The principle of operation of the cascade installation

Small boilers, having program control, go through the process of connecting to one system through a coolant. This makes it possible to smoothly and steplessly adjust the power of the entire boiler system. This boiler equipment uses informative technologies that allow you to perfectly control the system during operation.

The system works independently, there is no need for human intervention. Cascade boilers are the answer to user requirements, namely the consumption of heat and hot water.

For example, when installing 10 gas boilers with a power of 80 kW each, the total power will be 800 kW (10 * 80 kW = 800 kW), and the minimum power will be 26 kW (800 * 3.3 / 100 = 26 kW when adjusting the power 40% - 100%).

Advantages of these heating installations:

- the possibility of obtaining power up to 1mW;

- dispatching;

- non-polluting equipment is an important environmental aspect;

- financial attractiveness;

- savings in use;

- full autonomy;

- placement anywhere (roof, room, extension);

- quick installation of prepared equipment and installations;

- long service life;

- lack of construction of large and unaesthetic external thermal routes;

- remote control.

Traditional boiler systems are inferior to the cascade boiler in terms of service life. Achieving such reliability lies in the common work of several units working together and aimed at one common goal. The working system is programmed so that every day the next boiler takes over the launch of all heating equipment: today the first boiler starts work, and tomorrow it will be the last one in the queue list. Therefore, the resource of each boiler is not exhausted.

Connecting boilers to produce hot water, in addition to the main unit, in everyday life is also an advantage of a cascade boiler house. Accordingly, having 10 boilers in the system, 9 boilers can be installed. Even small volumes of each boiler will add up to a huge supply of water.

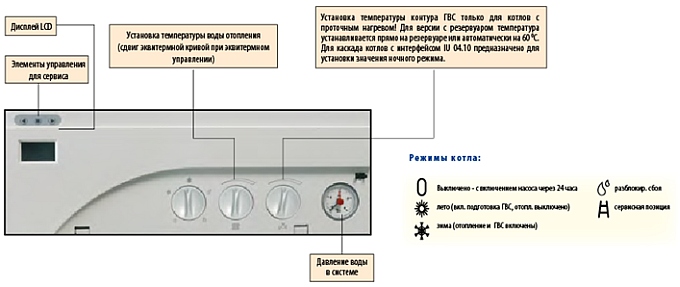

You can place the boiler system anywhere, it doesn’t matter: an attic, a basement, an attached room. The boiler room management software (Figure 2) controls the set temperature for a specific period of time. The required number of units is attracted to maintain the required capacity. An error will not occur, since the "human factor" is absent.

Climate control of the premises is provided completely and autonomously. In case of exceeding the temperature indicators, the program will turn off the system itself and, if necessary, start the air conditioning. With a low temperature indicator, everything is done exactly the opposite. The dispatcher, using a modem, from his own computer will be able to monitor the state of the equipment.

Smoke extraction of a cascade of boilers

The smoke removal of the system depends on the type of gas boilers and is implemented by the following methods:

- Separate coaxial chimneys;

- Separate chimneys of turbocharged boilers;

- Group smoke exhaust with reverse smoke dampers;

- Natural smoke removal - group or individual.

With group smoke removal, no more than 4 boilers are connected to a common chimney. With coaxial collective smoke exhaust, each boiler is equipped with a smoke check valve. It prevents the penetration of smoke into the room when the heat generator is idle.

Chimneys are constructed with a slope of 5 to 10% towards the boilers. When constructing a flue system for boilers with an open combustion chamber, it is necessary to make an aerodynamic calculation of the common chimney to ensure the necessary draft.

Heating circuit with Tichelman loop pros and cons

Two-pipe heating systems of a private house, as a rule, are dead-end systems, which leads to the fact that in the last radiator, due to the greatest distance, the pressure and flow of the coolant are weaker, respectively, the heater heats worse. This problem is solved by increasing the number of sections of radiators or adding regulators to each radiator.

The second solution, which is used when installing two-pipe heating systems for a private house, is balancing the system.

