to two atmospheres. When lowering, add water to the prepared tank and lower the hose into it lower. When the heating complex is full, water will be visible at the bottom of the expansion tank, the system can be considered full.

Scheme of installation of a water heating system.

Excess air will come out of the pipes at the first fire through the expander. It should be noted that during the heating season, when the system maintains a constantly high temperature, water will gradually evaporate from the expander. It is necessary to carry out make-up, adding water to the expander to the required level. You should also monitor the temperature on the thermometer attached to the heating boiler. When it reaches a level above 80 ° C, the water will soon begin to boil and splash out. In this case, it is necessary to block the access of oxygen to the furnace to reduce the intensity of combustion.

We fill the system from below

So, back to pumping fluid into the system. We use a container of a suitable volume (a plastic barrel with a volume of 200 liters is well suited). We lower a pump into it, which creates the pressure required for pumping liquid no higher than 1.5 atm (typical value in the range of 1-1.2 atm). Such pressure requires the creation of a pressure head of 15 m by the pump (for the submersible "Baby" it reaches 40 m).

After filling the barrel with water, we start the pump, watching the liquid level, which should be located above its inlet to prevent "airing". The level drops - add water. Antifreeze should be pumped from a container of a smaller volume (bucket) so as not to immerse the body of the submersible pump in the liquid (and then not wash it) - it is enough to immerse the inlet pipe. You will have to add antifreeze often, periodically turning off the pump.

The filling of the system is carried out with open Mayevsky taps on installed heating radiators with substituted containers for collecting water. When the liquid comes out of all the air vents, close the valves, continuing the pumping process.

We control the pressure on the pressure gauge (the boiler device is suitable). When its value exceeds the hydrostatic one, equal to the pressure in the liquid column with a height from the lower to the upper point of the system (a height of 5 m gives a static pressure of 0.5 atm), we continue to fill the system, monitoring the pressure gauge when the pressure reaches the required value.

Pumping antifreeze pump "Kid".

After filling the system, turn off the pump, open the air valves (the pressure will inevitably drop), and then pump up the water. We repeat the process several times, displacing air bubbles.

We complete the filling by inspecting the system for leaks. After the pump is turned off, the hose connected to the outlet is under pressure. If antifreeze was pumped in, first disconnect the hose from the pump inlet and drain the liquid into a container, trying not to pour over the mechanism body.

Types of circuits for closed heating systems

The main advantage of natural circulation schemes is their independence from the availability of electricity, but they have a limitation: the length of the circuit must be no more than 30 meters, otherwise the system will be inoperable. There is one more nuance - with natural circulation, even in a closed system, you need to put a drain valve at the top point, with which you can remove the air that got in, for example, when adding a coolant.

System with natural circulation of a one-story house. Single-pipe scheme, wiring - top

In a forced circulation circuit, pressure is generated by a circulation pump. Some boilers have it built in, some don't. Some long circuits require the installation of two pumps. Then it is not necessary to observe slopes, the most important thing is not to make the sections slope in the other direction, which will negatively affect the performance of the heating and may even require alteration.

On the one hand, the use of circulation pumps is a disadvantage, since its performance depends on the availability of electricity, and on the other hand, it is a big plus:

- allows the use of pipes of a smaller cross section and radiators of a smaller volume, which means less money spent on the purchase of materials;

- to increase the speed of movement of the coolant, which means to reduce its inertia and increase the level of comfort;

- less coolant, less fuel is spent on heating it - money is saved.

Reduced volumes of pipes and radiators mean a reduction in the volume of the system, which again allows to reduce the inertia of heating the coolant - it heats up faster, and heating is more efficient. A smaller volume of coolant means a smaller volume of the expansion tank, and there is no need to look for a place to install it. Modern boilers have built-in membrane tanks (for example, wall-mounted gas boilers), and the heating efficiency with their use is very high due to the fact that a powerful pump is installed (it is also built-in).

It is better to connect the pump with a bypass - so that it can be repaired / replaced without destroying the system

When choosing a pump, remember that there is a direct relationship between its power and heating efficiency. Therefore, choose low-noise, powerful and reliable.

It is worth noting that it is easy to make a closed system from an open system - you just need to change the expansion tank - put a membrane type and the system will already be operational. For greater efficiency, you will need to embed the pump. Moreover, modern pumps can be installed both in supply and return. Previously, they put it on the return line because the temperatures of the coolant are lower there. But modern pumps use heat-resistant materials; the temperatures of heating systems are not so critical for them.

