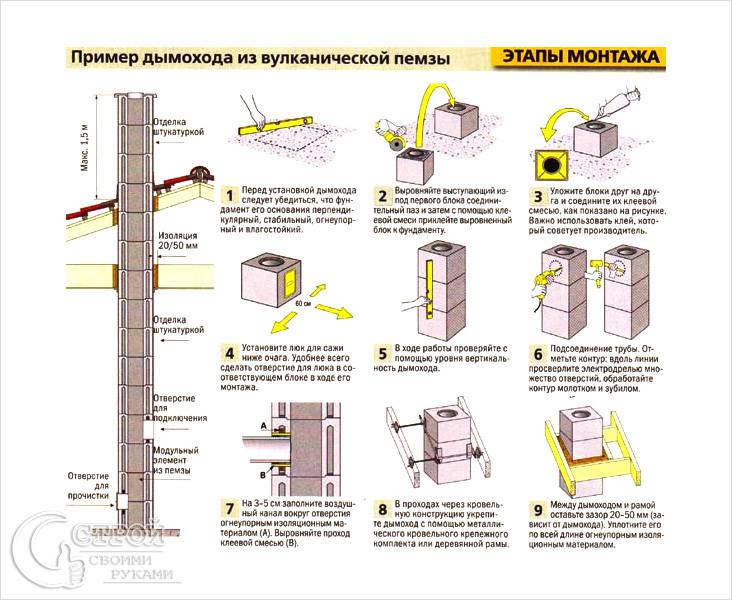

Important points when installing a chimney with your own hands

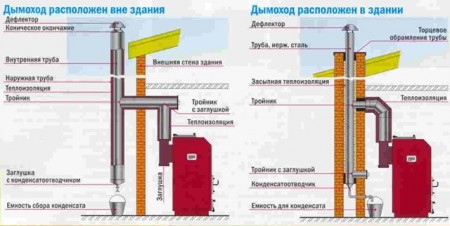

The products of combustion passing through the chimney have a high temperature. And the section of the wall passing next to the chimney gets very hot and can even catch fire. Therefore, internal chimneys should not be installed in walls made of flammable building materials. These systems are also not recommended for powerful boilers.

An external chimney is installed in industrial enterprises with large heating systems. It is customary to install them on an area of a heated room over 600 square meters. Such a chimney is also mounted if the installation of an internal chimney is fraught with a number of difficulties. For example, in a room with concrete floors and walls, it will be easier to break through the slab than to gouge a channel in the wall.

Installation of stainless steel and cast iron chimneys

Installation can be divided into several stages:

- Preparation of the channel for the chimney;

- Chimney installation;

- Installation of insulation around the pipe.

The channel for a metal pipe must be made several times larger than its diameter. To leave room for insulating material.

Chimney installation

Before installing the chimney, all pipes must be adjusted in length. The resulting design must be placed in a pre-prepared channel. Next, connect a condenser and a stove to the system. The finish is considered to be the installation of the head.

For rigid fixation of the pipe, it is attached to the wall every one and a half meters.

When using a metal pipe, you need to attach it to the ceiling every half a meter. In addition, the mounting holes must be made wider, about two pipe diameters.

Installing cast iron chimney pipes is justified, as such pipes will last much longer. But their installation is associated with certain difficulties. For example, you can cut a cast-iron pipe only with a grinder.

DIY sandwich chimney installation

When installing metal pipes, they are mounted like nesting dolls, and additional fasteners are not required to fix the pipe elbows. The pipe elbows in these chimneys are interconnected using building glue.

Chimney pipes are very sensitive to condensate, so they are not used when installing outdoor chimneys. With the correct installation of a sandwich chimney, the pipe will last up to 60 years.

Self-installation of an external chimney

The optimal material for the external chimney pipe is stainless steel. It is light in weight and works well with simple tools.

To install an external chimney from a stainless pipe, the following is required:

- Punch a hole in the pipe adjacent to the boiler. It should be located half a meter from the top of the heating system;

- Place fasteners on the outer wall at a distance of a meter from each other;

- Connect the chimney inlet to the boiler;

- Pull the bent pipe elbow out of the room;

- Install the capacitor;

- Fix the pipe on the wall;

- Install the chimney cap and its protection.

