Expert answers

Truculentus:

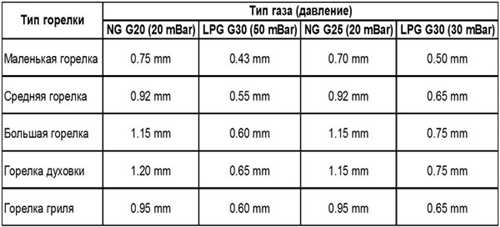

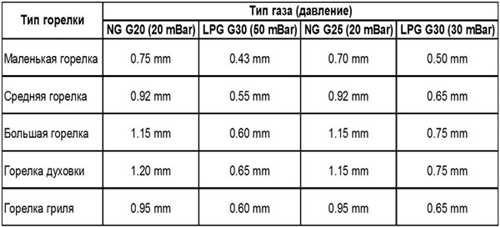

When operating gas stoves, various types of gas are used. The most common is natural gas - NG G20 (20 mBar), it is used in modern domestic gas pipelines. Also, in cases where there is no natural gas supply system, bottled or liquefied gas is still used - LPG G30 (50 mBar). Since the combustion process also occurs differently for different types of gas, when connecting a gas stove, it is necessary to use the appropriate gas nozzles for the burners. The table shows the average jet parameters for most gas stove models.

Anatoly Bondar:

More than on a balloon, and depending on the power of the burner. Or look at the passport, or pick up.

Dmitry dmb:

must be included with the plate

ihojp:

Is it imported or ours (I had it in Indesita) - there are two sets of jets, as a rule, a set is installed for natural (low-pressure main) gas. When working with bottled (liquefied) propane, change.

Josef Schweik:

Those that are indicated in the instructions for the gas stove.

Bear:

You need to watch the jack. If the hole in the jet is with a thick needle or about 0.8 mm, it is natural gas. A hole in the jet for balloon gas with a thin needle or about 0.4 mm.

PLATE on the drum. These burners are sharpened for different types of gas. For balloon holes wider.

Old hunter:

Jets for main gas (thicker hole) with a balloon will be smoked, sets of jets for balloon gas are sold.

Truculentus:

When operating gas stoves, various types of gas are used. The most common is natural gas - NG G20 (20 mBar), it is used in modern domestic gas pipelines. Also, in cases where there is no natural gas supply system, bottled or liquefied gas is still used - LPG G30 (50 mBar). Since the combustion process also occurs differently for different types of gas, when connecting a gas stove, it is necessary to use the appropriate gas nozzles for the burners. The table shows the average parameters of jets for most models of gas stoves.

Online magazine Tips for hosts:

Nothing to the eye. In the burners of the stove there are special "jets" - tiny holes through which gas is supplied. In modern stoves, they are made removable.

As a rule, when purchasing a stove, you also receive a set of jets for different gases as a set. Methane is supplied through pipes in propane (propane-butane) cylinders. When comparing jets, the difference is noticeable. For propane, those where the holes are smaller.

cheeky:

Adjustment for any gas is made by increasing or decreasing air suction - to achieve even combustion without soot.

The Scarlet Flower:

Yes, there is no difference, just to install the stove, call the master from the gas service and he will adjust it as you want. I called 4 years ago, paid only 137 rubles, well, now it will cost somewhere between 200-300 rubles.

Best Answers

Zel:

And what about the pressure? Remember chemistry - the number of molecules in the same volume in different gases is the same. And the heat of combustion of one molecule of butane is greater than that of methane. Therefore, in order for the burner to work normally, less propane-butane should be supplied per unit time; for this, smaller nozzles are placed on bottled gas. And if you leave them, then there will not be enough oxygen, and the burner will start to smoke. And if you lower the pressure, then the rate of gas flow will decrease, it will warm up and the flame will slip inside the burner. So the jets will have to be changed.

vadim dvoeglazou:

in my opinion, it’s not a matter of pressure, but the fact that there is propane butane in the cylinders and natural gas is a slightly different mixture .. accordingly, the combustion temperature is different ... that’s due to jets and compensate for it ... or rather, the amount of gas passed by them

Free wind:

Yes, each stove has its own set for bottled gas, but we (as a rule) do not know how to store them ....

