Do-it-yourself pyrolysis boiler manufacturing and safety rules

to the menu

Safety rules during the manufacture of the pyrolysis boiler

- use gloves during work;

- wear a safety helmet when welding;

- when using power tools, keep a distance of at least 50 cm;

- keep construction details in a protected place - away from children and animals;

- do not look at welding with the naked eye;

- the room for the boiler must be isolated from the environment. It is necessary to install a ventilation system in it;

- the walls and foundation for the boiler must consist of heat-absorbing materials.

to the menu

Safety rules for the operation of a homemade pyrolysis boiler

- do not lean your body against the boiler;

- use gloves when operating the device;

- do not forget to add water;

- do not leave open chambers for laying firewood and slag;

- do not install any structures near the unit, especially from wood;

- when removing slag, use a spatula;

- Do not put unprotected hands into the boiler chambers.

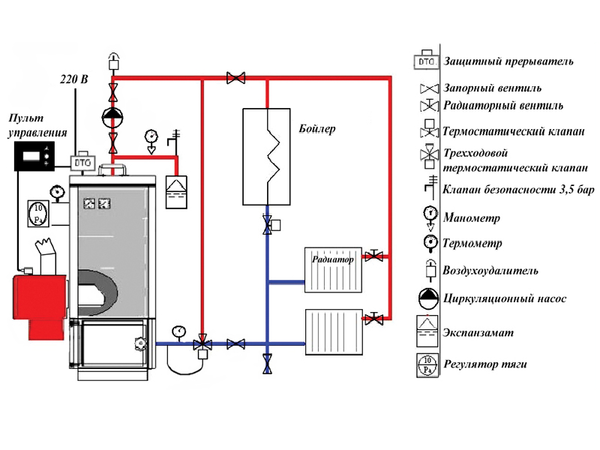

Pyrolysis boiler in the heating system

to the menu

Pyrolysis as a long burning process

In a nutshell, pyrolysis is the slow burning of a fuel to release products that are again used to generate heat. The isolated atoms do not mix with each other, they are a combustible substance ready for use. The essence of combustion lies in the minimum supply of oxygen to maintain the smoldering of briquettes or firewood, but at the same time also in a large generation of thermal energy. Savings is the main advantage of the unit.

Advantages of the pyrolysis boiler

Also, the pyrolysis boiler has the following advantages:

- High efficiency - efficiency factor. From 85% - this is an excellent indicator, indicating that fuel energy is converted into thermal energy with almost no residue. For comparison, a gas boiler generates 65% of energy.

- A boiler or a pyrolysis oven are economical units. In terms of fuel and money spent, they are in second place after the gas generator. And, of course, they are not comparable with electric boilers.

- The units process fuel in two stages - burning wood and using the released gas. The provided capacity for the accumulation of combustible gas allows you to arrange a second heating circuit with the generation of hot water for your own needs.

- A do-it-yourself long-burning boiler is a common thing, since the design is simple and you only need to have welding skills. Drawings and diagrams can be found on any network portal, as well as reviews of a home-made design.

- Do-it-yourself assembled solid fuel boiler for long burning does not require a permit, as for gas and electric boilers. But the recommendations of the installers should not be abandoned - these are still high-risk units, but assembly and installation at a certain place remain the prerogative of the owner, which does not require him to make material investments in compliance with the letter of the law.

- The time of complete combustion of one portion of fuel reaches several days. For example, a long burning boiler up to 7 days is a common case. This frees the owner from constant control over the unit, and its own automatic settings will allow you to leave the house with a working stove.