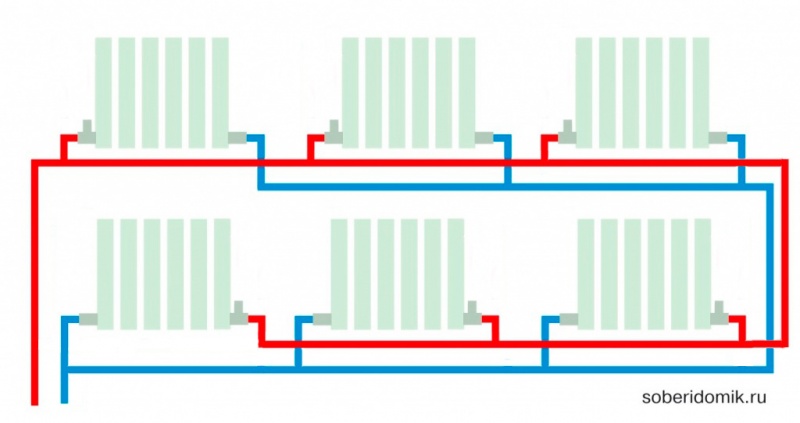

Tichelman's scheme is quite simple. In the classic two-pipe scheme, the return heating main starts from the last radiator and ends with the boiler, and the supply starts from the boiler and ends with the last radiator.

The features of the Tichelman loop are that the “return” starts from the first radiator, reaches the last one and returns to the boiler, and the supply, as in the classical scheme, starts from the boiler and ends with the last radiator.

It turns out that the first radiator from the boiler is the first on the supply and the last on the return, respectively, the last radiator is the last on the supply, but the first on the return.

This is a kind of direct-flow system in which the coolant in the supply and return heating mains moves in the same direction.

This scheme allows you to provide uniform resistance and flow in two-pipe systems.

Advantages and disadvantages of the Albert Tichelmann loop

Two-pipe heating systems of a private house, which were installed according to the Tichelman scheme, have the advantages of direct-flow single-pipe systems (“Leningradka”) and two-pipe systems, as well as a number of additional advantages.

First of all, we note the balance of the system and the absence of the need to install various adjustment equipment, which is quite expensive.

At the same time, the coolant flow throughout the system is the same, and the operation of heat-generating equipment is optimal and has a high efficiency.

The disadvantages of the Tichelman scheme include the need to use additional pipes and preferably a large diameter, and these are additional costs.

Moreover, the architectural features of a private house do not always allow the installation of an open heating system with three pipes. For example, doorways and a number of other architectural forms can interfere with the installation of a heating system of this type.

Therefore, it is not always possible to organize a circular movement of the intermediate coolant in a two-pipe heating system of a private house.

We also note that in most cases, when installing return heating systems of a reversible type according to the Tichelman scheme, horizontal wiring is used.

In terms of other characteristics and the heating equipment and heat generators used, the Tichelman loop does not differ from its two-pipe counterparts.

Features of operation and principle of operation

First you need to emphasize that the whole structure will resemble a simple boiler that is connected to radiators. But in fact, all used nodes have their own characteristics, created just for similar equipment. Just on the basis of this, experts should deal with such an installation if there is a finished project (see also the article “Selection of heating radiators: selection criteria dictated by practice”).

Boiler and its advantages

It is fundamentally important to immediately state that such boilers are among the most economical. Along with this, their price, as equipment, is also relatively small.

Given this, it is believed that such a system will be as efficient as possible and will reduce heating costs.

The principle of operation of this equipment is based on the course of water polarization by means of alternating current

Based on this, the power of the entire system sometimes does not even reach 400 watts.

Special attention should be paid to the fact that for the effective implementation of a similar project, it is required to have an anode made of special technological materials that do not contain either acid or alkali. The same requirement is put forward in fact to the entire highway.

For more efficient water transfer in similar designs, small pumps are used. But besides, if we take into account the additional costs of their operation, then all the same, the savings will not be huge.

