Application area

Currently, the main area of application of wooden flooring is the construction of small private houses. Especially often the floor on the logs is arranged in wooden houses and log cabins, in which the floors between the floors are made of beams.

Especially often the floor on the logs is arranged in wooden houses and log cabins, in which the floors between floors are made of beams.

Much less often, a wooden floor is laid in city apartments with reinforced concrete floors. Nevertheless, the technology is still used, especially in cases where the filling of a full-fledged leveling screed is impossible for some reason.

Wooden floor in the apartment

Sometimes plank flooring is the finish and part of the designer's idea for the renovation concept. In this case, beautiful wood species, such as oak, larch or pine, are chosen for flooring. The boards are carefully polished, impregnated with an antiseptic and varnished or waxed. The result is a very beautiful and durable coating, pleasing to the eye with a natural wood texture.

natural wood floor

A wooden floor can be used even in damp rooms, such as saunas and bathrooms. However, this is done infrequently, as it requires careful selection of wood, reliable waterproofing and impregnation of boards with very expensive solutions that prevent moisture absorption.

Wooden floor in the bathroom

floor laying

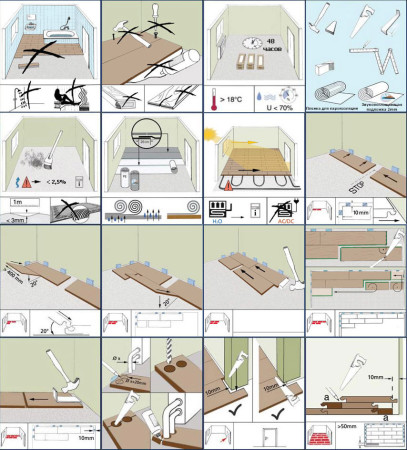

When proceeding directly to laying the finishing coating of the floating floor, you need to once again measure the dimensions of the room and correlate them with the format of the floor elements, parquet board, laminate or cork. This must be done in order to avoid a situation where the last die is cut more than half. At the same stage, the possible deviation of the angles is measured to be taken into account when trimming the extreme strips.

How to lay laminate correctly

For example, a laminate with a width of 185 mm will be laid on the floor, and the width of the room is 3410. It is easy to calculate that 18 whole strips will lie here and, taking into account the wall gaps of 12 mm, it will be necessary to lay the last strip 86 mm wide. It's not pretty and doesn't benefit strength. In this case, it is advisable to reduce the width of the laminate strips not at one wall, but at two opposite ones. By reducing the width of the two extreme strips of laminate by 50 mm, we get a more beautiful and durable floor. We also measure and plan the laying of the end sides.

laminate

Laminate and parquet boards are laid with a specific pattern of joints. The overlap of adjacent strips can be done in half a strip or a herringbone pattern. Deciding which method to use should be based on the aesthetics of the floor pattern and the economy of the layout.