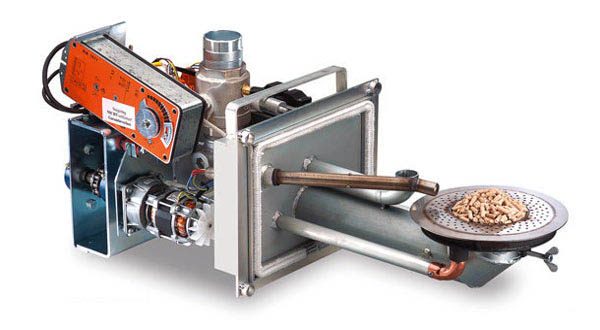

About the pellet burner

Pellet burner is a special heating device that generates heat by burning pellets or fuel pellets in a boiler. In some cases, these burners use waste dry grain.

There are manual and automatic burners, in automatic burners, fuel is fed into the combustion hopper using a special auger, and the whole process is controlled by sensors, due to which the device needs minimal control from the user. Pellet burners have found their application not only in everyday life, but also in industry. They are used for space heating, water heating and a number of other needs.

Pellets, or fuel pellets, are a special solid fuel that is obtained from wood waste or agricultural production by pressing and granulating under high temperatures.

In countries where agriculture and the woodworking industry occupy a leading position, the cost of pellet fuel is much lower than that of coal. The only exceptions are those regions in the immediate vicinity of which coal mining enterprises are located.

When burning pellets, dangerous fumes are not emitted, as is the case when burning liquid fuels.

Temperature levels of pyrolysis

to the menu

Low temperature degree

This is pyrolysis, the temperature of which is 450 - 900 degrees Celsius. In this process, the flue gas is released to a minimum, and the residues of raw materials, tar, are maximum. The amount of scrap (waste) is the largest. Considered environmentally friendly.

to the menu

High temperature degree

This is pyrolysis, the temperature of which is more than 900 degrees Celsius. In this process, the flue gas is released to the maximum, and the resin - to the minimum. The amount of scrap is the smallest.

As a result of pyrolysis, energy (heat and electricity), fuel oil, fuel (diesel oil, motor gasoline) can be obtained from waste. But subject to detailed sorting of garbage.

to the menu

DIY assembly

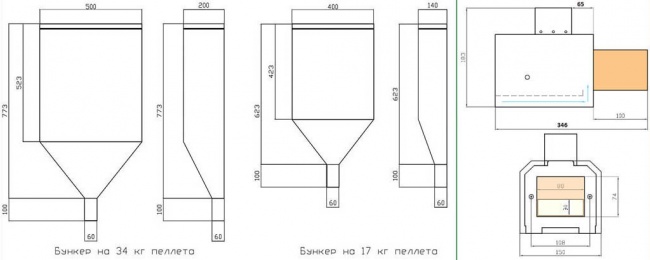

When making a pellet burner with your own hands, it is important to pay special attention to the basket. Often, due to its incorrect implementation, pellets can get stuck. In this case, the combustion process does not follow the required algorithm and the fire returns to the bunker

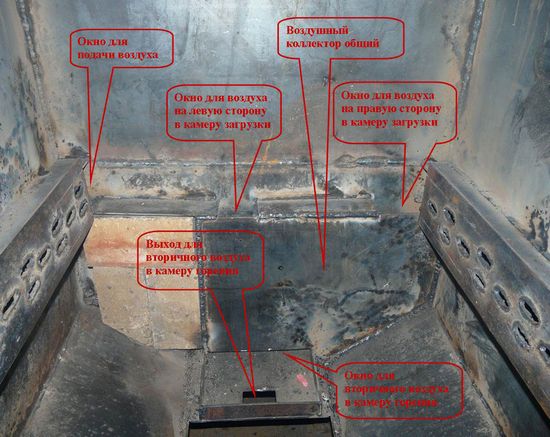

To eliminate this shortcoming, you need to look at the upper right part of the figure, which is shown below. The slot through which the pellets will be fed does not need to be made solid. It should be with holes that are 2 mm smaller than the pellets themselves. It is also worth paying attention to the gap between the bottom of the basket and the back wall. It must be at least 6 mm, but 2 mm smaller than the size of the pellets. The node where the pellet combustion chamber is separated from the pyrolysis gas combustion chamber must be made with solid cuts. If the burner is designed for a boiler with an area of 150 m2, then the height of the secondary air ducts that run under the bottom of the basket should be 30 mm.