Advice! it is better to buy a complete set of the necessary equipment from one manufacturer. This will help to avoid inconsistencies when docking.

Radiators

At the time when anodized heating radiators are mentioned, much more often they mean aluminum products coated with a protective layer by applying the electrolysis method. But right away it must be said that these designs were originally developed just to work with these boilers.

The fact is that the polarization of water is an active process that requires compliance with a whole range of conditions in order to achieve a great result, in particular, the absence of acids, salts and other elements capable of taking part in the reaction.

Taking into account such heating features, an anodized heating radiator was created, which must withstand these reactions and have a sufficient level of heat transfer. It is worth emphasizing that such spraying is also carried out on the outside of the product in order to protect it from external factors.

Special attention should be paid to the fact that there are batteries that have built-in independent electrodes. With this in mind, the finished product is transformed into personal heating systems that can be transferred

But the rhinestone should emphasize that the efficiency of the element is comparable to a simple electric heating element.

Advice! It is fundamentally important to understand that using boilers in order to make it possible to stop worrying about overheating, but this does not mean that it is possible to dismantle the protective valves or filters. If mishandled, in addition, such a system can become unsafe.

Expert advice

Typical installation instructions for such products may seem very simple and fully understandable. But most manufacturers in order to equipment strongly recommend using the services of specialists. Along with this, some of them require the presence of strictly defined masters.

Recently, insulated floors operating on the basis of the same systems have become especially popular. This is a fairly economical option to arrange high-quality indoor heating without resorting to the use of batteries. But the masters advise to combine these designs, creating various contours.

A clear indicator of the quality of the equipment is a huge warranty period

This is especially important if the manufacturer has personal service centers.

https://youtube.com/watch?v=S8gy75gxLz8

Parallel connection of boilers pros and cons

We have considered the main boilers above. Now consider the connection of backup boilers, which should be in the system of any modern home.

If backup boilers are connected in parallel, then this option has its pros and cons.

The advantages of parallel connection of reserve boilers are as follows:

- Each boiler can be connected and disconnected independently from each other.

- You can replace each heat generator with any other equipment. You can experiment with boiler settings.

Cons of parallel connection of backup boilers:

- We will have to work more with boiler piping, solder polypropylene pipes more, weld steel pipes more.

- As a result, more materials, pipes and fittings, and valves will be used.

- The boilers will not be able to work together, in a single system, without the use of additional equipment - hydraulic arrows.

- Even after using the hydraulic arrow, there remains the need for complex adjustment and coordination of such a system of boilers according to the temperature of the water supply to the system, and.

The indicated pros and cons of parallel connection can be applied both to the connection of the main and reserve heat generator, and to the connection of two or more reserve heat generators on any type of fuel.

Operating modes of controllers

Most cascade controllers are capable of operating in at least two operating modes. In heating mode, the weather-compensated control principle is implemented, i.e. the set value for the temperature of the heating medium supplied to the system depends on the outside temperature.

The lower the outside temperature, the higher the flow temperature setpoint. This system eliminates the need for a mixer between the boiler and heating consumers.

In the DHW mode, the system is programmed to control the system when the set value of the supply temperature does not depend on external temperatures. In other words, a certain, sufficiently high temperature value is set, which ensures a high level of heat transfer through the secondary heat exchanger.

This mode is usually used to provide a higher temperature of the heat carrier supplied through the heat exchanger to DHW consumers and anti-icing systems. Boiler power modulation leads to a significant decrease in the differential between the required and actual coolant temperatures, which prevents frequent “clocking” (on / off) of the boiler.

Some controllers are also responsible for the operation of the main circulation pump and are connected to the building's building management system. The modern generation of low-power boilers with modulating burners provides space savings, high efficiency, quiet operation and reliability. This is the ideal solution in low temperature systems; these boilers are ideal for underfloor heating, anti-icing, swimming pool heating, hot water systems, and heat pump systems, including geothermal ones. They have already won a position in the field of heating private houses.

As part of a cascade system, boilers with modulating burners represent a new alternative to industrial heating systems.

