How to properly dry a new brick oven

The whole process should be divided into two stages:

Stage 1 (natural):

We open all the valves in the furnace, windows and doors in the room and leave it for a week, and in wet weather it can be for two. At this time, moisture from the surface layers will evaporate. After 3 days, you can put a lamp with an incandescent lamp in the oven, it will warm the air and help the drying process, and on 5-7 days you can close the windows and doors in the room and put a heater in it, but not near the oven itself, but in the distance .

Stage 2 (forced):

After 7-14 days of natural drying, we proceed to the breeding of fire in the furnace - the firebox. The first firebox should be fast and not hot, for this a handful of torches, previously chopped with an ax, are suitable. Every day the amount of fuel increases. So the system is like this - we burn all the fuel with the door closed, as soon as the smoke leaves, we immediately close the valves, except for the main one, it must be left ajar, and after 2-3 hours we open everything for ventilation.

The main thing in the whole process is ventilation, so that moisture from the clay solution evaporates with it.

the system selected this answer as the best

If the stove is folded in the summer, when it is not yet needed, then you can safely open all the doors and latches and leave it to dry naturally. At the same time, it should be borne in mind that there is a lot of moisture in a freshly laid stove and it will evaporate, including into the room, so you can make a draft in this room. But here's what really happens in life. The owners usually remember about the stove, when white flies start to fall, and not only do they have to lay down the stove in extreme conditions, but also dry it too. I have already adapted to this factor and do the following. As soon as I fold the oven, I open the seams (since I make ovens for jointing, I like it better) and coat them with natural drying oil. Next, I begin to gradually heat the furnace, first opening both the summer course and the main valve. And drying oil at this time does not allow moisture to penetrate into the room and all moisture flies out into the pipe. This is how you can slowly dry the stove in three or four days (Russian, of course, longer, since it has more bricks than the stove). By the way, drying oil makes masonry much stronger, according to my observations. But, I repeat once again, it must be natural, otherwise, when heated, the oil or polymer smell will be simply unbearable.

add to favorites link thank you

The stove is placed on a clay mortar, the masonry contains a lot of moisture, before heating a new stove, it must be dried. The first week it should dry naturally. Pull out the dampers, open the doors of the wells, arrange air circulation. After 7-8 days, you can start heating the stove a little. We need dry, not large logs. It is enough to heat once a day. In the first days, burn about two kg of firewood, gradually increase the volume. After 10 days, you can heat at full capacity.

add to favorites link thank you

Project statistics for the month

New users: 78

Questions created: 243

Responses written: 976

Reputation points earned: 15139

Server connection.

Some tips on how to operate a brick oven, fireplace stove.

Like any technical device, a brick oven or a fireplace stove requires attention and constant monitoring during its operation. Before the start of the heating season, the stove must be checked and repaired.

Particular attention should be paid to the integrity of the masonry, from the bottom row to the top of the pipe. If cracks are found in the masonry, they should be filled with mortar, and the broken bricks should be replaced. Seal the gaps between stove appliances and masonry with kaolin wool soaked in clay mortar

Whiten the pipe in the attic, so the cracks that appear will be better visible.Treat wooden structures located in close proximity to chimneys with flame retardants. Cracks in the masonry, broken brick, can cause a fire. It is useful to read the Fire Safety Rules in the Russian Federation and GOST 9817-82 “Household Appliances Running on Solid Fuel”. The presence of a serviceable fire extinguisher in your home and the ability to use it will never be superfluous.

The process of burning wood in your stove is divided into three stages: kindling, intensive burning and afterburning. At each stage of the process of burning firewood, a different amount of air is needed, the volume of intake, which is regulated by valves and a blower door. Proper air supply maximizes the efficiency of your stove, complete combustion (i.e. maximum heat release) of loaded firewood, reduces the amount of soot formed to a minimum, increases the trouble-free life of the stove, thereby saving you money and time.

