Converter lining

The most important goal of the strategy for the development of the design of the lining of converters is to achieve its high resistance, which ensures such an efficiency of the converter, which corresponds to the minimum unit costs for refractories. The last decade is characterized by a radical increase in the durability of the converter lining due to the use of a combined balanced scheme, taking into account the wear characteristics of individual zones, including those subject to increased erosion. So, in different zones of the converter lining, products of different quality and thickness are used, which ultimately leads to a balanced wear of the lining as a whole (Table 4). An increase in the durability of the lining is facilitated by a reduction in the time of its direct contact with the oxygen jet. To do this, at the beginning of the blowing process, slag formation is forcibly accelerated by adding dolomitic lime to foam the slag. Of course, the automation of the converter process, which reduces the number of converter rolls and prevents overheating of the steel at the end of the melt, also contributes to the increase in the durability of the lining. To increase the durability of the lining, the American companies Practer and Grate Lakes Division proposed a technology for blowing slag in an oxygen converter, which involves injecting high-pressure nitrogen through the upper oxygen or auxiliary lance to spray the slag over the lining. At the same time, the slag covers the lining, cools and hardens, creating a strong protective crust that prevents refractory wear. The slag blowing technology involves swinging the converter to apply the coating to areas of the lining that are subject to increased wear during loading of scrap metal and draining metal. An additional positive effect of the slag scull is also achieved due to the fact that when cast iron is poured into the converter, the slag is partially melted, which leads to the creation of a certain layer of liquid slag even before the start of blowing. lining profile and its degree of wear. An example of such equipment is a laser lining profiling system. A full scan of the converter takes 25…30 minutes. The found areas with a small thickness of the lining are repaired with gunning and slag blowing. The lining is monitored 7…10 times during its operation. In general, already today, 2.5 ... 3.5 thousand heats are considered to be the normal durability of the converter lining. The record figures, based on system monitoring and additional repair of the lining, even reach 10...15 thousand heats and more.

Brick buildings for heating

The main advantage that stone stoves for summer cottages can boast of is the ability to retain heat for a long time. This is true when you have to stay in the building overnight on frosty days. However, it takes a long time to melt the structures, which is not very convenient for a short pastime.

Relevance of application

Dimensions, efficiency, manufacturing complexity and other parameters were taken into account.

- In the first place is the Dutch oven for giving, as it has a compact size, which means it can be actively used in many rooms. Due to the presence of vertical channels, it has a high thermal output.

- The second position is occupied by the Swedish brick heating structure. It will be able to fit in almost any buildings, of course, if these are not country houses from block containers.

- The third place belongs to the Russian stove due to its impressive size and complexity of manufacturing.This option is more suitable for residential buildings than for suburban buildings.

Classification of structures

Depending on the purpose, heating, cooking and combined facilities are distinguished. In the first case, only heating of the premises is carried out, in the second - only cooking. In addition, the structures can be combined directly with each other.

Furnaces can be classified by wall thickness, which can be thin or thick. The warm-up and cool-down times depend on their size. For a country house, it is recommended to choose thin-walled structures, as they do not require a massive foundation.

As for the configuration, the designs can be rectangular, square, angular, round and even T-shaped. The choice of form, as a rule, is made taking into account the interior design.

Design possibilities

With the help of various types of finishes, the aesthetic characteristics of a brick structure can be formed. Unlike metal counterparts, there are a lot of options for improving external data.

If necessary, the cladding can be easily replaced, radically changing the perception of the heating structure.

- Facing brick is able to bring a touch of modernity to the appearance, so it is very often used for decoration. Ideal for styles where straight lines are predominant.

- Ceramic tiles, with their variety of colors and installation options, can completely transform a design. The imitation of other materials, such as wood, looks interesting.

- Decorative plaster provides an opportunity to create coatings with an aesthetically attractive texture. The result is exquisite products.

- Hand-made tiles allow you to create exclusive designs, which, after finishing work, act as the main source of attention.

Metal products for heating

The basic advantage of such structures is the rapid transfer of heat to the surrounding air, although cooling also occurs in a short time. The decisive factor can be considered a low price, thanks to which the products successfully compete with brick counterparts. During operation, there is a risk of getting burned if the case has not been protected by other materials.