This completes the installation of the outdoor chimney. We hope that our article will help you deal with the installation and selection of a chimney.

https://youtube.com/watch?v=L4j8Bi2Ns68

https://youtube.com/watch?v=L4j8Bi2Ns68

Payment Methods

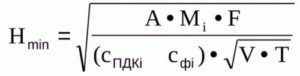

Exact method + formula

Calculate the chimney for the stove, not for beginners. It is better to entrust such work to professionals. But if you decide to calculate this parameter yourself, you will need knowledge of basic data and several formulas:

To determine the cubic capacity of the exhaust gases, it is important to know the power of the heating unit. For calculations, we use the formula:

, where:

- B is the coefficient of the combustion rate of solid fuel. This value is determined based on the data in table No. 10 of GOST 2127;

- V is the level of the volume of fuel burned.This value is indicated on the tag of the industrial device;

- T - the level of heating of exhaust gases at the point of exit from the chimney. For wood stoves - 1500.

- The total area of the chimney. It is calculated based on the ratio of the volumes of gases, this value is denoted by "Vr" and the speed of their movement in the pipeline. For a wood-burning household stove, this number is 2 m / s.

- The diameter of a round pipe is calculated by the formula - d² \u003d (4 * Vr) / (π * W), where W is the speed of gas advance. All calculations are best done on a calculator and carefully enter all values.

Calculate the optimal amount of thrust

This operation is performed to control the calculations of the optimal height and section of the chimney. Such a calculation can be carried out using 2 formulas. We will give a basic but complex one in this chapter, and we will give a basic, simple formula when performing a trial data calculation:

, where:

- C is a constant coefficient equal to 0.034 for wood-burning stoves;

- letter "a" - the value of atmospheric pressure. The value of natural pressure in the chimney - 4 Pa;

- the height of the chimney is indicated by the letter "h".

- Т0 is the average level of atmospheric temperatures;

- Ti - the value of heating of the exhaust gases when they exit the pipe.

An example of calculating the cross section of a chimney

We take as a basis:

- the potbelly stove runs on solid fuel;

- within 60 minutes, up to 10 kg of hardwood firewood burns in the oven;

- fuel moisture level - up to 25%.

Here is the basic formula again:

We carry out the calculation in several stages:

- We perform the action in brackets - 1 + 150/273. After calculations, we get the number 1.55.

- We determine the cubic capacity of the outgoing gases - Vr \u003d (10 * 10 * 1.55) / 3600. After calculations, we obtain a volume equal to 0.043 m3 / s.

- The area of the chimney pipe is (4 * 0.043) / 3.14 * 2. The calculation gives a value - 0.027 m2.

- We take the square root of the area of the chimney and calculate its diameter. It is equal to 165 mm.

Now we determine the thrust value using a simple formula:

- According to the power calculation formula, we calculate this value - 10 * 3300 * 1.16. this value is - 32.28 kW.

- We calculate the level of heat loss per meter of pipe. 0.34*0.196=1.730.

- The level of gas heating at the exit from the pipe. 150-(1.73*3)=144.80.

- Atmospheric pressure of the gas in the chimney. 3*(1.2932-0.8452)=1.34 m/sec.

Important! Using the data of your furnace, you can independently perform the calculation, but for safety, it is better to consult with specialists. The safety of your home and the efficiency of the operation of heating devices depend on the correct calculation.

Swedish calculation method

The size of the chimney for the stove can also be done using this method, but the main purpose of the Swedish method is to calculate the chimneys of fireplaces with an open firebox.

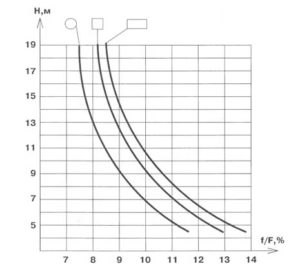

In this method, the size of the combustion chamber and the volume of air in it are not used for calculation. To determine the correctness of the calculation, a graph is used:

Here it is important to match the ratio of the area of the combustion chamber (“F”) and the opening of the flue pipe (“f”). For example:

- furnace dimensions 770/350 mm. We calculate the area of the compartment - 7.7 * 3.5 \u003d 26.95 m2;

- chimney size 260/130 mm, pipe area - 2.6 * 1.3 = 3.38 m2;

- calculate the ratio. (338/2695)*100=12.5%.

- we look at the value of 12.5 at the bottom of the table and we see that the calculation of the length and diameter is correct. For our furnace it is necessary to build a chimney, 5 m high.

Let's look at another calculation example:

- furnace 800/500 mm, its area - 40 m2;

- chimney section 200/200 mm, area 4 m2;

- we calculate the ratio (400/4000)*100=10%.

