Popular types of wood briquettes

We have already talked about the manufacture of fuel briquettes for heating boilers and furnaces, as well as their key advantages and disadvantages. It remains to figure out what types of briquettes are presented on the domestic market.

Fuel briquettes RUF

This fuel resembles white or wood-colored bricks in appearance (the shade varies widely). RUF briquettes are made from dry sawdust by pressing under high pressure. As a result, eurofirewood is born, which can be used in any type of stoves. Their distinguishing feature is the inscription RUF, squeezed out from two sides at once.

RUF fuel briquettes for furnaces are characterized by the release of a large amount of heat - they are almost one and a half times more profitable than firewood. They are easy to load combustion chambers and store them in stacks. Pressed bars are not afraid of moisture, but it is also not necessary to expose them to direct contact with water. This fuel is supplied by many manufacturers - a typical example of this is a company called Olezhka. By the way, it also sells many other types of solid fuels.

Eurobriquettes PINI KAY

An interesting feature of these eurobriquettes is their unusual shape - they resemble square pencils, from which someone took out the stylus. That is why they are called "pencils". In order for it to burn with the release of a large amount of heat, a hole was made in it, which increases traction. The "pencils" themselves look dark as they have been fired. This procedure makes them more durable and removes excess moisture.

The disadvantage of PINI KAY fuel briquettes for furnaces is that they cost more than firewood and even more than any other types of fuel. But they burn well, releasing a large amount of heat. They are also easy to transport and store. Due to their shape, they are ideal for kindling fireplaces. Some people take them with them to nature to use PINI KAY bars instead of firewood.

Simple cylindrical briquettes

On sale there are also the simplest fuel briquettes for furnaces - in the form of cylinders. They are made from pressed sawdust and small wood waste. All this is pressed under low pressure using a non-toxic adhesive base, after which the finished bars are sent to consumers. This fuel is cheap, but has one pronounced drawback - low strength. It easily disintegrates and crumbles, does not withstand moisture.

Fuel briquettes from coal and peat

Peat and coal fuel briquettes for the stove are made, respectively, from peat and coal. The raw materials are molded into small cylinders. The fuel can be used to kindle stoves and solid fuel boilers. Coal products give a high combustion temperature, but are characterized by a high ash content. As for peat fuel, it is very well suited for long-burning stoves, but it also produces a lot of ash.

If you have a stove at your disposal that needs to be heated with something, we recommend that you stop at PINI KAY or RUF fuel briquettes. They are convenient and have high calorific value, form a minimum of ash and provide long burning.

Choosing a boiler on wood briquettes

The choice of a long-burning boiler on pressed wood briquettes can be difficult, due to the large range of products offered. The domestic market offers models made in Russia, Europe and neighboring countries.

To facilitate the selection of equipment, all offered boilers for burning briquettes can be divided among themselves into several categories, according to a territorial basis - the country of origin:

- Germany - Bosch Solid.

- Czech Republic - ATMOS, Dakon (the company belongs to Bosch), Wattek.

- Russia - Nibe Viking, Zharstal Dobrynya, Dragon.

- Turkey - Radiator.

- Poland - Heiztechnik.

- Italy - Ferroli.

The proposed list includes boilers for burning briquettes using the principle of pyrolysis combustion. All models enjoy constant popularity, which is clearly proved by sales statistics.

The better to heat the boiler - wood or briquettes

A solid fuel boiler on wood briquettes, despite its good thermal performance, remains a rarity in most regions of Russia. But gradually the trends are changing.

To decide how to heat a solid fuel boiler, with firewood or briquettes, it is worth considering what characteristics distinguish pressed fuel:

- Relative humidity - the indicator does not exceed 8-10%. Firewood, even after two years of drying, has a moisture content of at least 20%.

- Calorific value - varies at the level of 4.5-5 kW / kg. The same characteristics distinguish pellets and coal.

- Profitability - the efficiency of a solid fuel pyrolysis boiler on wooden briquettes exceeds by 5.3% identical indicators when using coal.

The table of caloric content of wood briquettes shows that pressed fuel is superior in its characteristics to ordinary wood. The constant use of stoves is economically beneficial, it increases the battery life of solid fuel boilers.

In all respects, the use of briquettes is more profitable. There are a few more parameters to consider:

- Technological results - combustion is characterized by stability and uniformity. Under normal traction characteristics, the flame is bright yellow. During combustion, no soot is released. The chimney warms up quickly, there are no temperature drops. As a result of these features, there is a decrease in condensation.

- Environmental characteristics - the emitted smoke is transparent. There is a sour smell. There are no harmful substances and soot in the combustion products that adversely affect human health.

- Production characteristics - briquettes facilitate the work of service personnel. Even when using stoves in classic units, the operating time from one tab increases to 8 hours. In pyrolysis or long burning equipment, the time is increased to 20 hours.

Considering all the characteristics, it is better to heat the boiler not with firewood, but with briquettes.

