Selection of a distribution manifold

The main rule is that the diameter of the collector should in no case be less than the size of the supply pipe. The larger the diameter of the distribution “comb”, the better for pressure uniformity at the points of water and / or coolant dispensing.

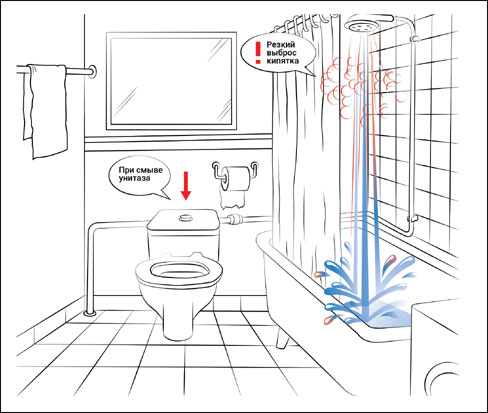

Incorrect selection of the “comb” (see recommendations above), for example, for plumbing, can cause jumps in flow on different devices (see Fig. 2) and cause imbalance, for example, on a mixer.

If control valves are not installed on the apartment inlet of hot and cold water, forcibly stabilizing the pressure in the “comb”, then it is especially important for apartment collectors to follow the connection sequence rules. It is necessary to connect devices, the uneven flow of which has little effect on the performance or comfort of the water supply, as “downstream” as possible along the water flow in the “comb”

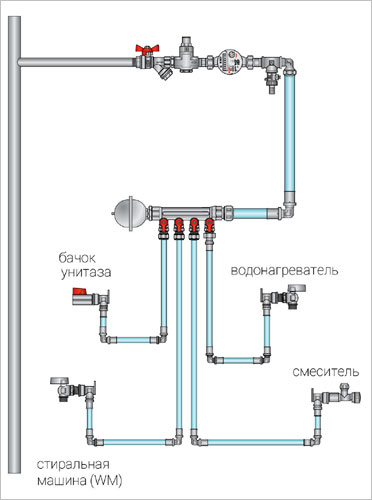

The water heater should be connected first, then the faucets, followed by the washing machine and dishwashers (making sure that the “no water” shut-off valve is set to a pressure lower than the drop caused by the change in water intake), and at the very end of the collector, the drain pipe ( see Fig. 3).

Solar collector saving opportunity

It is possible to connect several heat carrier heating sources to the heating circuit. Often solid fuel boilers operate in parallel with electric ones. this allows you to maintain the mode of operation of the heating system at night or in the absence of the owners for several days.

But such a regime cannot be called economical - electricity is one of the most expensive resources. Modern developments make it possible to use solar energy for heating the coolant by installing a solar collector.

A solar collector is an installation that can be used all year round even at cloudy temperatures. On sunny days, it is most efficient and heats up to the temperature of the boiler supply circuit - up to 70-90 degrees.

Homemade solar collector

The solar collector is a fairly simple device, it is not difficult to make it yourself. In terms of efficiency, a home-made solar water heater may be inferior to industrial models, but given their price - from 10 to 150 thousand rubles, a do-it-yourself solar collector will very quickly justify itself.

For its manufacture you need:

- a coil made of a metal tube, usually copper, you can take a suitable one from an old refrigerator;

- cuttings of a copper pipe with a thread of 16 mm on one side;

- plugs and valves;

- pipes for connection to the collector node;

- storage tank with a volume of 50 to 80 liters;

- wooden planks for the manufacture of the frame;

- expanded polystyrene sheet 30-40 mm thick;

- glass, you can take window glass;

- aluminum thick foil.

The coil is freed from freon residues by washing it with a stream of running water. From a wooden slat or bar, a frame is made with a size slightly larger than the coil. Holes are drilled in the lower part of the frame for the output of the coil tubes.

On the reverse side, a sheet of polystyrene foam is attached to it with glue or screws - this will be the bottom of the collector. This material has excellent thermal insulation characteristics, which will help reduce heat loss.

The top of the solar collector is covered with glass, fixing it on glazing beads or rails. Pipes are attached to the ends of the coil for connection to the heating manifold assembly.This can be done using adapters or flexible piping.