floor laying

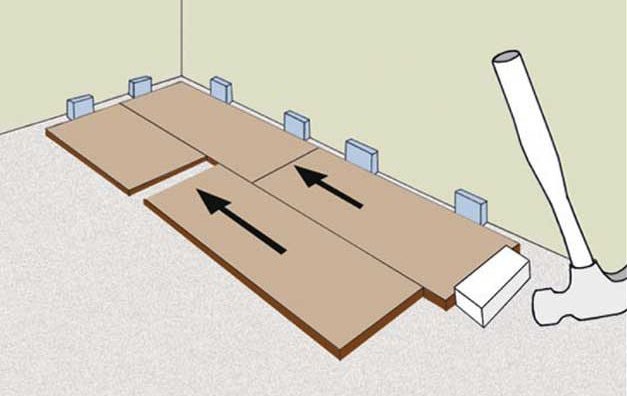

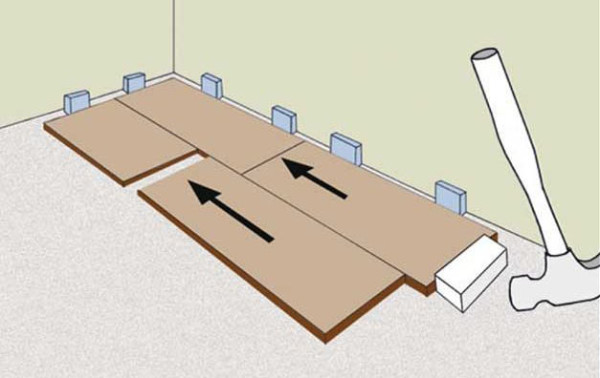

Boards are laid along the line of light. Choose the wall where the first row will be laid, focusing on the greatest visibility. The first row is laid, relying on pre-prepared dies, providing a gap between the wall and the floor. At the final stage, this gap will be hidden by the plinth. Its size can be in the range of 10-18 mm.

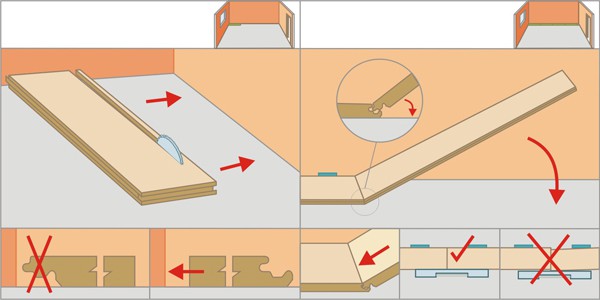

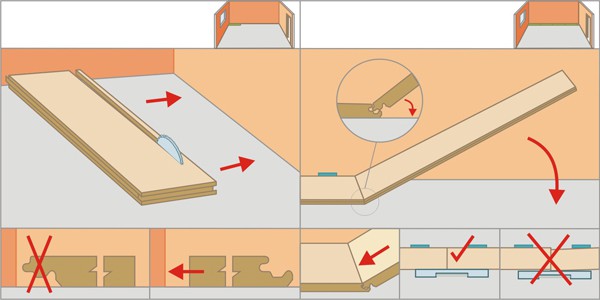

The method of connection between the floor plates depends on the specific material. There are options for locking and adhesive. Before laying, read the installation instructions from the flooring manufacturer. The key connection can be made according to the Lock or Click type.

Lock - this type of connection, in which a spike of an adjacent die is placed in a groove selected in one die. To do this, all panels are tapped through the protective gasket with a mallet. Unfortunately, the Locke lock becomes loose over time and does not allow secondary installation.

Click - the connection is more reliable, and besides, such a floor is mounted without using a tool. It is enough to raise the adjacent die by about 40 degrees and insert the protrusion into the groove intended for it.

To protect against possible liquid ingress, it is more reliable to treat the ends of all strips with silicone sealant. The only type of LockTec locks from Witex is already factory waxed, so it does not need further protection.

Some floors, such as parquet, require adhesive bonding in addition to the lock. It must be carried out according to the instructions.

As for the transverse joints, they are knocked out in any case. It is advisable to leave an overlap between adjacent joints of at least 300 mm. In this case, the load on the floor will be better distributed, and its wear resistance will increase. Do not forget to leave technological gaps at the end walls. Thus, gradually fasten together all the elements of the floating floor.

Sometimes you need to cut holes in the floor for pipes, go around small corners and ledges. It is most reliable to make a stencil for each such element and use it to trim the corners and make holes in the floor slabs.

parquet

When you reach the door to the next room, be sure to leave a gap. This is necessary so that after installing heavy furniture in different rooms there is no height difference at the junction from lifting the edge of the floor. The joint is made out with a small threshold.

How to lay laminate correctly: from A to Z

Stages of laying a floating floor with your own hands

- Calculation of trimming dies, taking into account the selected laying pattern.

- Determination of the most visible wall and the direction of the light flux.