Wood briquettes for boiler

At the moment, the production technology has been changed. The consumer began to offer cylindrical fuel, up to several centimeters long, which made it possible to use wood fuel briquettes in automatic boilers.

How and from what wood briquettes are made

Heating wood briquettes for boilers are made in three different ways, each of which has its own characteristics and marking:

- Rectangular RUF briquettes - got the mark due to the fact that the first compressed fuel was created on equipment manufactured by the German manufacturer RUF. In its form, the finished product resembles a small brick. The principle of production is based on the pressing of sawdust and waste, by means of hydraulic presses, at a pressure of 300-400 bar.

Cylindrical briquette - pressing briquettes for solid fuel boilers of this type is carried out on hydraulic or mechanical shock equipment. When pressing, the pressure increases to 600 bar. The disadvantage of the cylindrical type of fuel is the fear of moisture and susceptibility to mechanical damage.

Pini&Kay – pressing of wood briquettes for heating boilers is carried out on mechanical screw equipment.The difference between the production is the simultaneous use of high pressure (up to 1100 bar) and thermal firing. The resulting "logs" have edges and a characteristic dark brown color.

Washers - in their structure they resemble Pini & Kay, they have four or six faces and a radial hole in the center. The length of the briquette is only a few centimeters.

The technology used for the production of briquettes is reflected in the quality and cost of fuel. Pini & Kay have the highest calorific value, they are resistant to moisture and mechanical stress, and also burn longer when fired.

Consumption of briquettes in the boiler

Solid fuel for boilers in briquettes is made from various types of wood. Burning time and fuel consumption depend on the type and type of wood:

- Coniferous briquettes - quickly flare up and create a high temperature in the furnace, but quickly burn out, due to the large amount of resin released. Heating with coniferous briquettes is not profitable, due to the high fuel consumption, but it is advisable to use them to kindle the boiler.

- Pressed hardwood boards have a high calorific value, flare up hard and burn out slowly. The average consumption is 10 kg for 6-7 hours.

Another type of briquette that has not found wide application is slabs made exclusively from bark. This type of fuel burns heavily, but during combustion, it practically does not have a flame and slowly smolders. At the same time, the temperature is maintained until the plates burn out. The average burning time is 12 hours.

The cost of wood briquettes

It is economically advantageous to use fuel briquettes, due to the high calorific value and low content of non-combustible residue.

What are fuel briquettes

Briquettes differ in shape and material of manufacture.

Differences in form

There are three main forms of fuel briquettes: pini-cay, ruf and nestro. Their difference is only in the maximum density that can be achieved in each of the forms. In terms of chemical composition or mass calorific value, there are no differences between European firewood.

Fuel briquettes pini-kay

The highest density is from 1.08 to 1.40 g/cm 3 . Section shape - square or hexagon. There is a through hole in the center, which provides better air movement and combustion of the briquette.

Fuel briquettes RUF

Fuel briquettes from sawdust ruf, in the form of a brick. They have a small size and the lowest density - 0.75-0.8 g / cm 3.

Briquettes Nestro

Nestro fuel briquettes have a cylinder shape and an average density of 1 - 1.15 g / cm 3.

Peat briquettes

Peat fuel briquettes have a special shape, unlike the others. And because of the high ash content and the presence of other harmful impurities in the composition, they are not recommended for use at home. Such briquettes are suitable for industrial furnaces or boilers that can run on low-quality fuel.

Fuel briquette from peat

Differences in material

Eurowood is made from sawdust, seed husks, rice and buckwheat, straw, tyrsa, peat and other materials. The material affects the calorie content of the fuel briquette, ash content, the amount of soot emitted, the quality and completeness of combustion.

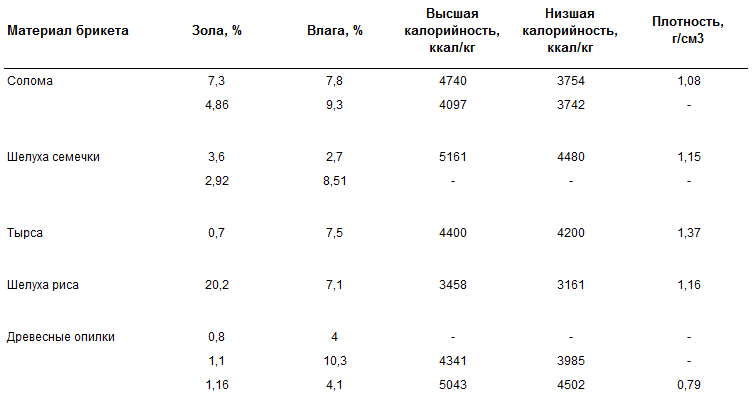

Below in the table is a comparison of the characteristics of briquettes from different materials - seed husks, rice, straw, tyrsa and sawdust. Such an analysis shows not only that briquettes made of different materials differ from each other. But also the fact that even briquettes from the same material differ in quality and properties.

All data are taken from real test reports of fuel briquettes.

Calorie content, humidity, ash content and density of fuel briquettes from different materials.