At the stage of kindling and afterburning, a small amount of air is required. At the stage of intense combustion, the largest amount of air supplied to the furnace is required, but this amount must be optimal. The air supply is regulated by a blower door. How much to open or close it, i.e. increase or decrease the amount of air supplied, can be determined by the color of the flame. If the flame is dark yellow with black smoke, then there is not enough air, the door must be slightly opened, and if the flame is bright white, the stove is buzzing, then there is excess air, the door must be closed. The light yellow (straw) color of the flame will tell you about normal combustion (“correct”). At the stage of afterburning, the blower door can be closed completely, and the draft in the pipe can be reduced with a valve. Try to open the furnace door as little as possible.

In cold weather, the stove, stove-fireplace is heated twice a day (in the morning and in the evening), while the maximum heat transfer of the stove is achieved. In warm weather, it is enough to heat the stove once.

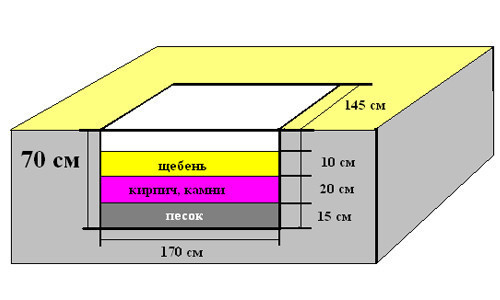

The device of the foundation for the furnace

The scheme of the foundation for a brick oven.

Laying furnaces is not only the implementation of the rules for ordering, but also the construction of the foundation. The design of the fireplace is quite heavy, so you will have to provide for a solid and reliable base that can withstand it. The most common option is a free-standing reinforced concrete foundation, which is made in the form of a tape or slab. Such a foundation is poured even during the construction of the foundation for the whole house, it is buried in the ground by about 0.5-1 m. The depth is selected taking into account the dimensions of the structure itself. If construction is carried out on soil with a high level of groundwater, then a single monolithic slab is made for the whole house; a separate foundation is not made under the fireplace.

When constructing a separate foundation, it is necessary to correctly calculate the loads. A brick accounts for 4 kg of weight, that is, to calculate the total load from the fireplace, you need to count the number of bricks in the masonry, add weight to the mortar, fittings. When pouring, it is better to make the base a little wider, so the loads will be distributed more evenly and correctly.

Drying the oven before use

Furnace techniques.

After the fireplace or stove is ready, that is, the masonry is completed, it is necessary to properly dry the structure, it is still too early to heat it. If you do not follow these simple recommendations, then the surface of the brickwork can quickly become covered with a network of cracks, i.e. the furnace will cease to perform its functions by 100%. The duration of the drying of the fireplace will depend on many circumstances. This is not only the humidity of the brick itself, but also the season, the dimensions of the furnace itself.

Drying can be natural or forced.

- natural is the best option. How to implement it correctly? After the masonry is completed, it is necessary to open all the doors, dampers of the structure.This continues until the oven is completely dry. In this case, the fireplace will dry out evenly, cracking will not occur. But there is a big minus - such an oven will dry for a long time. Natural drying can last 6-9 months, but this option is not suitable if people constantly live in the house, since the heat will go outside through the fully open stove;

- forced drying after masonry is used much more often today, especially if it is necessary to minimize the time to prepare for the first full-fledged firebox. The process is as follows: after the masonry is finished, thinly chopped chips are taken in such an amount that they fit in the hands of an adult man. After that, you need to start heating the stove 6-7 times a day. During the procedure, it is necessary to close all cleaning doors, open the blower and furnace doors a little. The shutter must be fully open. The firebox itself is carried out in stages. After the first batch of chips has completely burned out, it is necessary to open all the doors, leave the structure for ventilation. Toward the end of the drying of the furnace, the amount of fuel can be increased, but not by much, since drying should take place smoothly and evenly. The surface of the fireplace at this time should not be hot, just a little warm.

https://youtube.com/watch?v=tKemktKq940

Continue drying the fireplace until the condensate is completely gone from the cleaning doors. Forced drying takes approximately 3 weeks, although the duration also depends on external conditions. This method is rather difficult, since it will have to be heated every day, patience is required, the constant presence of an observer of the process.

Why is it forbidden to heat an unseasoned stove?