- according to the table we determine the length of the chimney. In our case, for a round sandwich pipe, it should be 7 m.

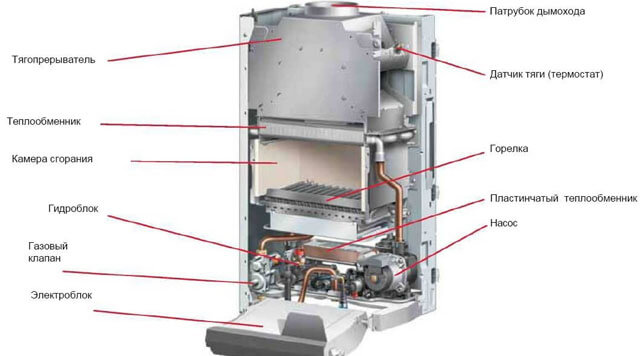

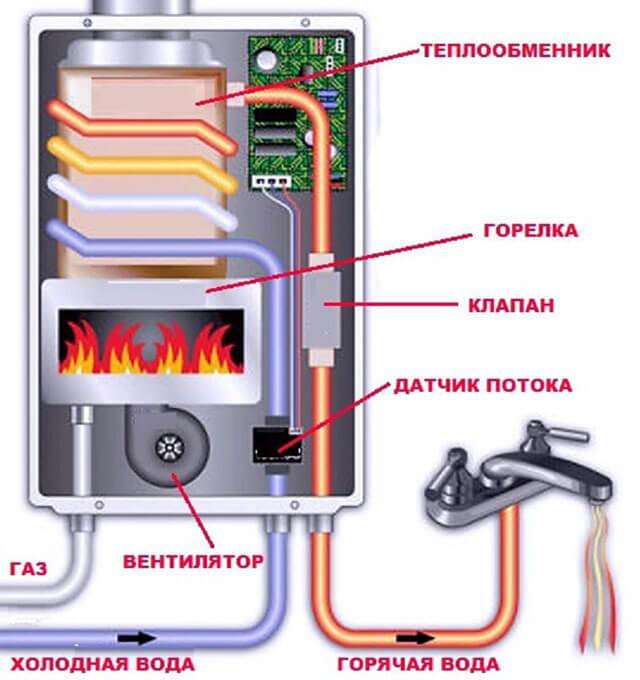

The principle of operation of a chimney column

A geyser that is not equipped with a chimney allows you to heat water using the energy generated during the combustion of gas. In the future, heated water can be used for any purpose - hot water supply carries a lot of functions. For operation of the device, both main and bottled gas can be used.

A characteristic feature of chimneyless devices is the method of output of combustion products. The combustion chamber in such water heaters is hermetically sealed, and a coaxial chimney is used to remove exhaust gases, which is led outside through the wall. Removal of combustion products is carried out by a fan, originally built into the heater.The supply of oxygen necessary for combustion is carried out through the outer part of the chimney.

A gas water heater without a chimney, due to its design, is great for rooms that do not have a chimney. To ensure the connection of the device with the atmosphere, it is only necessary to make a hole in the wall and insert a coaxial chimney into it.

The positive aspect associated with the use of chimneyless heaters is the fact that they do not burn out oxygen in the room and do not require forced air intake from the street. In addition, you can save a lot on the installation of such devices - a traditional full-fledged chimney is very expensive, and there are many difficulties in installing it.

When choosing a chimneyless gas column, you need to pay attention to several characteristics:

- Power of the gas water heater;

- Correspondence of power to the specific operating conditions of the device;

- Water heater performance;

- Type of burner and ignition;

- Degree of security.

Power and performance of a chimneyless geyser

The power of a gas water heater is the most important indicator that directly affects the efficiency of the device and its capabilities. For example, in flow devices, power is required to fully heat the water flow. The power of devices is traditionally measured in watts (kW), regardless of the type of fuel used. However, in this article we are talking only about gas devices.

Performance is also a very important parameter of any water heater. This parameter, always displayed in the documentation for the device, displays the amount of water that an instantaneous gas water heater without a chimney can heat in one minute, depending on the temperature.

It is worth considering a couple of examples:

- The documentation indicates that the performance of the device at a temperature of 25 degrees is 13 liters per minute. This means that such a water heater in one minute heats 13 liters of water to a temperature exceeding the input by 25 degrees, i.e. if initially the water had a temperature of 10 degrees, then in the heater it will heat up to 35 degrees.