- Gap setting.

- Laying dies from the wall in accordance with the type of fastening.

- Laying of each subsequent row, taking into account possible irregularities of the end walls.

- Marking the location of pipes, door jambs and their design.

- Laying the last row, taking into account the technological gap.

- Installation of skirting boards.

Stages of laying a floating floor with your own hands

If everything is done according to the rules, the surface of the base base does not have a significant difference in height, is well prepared for laying the floor, the substrate is selected and correctly laid, the recommendations of the manufacturers of the finishing coating for its installation are taken into account, then as a result we will get a high-quality, durable floor.

Floor types

Depending on the features of the building project, there are two types of floors on the second floor on wooden beams.

Table. Types of floors on the second floor on wooden beams.

| floor type | Description of technical and operational features |

|---|---|

|

Cold |

Such floors are currently almost never used, but in vain. Below we will consider options for when it is advisable to install non-insulated floors. In terms of cost, they are the cheapest, laying them is not difficult even for beginners. |

|

insulated |

A complex design from an engineering point of view, it consists of several layers, each of which has a noticeable effect on the overall performance. It is much more expensive than cold ones, but it can significantly reduce heat losses. Due to this, an expensive design quickly pays off and begins to bring direct profit. But this is possible only under one condition - warm floors are laid in strict accordance with existing building codes and regulations. Otherwise, they quickly lose their original properties and require complex and expensive repairs. |

Scheme of interfloor overlapping in a wooden house

The use of insulation as a sound insulator

If you look carefully, you can find heat insulators that act very well as sound insulators.

Among these heaters, the most popular are:

In the first place, of course, mineral wool. It does not burn, does not evaporate allergens, does not shrink during installation and is well insulated.

The main areas of use of mineral wool:

- isolation of airborne noise in a frame partition;

- limits impact noise in a floating field;

- in a sound-absorbing structure - wall cladding.

One of the types of mineral wool is ecowool. This material is well insulated and isolates from unnecessary sounds. Also, it protects against condensation. It needs to be sprayed using special blowing machines and fill the voids. This forms a solid wall of sound insulation. For the full effect, you need to use sound reflectors and sound-absorbing materials. Such materials can be double drywall or concrete screeds.

Stone wool will help to achieve the same effect. It is very easy to install:

- Mount the frame racks through 500-600 millimeters.

- Between the racks lay mineral wool slabs, so as to close the gaps. The thickness of the plates should be 50-100 millimeters.

- Sheathe the frame with heavy material (for example, drywall).

- Plaster the seams.

floating floor

The most effective is the soundproofing of the floor in a wooden house using the technology of a "floating" structure.

Here it is important to observe the key condition - "floating" floors should not come into direct contact with the structures of the house. Therefore, at the points of contact, a special damping material is laid, which dampens the shock wave of sound.

The soundproofing material is laid on wooden beams with a lapel of their edge for mounting the plinth. Logs are installed on top of the soundproofing material, on top of which a fine decorative floor covering is laid. The logs are nailed to the floor beams, and the skirting boards are fixed not to the walls, but to the floor, due to which a “floating” structure is obtained.

Floor device on logs

By and large, the floor on the logs is part of the hollow wooden floors that were arranged in houses earlier, now this technology is also actively used in low-rise construction. The idea is very simple and consists in the following. The base of the floor is formed by beams installed with a certain step, a rough flooring is made on top of them, which, in fact, is already the floor.

The structure of the wooden floor in the section

If powerful beams are used in the ceiling that can withstand the weight of the entire structure, as well as furniture and people in the room, then when leveling or raising the floor on the logs, it is enough to use a beam of small section, since there is already a solid foundation under it, on which it will reliably rest .

Varieties of timber for log

The lags are set in one plane and, if necessary, are securely fixed. The average section of the log laid on a concrete base is 50 * 50 mm. This means that such a floor will be higher than the old one. On the one hand, this may be a disadvantage, for example, doors have already been installed in the room, or the floor will become trite above the entrance threshold. This happens mainly in apartments and houses where such structures were not originally planned.

