Gas heating source

It is not advisable to do the gas version of the heating boiler for three reasons, which are closely related to the features of its operation:

- Firstly, it is very difficult to comply with all the regulatory requirements of GOST, so it is almost impossible to obtain an operating permit from gas service inspectors.

- Secondly, in the premises of certain categories (in particular, in the basement of the house) it is forbidden to install equipment of this class. Thus, in private homes, its use is significantly limited.

- Thirdly, there is a high degree of explosion hazard during the operation of a gas boiler. made by hand.

Solid fuel boilers, wood-fired production

The distinctive qualities of wood-fired heating boilers are an efficiency of 70-80%, as well as a rather uneven calorific value. For firewood, this figure is somewhat lower than for coal, and this feature is taken into account in the process of designing the furnace, depending on the required volume of the calorific effect. Solid fuel boilers of Russian production, as well as solid fuel boilers of Belarusian production, and many others were built on this action. However, boilers of this type cannot operate automatically and require a constant load of fuel (for firewood, this figure is approximately 2-3 hours, for coal - from 6 to 8 hours). It is quite difficult to regulate the combustion process of solid materials, and this negatively affects the ability to maintain the temperature regime at the required level. (See also: Sitemap)

However, it is worth noting that modern Russian-made gas heating boilers are devoid of such shortcomings. Modern models are more reliable, safe and efficient. Maximum energy extraction is ensured by equipping modern boilers with special burners. The smoldering of firewood takes place in the lower section of the firebox, the combustion products undergo final processing in an additional chamber. Heat losses of the equipment due to good thermal insulation are minimal.

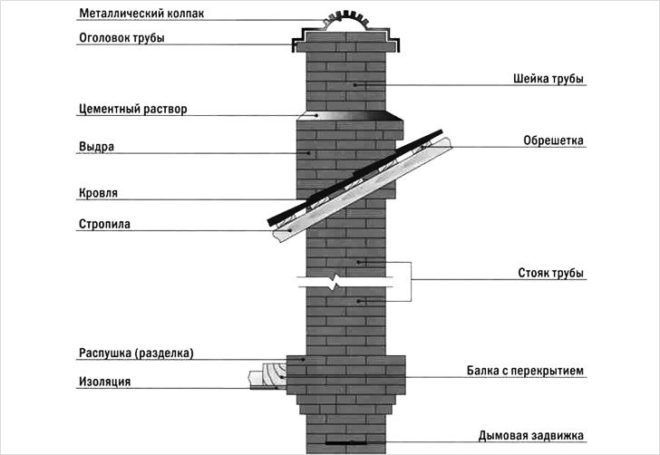

Installing a damper in the chimney

The chimney is easy to build from a pipe or lay out of brick. In the first case, it is necessary to prudently leave a hole for connecting the pipe, in the second case, the specialist continues laying along with the construction of the boiler.

After the masonry has dried, the pipes of the heat exchanger are connected to the pipelines by welding. After installation, it is necessary to test the furnace and establish the operability of the resulting device.

But it is necessary to perform such a test with the condition of sufficient ventilation of the room, if there are deficiencies, the person who checks will maintain his health.

Features of the production of gas boilers in Russia and abroad.

The production of boilers for heating is the main activity of many modern enterprises. In this regard, a fairly wide range of these products is presented on the construction market. Since the production of boilers involves the use of high technologies and the use of many methods for manufacturing parts, a huge variety of models are presented to the attention of buyers, which differ quite a lot from each other in terms of functionality, quality and price. The last factor often has a very significant impact on the choice of our compatriots.

Modern production of gas boilers is aimed at automating the working process of heating equipment. Thanks to this, all products responsible for providing heat in the house can now function independently, that is, with minimal human participation.In the event of an emergency, such equipment is able to notify the owner of the incident itself - sound and light signals will be transmitted to the control room.

The production of gas boilers is considered a fairly profitable business. This is not at all surprising, because a greater number of Russian consumers prefer this product. The reason for such popularity of these devices is that gas boilers have many advantages: they are easy to install, easy to operate, require minimal maintenance, and, thanks to the use of cheap fuel, they are also economical.