During the heating season and the off-season, any heating system tends to have an uneven and often low load on the equipment. This problem needs to be solved, where there is a need for a wide range of adjustment of the heat output of an individual boiler, and a boiler system. But this often leads to a decrease in the effect of the boiler plant, a decrease in efficiency, and an increase in the consumption of combustible raw materials. Cascade boilers (Figure 1) represent the optimal solution to the problem.

Cascade - a connection that involves the connection of small heating units into one system.

Rice. one

Automation of cascade boiler houses

The role of automation tools cannot be overestimated in terms of the convenience of organizing cascade boiler houses, their reliability and efficiency.

It is automation that is responsible for “squeezing out” the maximum efficiency from boilers operating in a cascade, while ensuring the responsiveness of heat generators to signals from consumers.

In modern condensing boilers of industrial series, cascade logic is included in the basic automation and optimized for specific equipment.

The main functions of automation of a cascade boiler house:

-

Collection of requirements from consumers for heat generation and prioritization (DHW, heating, ventilation, etc.)

-

Determination of the optimal mode of operation of each individual boiler to ensure the required power.

-

Ensuring uniform development of the resource of boilers (with the rare exception discussed above).

-

Monitoring of accidents on boilers and signaling about them.

If we talk about the peculiarities of the operation of automation with a cascade of condensing boilers, then it consists in the strategy of turning on and taking the boilers out of the current operation. There are three main strategies:

-

Turn on later, turn off earlier.

In this mode of operation, additional boilers are added to the operation as late as possible with an increase in heat demand, that is, already switched on boilers operate at maximum power. With a decrease in power demand, the boilers are removed from the cascade as early as possible. This strategy ensures the smallest number of simultaneously operating boilers, their operation at maximum power and the shortest operating time of additional boilers.Standard for non-condensing boilers. This is due to the fact that for non-condensing boilers there is a slight decrease in efficiency when operating at reduced modulation.

-

Turn on later, turn off later.

Turning additional boilers on as late as possible, but also turning off as late as possible. It is used when it is necessary to ensure the minimum number of operations for turning on the boiler burners.

-

Turn on earlier, turn off later.

Switching additional boilers on as early as possible with an increase in heat demand and switching off as late as possible with a decrease in heat demand.

It is this control strategy that is used with modern condensing boilers. At the same time, each individual boiler operates at a minimum modulation that ensures the need for heat. The number of operating boilers is maximum. As a result, we get the maximum efficiency of a cascade installation with the most uniform depletion of the boiler resource.

Serial connection of boilers pros and cons

If two or more boilers are connected in series, they will work in the same way as the main boilers connected in cascade. The first boiler will heat the water, the second boiler will heat it up.

In this case, the first thing to do is to put the boiler on the cheapest type of fuel for you. It can be a wood, coal or waste oil boiler. And behind it, any backup boiler can stand in a cascade - even a diesel one, even a pellet one.

The main advantages of parallel connection of boilers:

- In the case of working first, the heat exchangers of the second boiler will play the role of a kind of hydraulic separator, softening the impact on the entire heating system.

- The second backup boiler can be turned on to heat water in the heating system in the coldest days.

Cons when using the parallel method of connecting backup heat generators in the boiler room:

Longer water path through the system with more twists and turns in connections and fittings.

Naturally, it is impossible to directly let the flow from one boiler into the input of another. In this case, you will not be able to disconnect either the first or the second boiler, if necessary.

Although from the point of view of coordinated heating of boiler water, this method will just be the most effective. It can be implemented by installing bypass loops for each boiler.

The main advantages of using boiler cascades

Most of the advantages listed below can be attributed not only to condensing boilers, but we will separately pay attention to what specifically distinguishes this type of equipment within the framework of the relevant topic

Increasing the overall power modulation range

As noted above, the main reason for installing several boilers in a cascade is to increase the maximum capacity of the boiler house while limiting the performance of a single unit.From this point of view, any boilers are, one might say, in an equal position.