This will only cause the brickwork to crack. It will be especially noticeable in the area of \u200b\u200bthe firebox, since here the temperature will be the highest, and for wet bricks this is quite dangerous. After cooling, the cracks may decrease slightly, but in any case they will remain forever, smearing with a solution will give absolutely nothing.

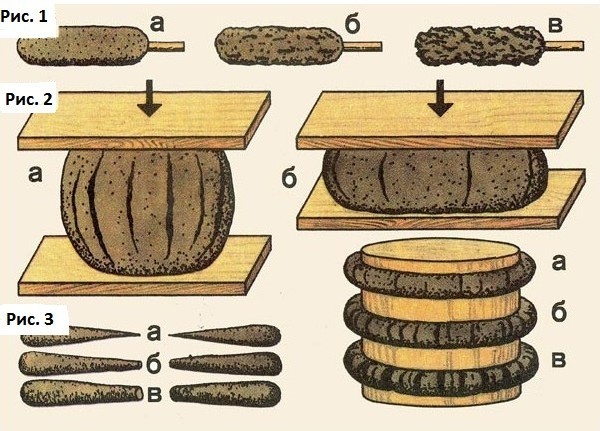

Definition of mortar for laying the furnace: Fig. 1 a - clay strongly sticks to the oar, too oily; rice. 1 b - separate clots remain on the oar - the clay is normal; rice. 1 in - the veselka is covered with a thin layer - the clay is skinny; rice. 2a - a ball compressed by 1/5 of the diameter from lean clay cracked; rice. 2 b - a ball compressed by 1/2 of the diameter from oily clay cracked; rice. 3a - flagella smoothly stretched out, sharp ends in places of rupture, no cracks when bent - too oily; rice. 3b - flagella smoothly extended, in places of rupture thickening of 20% of the original thickness - normal clay; rice. 3 c - flagella stretch little, when bent there are many cracks - skinny clay.

Much attention should be paid to the first firebox of the fireplace. There is less hassle than drying, but there are certain requirements that must be observed.

For the first time, it is necessary to heat only with dry chopped firewood 4 times a day for 15 minutes. The duration of each furnace gradually and slowly increases. It is impossible to use large firewood for a damp fireplace, which can give a lot of heat. After the fireplace is completely dry, you can already start heating it.

Laying stoves made of natural bricks is a complex, responsible process that requires utmost attention and adherence to technology. But it is not enough to lay out the brick according to the order - it is necessary to properly arrange the base for the stove, after finishing the work, dry the fireplace, and complete the first firebox. Only in this case, you can be sure that the fireplace will serve for a long time.

Best Answers

sergey antishin:

The old stove-makers never immediately flooded a freshly built stove, but let it dry for at least a day.

Adam from Paradise:

It is not possible, but it is necessary to immediately drown, so that the clay not only dries up, but becomes hard

KERK:

1 Preparation for operation and commissioning.After the furnace is folded, an equally important stage in its life begins - commissioning. When laying the furnace, the materials from which it is made are intensively saturated with water, which must be removed from the furnace before operation. The drier the oven before the first kindling, the longer it will work in the future. We dry the oven for at least 14 days. At the same time, we open all stove appliances - doors, views, valves (when it rains, views and valves must be closed). It is desirable that the room in which the oven is located is constantly ventilated. Drying can be considered complete when wet spots disappear from the surface of the furnace, and water condensate ceases to appear on the surfaces of furnace appliances (especially on valves). 2. First kindling A. The first kindling is carried out with a small amount of paper (0.5 kg), and serves mainly to determine the correct laying of the stove, the presence of draft and in order to remove moisture residues from the inner surfaces of the stove. Before the first kindling, it is necessary to fully open the blower door, which is located under the furnace door. We open the gate completely. Sometimes, especially in wet and cold weather, in order to create primary thrust, it is necessary to “burn through” the pipe, for which a newspaper rolled into a tube or a small amount of wood chips is burned in a view, or in the uppermost cleaning door. Then, laying paper in the firebox, they set fire to it and keep it burning by adding new portions of paper. The time of the first kindling is no more than 20 minutes. After kindling, the oven is left completely open for a day. C. Subsequent firings must be made every day for a week with an increasing amount of firewood. - The second furnace - on the second day - 1 kg. Paper, chips and splinter; -The third furnace - the third day - 1.5 kg. Paper, chips and splinter; - The fourth furnace - the fourth day - 2, kg. Paper and chips; -Fifth firebox - fifth day - 3 kg of wood chips and small firewood (logs 3-5 cm thick); - The sixth furnace - the sixth day - 3.5 kg of paper, chips and small firewood; -The seventh furnace - the seventh day - 3.5 kg of paper, wood chips and small firewood