Basic classification methods

First of all, all products can be divided according to the material of manufacture. In modern markets, ordinary or heat-resistant steel are presented. The choice should primarily be based on operating conditions, since the characteristics of the metals are completely different.

Another classification option takes into account the location of the product. Particularly popular are corner stoves for summer cottages, which do not take up much space, therefore they are more suitable for small rooms. The choice in this case depends on the design decision.

The most important factor is the way the system is designed, which is explained by the special effect on efficiency.

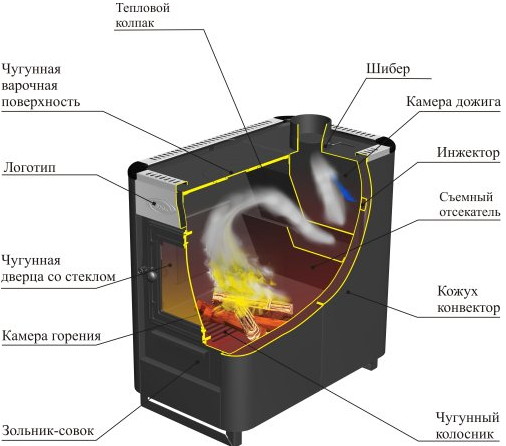

-

Chamber structures involve the combustion of residual air through natural circulation

. With this option, the afterburner is combined with the furnace into a single module - the crucible. -

Duct products imply the presence of special partitions between which flue gases pass, retaining heat

. As a rule, the efficiency of the system does not exceed 60 percent. -

Bell-type analogues are able to retain the initial products of combustion under a kind of capacity until they give up all the energy

. Therefore, they are characterized by high efficiency.

The most popular representatives

Thanks to a competent design, air injection proceeds without the use of additional devices. The temperature difference between the inlet and outlet flows leads to heat transfer in gases. Convection ovens for giving this type allow you to achieve high efficiency.

Homemade systems

If necessary, a metal structure for heating can be made by hand. Of course, it is hardly worth claiming to create a creation that is distinguished by aesthetic data, but it is quite possible to build a neat structure, especially since practicality plays the main role with a lack of budget.

At the initial stage of work, special attention is paid to the preparation of the elements necessary for assembly. As for the tools, the list is not so long, because home-made stoves for summer cottages are made using a grinder and a welding machine.

In a pipe with a diameter of at least 40 mm, two rectangular holes are first cut. One of them will be a firebox, and the other will be a blower. A hole for the chimney is created in the upper part. From wire 6 mm thick grate is made.

Two circles are cut out of the steel sheet, the diameter of which will correspond to the width of the pipe. They are welded from the bottom and top sides, forming a sealed structure. At the last stage, doors are installed from cut pieces using steel hinges.

Convection modes

In order to ensure an even and constant flow of heat energy from all sides of the oven, forced convection is used in it.

The fan effectively creates a uniform and continuous blowing of hot air on the products on the baking sheet. This prevents them from burning or not baking. In addition, convection helps to create a beautiful golden brown on pies and other products.

In simpler models of electric stoves, ordinary fans of a simple design are installed, the task of which is to force the air to move inside the cabinet. In more complex units, the fan can be additionally equipped with a heating element, which is more efficient.

Ovens can be equipped with heavy-duty fans that quickly create a dense, even stream of hot air. This allows you to make pastries more juicy and soft inside.

There is also humid convection, during which steam is created inside the oven. As a result, pastries do not dry out, pies and cakes rise well. In addition, the steam effect allows you to save oil and cook healthy foods without deep frying.

Basically, electric models of ovens are equipped with different convection modes. In gas ovens, this function is much less common. This is due to the fact that the gas model has its own specifics in design. Open fire in gas burners creates certain difficulties for creating forced circulation of heat.

Features of convection ovens

Installing household convection ovens allows not only to solve the problem of cooking several portions of dishes at the same time, but also save money on electricity consumption (especially useful during the heating season). Technology features:

- Even cooking. Hot air evenly warms up the dishes and allows you to maintain the temperature at a given level. Small dimensions allow you to use the equipment both at home and at catering points for heating food and preparing semi-finished products. The temperature rises quickly. Already in 20 minutes the maximum values \u200b\u200bwill be reached. Thanks to this, dishes are prepared quickly. Now in the country you can forget about the classic heating in the form of a wood-burning stove, and cook on professional equipment.