The production of heating boilers abroad is quite different from what we have in our country. Therefore, it is simply impractical to purchase foreign products that have a fairly high cost. It is better for compatriots to give preference to products created at Russian factories, because during their development the climatic conditions of our homeland and the design features of heating systems were taken into account. This means that heating boilers. made in Russia, have the maximum adaptation to our situation and will serve here much better than imported counterparts.

Domestic production of heating boilers is aimed at providing heating equipment to owners of suburban real estate and private houses, the total area of which does not exceed three hundred and fifty square meters. Most of the consumers who purchase Russian-made boilers are residents of cities and urban-type settlements with an average income level.

The production of heating boilers is so popular in Russia for another reason. The fact is that gas, which acts as a fuel in these systems, is by far the most common fuel, which, among other advantages, has a low cost and a fairly high efficiency. And since our compatriots are used to benefiting from all their acquisitions, it is not surprising that they give their preference to gas boilers. Due to the high demand for products manufactured by heating appliance factories, these enterprises are flourishing.

As the last argument explaining the popularity of the production of gas boilers, one can cite the problem of constant uninterrupted power supply in our country. The fact is that heating systems that use gas as fuel are completely non-volatile, which means they are able to provide heat to the room, regardless of the availability of electricity. All these characteristics make these devices ideal for domestic consumers.

620026, Yekaterinburg, Belinsky-76 tel. (343)251-66-69, f.269-40-80

STEK Sverdlovsk Heat and Power Company

1. Production of hot water and steam boilers up to 2 MW

2. Reconstruction of existing boiler houses with their transfer to solid fuels

3. Installation of a fluidized bed furnace with a fiery mass and sharp blast for DKVR, KE boilers (replacement of Pomerantsev, Sherstnev furnaces, mine furnace, etc.), in which

– Kiev, Starokievskiy lane, 5, phone (03116)243-48-80/81/86, f.243-48-86

KOMINVEST LLC has been successfully operating in the Ukrainian market since October 1990.

Main activities:

Design, installation and commissioning of boiler houses, individual heating points, pumping stations, heating, water supply, sanitation;

What solid fuel boilers are the best-selling in Russia

Single-circuit household Russian solid fuel boilers for long burning are produced by more than ten different manufacturers. The popularity of products is influenced by several factors:

- Price.

- Reliability.

- Automation of the combustion process.

- Consumer reviews.

If we take into account all these aspects and compare them with the number of sales of heating equipment, we can come to the following conclusions:

- One of the best-selling models among the range of domestic pyrolysis solid fuel heating boilers is Bourgeois-K and Termofor equipment. The models Teplov and F.B.R.Zh. are practically catching up with them in popularity.

- The main Russian manufacturers of solid fuel boilers are constantly releasing new modifications with an improved design, so the popularity rating is constantly changing.

- In addition to the "premium" series, Russian companies offer "budget" models of heating equipment suitable for country houses.

The rating of domestic solid fuel heating boilers is constantly changing, but for several years now, the leading positions have been shared by Termofor, Teplodar and Bourgeois-K.

What brand of domestic solid fuel boiler is better to choose

The choice of a solid fuel heating boiler from a domestic manufacturer is best based not on a specific manufacturer (although this factor also matters), but on the operating parameters and technical characteristics of the equipment:

For country and country houses, models with a hob are optimal

The best choice would be the Kupper OK (Teplodar) and Tashkent (Termofor) models.

Heating of large areas should be entrusted to the heating equipment of Gazgen and Geyser.

If you want to save money and purchase a cheap boiler with good thermal characteristics, you can pay attention to the "anti-crisis" offer from the Termofor company. Prices for models of heating equipment in this category of goods were reduced by using structural steel instead of stainless steel in the production of the heat exchanger.

If the necessary criterion for the operation of the boiler is autonomy and safety, Lavoro models are optimal

A good choice would be the boiler Bourgeois-K and Pragmatik (Termofor).

There are positive trends associated with the production of solid fuel boilers in Russia

The domestic manufacturer began to pay more and more attention to the quality of manufactured equipment, comfort and safety of operation. Leading companies focus on reducing the cost of their products, without a significant loss in quality and service life.