The collector is placed on the southern slope of the roof. Pipes lead to a storage tank equipped with an air valve, and from there to a heating distribution manifold.

Video: how to make a solar heater yourself

A collector heating system is the most efficient way to connect various heaters to one or more heating sources. With it, you can ensure a stable temperature and comfort in the house, as well as uninterrupted and coordinated operation of all elements of the system.

Advantages of the scheme

The advantages of such a coolant supply scheme are ease of use. The operation of the system and the control of heating devices are as comfortable as possible:

- The temperature of each circuit element can be controlled centrally. Being near the collector, the homeowner can limit the supply of coolant to any register or turn it off altogether. It is convenient to control the temperature in each room.

- Each branch that departs from the collector feeds only one radiator. Therefore, pipes of small diameter can be used for laying highways. In most cases, the highways are laid in a concrete base. This heats up the floor.

- If necessary, using a collector, it is easy to form several independent circuits with different temperature indicators. For this, it is preferable to use the so-called hydraulic gun - a type of collector. It is characterized by a large internal diameter of the pipe.

The installation of this variant of collector heating is somewhat unusual. It is planned to create short circuits between the hot water supply and the return lines.

The water heated by the boiler constantly circulates along the contours of the hydraulic arrow. At the same time, hot coolant can be taken at different distances from the collector, creating a temperature difference even in a single room. This option can be used for complex heating of the house - using traditional systems and "warm floors".

An example of selecting an apartment distribution manifold

Consider an example of selecting an apartment collector according to the connection diagram shown in fig. 3, that is, four points of water intake. Table 2 regulates the required flow rate at the level of 0.28 l/s. Let the water supply to the house be made of a 1/2″ steel pipe (DN = 15 mm), allowing a flow rate of 0.29 l / s at a flow rate of up to 1.5 m / s. The supply to the "comb" is carried out by a metal-polymer pipe 20 × 2.0 (3/4 "). According to the manufacturer, we determine that the allowable flow through such a pipe is 0.3 l / s, which exceeds the capacity of the house input (1/2 ″). Having chosen a VTc.500NE collector with a nominal diameter of 1″ (Dn = 30 mm), we check the general recommendations for choosing collectors (see above).

The cross-sectional areas of the “comb” (see Table 3) and the inlet (1/2″) differ by a factor of 4. With such a ratio of conditional diameters, the reduction in losses along the length of the "comb" (formula 1) will be 23 times. This is not ideal (the ratio of the diameters of the comb and the inlet is not: 1, but 2: 1), but in this case it is not critical: if the connection order is followed (see Fig. 3), the distribution manifold for water supply with 4 outlets will be able to perform its balancing role in dynamic mode of operation.

Large range of distribution manifolds

Table 3 shows, as an example, for a different number of outputs designed to connect floor and apartment water supply and heating systems. In addition to water supply, these systems are suitable for both radiator heating and low-temperature systems, such as underfloor heating and open area heating.

Table 3. VALTEC manifolds and manifold blocks

Distribution manifolds made of stainless steel, such as VTc.510.SS, are especially popular.They are successfully operated in storey distribution units of water heating systems of typical multi-apartment buildings.

Viewed: 4 713

Collectors without taps

It is not always necessary in a house or apartment to regulate the flow of water in pipes running from water distribution to plumbing fixtures. Moreover, with a small number of devices, it is not necessary to be able to turn off these devices individually.

In this case, you can get away from collectors with control valves, and use a simplified collector water supply scheme, using collectors without taps.

The main function of such collectors - pressure equalization in the distribution pipeline will remain the same, but monitoring tasks will disappear.

For example, you have a large number of water consumers in your apartment: a washing machine, a water heater, a toilet bowl, a kitchen sink, a shower in the bathroom, a sink in the bathroom, a shower in the toilet. With such and more consumers, a series (tee) circuit may not be effective and the use of several devices may be difficult.

If the apartment (house) has normal water pressure, then the simplest distribution manifolds without taps can solve the problem of comfortable use. They are not suitable for underfloor heating systems, but they will do an excellent job in plumbing and heating.