In this case, the combustion process does not follow the required algorithm and the fire returns to the bunker. To eliminate this shortcoming, you need to look at the upper right part of the figure, which is shown below. The slot through which the pellets will be fed does not need to be made solid. It should be with holes that are 2 mm smaller than the pellets themselves. It is also worth paying attention to the gap between the bottom of the basket and the back wall. It must be at least 6 mm, but 2 mm smaller than the size of the pellets. The node where the pellet combustion chamber is separated from the pyrolysis gas combustion chamber must be made with solid cuts. If the burner is designed for a boiler with an area of 150 m2, then the height of the secondary air ducts that run under the bottom of the basket should be 30 mm.

In addition to the basket, a scrupulous approach also requires a bunker in which pellets will be stored. Problems begin with those pellet bins that are made by eye and according to a free drawing. On the left in the diagram above are the dimensions and drawings of the bunkers that are used in Pelletrons. With a dwelling area of 150 m 2, one such bunker is enough for a day. On the lower right in the same figure is a drawing and dimensions of the combustion chamber. The basis for them was the pellet burner Pelletron 15.The corridor along which the secondary air will move is best done in the shape of the letter “G”. This is necessary for better mixing of secondary air with pyrolysis gases. Thus, the efficiency of the installation will increase. For the combustion chamber, you will need a special type of steel that can withstand high temperatures. At the same time, it will be possible to weld it at home only if there is spot welding, since a conventional welding machine can hardly warm it up. You will need sheets with a minimum thickness of 2 mm. An interesting design of the pellet burner is shown in the video below.

Principle of operation

All pellet plants that can be purchased at the store are equipped with additional units:

- Auger - supplies fuel from the bunker to the combustion chamber;

- Controllers for automating the work process;

- Bunker - a place in which the fuel is located before being fed into the combustion chamber;

- Lambda probe is a special sensor that monitors the oxygen content in the smoke chambers and independently controls the fuel combustion process depending on the conditions.

The pellet burner must be protected with a plastic corrugated pipe. It acts as a fuse in the event of reverse thrust. If the fire starts moving towards the bunker, the pipe will burn out, preventing the flame from spreading.

Additionally, a fan is used, which enhances the combustion of pellets by forcing air, as well as a thermoelectric heater, which allows you to ignite the fuel without human intervention.

In automated devices, pellets are fed into the combustion chamber automatically; a person only needs to monitor the amount of fuel in the bunker. The need to supply fuel to the combustion chamber is determined using temperature sensors (they can monitor the air temperature in the room, the water temperature, or any other environmental indicators, depending on the operating mode of the equipment).

The desired temperature of the heat carrier is set by the user, all further increases and decreases are controlled using automated equipment. As soon as the temperature reaches the set level, the burner starts to work in standby mode (the pellets do not go out, they start to smolder). If the temperature, on the contrary, has dropped, the controller activates the built-in fan. Under the action of air, the pellets flare up, the burner goes into operating mode. If during the downtime the pellets go out for any reason, the heating element is activated, which re-ignites.