All equipment manufactured in Russia undergoes mandatory certification and receives a permit for operation in Rostekhnadzor.

What is the difference between imported solid fuel boilers and Russian ones

Comparative characteristics of domestic and imported solid fuel boilers help to understand the main difference between the products of Western and Russian manufacturers.

Thanks to more than half a century of history, some European companies, the production process has been worked out almost to perfection. The service life of the Buderus, Wiesmann, OPOP and Atmos boilers is approximately 20-25 years (for models with a steel heat exchanger) and 35-50 years (with a cast-iron structure).

Russian boilers will work less. The advantage of domestic equipment is unpretentiousness to the quality of the fuel used. Gas-generating models are able to use firewood and wood waste with a moisture content of up to 41%. There are Russian boilers, almost two times cheaper.

As statistics show, the share of solid fuel units of Russian manufacturers is only 30-40% of the total number of purchased products. The main number of sales falls on boilers of well-known German and Czech brands.

Design features of digesters

Cooker, universal

digester, digester is a two- or three-layer

tank in vacuum or atmospheric design, vertical or

horizontal types, from food stainless or carbon steels,

mounted on a rigid frame or on adjustable legs with tilt function

or without a brewing vessel, with a welded, removable or lifting lid, with a jacket

for steam, water, oil, glycerin and can be equipped with low-speed and

high-speed mixers of various types and configurations: frame type with

fluoroplastic scrapers, scraper, paddle, anchor, high-speed type

cutter, squirrel wheel, etc. Cooking kettles, cooking kettles, cooking kettles

equipped with automatic or program control panels with

using TOUCH-panels to automate processes

product preparation.

There are four main types of product heating: 1-Steam heating.

2-Electric. 3-Gas. 4-Combined (Electricity + steam).

You can buy a digester at

pre-agreed options, dimensions and performance. Despite

on the demand for digesters, the price of a digester is always negotiable due to

cost unpredictability.

Solid fuel heating boilers

For one reason or another, all of the above types of boilers are not entirely suitable for making them yourself. The only option left is a solid fuel boiler unit. Wood is used as fuel. The fuel burns quickly and, with a high efficiency at the beginning of combustion, does not provide long-term energy production. But even here you can find a way out. Consider a couple of options for solid fuel boilers with the maximum percentage of its combustion.

Pyrolysis boilers or pellet boilers are great for domestic purposes and are easy to install at home.

Such options for do-it-yourself heaters make it possible to simplify many operations for tying heating boilers and make it possible to equip them with an emergency shutdown system that works when overheated.

Pyrolysis heating source

Scheme of a liquid fuel burner.

A pyrolysis-type heating boiler is designed specifically for burning firewood, it is also called a gas-generating boiler. The principle of operation of the boiler is based on the fact that the firewood itself and the combustible substances that they contain are separated during the combustion process. The pyrolysis process allows the boilers to provide the required temperature of the coolant for a long period of time (up to 10 hours) with one portion of the firewood.

To make a pyrolysis heating boiler with your own hands, you need to stock up on a set of equipment for welding and the following materials:

- sheet steel 4-6 mm thick;

- sheet asbestos;

- cast iron sheet 10 mm thick;

- a piece of steel pipe 4 mm thick;

- grate (according to the size of the combustion chamber);

- sealing cord;

- as well as electrodes and automation.

When constructing a pyrolysis boiler with your own hands, you need to organize forced draft, which supports the combustion process. To create it, you can use a low-power centrifugal fan. Also, a pyrolysis-type boiler needs a large volume water tank (about 500 liters). The working volume can be 1700x750x1500 mm, and in terms of power you get a 50 kW unit. These parameters are considered as a starting point, but it is possible to manufacture a boiler of various sizes, depending on the needs of the operation.

Pellet heating source

The pellet boiler is well improved and automated in terms of operation and maintenance. His work is based on the use of pellets as an energy carrier. Pellets are wood pellets of a special type, which are made from wood waste (sawdust and shavings). Since these wood pellets are a bulk material, they make it possible to organize their supply to the furnace using an automatic screw mode or self-loading through the gates from the bunker.