Just when buying, pay attention to the operating temperature range, well, or put it in the return line - just so that it “presses” into the boiler. In this case, the pump power can be small, since in open systems larger pipe diameters are used than in closed ones, and the hydraulic resistance of the system is small

There are many nuances and features in heating a private house, and it is not easy to figure it out. But having set a goal, you can do everything yourself - create a workable good project, choose the right equipment and mount everything yourself. And closed systems in this sense are no exception.

Filling technology where to supply the coolant

The necessary means are a container and a pump that creates the required pressure of the heat transfer fluid. Submersible type "Gnome" or "Baby" are quite suitable (popular with gardeners who use them to irrigate areas located above the levels of water bodies). There is evidence of successful filling of closed systems with hand pumps ranging from those used for spraying horticultural crops with protective solutions to specialized hand pumps used for drumming motor fuels or liquid chemicals. Any heating scheme can be successfully filled by controlling the pressure on the manometer.

Filling the system with antifreeze by means of a submersible vibration pump.

The first operation is to select the fluid entry point. If the pressure created by the pump raises the liquid to the top of the system, it should be connected at the lowest point of the boiler room - the coolant feed pipe, embedded in front of the boiler into the "return".In addition to the make-up inlet, a structurally separate drain outlet is required (two different system nodes). The first is equipped with a valve (ball valve) and a check valve, the second - only with a valve (ball valve). If the lowest point of the system is the boiler outlet, then the system can be drained/filled with water through it. Since a non-return valve is not installed behind the boiler drain (generally behind the drain), any shutdown of the pump will result in the outflow of the pumped liquid - you need to quickly turn off the tap in front of the fitting.

The design of a typical drain / make-up unit.

When filling with coolant

There are only two situations that require the implementation of this technological operation:

- putting heating into operation (at the beginning of the heating season);

- restart after repair work.

Usually, the heat carrier water is drained in late spring for two reasons:

- Water is inevitably polluted by corrosion products (inside radiators, metal-plastic and polypropylene pipes are not subject to it). Leaving the old water for the new season, you risk breaking the circulation pump with solid contaminants.

- Non-launched flooded systems of country houses can “thaw out” during a sudden cold snap - such cases are not uncommon. In this sense, antifreeze coolant is preferable. The high-quality composition has high anti-corrosion properties, which increase the “drainage” interval up to 5-6 years. There are known cases of uninterrupted operation of heating on the same volume of antifreeze for 15-17 years. Low-quality antifreeze is recommended to be drained after 2-3 years.

Pumping antifreeze into the heating system.

Features of starting a closed heating system with distilled water

Filling a closed heating system with water has the following features:

It will be much easier to provide the heating circuit with the necessary pressure if the dwelling has access to the central water supply. In this situation, to pressure test the heating system, it is enough to fill it with water through a jumper that separates the water supply, while carefully monitoring the increase in pressure on the pressure gauge. After completing such an event, unnecessary water can be removed using any of the valves or through an air vent.

Many are wondering whether special water treatment for the heating system should be carried out or whether it can be limited to water from the nearest reservoir. At the same time, some argue that distilled water in the heating system will have a beneficial effect on the life of the equipment and will prevent it from failing ahead of time. But it is much more important to figure out how to prepare water for heating if a special non-freezing liquid like ethylene glycol is added to it and how to subsequently fill the heating circuit with such a coolant.

For these purposes, it is customary to use a special pump that serves to fill the system with water, and it can be controlled both automatically and manually. The connection of this pump is carried out using a valve, and after providing the necessary pressure, the valve is closed. There are situations when such equipment is not at hand. As an option, it is allowed to connect a standard garden hose to the discharge valve, the second end of which should be raised to a height of 15 meters and filled with water using a funnel. This method will be especially relevant if there are tall trees near the building to be equipped.

Another option for filling the heating system is to use an expansion tank, which performs the function of containing excess coolant caused by its expansion during the heating process.

Such a tank has the form of a reservoir, which is divided in half by a special elastic rubber membrane. One part of the container is for water, and the other for air.The design of any expansion tank also includes a nipple, with which it becomes possible to set the desired pressure inside the unit by removing excess air. If the pressure is insufficient, then this parameter can be compensated by pumping air into the system using a usually bicycle pump.

The whole process is not particularly difficult:

first, air is eliminated from the expansion tank, for which you need to unscrew the nipple. Ready tanks go on sale with a slightly overpressure, which is equal to 1.5 atmospheres;

then the heating circuit is filled with water. In this case, the expansion tank must be mounted so that it is located with the thread up

It is important to remember that it is absolutely not worth filling the tank with water completely. It would be more correct if the total volume of air in this apparatus is approximately one tenth of the total volume of water, otherwise the tank will not be able to cope with its main function and will not be able to accommodate excess heated coolant;

after that, air is pumped into the system through the nipple, which, as mentioned above, can be done using a conventional bicycle pump

The pressure must be controlled with a manometer.