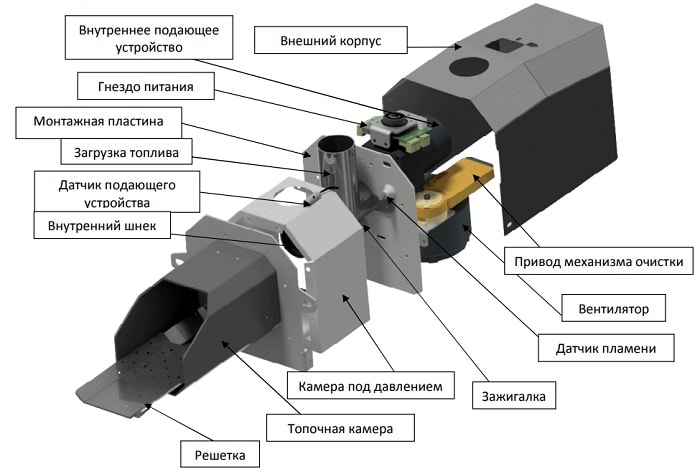

The device and principle of operation of the pellet burner

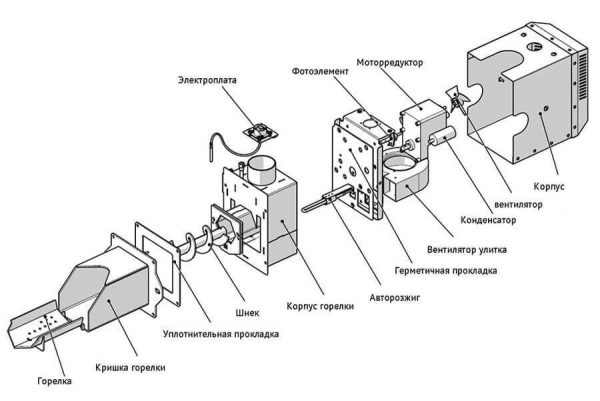

Most pellet burners include the following modules:

- Screw conveyor, through which granular fuel is supplied to the combustion chamber;

- Drive motor;

- An electronic controller that monitors the parameters of fuel combustion and ensures that timely adjustments are made to the operation of the device;

- A special sensor that controls the amount of oxygen in the exhaust gases;

- Corrugated sleeve, which helps to prevent the ignition of pellets in the bunker in the event of a reverse draft;

- Combustion chambers with built-in grate;

- A blower fan that provides the air supply necessary for the efficient combustion of pellets. The amount of air supplied to the combustion chamber depends on the fan speed and is automatically regulated depending on the selected temperature regime;

- An electric heating element that provides automatic ignition of the pellets in the combustion chamber.

The principle of operation of the pellet burner

From the external hopper, the pellets enter the loading window of the screw conveyor, which delivers the pellets to the combustion chamber of the burner.The intensity of combustion depends on the amount of fuel entering the combustion chamber, which is directly related to the rotational speed of the drive motor shaft. The engine speed required to ensure the set temperature is regulated by an electronic controller.

An equally important factor for ensuring the stability of the combustion process and complete combustion of the fuel is the presence of a sufficient amount of oxygen in the combustion chamber. In pellet modules, air is supplied to the combustion chamber using a special fan, also controlled by an electronic controller.

The scheme for adjusting the temperature of the coolant is as follows:

- From the bunker, with the help of a screw conveyor, the pellets enter the combustion chamber. At the same time, the fan turns on to supply air.

- At the signal of the controller, the pellets are ignited using an electric heating element;

- As soon as the temperature of the coolant reaches the set value, the temperature sensor transmits a corresponding signal to the electronic control unit, which puts the device into standby mode;

- If the coolant temperature drops below the programmed value, the temperature sensor again sends a signal to the electronic controller. The automatic control unit turns on the fan, thereby providing additional oxygen to the combustion chamber. An excess of oxygen leads to an increase in the intensity of the combustion process and the coolant is again heated to a predetermined temperature.

- If attenuation of the pellets occurs in the standby mode, the ACS sends a corresponding signal to the electric heating element, which provides automatic ignition.

Despite the fact that the principle of operation of a pellet burner is not particularly difficult, the cost of this unit is quite high. To reduce the material costs associated with converting the boiler to pellet fuel, some owners of solid fuel heating units make a pellet burner with their own hands. Like any other production, the manufacture of this device begins with the creation of a set of technical documentation, in other words, drawings.

How to make a pyrolysis boiler with your own hands step by step instructions and drawings

How and from what to assemble a pyrolysis boiler for domestic use with your own hands is the topic of the proposed article-instruction.