Self-production of a heating boiler of this type is difficult because you need to have a certain amount of electrical equipment with you. For example, electric motors that ensure the operation of the auger and automation of the shutter.

A heating pellet boiler will appeal to those who do not want to approach it often in order to melt or throw up fuel. The duration of continuous operation of the boiler depends on the capacity of its bunker.

By reducing or increasing the supply of pellets to the furnace, it is possible to regulate the amount of heat generated by the boiler. Thus, if it is necessary to increase the temperature, the supply of pellets is increased, and vice versa.

Both solid fuel boiler units have been tested by amateur craftsmen in practice. Choose a suitable boiler for yourself and build it with your own hands under the power of everyone. It all depends on the ability to use one or another type of fuel, the need for heat and the desire to make a heating source.

The heating boiler is the main component of any water heating system. That is why the production of heating boilers is a responsible task, the solution of which requires taking into account all the fundamental laws, one way or another related to the design of the house, the purpose of the equipment. To take into account all the necessary requirements and provide the client with the highest quality reliable products - this is the goal pursued by modern boiler manufacturers.

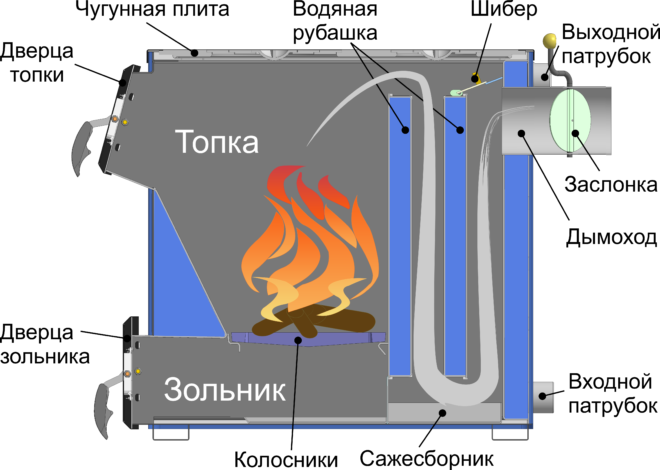

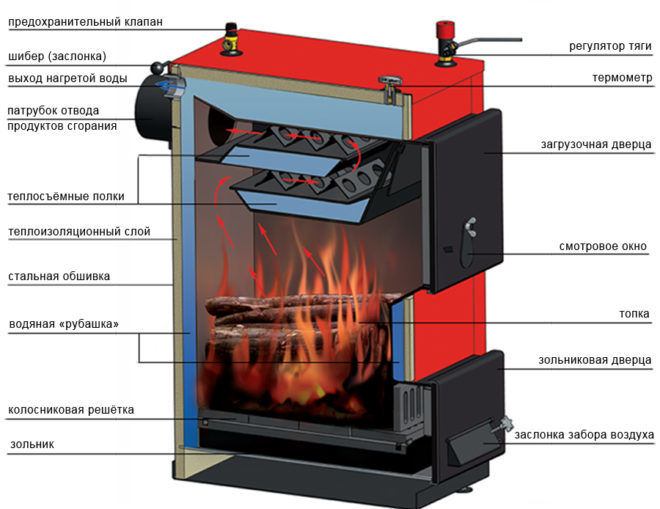

The main elements of the unit

The central part of the heating boiler is the furnace, inside which the temperature sometimes exceeds 1,000 degrees. To assemble the equipment, you will need to select the appropriate heat-resistant materials.

Boiler body manufacturing

If heat-resistant steel was not at hand, then some craftsmen advise taking a regular sheet and making double walls out of it. With the help of a grinder, all the walls of the firebox are cut out, except for the top cover.

According to the drawing, all patterns of parts must be transferred to the metal using a tape measure. Stiffening ribs are cut out of the steel profile, a steel corner is cut to reinforce the joints of the boiler parts.

In the cut sheet, but the front part, a hole is cut under the stove door. To avoid damage to the sheet, you need to make small holes in the corners with an electric drill and a grinder to make perpendicular cuts.