Nozzle oven

The stove nozzles may only be ignited using a torch or igniters.

It is forbidden to ignite the furnace nozzles without first purging the combustion chamber with water vapor. For multi-chamber furnaces, it is allowed to purge the combustion chambers by at least 20 mm, counting from the moment the last valve is opened.

It is allowed to light the stove nozzles only with the use of a torch or an igniter.

It is forbidden to ignite the furnace nozzles without first purging the combustion chamber with water vapor.

It is allowed to light the stove nozzles only with the use of a torch or an igniter.

It is forbidden to ignite the furnace nozzles without first purging the combustion chamber with water vapor. Purging should be carried out for at least 15 minutes after the appearance of steam from the chimney.

It is allowed to ignite the stove nozzles only after pre-purging the combustion chamber with water vapor.

It is forbidden to ignite the furnace nozzles without first purging the combustion chamber with water vapor. Purging should be carried out for at least 15 minutes after the appearance of steam from the chimney.

It is forbidden to ignite the furnace nozzles without first purging the combustion chamber with water vapor. Purging should be carried out for at least 15 minutes from the moment steam appears from the chimney. For multi-chamber furnaces, it is permissible to purge the combustion chambers for at least 20 minutes, counting from the moment the last valve is opened. Ignite the furnace nozzles only with a torch or igniter. When igniting a liquid fuel nozzle, you must first bring the ignited torch to it, then open the steam and air supply, and only then gradually open the valve on the fuel pipeline near the nozzle.

It is forbidden to ignite the furnace nozzles without first purging the combustion chamber with water vapor. Purging should be carried out for at least 15 minutes after the appearance of steam from the chimney.

The ignition of the nozzles of the P-2 furnace is carried out similarly to the ignition of the nozzles of the P-1 furnace of the atmospheric unit. When gas appears in the E-2 tank, the automatic pressure regulator valve is turned on to discharge gas into the fuel network and the pressure in the K-8 column is adjusted to comply with the requirements of the technological map. Upon reaching the temperature of the product at the outlet of the furnaces 130 - 150 C and at the top of the columns K-8, K-3, K-4, K-5, K-11 80 - 110 C, further temperature rise is suspended until the water is completely removed from the system, the first a sign of the removal of which will be a sharp increase in the temperature of the top of the columns at constant temperatures of the exits from the furnace. E-2, E-4, E-5 and E-6 periodically drain the water. After evaporation of water from the system, the irrigation tanks are freed from water, irrigation is given to the top of the columns and the temperatures continue to be raised to those required by the technological map.

Then the furnace nozzles are turned on and, gradually raising the temperature, the installation is transferred to hot gas circulation. At the same time, the section for stabilization of the hydrogenation product is heated. Then, raw materials are taken to the installation and they begin to gradually supply raw materials to the reactors, gradually bringing the supply to normal. In the absence of hydrogen, it is possible to start up the unit on a mixture of raw materials and inert gas at a productivity of 25% of the norm.

Before igniting the burners of a gas-fired stove, it is necessary to check whether the operating and control valves on all burners are tightly closed, whether condensate has been drained from the fuel line, or whether the fuel lily has been purged with gas to the candle or flare line. If for some reason the gas did not ignite or the nozzles went out, it is necessary to close the working valve, blow out the furnace and the gas pipeline leading to the nozzles, and then repeat the ignition of the nozzle.

Before the front of the furnace nozzles, fuel manifolds are laid, in which a constant pressure is maintained by fuel pumps. There should be no stagnant areas in the collectors, which eventually become clogged with dirt.

The area in front of the stove nozzles must be in good condition and kept clean.

Source www.ngpedia.ru