Mineral wool for floor insulation

On the other hand, such a structure promises us the following possibilities. Firstly, under the lags or between them, we can skip various communication lines, for example, heating or water supply pipes. In this case, you do not need to ditch or mask anything. Secondly, it becomes possible to place layers of heat and sound insulation under the floor (basically we are talking about the first point). Thirdly, in this way you will level your floors quickly and efficiently enough, you do not need to mess around with a wet and dirty screed. And fourthly, it is possible to raise the floor to the desired level in a short time.

Laying mineral wool insulation between the lag

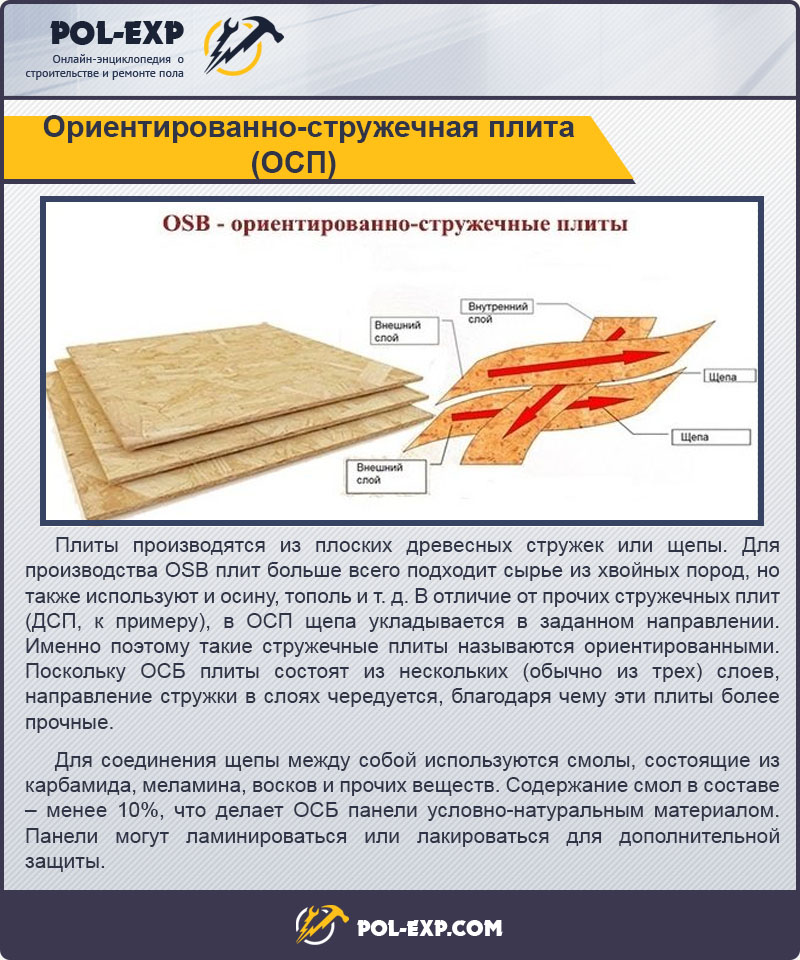

A rough coating is laid on the logs. It can be wooden boards or made from wood-polymer composite (WPC) - the second material is more often used for laying on the street.Sheet materials are also popular: plywood and OSB. It is easiest to sheathe logs with them, since the size of one sheet is on average 1.5 * 1.5 m, however, unlike boards, they must be finished with a finishing material, while they can also be a finish coating.