The reversible fans of professional domestic convection ovens work together with high power heating elements, due to which the air flow circulates.

Traditional structures for heating country houses are mainly made of two materials - metal and brick, which is explained by their ability to tolerate thermal effects well.To simplify the choice, you should consider both options in detail. Familiarization with all types of furnaces will provide an opportunity to choose a system suitable for specific needs of the consumer.

Shotcrete converter lining

Shotcrete lining is a method of hot repair by applying a refractory mass to worn areas of the lining using shotcrete machines. Apply torch and semi-dry shotcrete.

During flare shotcrete, the main working body of the machine is a water-cooled shotcrete lance introduced into the converter cavity. Oxygen is supplied through it and, with the help of compressed air, a shotcrete mass consisting of magnesite powder and coke dust. Combustion of coke in oxygen ensures the formation of a flame with a temperature of 1800–2000 °C. At this temperature, the refractory powder passes into a plastic state and, applied by a torch to the surface of the lining, is firmly welded to it.

In semi-dry gunning, the moistened refractory mass is applied to the lining of the converter using the nozzle of a shotcrete machine with a jet of compressed air, and the mass is mixed with water in the nozzle. The moistened mass sticks to the lining and is subsequently welded to it. The disadvantage of this method is that the evaporation of moisture makes the structure of the applied layer relatively loose and its durability is low. Therefore, torch shotcrete is more effective.

Shotcrete as individual sections of the lining, and its entire surface. Gunning begins after the wear of the lining by about half of its allowable value, its duration is 4–20 min, the frequency of carrying out is after 2–18 melts, the thickness of the applied layer is 5–100 mm. The durability of the lining can be increased to one to three thousand heats.

Slagged linings by slag blowing. After draining the metal, the slag in the converter is thickened with the addition of burnt dolomite. Next, through the nozzles of an oxygen or special lance, nitrogen is blown into the slag, splashes of slag adhere to the lining, forming a slag layer, which is destroyed in subsequent heats; the actual lining remains almost unchanged. The applied slag layer withstands at least two heats.

With this method of hot repair, the durability of the lining made of magnesite-carbon refractories reaches 5-10 thousand melts. One of the options for slag blowing provides for its implementation for 10-12 minutes every two heats.

Slagging of the lining and its gunning reduces the number of cold repairs of the lining, which require heavy manual labor, and reduces the consumption of molded refractories. But when shotcrete, powdered refractories (magnesite powder, lime-based mixtures, etc.) are additionally consumed.

Top blown oxygen converters BOF Shape BOF dimensions Converter body and bottom Pins and support ring BOF Swing Mechanism oxygen lance

The difference between the two ways

The above production is subdivided into Bessemer and Thomas processes. The differences between them are in the main components of the converter linings.

The Bessemer steelmaking process allows the use of low phosphorus and sulfur content. With the Thomas method, on the contrary, cast iron is remelted by means of a high phosphorus content.

The essence of oxygen-converter production is the smelting of steel by lining and purging with oxygen from a liquid cast-iron base. Without fail, a water-cooling form is used for this.

In units, oxygen is supplied from below. This method is most common in Russia. Although in foreign countries a combined purge method is often used. In metallurgy, the oxygen-converter smelting method is recognized as practically one of the most efficient in several respects:

- The reproduction of one steel-smelting unit exceeds in power other methods by several tons.

- In heavy converters, reproduction reaches about 500 tons in 1 hour.

- Costs are much lower than in other production.

- Pretty economical arrangement of any workshop, even regardless of the power of the melting units.

- The simplicity of the process lies in the automation of the steelmaking method.

Due to the fact that pure oxygen is used, the resulting steel does not have a high nitrogen content. This allows the material to be used in a wide range of small industries.

It is also important that the relative safety for health allows the involvement of mid-level specialists

What is called convector heating

A convector heating system is a system in which heat is transferred from the heat carrier of the heating element by means of convection. That is, heat transfer is carried out by continuously moving air streams. Thanks to this, it is possible to evenly heat the room.