Firewood must be placed in the stove carefully, in no case should it be thrown, so as not to damage the inner surface of the firebox and loosen the firebox door and bricks around it. After the seventh firebox, you can gradually increase the amount of firewood laid in such a way that by the end of the third week you will gradually switch to the firebox with the normal amount of firewood for this stove

Appearing cracks in the masonry - immediately cover with oven mortar !!! In no case do not try to speed up the process of drying and commissioning the oven. Do not try to increase the amount of firewood or the duration of the fire, do not fire the stove during commissioning two or more times a day. By doing this, you can cause irreparable damage to your stove, which will lead to the need for a complete disassembly of the stove and its subsequent laying again at your expense. Violations of the drying process and commissioning of the kiln are very easy to detect and do not allow shifting the blame for the destruction of the kiln to the kiln operator or substandard materials. Be attentive and careful!!!

Torbablikh:

Only when it dries out and then drown. Down right away.

Natural drying of the new oven

Natural drying of the stove after laying lasts approximately 5 days. During it, all valves and doors should be opened, through which natural air circulation will be carried out. It is thanks to the draft that the air, passing through the interior of the furnace, takes with it all the evaporating moisture and removes it through the chimney. In a natural way, only the surface layers of the masonry are dried.

To increase the efficiency of the natural drying process, it is recommended to place a 200 W light bulb in the furnace or place a fan heater in front of the furnace door in such a way that the stream of warm air is directed directly into the furnace.

What glue to choose for cladding

The variety of mixtures that are recommended for such a case stupefies anyone. And the range of prices is completely confusing.

The one who makes the decision for the first time, takes what is heard, without going into details. Professionals usually stop at one mixture that has a stable result.

If you try to understand the mixtures for ovens and discard the advertising on the packaging, then grouping according to certain criteria, you can see some regularity.

Mixtures that present themselves, first of all, as heat-resistant, have adhesion to the base from 0.5 MPa to 0.9 MPa:

- 0.5 MPa. "Budmaster GLUE-16", "PLITONIT SUPERFIREPLACE THERMAL ADHESIVE", "PALADIUM PalaTermo - 601".

- 8-0.9 MPa. "Scanmix Teplo", "Glue SBS 17", "REDBAG119", "POLYPLAST PP-018", "Terracotta".

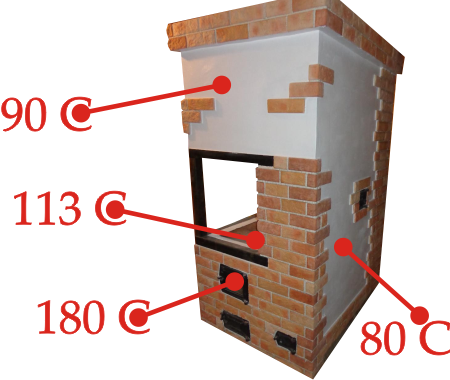

Manufacturers "Ceresit", "Litokol" do not have an adhesive mixture specially designed for lining stoves and fireplaces. There is simply a class C2 adhesive with a high content of polymer additives that can be used on surfaces with a maximum heating temperature of 90 degrees ("SUPERFLEX K77") and 80 degrees ("Ceresit CM 17"). At the same time, their adhesion strength to the base is more than 1.0 MPa.

1.0-1.3 MPa. "Anserglob VSH-35", "Ceresit CM 17", "Hercules GM-215" "SUPERFLEX K77", "LITOPLUS K55".