Finishing the plywood floor on the logs can be anything: laminate, linoleum, carpet and even ceramic tiles.

floating floor structure

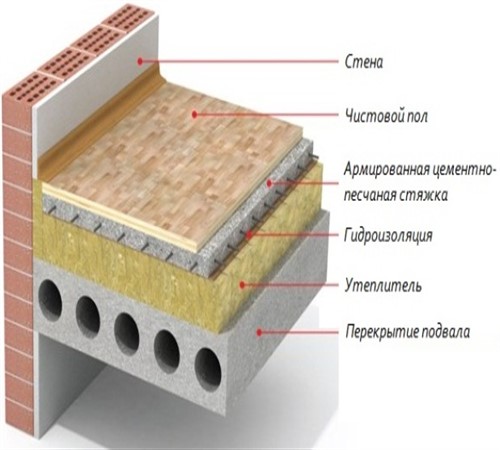

In most cases, a floating floor is created as a multi-layer structure, including:

- vapor barrier;

- insulation, which simultaneously performs the functions of sound absorption;

- waterproofing;

- the top layer of the floor, which contributes to the final leveling of the surface for laying the floor covering, while providing additional insulation. The top layer is carried out by means of a concrete screed, plywood, chipboard, gypsum fiber sheets and other materials. The main thing is that the material is strong enough and able to withstand the weight of furniture, people during operation.

It is not by chance that the floor design is called floating, because its main feature is the absence of any rigid ligament in relation to the load-bearing elements of the room. When installing the floor, any fixation of materials using nails, self-tapping screws, glue and other fasteners to the walls and the base is excluded. In this case, the materials can be fastened together in any way. Despite the absence of fasteners, the floating floor has sufficient strength to withstand heavy loads, typical even for industrial premises.

Currently, for the manufacture of a floating structure, a fairly wide range of building materials are used, differing in properties and purpose. In this regard, the structure of the floor largely depends on the combination of a certain type of material, forming a variety of subspecies of this new technology.

Prefabricated floating covers

The easiest option: on top of a flat base covered with a special substrate, a laminate, parquet or grooved board is mounted. Such a floor has only minor heat and sound insulation properties, its main task is to create a beautiful and durable coating. The design turns out to be floating, but this is a feature of its assembly, and not the intention of the developer.

Stages of work

-

Laying an underlayment suitable for the selected flooring. For example, under the laminate, you can take foamed polyethylene, isolon or cork.

-

Assembling a decorative coating, before which the materials need to lie down in the room for at least a day. Usually the elements of such a floor have special grooves to connect with each other, so that no fasteners are required. The finished coating layer should not adjoin the walls closely, a gap of 1.5-2 cm is left. This will protect the flooring from damage due to possible expansions.

Surface preparation

Conduct an audit of the state of the base base and, if necessary, align it

This stage should be given great attention, since it is he who largely determines the quality of the floating floor.

The floating floor can be laid on a concrete screed or on a plywood underlay. The latter option is more often used in houses of the old housing stock.

If the logs and floor boards are strong enough, such a floor can be leveled to an acceptable height difference (no more than 2 mm per 2 m of the length of the room according to SNiP 3.04.01-87). If the floor “walks” much more, a dry screed or sand is used, sawdust with an epoxy binder layer, and it is easier to finish the leveling by laying two layers of thin plywood. Two layers - so that the joints of the upper layer lay with an overlap on the lower sheets.

Floor leveling with plywood

The concrete base, if the floor is laid directly on it, must be brought to perfect evenness.Bumps, sags, dents and pits will have to be sanded or filled.

Leveling the concrete floor

You can check how fresh the screed has dried up and is ready for laying the floor by checking for condensation in a three-liter glass jar, left for a day on the concrete floor with the neck down.

Wooden floor and its soundproofing

Wooden floors transmit extra sounds very well. To isolate them, you can use a floating floor, but you will have to install it a little differently. To avoid the appearance of a bridge that will transmit noise, insulation is placed between the joist and the floor beam. They are not attached to anything. They can be attached, but then you need to remove the mount.

The sound insulator is placed on the entire space that the beams create. Another insulator is placed on the logs. It is advised to use foamed polymer or roll plugs. You can also use synthetic felt, but this can hit your pocket. On this all lay the OSB plate, which must be attached to the logs.