Heating is arranged as follows. Its main elements are convector heating radiators. In the lower part there is a heat exchanger in which a heated coolant constantly circulates, which plays a major role in the heat exchange process. In order for the area of contact of cold air with the heater to be larger, it is provided with flat metal fins or tubes, which are guides for the flow of heated air.

Pros and cons

The choice fell on bimetallic radiators with a bottom connection? How to choose read here.

Heating convector device

So, cold air enters the heat exchanger, which, heating up, moves up.

One of the advantages of such heating is that the air in the room can be heated quite quickly.

Oxygen converter smelting process description

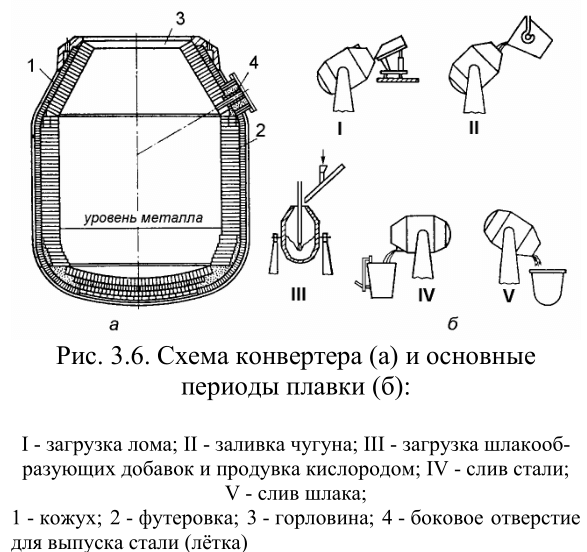

The oxygen converter is a pear-shaped steel vessel. Its inner part is protected by resin-dolomite (basic) brick. The capacity of the steelmaking plant varies from 50 to 350 tons. The vessel is located on trunnions and is able to rotate around a horizontal axis, which allows you to freely pour iron into it, lay other additives and merge the metal with slag.

To obtain the final product, not only cast iron is poured into the converter, but also additives are added. These include:

- scrap metal;

- slag-forming materials (iron ore, lime, feldspar, bauxite).

The converter method with oxygen purge involves pouring cast iron heated to 1250–1400°C into the converter. Having installed the converter in a vertical position, oxygen is supplied to it. As soon as blowing has begun, the remaining components that make up the slag are introduced into the molten iron. The mixing of cast iron with slag is carried out under the action of blowing.

A feature of the main slag is the high content of calcium oxide and iron oxide, which, at the beginning of blowing, contribute to the removal of phosphorus. If the phosphorus content exceeds the required value, the slag is drained and a new one is introduced. The oxygen purge is terminated when the carbon content of the final product meets a certain parameter. After that, the converter is turned over and the steel is drained into a ladle, where deoxidizers and other additives are added.

Related video: Basics of BOF production

A selection of questions

- Mikhail, Lipetsk — What discs for metal cutting should be used?

- Ivan, Moscow — What is the GOST of metal-rolled sheet steel?

- Maksim, Tver — What are the best racks for storing rolled metal products?

- Vladimir, Novosibirsk — What does ultrasonic processing of metals mean without the use of abrasive substances?

- Valery, Moscow — How to forge a knife from a bearing with your own hands?

- Stanislav, Voronezh — What equipment is used for the production of galvanized steel air ducts?

Convector heating at home is your step towards home comfort

Among the various ways of heating a house, convector rightfully occupies not the last place. Its main advantages are that when using this method, it is not necessary to create a complex design of the heating system, and pipes and expensive water-heating boilers are not required.

Let's try to figure out what convector heating is. As the name implies, this is a method of heating a room, which is based on air convection in the room itself.

From the laws of physics, it follows that when heated, warm air rises, and cold air goes down.

Thus, there is a natural circulation of air and gradual heating of the room. It is this type of heating that is quite simple, but at the same time an effective way of heating.

Wood-burning heaters

Most ovens

available on the market are wood-burning. Wood burning stoves are traditionally used as an additional source of heat. To increase the amount of heat produced, you can try burning more wood. Well-dried wood burns much better than wet wood.