- If the flow rate of DHW at 50 degrees is 6 liters per minute, then the calculation looks exactly the same as in the previous case. The relationship between these parameters is very simple and clear, so there are no special problems with them.

Homemade stoves

Gas heater 4.2 kW

One of the above disadvantages of gas-fired dacha stoves is the high cost of equipment. If you have building and engineering skills, you can try to get around this minus by redoing an ordinary brick wood-burning stove. In general, the modification is quite simple. A burner is installed in the furnace and the design of the chimney changes. Unlike a wood-burning stove, such a stove is already capable of operating continuously, maintaining a constant comfortable temperature.

Installation of an automation kit allows you to get an autonomous heater in the full sense of the word. In the absence of traction, an increase in temperature, or a cutoff in the gas supply, the sensors are triggered, and the automation simply turns off the furnace. What is the catch of homemade stoves? In the complexity of the conversion of the chimney. In order to make it technically possible to connect gas, it is necessary to create a system for the removal of combustion products that meets the requirements of the gas service. Whether it is worth doing such a difficult job, if the question concerns heating a summer residence with seasonal residence, it is up to its owner to decide. As practice shows, for such houses a ready-made model of a gas stove will be a good choice.

Chimney pipes

The device of the chimney is quite simple, it involves the use of special pipes for this, through which polluted air or combustion products are removed outside the room.

Pipes are:

- brick,

- metal,

- ceramic,

- polymeric.

Distinctive features of a brick chimney

Despite the fact that today there are a very large number of materials that can be used to build a chimney, brick chimneys have been very popular for many years.

This type of chimney has its advantages. It cannot be plastered inside, which will help save on finishing materials. It is also worth considering that the masonry of a brick chimney should have a seam of 1 cm. If it is recommended to use cement-lime or lime mortar indoors, then in the upper part of the building you can already use ordinary concrete mix for masonry.

Advice. In order to use a brick chimney in the house, it is necessary to make a more powerful foundation of the building - the brick will add an extra load to the walls of the building and to its foundation.

In addition to the advantages, there are also a number of design flaws. Brick due to its rough surface can accumulate dirt. That is why such a pipe becomes clogged with soot very quickly.

Since combustion products exit through the brick chimney, oxygen condensate is formed, from which the brick pipe is subject to destruction. It happens that a piece of brick breaks off and falls into the pipe. All this can significantly narrow the chimney channel and make it difficult for air masses to escape.

Ceramic structures

Ceramic pipes are ready-made structures for the construction of a chimney. They are sold in modular design. Its inner tube is made of acid-resistant, heat-resistant and durable ceramic.

Ceramic chimney pipes have a number of advantages and have a very smooth surface. Due to this, soot is not collected on it, which is formed as a result of the passage of polluted air masses formed during the combustion process.

Like brick chimneys, ceramic chimneys are quite heavy. It is for this reason that it is worth using the foundation for the structure.

Types of chimneys

To date, there are two types of chimney structures: a structure located inside the building and a chimney outside the house. They differ not only in the materials from which they can be built, but also in size and types.

Usually, in order to build a chimney inside the house, brick or ceramic pipes are used. On the street, it is more rational to use metal chimneys, as they are resistant to temperature extremes and are not exposed to moisture.

The chimney inside the house can also be done in two ways, this is in the video

https://youtube.com/watch?v=U9_9A-wIkVQ

https://youtube.com/watch?v=U9_9A-wIkVQ

Sources

- http://teploguru.ru/pechi/pechi-bez-dymoxoda.html

- http://StroySvoimiRukami.ru/truba-dlya-pechi-svoimi-rukami/

- http://DomSdelat.ru/otoplenie/ustanovka-dymoxoda-v-dome-svoimi-rukami-sovety.html

- https://pechnoy.guru/pechi/izgotovlenie-pechi/dymohod/diametr-dymohoda-dlya-pechi-na-drovah.html

- https://9dach.ru/obogrev/276-pechi-dlya-dachi

- https://Proekt-sam.ru/proektsistem/dymoxod-v-chastnom-dome.html

What should be the height of the chimney pipe for the furnace

The calculation of this parameter allows you to avoid the occurrence of reverse thrust and other possible troubles. This issue is regulated by the rules of SNiP and other documents.

Why is this parameter needed?