At the same time, one should not forget that modern heating systems are subject to increased requirements in terms of energy efficiency. And one of the main principles in ensuring this principle is to ensure that the current power of heat generators is equal to the needs of the system, no more and no less. Accordingly, the lower limit of the boiler capacity modulation also plays an important role. The use of a cascade helps to significantly reduce this boundary. It is also worth remembering that for mid-latitudes most of the year the need for heat is no more than 30-40% of the maximum.

When using identical heat generators in a cascade, the lower power limit is determined simply by dividing the minimum performance of an individual boiler by their number. And here it is easy to see in what a favorable light condensing boilers appear. The minimum modulation for the most modern wall-mounted boilers is approximately 15%. Accordingly, using, for example, four such boilers, we obtain a total stepless modulation range of 4-100%. Moreover, unlike traditional boilers, the efficiency of condensing boilers only increases with a decrease in modulation.

Ensuring a high level of fault tolerance of the boiler room

A fairly obvious advantage. The more boilers in a cascade are used, there is less drop in total power in the event of failure and maintenance of an individual heat generator.

Ease of installation and maintenance of equipment

Regardless of the total capacity of the boiler house, we often face space constraints both during design and installation.

|

From the designer's point of view, the use of a cascade of several boilers allows more flexible use of the available space, especially when using wall-mounted boilers. For most series of industrial wall-mounted boilers, there are ready-made hydraulic solutions for organizing cascades. |

|

The most modern floor-standing condensing boilers also provide for the possibility of compact installation and convenient hydraulic piping. |

Convenience for mounting and servicing organizations lies in the ease of delivery of a separate boiler to the place of direct installation at any stage. This is especially true for rooftop boilers, where, if it is necessary to replace the heat generator (albeit extremely unlikely), its lightness and compactness can play a critical role. In this context, do not forget about the previous paragraph of this section.

Possibility of successive increase in boiler capacity

Increasingly used in recent times, the possibility of distributing investments to different stages of construction.

Cascade solutions allow you to sequentially add capacity to an existing system. Naturally, the hydraulic part should provide for the possibility of such expansion.

Article: Cascade solutions for floor standing boilers HL

Necessary conditions for a modulated cascade

There are three important conditions that must be met when designing a "modulated" cascade system.

Firstly,

line connections and controllers must be implemented in such a way that independent adjustment of the flow circulation through each boiler is possible. Water must not be circulated through a non-operating boiler, otherwise the heat of the heating medium will be dissipated through the heat exchanger or boiler casing.

This also applies to the simple cascade system. Independent adjustment of the heat carrier flow is achieved by equipping each boiler with an individual circulation pump.When installing circulation pumps in parallel, check valves should be installed to prevent the return flow of the coolant through idle boilers downstream of the pumps.

The supply of coolant to each boiler with the help of individual circulation pumps makes it possible to increase the pressure in the heat exchanger of the operating boiler in order to prevent cavitation and explosive vaporization.

Secondly,

The flow and return connections for each boiler must be made in parallel (especially when using condensing boilers).

This allows you to maintain the same water temperature at the inlet to each boiler and, if necessary, to exclude the flow of coolant between the circuits. The low temperature of the coolant supplied to the boiler contributes to condensation water vapor from combustion products and improve system efficiency. Some cascade controllers for boilers with modulating burners are equipped with a “time delay” function, that is, they are able to turn on the circulation pump of a certain boiler shortly before the burner is turned on.

In addition, they can keep the pumps running for some time after the burner has been switched off.

The first ensures that the heat exchanger of the boiler is heated by the warm supplying heat carrier of the system, which prevents thermal shock due to a significant temperature difference (and condensation of flue gases for conventional boilers) when the burner is ignited. The second is to utilize the residual heat of the heat exchanger, and not to remove it through the ventilation system after the end of the boiler operation.

And thirdly,

It is very important that the circulation pumps provide an adequate flow of coolant through the operating boilers, regardless of the flow rate of the heating system. A natural solution to this issue is the use of a low pressure hydraulic separator