Top floor finish.

Dry screed technology for wooden floors

The dry screed method is very popular among the owners of wooden houses. The secret is that it does not take much time and it is very easy to do everything yourself.

Dry screed laying technology for floor soundproofing:

- sprinkle the dry mixture on the floor and evenly distribute;

- place drywall or fiberboard slabs on top;

- then, the floor is laid. Joints should be easily attached to each other;

- fasten the joints with self-tapping screws and glue.

This method of soundproofing the floor is available to everyone.

Floor insulation materials

The modern market offers a wide range of materials suitable for insulating a wooden floor on logs. You can find the properties of the most commonly used heaters in the following table.

Table. Popular heaters

| Thermal insulation material | Basic properties |

|---|---|

| Sawdust | One of the most budgetary, and sometimes completely free thermal insulation material. It is characterized by good thermal insulation properties, helps to normalize the level of humidity inside the floor structure. The main disadvantage of sawdust is its poor resistance to various kinds of insects, fungi and other harmful microorganisms. In addition to this, the material supports combustion, which is also a big minus. |

| Mineral wool insulation | Materials based on mineral wool are characterized by high thermal insulation properties and do not support combustion. Along with this, the material does not tolerate contact with moisture - under the influence of water, it swells and loses its original performance characteristics. In the case of using mineral wool for insulation, waterproofing will need to be equipped on both sides of the material. |

| Expanded clay | Relatively inexpensive and easy to arrange material with good thermal insulation characteristics. For insulation, it is recommended to use granules of different sizes - so the backfill will turn out to be more dense. |

| Styrofoam | One of the most popular heaters. It is sold at a relatively affordable cost, provides highly efficient insulation, is not afraid of contact with moisture, but supports combustion, releasing, at the same time, substances that are unsafe for human health. In addition, the foam plastic attracts rodents, "meetings" with which do not affect the service life of the material in the best way. |

How to sound a cement screed

The best way to voice the cement screed is to remove it completely, dismantle it to the floor slabs. Then you need to make a new one with floating technology. You need to start by taking a thick cellophane film and cover all the plates. This is done so as not to flood the neighbors when installing a new screed. For soundproofing, it is best to use foam. But not the first comer.

There are a number of requirements for foam for sound insulation:

- it should have a maximum density, you can use expanded polystyrene;

- the thickness should be 50 millimeters, for polystyrene 30 millimeters.

Thin polystyrene pads should be laid along the walls to separate the screed from the walls. After that, you need to install beacons and fill in a new screed, but a little by a different method, namely:

- Beacons must be installed using a special adjustable mount. All due to the fact that the foam can bend in some places and violate the integrity and evenness of the coating, besides, the cement does not stick to the foam.

- The thickness of the screed must be more than 50 millimeters, otherwise the screed will crack after drying.

- You have to wait until it is completely dry. If it is bad to dry the screed, then under load the foam will bend, the screed will crack.

Such a soundproofing process takes a lot of time, but it qualitatively soundproofs the entire room and makes it possible to enjoy the silence.

Materials for water floor heating

Pipe selection

For installation, use copper, polyethylene, plastic and metal-plastic pipes with a diameter of 15-20 mm, the larger the area of \u200b\u200bthe room, the larger the diameter must be used. Lay the water circuit of each room from one piece of pipe. Therefore, purchase pipes sold in coils and coils.

Copper pipes are 10-15 percent more efficient than others, but are expensive and difficult to install. Polyethylene pipes are cheaper, and inferior in quality slightly. Therefore, the choice of pipes depends on financial capabilities.

The choice of insulation

Used as a heater:

- foam, polystyrene or foamed polyurethane boards;

- foil reflective insulation;

- mineral wool;

- expanded clay;

- washed slag.