If we continue to study and sort the mixtures by cost, then we will not see a proportional relationship between the price and the adhesion strength (MPa) and the maximum heating temperature. Immediately striking is the suspicious discrepancy between the indicators of the glue "Glue SBS 17".

It is clear that the price is a conditional indicator. It partly depends on where they are being taken, from where and by whom.

But still, there is a pattern. The bulk of new (unknown) mixtures has a price of $ 4-6. Well-known manufacturers raise the cost by three to four times, with technical characteristics that do not have such an excess.

It is interesting that some relatively new mixtures with a high price appear on the market.

Perhaps the consistently high performance has attracted attention, and manufacturers are no longer afraid of losing the market.

In addition to the price, such a characteristic of the adhesive as the maximum surface heating temperature is of interest. To be guided by it, you need to know to what temperature the surface at the furnaces heats up?

This can only be determined with a thermal imager and in a specific area. The temperature depends on the thickness of the walls and the design of the hearth - the presence of a second circuit, the scheme of movement of gases.

If we take the average heating indicators of a double-circuit structure, then different sections will have approximately the following temperature:

The heating temperature of various parts of the furnace.

Ceramic tiling technology for stoves and fireplaces.

Before lining, the stove must warm up to operating temperatures, undergo shrinkage, movement and cool down to room temperature. The cladding technology itself is no different from the generally accepted rules for laying tiles and stone on complex bases:

- Priming a brick surface without fanaticism - the glue must penetrate the structure of the brick, and not cling to the film from the soil. Abundant priming is possible at the seams, which will strengthen the clay mortar. The surface of the bricks must be cleaned of the clay mortar on which the structure was laid.

- Fastening of a metal mesh with a knitting wire laid in the seams at the time of the construction of the hearth.

- Leveling the surface on the grid with glue, using the rule.

- Additional leveling the next day with dried adhesive, aluminum wedge.

- Primer.

- Laying tiles on adhesive class C 2 ....

- Filling joints with elastic grout.

Most errors occur at the stage "How to level the surface of the furnace and with what?"

For this stage, the general rule of any finishing process is true: "Each subsequent layer in terms of strength should not be stronger than the previous one." That is, the adhesive on which the cladding is laid must also be used to level the surface.

It is possible to understand what characteristics a particular glue actually has only after several years of using the stove. And the more such stoves there are, the more reliable the conclusion will be. Therefore, it is better to look for such information from masters who have been doing this for a long time.

>

Forced drying of a new oven

Forced drying is drying with dry firewood that burns in a firebox.

Such a furnace should be carried out once a day, using finely chopped logs with a diameter of no more than 3-4 cm.

Before drying the stove, the blower must be slightly opened, and the main valve can be half open. But the secondary air supply doors must be kept closed.

After the combustion process is completed, when the firewood turns into coals, the blower door must be closed so that there is a gap of about 1 cm wide, and the main valve must be closed, leaving a gap of 1-2 cm wide for humid air to exit. The secondary air supply doors must be ajar.

After 4-6 hours after the firebox, it is necessary to fully open all the valves and doors, except for the door of the heater

Particular attention should be paid to the fact that during the entire period of forced drying of the oven, the heater door must be closed. Such forced drying must be carried out within 7-10 days.

On the first day, about 2 kg of firewood should be burned. Then every two days you need to increase the amount of firewood burned by 1 kg.

In the cold season, the duration of forced drying increases and can be 2-3 weeks. But at the same time, the amount of firewood burned in one session should not exceed 7 kg. An indicator of the completion of the drying of the oven is the absence of condensate on the doors and the main valve after the oven has been closed for 3-4 hours.

After the end of the drying process, it is necessary to carry out a control firebox. It is already possible to heat the stove with normal firewood and at full capacity. The amount of firewood for one firebox will be approximately 20 kg. After burning firewood and forming coals, close all doors and the main valve. Over the next 3-5 hours, you still need to observe the outer surface of the furnace, check if any cracks have formed in the seams. The cause of cracks may be improper masonry or poor-quality materials.