Thus, in order to increase the amount of heat, it is advisable to use the so-called first (highest) grade of firewood (birch, ash, oak, maple, hornbeam). On average, one bookmark of the stove is enough for 4 hours of burning, but with good firewood, the room will warm up faster and with less firewood consumption. The ability to heat only one room, without the possibility of connecting to the heating system of the house, in this case can be regarded as a disadvantage of this type of stove.

How different are wood stoves

. Steel stoves are often smooth, without distinctive surface textures, suitable for modern home interiors. Cast iron stoves are often reminiscent of old stoves, often produced with ornaments on the surface, suitable for classic interiors.

Steel and cast iron ovens

are made with built-in glass doors that allow you to control the fire burning in the evening, gently illuminating the room. For such doors, special, heat-resistant glass is used. Glass, with an extremely low coefficient of thermal expansion.

Convection ovens are often used to heat houses or cottages. The main difference between such ovens is the presence of gratings or tubes for air circulation. Convection ovens, as their name suggests, work on the principle of convection.

Cold air passes through the lower grilles during movement, heats up and rises, exits into the room through the upper outlets. Thanks to this movement, good air circulation is ensured and it becomes possible to heat not one, but several rooms, and not necessarily on the same floor.

A conventional wood-burning stove gives off much less heat to a room than a convection oven does. Convection ovens are often lined with refractory tiles. Models of convective ovens are produced that do not work on wood, but on coal. They have slightly smaller volumes and differ in the design features of the firebox. It should be noted that convection ovens can be automated.

Convection ovens can be of any size, which means they can be adapted to any room size. The power of the furnaces is at least 7 kW; the largest ones are about 16 kW. The external design of convection ovens is somewhat similar to steel and cast-iron wood-burning ones.

Basic practical advice for the installation of plates

Please note that as much distance as possible must be kept from the heater to combustible surfaces. Furnaces must be placed on non-combustible surfaces, t

e., ceramic tiles, metal, tempered glass, tin sheets

When choosing any type of stove, it is important to remember that for the stove to work efficiently, the chimney must be at least 100 - 130 mm in diameter.

It is important to note that the chimney above the roof should be just above the roof ridge. Distance from the ridge up to 1.5 meters

The chimney should protrude 50 cm. If the chimney is in the center of the ridge, the height of the pipe can be 70 cm above the roof. With the correct pipe height, good air circulation will be guaranteed.

More interesting articles

Menu

OUR HOME - apartment renovation - apartment design - search for a private master CALCULATOR OCCUPATIONAL SAFETY AND HSE BUSINESS NEWS - land plots - real estate - real estate purchase - rent sale CONSTRUCTION - foundations - waterproofing - walls and facade - roofing and attic - thermal insulation - windows and doors — floors and floor coverings — finishing works — engineering systems — building materials — ventilation and air conditioning — ceiling — heating systems — houses and cottages — window design — door design — repair work — water supply systems — design — construction technologies SAUNA BATH — features of the Russian bath — construction and materials STOVES FIREPLACES — stoves, boilers, fireplaces ARCHITECTURE — ancient architecture — modern architecture — interior design — landscape design — decoration — furniture and furnishings — interior styles USEFUL — scientific and technological progress — builder's library — engineering equipment — machine tools — equipment and tool - service gi - construction equipment - energy saving ABOUT THE PROJECT SITE MAP

The principle of the Bessemer method

For the first time, mass production of liquid steel became possible in 1856 thanks to G. Bessemer, an inventor from England. He figured out how to heat the metal to a temperature exceeding 1500°C. It is this temperature that is necessary in order to melt a metal with a reduced carbon content.

The Bessemer process involves blowing the melt with atmospheric air. For these purposes, converters are used, in which the inside of the combustion chamber is protected by silica bricks. Due to this protection, the Bessemer process is called acid converter lining.

Melting in the Bessemer steel-smelting unit is carried out by pouring cast iron at a temperature of 1250–1300°C. It should be noted that the smelting of Bessemer cast iron requires iron ores with a low content of sulfur and phosphorus.

Poured cast iron is blown with air, as a result of which carbon, manganese and silicon are oxidized. During oxidation, oxides are formed, forming an acidic slag. Air purge is completed after the carbon has oxidized to the required values.