Table comments

Seed. The highest calorific value of seed husk briquettes is 5151kcal/kg. This is due to their low ash content (2.9-3.6%) and the presence of oil in the briquette, which burns and is of energy value.On the other hand, due to oil, such briquettes more intensively pollute the chimney with soot, and it has to be cleaned more often.

Tree. Wood sawdust briquettes are in second place in terms of calorific value - 5043kcal/kg at 4% humidity and 4341kcal/kg at 10.3% humidity. The ash content of wood briquettes is the same as that of a whole tree - 0.5-2.5%.

Straw. Straw briquettes are not much inferior to seed husks or sawdust and have a good potential for use. They have a slightly lower calorie content - 4740 kcal / kg and 4097 kcal / kg, and a relatively high ash content - 4.8-7.3%.

Tyrsa. Tyrsa is a perennial herb. Such briquettes have a fairly low ash content - 0.7% and good heat transfer of 4400 kcal / kg.

Rice. Rice husk briquettes have the highest ash content - 20% and low calorific value - 3458 kcal / kg. This is even less than that of wood, at 20% humidity.

Advantages of fuel briquettes

The main advantage of a briquette is that the combustion temperature is 1.5-2 times higher than that of firewood. At a humidity of 20%, the calorific value of wood is 2500-2700 kcal/kg, the briquette is 4500-4900 kcal/kg.

And there are simple and logical explanations for this:

- Briquettes have low humidity. The lower the moisture content of firewood, the higher their heat transfer. The normal moisture content of wood with proper storage is 15-20%. Briquettes have a moisture content of 4-8% and is achieved through forced drying - an obligatory stage in their production.

- Briquettes have a high density. Why does oak wood burn hotter than poplar wood? Because of the density. Density of oak is 0.81g/cm3, poplar is 0.4g/cm3. That is, each cm3 of oak contains more useful and combustible woody substance than poplar. The density of the briquette is 0.95-1g/cm3. In them, the content of combustible matter per unit volume is even higher than that of oak. Accordingly, the calorific value is higher.

Low humidity and high density are the key to the success of briquettes. If you dry firewood to a moisture content of 4-8%, then in terms of calorific value they will be compared with briquettes.

Other advantages of the briquette:

- They take up less space.

- Burn more evenly and last longer.

- Made from waste. If you care about the environment and the environment.

- Due to the low humidity, briquettes emit less soot and pollute the chimney less.

- How to clean the chimney from soot? Simple ways to remove soot in the chimney at home.

- Firewood does not burn well and there is a smell of burning in the room? Read these causes of chimney backdraft.

Two important takeaways

1. Different ash content

Two samples of straw briquettes have different ash content - 4.86 and 7.3%.

Ashes are mineral substances in the composition of wood, which either represent a weak energy value, or simply do not burn. And therefore, the more ash in the wood, the less its heat transfer.

Different ash content of fuel briquettes indicates different quality of production and raw materials. One manufacturer does not clean the straw well enough to remove dirt and external ash. The other one adds foliage and other materials for volume. At the output, this greatly affects the quality, calorific value and burning time of the fuel briquette. And this situation can be with any briquettes, not just straw.

2. Different humidity

Humidity of briquettes from seed husks in one case is 2.7%, and in the other - 8.51%. Some sawdust wood briquettes have a moisture content of 4.1%, while others have 10.3%.

This means that the moisture content of fuel briquettes is also different. Their strength and calorific value depend on this: at a humidity of 4.1%, the heat transfer of a briquette is 5043 kcal / kg, and at 10% - 4341 kcal / kg.

So in the end, firewood or briquettes are cheaper

The main thing in firewood is not weight and cost, but the cost of a unit of heat. You can burn 5kg and 10kg of different firewood, but get the same amount of heat. Let's carry out a simple calculation (figures as of the winter of 2013):

- 1 m 3 of firewood weighs 500-600kg and costs 550 UAH;

- 1 m3 of briquettes weighs 1000 kg and costs 1800 UAH;

1 m 3 of wood contains 40-50% less real fuel than the same volume of briquettes. Let's determine the cost of 1 ton of firewood.

1 ton of wood \u003d 1.66 m 3. Its cost will be 550 * 1.66 = 913 hryvnia.

Now let's calculate the cost of 1W of heat emitted by firewood and briquettes

| Firewood | Briquettes | |

| Price for 1 ton | 913 UAH | 1800 UAH |

| The amount of heat | 2900 kcal-h/ | 5200 Wh |

| Price for 1W | 0.31 UAH | 0.35 UAH |

As a result, it can be seen that the difference is insignificant - 4 kopecks per 1 watt of thermal energy. It turns out that the effect of firewood and briquettes is almost the same, despite the significant difference in price at first glance.

It is important to take into account:

- Poor wood quality. Often, when buying firewood, you can stumble upon freshly sawn wood with a moisture content of 40-50%. The calorific value of such firewood is even less

- Firewood takes up more space, which means that their transportation will cost even more.