All these actions will allow you to accurately fill the heating system with water and ensure stable and high-quality functioning of the entire circuit. If necessary, you can always seek help from specialists who always have various photos of the devices necessary for such work that can help in connection.

Filling the heating system with water in the video:

Closed heating system. How to properly fill with water

Now a lot of owners of apartments and private houses choose closed heating systems. A closed system is a scheme within which the movement of the coolant is carried out with the help of the movement of the coolant - the pump, that is, forcibly. A special feature is a membrane-type expansion tank. Essential elements. boiler, tank - membrane, radiators, pump, pipes, also fittings, fasteners and filtering equipment. But very often, buyers of such a “closed heating system” soon wonder how to fill it and how to close the heating pipes. Below we will tell you how to properly fill a closed heating system with water.

The filling of the heating system takes place through the supply of the boiler. This is carried out using an electric pump, as well as a manual crimping machine. The system is filled with prepared network water or antifreeze made according to a special technique - it is a non-freezing coolant. At this time, air is released in the entire internal part of the system (faucets, radiators, air vents, and so on). When the desired pressure is reached, you can already start the system in working condition. Sometimes there are difficulties with creating the ideal pressure. Closing the heating pipes will largely depend on individual wishes, the design solution of the room and the location of the pipes themselves in the apartment, their number and size.

Difficulties often arise when filling with water. If the system is closed, then the expansion membrane tank must also be closed (up to 6 bar pressure inside the tank), safety valve up to 3 bar. Special taps should also be installed to release air in places of accumulation, as well as a tap for feeding and filling pipes and heating equipment. The sequence of actions when filling a closed system is as follows:

Loosen the screw on the pump. Unscrew the shaft of the pumping system with a screwdriver. Tighten the screw tightly. Open the make-up screw. Fill the system until the pressure reaches approx. 0.5 bar. (you can start from 0.3 bar).Be sure to check if there are any leaks during this procedure! Raise the operating pressure in the system to 2 bar. Make sure that it doesn’t leak anywhere. Release the air in absolutely all internal places of the system. The next step is to make the pressure in the system about one and a half bar. This will be the most optimal pressure for a closed heating system. If the system will be cooling or heating, then the fluctuations should not be significant (from 0.1 bar to 0.5 bar). Watch out for the swing range! Sudden drops threaten to break all equipment, pipes and fittings!

There is no water level in such closed systems. The presence or absence of water is controlled by pressure. With its normal amount, it should be from one to two bar.

The closed heating system is easy to operate, less prone to corrosion and damage, it is easy to replenish and, if necessary, lower it. If you have any questions or find malfunctions in the operation of the heating system (freezing, leaking, etc.), then immediately contact the support service!

Heating boilers are one of the main types of heating equipment and are devices for heating the heat carriers entering the heating system to a certain temperature. The coolant passes through a vicious circle of the heating system.

Before you start looking for contractors to improve your own balcony, answer yourself one question: what do I want to get as a result of glazing? Perhaps you just want to use this room for drying.

Such cast-iron batteries, familiar to the majority of the population, installed many years ago, can no longer fully cope with the functions assigned to them for space heating and have a rather unattractive appearance.

Solid fuel heating boilers are devices that produce space heating thanks to solid fuels (for example, wood, coke, briquettes or coal). Typically, these boilers are universal, as they can work on any.

What to do if the pressure drops in the system

If you find a decrease in pressure, the first step is to turn off the pump. And then act on the basis of the readings of the pressure gauge:

- If the static pressure also drops, there is a leak somewhere. You need to inspect all the elements and eliminate it. Please note that even a very small hole (less than a millimeter) can be the cause, so finding damage can be difficult. With a large length of the pipeline, it is possible to localize the leak area: turn off the branches one by one. As soon as the fall stopped, the site was determined - depressurization on the one that had just been turned off.

- If the pressure is stable when the pump is turned off, the pump is out of order, it must be carried in for repair or replaced.

An increase in pressure is less common, but it also happens. It is usually caused by an increase in temperature in the system, and it rises due to insufficient circulation of the coolant. But why the coolant circulates poorly needs to be dealt with.

- First, we check the performance of the pump. Turn off and watch. If the pressure continues to rise, it's not the pump. If it stabilizes, it's his fault.

- We clean the filters and mudguards.

- If the pressure continues to rise, an air lock may have formed - we bleed the air in the system.

- If this does not help, we check the condition of the shut-off valves - maybe someone accidentally or intentionally closed it, blocking the coolant flow.

- Another reason - due to a breakdown or failure of automation, the system is under constant replenishment.

Using this algorithm, you can independently determine the cause of the abnormal state of the heating system and eliminate it.