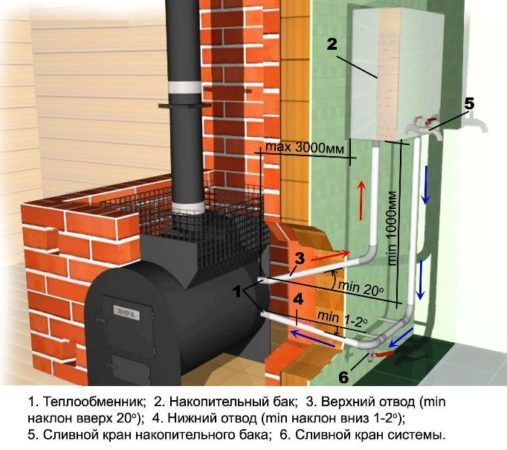

Creation of water tanks, heat exchanger

Two water tanks are welded from rectangular sheets of stainless steel. A heat exchanger is welded from a set of pipes, with the obligatory condition to create a maximum flow cycle. Due to the increased area, the effect of heat exchange between the fuel and the coolant is enhanced.

Domestic manufacturers of solid fuel boilers

The principle of operation and design of domestic and foreign boilers are almost identical. Regardless of the manufacturer, the scheme of operation of solid fuel units is the same. The difference lies in the thoughtfulness and smoothness of the combustion process.

The highest quality Russian-made solid fuel boilers are made of cast iron. But, in most cases, for the production of a heat exchanger, high-quality stainless steel is used.

The entire range of products of domestic manufacturers can be divided according to the following criteria:

- Combustion principle - Russian-made solid fuel boilers are manufactured in classic and pyrolysis versions.

-

Automation - heat generators are equipped with mechanical draft regulators. The latest models of the Teplodar, Termofor, Medved companies are offered with automation that makes the operation of the boilers as autonomous as possible.

- The design of the combustion chamber - the consumer is offered boilers with top and bottom loading. One of the most popular solutions is a shaft-type heat generator.These models are unpretentious to the quality of fuel, it is allowed to use firewood with a moisture content of up to 42%.

-

Fuel - most manufacturers produce single-fuel and universal models. So, two-furnace boilers Phantom, from the company F.B.R.Zh., are absolutely omnivorous. By means of built-in automation, the combustion mode is selected, which is optimal for each type of fuel. It is allowed to use coal, wood waste, fuel briquettes, etc. in the work. The same characteristics distinguish the Trajan models.

- The heat exchanger material is Russian-made cast-iron solid fuel heating boilers, which are practically not produced. The domestic manufacturer focuses on the manufacture of cheaper models from structural or stainless steel. There is a partial complete set of cast-iron inserts: grate and hob.

- Power - high power boilers are represented by the Gasgen and Geyser models. Low power boilers, you can choose from the series Bourgeois-K, Teplov, etc.

- Equipment - heat generators offered by Lavoro are assembled according to Italian technology. Automation and some of the most important components are supplied from the factories of partner Lavoro, located in Italy.

- Equipment with a tubular heater - in the configuration of the best boilers of the latest development, a built-in heating element is provided. The automation that controls the combustion process, after the combustion of the main fuel, gives a signal to turn on the electric heater. The house is heated with electricity. This function is provided in the products of Bastion, Termofor, etc.

Domestic companies have almost completely abandoned the use of cast-iron heat exchangers, therefore, the buyer is mainly offered Russian-made steel pyrolysis solid fuel boilers.

Technology Secrets

You need to understand that a do-it-yourself solid fuel boiler is a stove installed in a container of water.

The task of the mechanism is to heat the water circulating through the heating radiators due to the combustion of fuel. But the simplest design of the boiler will be ineffective, so it is necessary to work out the drawing of the boiler and the ventilation scheme in advance.

The standard design involves the construction of a firebox with grates for the required air ventilation, a chimney, a damper system for regulating air draft and a tank that heats water.

The standard design includes the following elements:

- The furnace, equipped with grates, maintains the required volume of air inside the boiler.

- Robust tank for the accumulation of hot water in the system.

- Chimney for the removal of carbon monoxide by creating traction.