In order to understand the importance of this factor, let's take a closer look at several physical laws and the consequences of improperly made chimneys. As heated gases pass, the temperature drops, but warm air or gases always rise.

At the outlet of the pipe, the temperature decreases even more. Exhaust gases located in a pipeline with a reliable layer of thermal insulation have a high temperature and a column of heated smoke, rising, increases draft in the furnace.

Let's analyze the situation - we reduce the internal section of the pipe and increase the height of the pipe above the roof ridge. If you think that the volume of heated gas increases, the cooling time of the smoke increases and the thrust increases - this statement is only half true. Traction will be excellent, even with a large excess. Firewood will burn quickly and the cost of buying fuel will increase.

An excessive increase in the height of the chimney can cause an increase in aerodynamic turbulence and a decrease in the draft level. This is fraught with the occurrence of reverse thrust and the release of smoke into the living quarters.

SNiP requirements

The length of exhaust gas exhaust pipelines is regulated by the requirements of SNiP 2.04.05. the rules prescribe to observe several basic installation rules:

- the minimum distance from the grate in the furnace to the protective canopy on the roof is 5000 mm. Height above the flat roof covering level 500 mm;

- the height of the pipe above the roof slope or ridge should be as recommended. We will talk about this in a separate chapter;

- if there are buildings on a flat roof, the pipe should be higher. In this case, with a high pipe height, it is unfastened with wire or cable extensions;

- if the building is equipped with a ventilation system, their height should not exceed the cap of the flue gas outlet pipe.

Self-calculation technique

How to independently calculate the height of the smoke channel, for this you will need to calculate according to the formula:

, where:

- "A" - climatic and weather conditions in the region. For the north, this coefficient is 160. You can find the value in other areas on the Internet;

- "Mi" - the mass of gases passing through the chimney in a certain time. This value can be found in the documentation of your heater;

- "F" - the time of settling of ash and other waste on the walls of the chimney. For wood stoves, the coefficient is 25, for electrical units - 1;

- "Spdki", "Sfi" - the level of concentration of substances in the exhaust gas;

- "V" - the level of the volume of exhaust gases;

- "T" - the temperature difference between the air entering from the atmosphere and the exhaust gases.

Important! Self-calculation will require finding a large number of quantities and performing complex calculations. Therefore, we recommend contacting professionals

It makes no sense to give a trial calculation - the coefficients and other values \u200b\u200bare not suitable for your unit, and extracting square roots will require you to download an engineering calculator.

Pipe material

It is worth choosing from what the pipe for the furnace will be created from four non-combustible options - these are brick, metal (steel), concrete or modules with ceramic cores.

Most often, until now, the owners of furnaces prefer to arrange brick-mounted pipes, which, in turn, consist of the following elements:

- the neck is the part of the pipe between the furnace body and the groove in the thickness of the ceiling;

- cutting - thickening of the pipe in the body of the ceiling;

- a riser is a pipe located in the attic space;

- cutting at the roof (it is also called "otter");

- pipe head.

For the pipe, you will have to use only special high-quality bricks designed for laying heating structures. The solution on which it will be laid must also be heat-resistant and plastic.

Types of energy carriers used

Before proceeding to the choice of a particular furnace model, you should decide on the type of energy that will be used.

In modern conditions, three of the most common are:

- electricity;

- natural gas;

- wood or other solid fuel.

The advantages of the first two are obvious - they can work without a chimney. However, the use of electricity is quite expensive, and the use of natural gas requires the availability of an appropriate centralized engineering network in the summer cottage.

Electric heaters - a compact and convenient option for a block container

In addition, in this case, you will depend on the uninterrupted functioning of utility networks. For example, in the event of a power outage, the electric oven will not work. Only renting a diesel generator for a summer residence will help out.

As an alternative, the following coolants are widely used:

- pallets - granules, for the manufacture of which wood pulp is left as waste in furniture or other similar production;

- Biofuel is a gas created as a result of the processing of biological materials.

Photo of a wood-burning stove for a country house

There are other options, but their use for country houses is irrational and expensive.

After all, a compact stove for a summer residence should have the following advantages:

- economy;

- ease of operation.

When choosing a model, you should focus on the fuel that is most common and cheapest in your area. If the country house is not intended for year-round use, it is advisable to choose inexpensive models designed for the use of solid fuels.

As for the rest of the factors, it all depends on your individual preferences and needs.

Foreign and domestic manufacturers offer many options:

- huge and small;

- expensive and not so;

- standard and refined.