Flaws

Despite the wide range of control options, the collector wiring of heating has not become widespread. And there are good reasons for this:

- Increased consumption of main pipes compared to conventional heating schemes. The more complex the geometry of the building, the more material you need to purchase. The increase in installation costs is also one of the significant reasons for the low consumer demand.

- Conventional systems can be mounted on the wall without problems in open or hidden versions. It is possible to lay a mass of highways from the comb only under the floor. Otherwise, a very depressing picture will turn out, where heat pipes will prevail in the interior. And the consumption of material during wall mounting will increase significantly.

- A prerequisite for the installation of an eyeliner inside a concrete screed is the absence of joints. Each junction is potentially dangerous in terms of breakouts. The prospect of destroying the foundation in order to eliminate the leakage of the coolant looks depressing and requires a lot of money, labor and time.

- The hydraulic resistance of the system with the mass of pipelines increases significantly. Especially if the diameter of the highways is small. Therefore, no gravitational heating systems can even be considered. Only forced circulation of heated water.

- If you plan to use several independent heating circuits, then for each of them it is necessary to install a circulation pump. Otherwise, the scheme simply will not work. Hence another item of additional costs.

- In any case, the system turns out to be volatile, since it cannot function without a heating pump. Again, a nuisance if for some reason there is no electricity. Or you will have to take care of an autonomous power supply.

All shortcomings ultimately come down to additional material costs. We can safely say that the collector wiring option cannot be attributed to budget solutions.

General design principles

There is no single instruction for drawing up a working draft of collector heating systems. In each case, heating devices and equipment are selected individually. But it will be useful for every interested person to get acquainted with a few tips of a general nature.

The collector scheme is not for a city apartment.

An exception can be considered cases when builders in new houses additionally install one pair of valves in apartments, to which a heating circuit of an arbitrary configuration can be connected. In this case, the collector wiring is boldly installed. With common risers for all apartments, a collector system is not possible.

Suppose there are several risers in the apartment and one or two heating devices are connected to each. You want a common collector circuit to be mounted, and install a pair of combs with heat distribution throughout the apartment on one riser, disconnecting from all other risers. As a result, you will get a large pressure drop and return temperature on your tie-in. This will lead to the fact that the batteries in the apartments of the neighbors in the riser will be almost cold. As a result, the visit of a representative of the housing office is inevitable, who will draw up an act on an illegal change in the heating configuration and oblige to make an expensive alteration of the heating system.

The system must be mounted so that the automatic air vent is located directly on the collectors. This is the best option, because sooner or later all the air will pass through them in the circuit.

The collector wiring system has many features, but some of them are also characteristic of other types of heating systems:

- The circuit must be equipped with an expansion tank, the volume of which must exceed 10% of the total volume of the coolant.

- The expansion tank is best placed in front of the circulation pump, on the "return", in the direction of water movement. When using a hydraulic arrow, the circuit must be designed so that the tank is installed in front of the main pump, which circulates water in a small circuit.

- The choice of the installation location of the circulation pumps in each circuit is not fundamental, but it is better to install them on the return flow. Here the operating temperature is lower. It is necessary to mount the pump so that the shaft is positioned strictly horizontally. Otherwise, at the first air bubble, the device will remain without lubrication and cooling.

Pipe selection

To determine which pipes the collector heating system is mounted on, it is necessary to understand the specifics of the collector wiring. Let's remember what can affect our choice:

- Pipes must be selected from those sold in coils. This allows you not to make connections in the wiring installed inside the screed.

- Pipes should not be afraid of corrosion, have a long service life. The reason is the same: to open the concrete floor due to the replacement of pipes is not included in our plans.

- The tensile strength and heat resistance of the pipes is selected depending on the operating parameters of the heating. For radiators in a private house, the optimal parameters are 50 - 75 ° C water temperature and a pressure of 1.5 atm., For warm floors at the same pressure, 30 - 40 ° C is enough.

When a collector heating system is installed in apartment buildings, which is quite rare, the operating pressure should be 10 - 15 atm. at the admissible temperature of the water carrier - 110 - 120 ° С. Based on these parameters, you have to make a choice of pipes.

Mounting the collector wiring is necessary when building a house. After laying the finishing floor, the installation of this system will not be economically feasible, since the floors will have to be opened. Most often, in this case, open wiring of heating systems is used.