Expanded clay and washed slag are used for warming the contour laid on a wooden floor. In this case, the voids between the coating and concrete or soil are covered with insulation. To use foam boards, foil insulation or mineral wool, you will need to create a base - plywood sheets fixed to the logs.

Properly executed thermal insulation for a warm water floor, as well as its electric version, will halve heating costs. And thermal insulation, made with errors, increases up to two or three times.

Use high-density foam boards to insulate concrete.

How to make soundproofing in the crate

If you level the floor with special plates, then you need to mount the crate. For greater effect, it is better to mount it from wooden beams. They are attached to the floor with ordinary dowels. To prevent vibrations and structural noise, throw a layer of texound between the dowel and the beam.

Under the crate, you can put any material on the floor, both rolled and tiled. It is placed between the crate. The only negative is that you need to buy material on the floor a few centimeters longer so that it fits snugly against the beams. If you use plywood, it is better to throw a soundproofing ball Noise Stop.

On top of the sound insulation it is necessary to lay a vapor barrier material: polyethylene or polypropylene. After that, you need to make a plywood frame. There are screws with soundproofing gaskets. It is they who must be used to fasten the plates to the already attached logs. Now you can lay linoleum on the floor. You can do all this yourself.

Advantages Disadvantages of a floating floor

The popularity of the floating floor device is largely due to its advantages over other types of rough coating, including:

- high strength of the floor, due to the multi-layer construction;

- high sound insulation rates due to the lack of fixation to the walls and the base of the building;

- the finish coating is not deformed during shrinkage or diffusion due to the presence of an expansion joint made of dense insulation;

- the invariance of the floor structure with significant temperature fluctuations caused by the device of the underfloor heating system;

- uniform load distribution during operation;

- the absence of a creak, due to the lack of fasteners, which weaken and become unusable after a short period of time;

- simplicity and high speed of installation due to the absence of labor-intensive work;

- duration of operation.

Of course, like any structure, a floating floor has one significant drawback - a decrease in the height of the room. In connection with this circumstance, it is better to install the floor during a major overhaul.

Thus, the mass of advantages far outweighs the only disadvantage of the design, which fully explains the promising interest of the population in the construction of a floating floor.

The main stages of arranging the screed

Of course, the complex of works associated with the installation of a floating screed largely depends on the size of the room, its configuration, type and specifics of the building.

However, in general, it is possible, albeit rather schematically, to single out the main stages of this type of work.

Video:

Moreover, regardless of whether the floor screed is carried out industrially, with the help of highly qualified specialists in the field of construction, or is made by hand.

A typical algorithm for how to competently make such a screed looks something like this:

- In the case of using a heat-insulating material such as polyethylene or mineral wool, it is necessary to make a vapor barrier layer, which is easily equipped with your own hands using the most common polyethylene or other moisture-proof material;

- The next step is to lay the heat-insulating material itself on the floor slab. At the same time, it must not only completely cover the surface of the floor - a partition that enters the wall is necessary, which must be done so that in case of heating the floor, it would not deform the walls of the building;

- After that, the floating screed itself is created. The dry mixture is diluted with water in the required proportions, poured to the desired layer depth and left to dry. All these operations can be carried out with your own hands, with known skills and building dexterity. Of course, it is necessary to ensure that the outer surface is perfectly smooth, which may require a spatula, trowel or other special tool;

- After the screed has dried, it is possible to mount a floor heating system and floor covering - laminate, parquet, linoleum, and so on.

As you can easily see, the arrangement of a floating concrete floor screed is not such a difficult, time-consuming and time-consuming matter.

With its relatively low cost, this design allows you to make the room warmer, less accessible to extraneous noise, and reduce the appearance of vibration.

Video:

In addition, this technology is the best solution for arranging heated floors (including water).

And of course - another undoubted advantage of a concrete floating screed is the fact that it is quite possible to do it yourself!

The main thing is to choose the right materials and strictly comply with all technological requirements for this type of work.