For special connoisseurs, there is even a stove for giving with a stove bench, which perfectly complements the interior of the house, made in the old Russian style.

Russian stove with a bench - for true connoisseurs

Self-made oven

A stove-maker is a very respected and responsible construction profession. They have always been revered in Russia.

No structure is subject to such high requirements as a stone oven, because if it heats poorly, or smokes heavily, life in the house will become unbearable. And the necessary experience and skills can be acquired only with experience, including unsuccessful ones.

If you decide to do all the work yourself, you should carefully and painstakingly study all available sources of information. It is better to choose the simplest project for implementation. But even in this case, no one can guarantee that the stove will be folded correctly and nothing will have to be redone.

Laying a furnace is a complex and responsible process, but doable

But if you have such a quality as perseverance and have a lot of free time, you can save a lot on building a furnace.

Gas fireplace for a summer residence

Gas fireplaces for summer cottages have a high efficiency, up to 85% and a power of up to 15 kW, which means that fuel is not wasted, but high-quality space heating is performed. With this power, you can heat a house of 150 square meters; for small buildings, you can choose a fireplace with a power of up to 6 kW.

The fuel is environmentally friendly, after combustion, steam and carbon dioxide are released into the open air, since the decor elements are not combustible and do not emit toxic substances.

The gas fireplace consists of a steel or cast-iron firebox, it can be open and closed, in the first case, the design is installed away from objects that can catch fire. In the second case, the firebox is closed with a special glass that is resistant to fire. Inside there is a burner, from which fire is supplied to decorative elements, artificial coals or firewood. In the same part is the ignition device. On the outside there is a control panel, you can also change the operating modes of the fireplace using the remote control. The gas fireplace has an automatic control that regulates combustion, special sensors that stop the gas supply in the event of a malfunction, a thermostat that maintains the temperature in the room. Also, the last device can be purchased separately.

Gas burners can be simple, and with infrared radiation, decorative elements are located on top of it.

Gas fireplaces can be placed in the country without a chimney in the classic form. In order to remove the products of combustion, you can use a ventilation pipe made of steel, it has a heat-insulating intermediate part that prevents the accumulation of condensate.

Outdoor fireplaces are placed in gazebos, on open verandas, they do not need a chimney, as combustion products are thrown into the air.

Model selection

Types of furnaces

When the device is to be used for heating only, the area to be heated should be clarified. If you intend to cook food on it, you need to take this into account when choosing. (See also the article Convector heater for giving: features.)

Consider the most common designs.

| View | Description |

| Potbelly stove | Suitable in the case when the heated area is small, and the owners visit the cottage only on short trips. These are very cheap stoves, but they are a safe and effective way to keep the air at a comfortable temperature during the winter. |

| Metal fireplace or stove | Such structures are made of stainless steel or cast iron. The latter option is preferable, as it has a higher efficiency. Fireplaces consume fuel faster, therefore it is more expedient to purchase a stove. The presence of cooking surfaces on it allows you to cook food. The disadvantage is the high price. |

| brick oven | The most effective and fairly inexpensive design, which, with due diligence and skill, is made by hand. It is rare to hear negative reviews about such a furnace. It warms perfectly, accumulating heat inside itself, and also allows you to cook food. |

Modern potbelly stove

Requirements for country stoves

When choosing a model for use in a country house, you should pay attention to the following factors:

- simplicity and ergonomics of its operation in the specific conditions of the suburban area;

- high efficiency, expressed in the ability to quickly heat the room using a small amount of fuel;

- small size, which is important for a cramped room or block container;

- ease of ignition of the firebox as needed - this is especially true when the stove is used for cooking;

- efficiency - maximum heat transfer during the combustion of the selected fuel;

- the possibility of using alternative heat carriers - wood chips, briquettes, pallets, and so on;

- small cost.

Country stove - compactness, versatility and efficiency

In most cases, all these conditions are met by furnaces sold in the domestic distribution network.

Burners for chimney columns

In chimneyless gas water heaters, two types of burners are installed:

- Variables with automatic power adjustment;

- Constants in which power changes in steps.

The step burner makes it possible to adjust the power of the fire, which ultimately affects the temperature regime of the water heater. This solution may seem convenient, but only at first glance. In practice, it often turns out that the temperature of water heating during the operation of the column varies over a fairly wide range.