Automatic fuel supply and its features

Automatic fuel supply to the boiler is also one of the functions that are typical for modern solid fuel boilers. The design includes such elements as the boiler itself, the burner, the blower fan and the automatic fuel supply mechanism. Pellets (pressed wood waste) are most often used as fuel in such equipment. A significant advantage of this type of fuel is its high environmental friendliness and the absence of any chemical additives in them. If the boiler capacity is about 150 liters, the fuel can be enough for about two days of continuous operation (more accurate data depends on the parameters of the outside air).

No less common is the use of both the main and reserve (or additional) type of fuel. Knowing both types of fuel is essential in order to avoid many equipment problems. Additionally, you can take care to purchase a Russian-made gas floor boiler.Designed taking into account domestic weather conditions, they are able to work smoothly in almost any region of Russia. An essential advantage of such equipment is complete independence from electricity. (See also: Voltage stabilizers for gas boilers)

Production of solid fuel boilers and its features

Solid fuel heating equipment is designed specifically to perform the most effective work in areas where gasification is difficult, as well as where there are interruptions in the delivery of liquid fuel and electricity. Currently, it is solid fuel boilers that own at least 20% of the market for heating appliances and other equipment. The main consumers of such goods are residents of private sectors who require equipment with a capacity of no more than 30-100 kW. Despite the fact that the use of liquid fuel boilers allows you to get a much higher efficiency and leaves behind much less harmful substances, in this case the use of solid fuel boilers is much more justified. (See also: Advantages and disadvantages of mounted gas boilers)

To ensure the operation of solid fuel boilers, wood chips, coke, firewood, coal, pellets, as well as peat briquettes are used. Gas-fired boilers can also run on gas emitted from the fuel. This is due to the fact that air penetrates into the bunker containing glowing coals, as a result of which a saturated combustible gas is formed. After this gas passes through the nozzle and mixes with air, the gas-air mixture thus formed comes into contact with the steam generator and ignites in the area of the combustion chamber of the heating boiler.

The production of solid fuel boilers of this type allows the buyer to enjoy a number of advantages. Pyrolysis boilers have a wide range of power regulation, significant efficiency, reaching 85%, as well as combustion of fuel materials, leaving a minimum amount of ash and soot. The flue gases emitted by such a heating boiler practically do not contain toxic impurities. However, it is worth noting that the dependence of pyrolysis boilers on electricity is quite high.

Assembly of equipment and its features

It must be borne in mind that when assembled, a home-made boiler has a huge weight, so it will be more prudent to assemble it immediately in the boiler room.

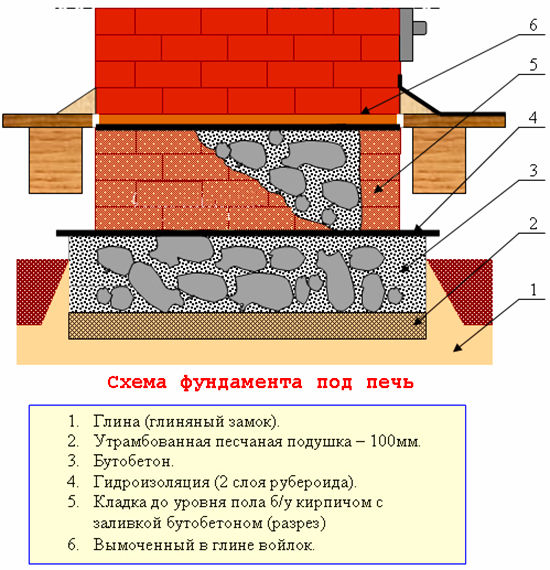

Before installation, a foundation of heat-resistant brick is laid out. The bottom of the ash pan is placed on the leveled masonry, vertical racks welded together are placed on the sides. Housing guides are installed, grates are placed on them. The stiffeners are welded on the outside of the boiler.

After that, it remains to weld the walls and the upper part of the boiler equipment. Sifted river sand is poured between the walls, it accumulates the resulting heat and prevents the structure from overheating. Water tanks are placed on top, they are connected to the circuits. In the final, it remains only to connect the doors - the boiler can be started.