With the appearance of cracks with a thickness of 2-3 mm, it becomes obvious that a marriage was made during the laying and these cracks must be repaired. But you should not do this right away, it is best to operate the furnace for 3-6 months, and only after this period begin to repair problem areas using an elastic clay-sand mortar.

In general, thread-like cracks for a sauna stove are considered quite normal. The sauna stove is operated in rather harsh conditions. For example, in winter, only the outer surface can heat up from 1-5 °C to 70-80 °C in a few hours, and this is a very large temperature range. In addition, there are significant internal temperature differences. To prepare the heater in winter, it is necessary to burn up to 40 kg of firewood, and in summer - up to 30 kg per firebox. The laying of the furnace is subject to intensive thermal expansion, therefore, in some heat-stressed places after the furnace, thread-like cracks may form, which is not a sign of marriage.

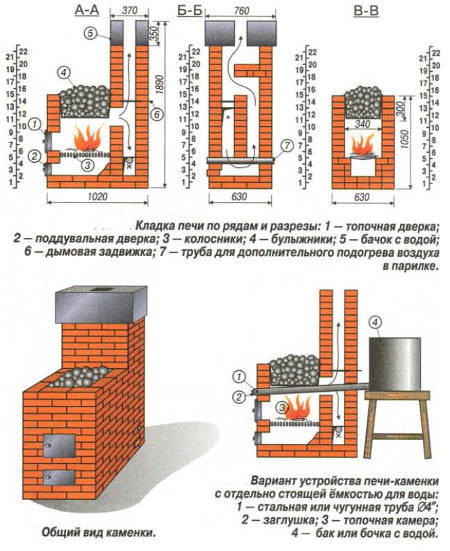

What is ordering

What is order and why is it needed? This is a detailed scheme, according to which the laying of the furnace is carried out, without it it is impossible to start work. Even experienced stove-makers first draw up an ordering plan, and then begin laying. In this order, the location of the bricks for each individual row, their dimensions, places for installing doors, furnace and other grates are indicated.

An example of ordering a brick oven.

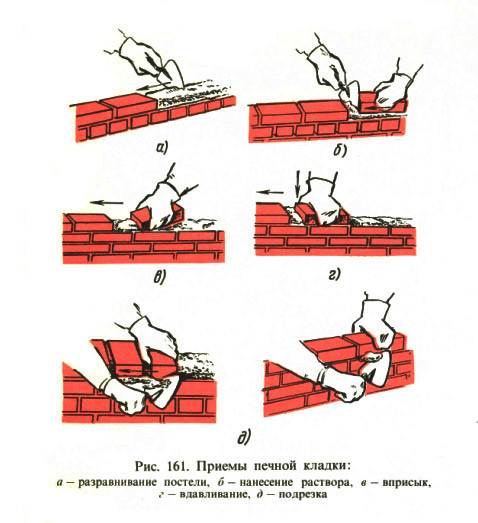

The laying of stoves can be carried out according to various methods, for example, undercut or with empty seams.If the first method is used, then after completion of the work, the surface of the furnace is not plastered, since the solution has already filled all the seams. Masonry can be carried out in one brick, in ¾, in ½ - it all depends on the size and appearance of the structure.

Masonry rules provide for the use of only special kiln bricks. The use of slotted, silicate, conventional refractory, expanded clay is not allowed in any case. The first row must be laid out dry, that is, the solution is not used. It is necessary to clearly define the direction of the future masonry, if necessary, it is easy to shift the brick. At the same time, the position of each door, front wall is determined. The second row is laid out with a solution, then the corners of the future fireplace or stove are laid. During work, plumb lines and twine are necessarily used so that the wall goes vertically upwards, does not have displacements, deviations. Masonry rules are the same for any design. The ash pan, firebox, blower can be located in different places, but their fastening and reinforcement remain the same.

This masonry begins after the second row above the furnace of the future furnace. When laying the cladding, it must be remembered that it is impossible to make a rigid connection between it and the furnace, since the temperature characteristics will be completely different, cracking is possible. When the laying of the chimney begins, it is necessary to remember to install a special valve, it must be smoothly and well regulated.