The degree of heating can be affected by pressure drops in gas, air or water inlet temperature. The latter factor often occurs if the heater was adjusted with warmer water, and then colder water from the street began to enter the system.

When the desired power level is set, the water temperature can be changed by the degree of opening of the tap. However, excessive efforts in this case will not lead to the desired result - if you screw the tap too hard in an attempt to get extremely hot water, you can simply get a completely cold stream. Trying to change the outlet water temperature by mixing cold water from the water supply is strongly discouraged.

Stove without a chimney principle of operation, types, choice

For the first time, stoves without a chimney began to actively appear quite a long time ago - several centuries ago, but then this technology did not take root for several reasons. First of all, this was due to the high complexity of the design and low energy efficiency of the furnace. This parameter was very important, since it was the only source of heat in the house.

There are no restrictions on purchasing heating stoves without a chimney right now. Their installation can be carried out both at the design and construction stage, and at a later time. Be sure that in every dwelling there is a place for a hearth.

Device types

Engineers from various companies successfully cope with the task of creating devices that do not require a chimney. All of them have their own advantages and disadvantages, individual appearance and unique functionality. The cost of such products also plays an important role, since for many people such fireplaces go far beyond the previously allocated budget.

In specialized stores you can find the following types:

- Electrical;

- Ecological (biofuel stoves);

- Wood burning (one caveat - not a chimney is used, but a chimney).

According to the material of manufacture:

- Tiled stoves;

- brick;

- metal devices.

If you have a desire to equip your home quickly and on a budget, then you are guaranteed to choose the right solution among these devices. Everything will depend on financial capabilities and individual preferences.

Excellent stoves for summer cottages without a chimney can be found in a wide range of bifireplaces

These solutions appeared on the wide market relatively recently, but in a short time such models managed to earn the attention of a large number of customers.

The main principle of operation of biofireplaces lies in the use of special fuel that burns without smoke, soot and combustion products. All of its components burn out completely, which was the reason for the name of the fireplace.

The device has a special compartment where a certain amount of fuel is located. The total volume is enough for 5-8 hours of continuous operation, however, more accurate numbers can be obtained in the technical data sheet, as it all depends on the model. In more expensive bio-fireplaces, special reflectors are installed to concentrate thermal energy.

On the territory of the Russian Federation and the CIS countries, the following manufacturers of biofireplaces have received the greatest popularity:

- ZeFire;

- BioKamino;

- Kratky;

- planika;

- Silver Smith;

- wildflame;

- Bioheat.

As you can see, the choice is really great, so take a few hours of your personal time to choose the best heaters without a chimney!

Brick ovens without a chimney

Brick stoves without a chimney are a fantasy for many, however, such designs are still real, however, this imposes serious restrictions on their scope. Due to the high probability of release of combustion products into the surrounding space, such models are installed outdoors: in the garden or near the house.

Such brick and stone stoves are also known as “black sauna stoves”, since during their operation a large amount of burning and soot is formed, which are deposited on the walls of the furnace.

It does not make the slightest sense to clean off such soot, since over time the result will be the same.

Emission reduction is achieved by complete combustion of all components in the furnace under high temperature.

Black baths and stoves for them have been actively used for thousands of years, so modern projects are based on the buildings that were invented by our ancestors.

The most popular types of black saunas are:

- Chum or yurt;

- Semi-dugouts;

- "Vlaznye" pits;

- Old Slavonic "origins".

There are really a lot of options, but most often they create dugouts and their analogues, as they have an authentic appearance and a pleasant atmosphere inside!

Conclusion

There are no difficulties in purchasing and installing a stove without a chimney - it all depends on the available budget and the required functionality. Be sure that an experienced master will be able to realize all your ideas and wishes!

Ignition of a chimneyless geyser

An important component of a gas water heater is the column ignition system. This element affects not only the usability of the device, but also the degree of its security.

In chimneyless gas water heaters, three types of ignition can be installed:

- Electronic;

- Piezo ignition;

- Ignition from a hydraulic turbine.

Devices equipped with an electronic ignition system have one important feature - they do not have to be in standby mode all the time. If it is necessary to ignite the device, a spark is created, the energy for which is taken from the batteries. Ignition is carried out at each opening of the tap, and the rest of the time the system is in an inactive state.

Piezo ignition works due to the piezoelectric effect, i.e. applied mechanical force creates a spark. Unlike the previous design, the operation of the piezoelectric ignition requires a constantly burning igniter, which ensures the operation of the water heater.