Next, the metal is poured through the neck into the ladle, simultaneously oxidizing it. This method has one significant drawback, which is the low quality of the final product, which is too brittle due to incomplete removal of sulfur and phosphorus.

Features and secrets of the process

This method differs from other methods of steel production in that it is tied at very high speeds. The whole method, as a rule, takes literally 14-24 minutes. High temperatures allow you to set the instantaneous rate of dissolution of lime in slag contents.

Therefore, steel smelting in one converter, including the entire production process, does not exceed 30 minutes.

It is important to note that the quality of the main process is directly affected by the uneven oxidation of each of the components contained in the aggregate.

The leading principle of the oxygen-converter process is due to the regulation of the temperature regime and the change in the number of purges.A necessary condition for the efficiency of smelting is the introduction of coolants as iron ore, scrap metal, limestone.

Dust waste is cleaned using a waste heat boiler. All off-gases from the smelting process enter the installation for their purification. All steel production by the oxygen process is controlled by powerful modern computers.

It should be noted that with bottom blowing, the specific volume of finished steel is much less than with top blowing. It is with the bottom method that the rate of obtaining finished steel is much higher.

In addition, as regards the finished metal, after the completion of all production work, the result is 1–2% more efficient.

Additionally, during the process, the duration of blowing is reduced, and the melting of scrap is accelerated. All this makes it possible to establish a specific technological process at a lower height of the production building.

Furnace Requirements

When choosing a stove based on the principle of convection, it is important to pay attention to the main parameters. So you will be able to purchase the model that is optimal in terms of characteristics and cost.

- No handicraft. Choose only those stoves that are made by leading manufacturers. Never be shy even for well-known brand products to require all certificates.

- Power. To cook pastries and dishes in certain quantities, the appropriate power is required. Mini ovens for baking have small parameters, but they are quite enough for home use. It makes no sense to pay for powerful devices if you do not plan to make large-scale baking for sale or open some kind of fast food.

- Functions. Modern convection ovens are filled with all kinds of functionality. But experience shows that users often do not use even half of the oven's capabilities. What's the point of paying money for something you won't use?

- Doors. Look at the design of the stove door. In the best convection ovens, the door is made of two layers of glass, between which air is enclosed. This ensures natural convection which prevents the outer glass from overheating. Plus, with this structure, less heat loss is observed.

- Service centers. It is not worth repairing a convection oven on your own. It is better to choose manufacturers whose service centers are in your city.

- Dimensions. Mini models are used for home use, and larger devices are suitable for production. It all depends on the purpose for which you buy a convection oven.

- Maximum heating temperature. Certain dishes require high temperatures to cook. Not all models of convection ovens are designed for them. Therefore, determine in advance what the stove will be used for and what temperature parameters you need.

- Appearance. Here already focus on your own tastes. There are a huge number of design options for convection ovens, so you will have plenty to choose from.

What is convection and why is it needed

Those who are planning to buy household appliances for the kitchen should learn about convection in the oven: what it is and how it works. It participates in heat transfer, it can be natural and forced. In the first case, the movement of air masses occurs due to the temperature difference between the surface and the gas, in the second case, due to external influence (using a fan).

The heat transfer modes available in modern ovens improve the quality of food and save time. The simplest models have natural convection: the baking sheet warms up from below, hot air circulates in the upper part of the oven, because of this, the food is baked unevenly.

Flour products located closer to the back of the oven brown faster, while those near the front door take longer to cook. The oven is opened and the baking sheet is turned over.Ovens with natural convection have a drawback: pastries are baked unevenly.

The biscuit begins to fall off if the door is opened prematurely. Modern ovens are equipped with a top heating element that improves natural heat transfer. More popular models with a built-in fan that evenly distributes heated air.

This part is involved in the regulation of the air flow. Forced ventilation has many advantages. It provides uniform air circulation in all departments, so the flour product is well baked.

After reaching the required temperature, the ventilation is turned off. The convection mode in the oven saves energy, allows you to cook various dishes, and, if necessary, use the grill.

The modes are chosen taking into account the recipe. Before using the device, study the instructions. Gas ovens with convection are not as common as electric ones, there is no sealing inside such devices. Fans are not installed, as they inflate the gas.