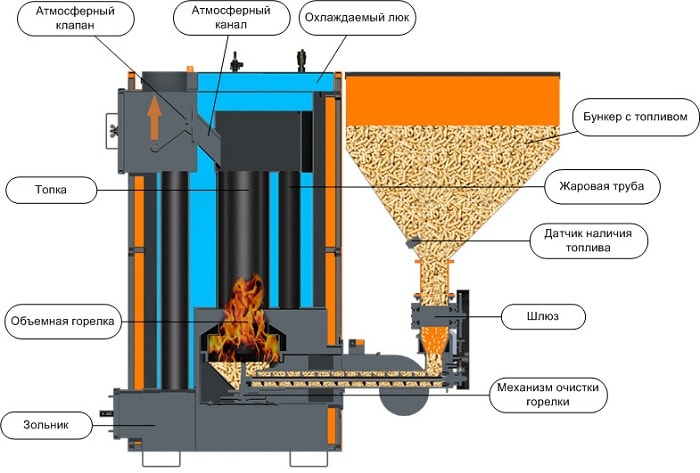

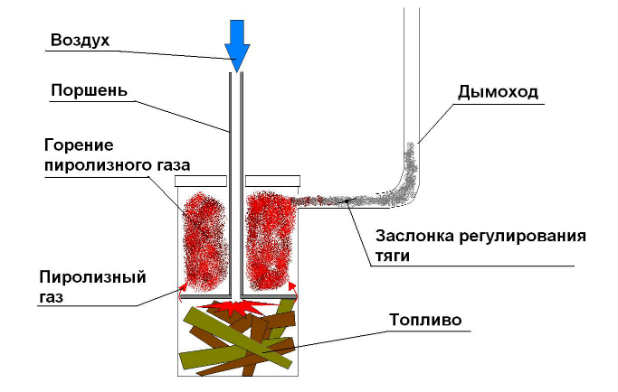

The principle of operation of pyrolysis boilers

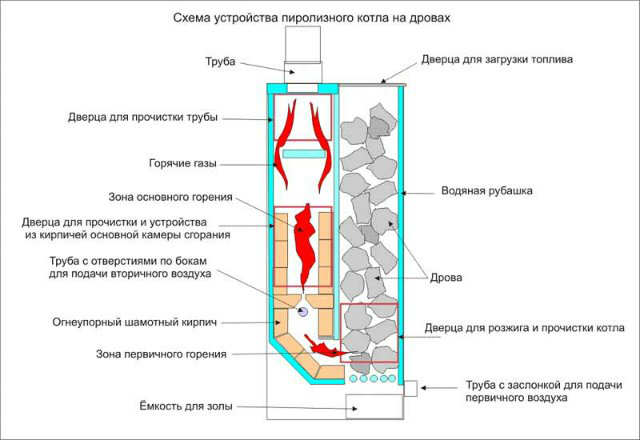

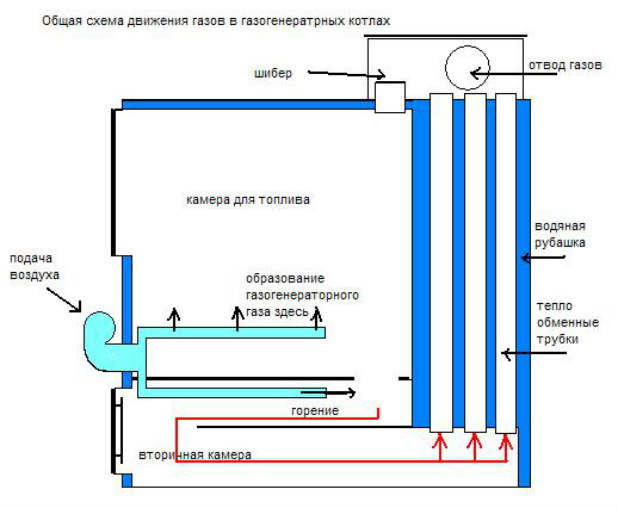

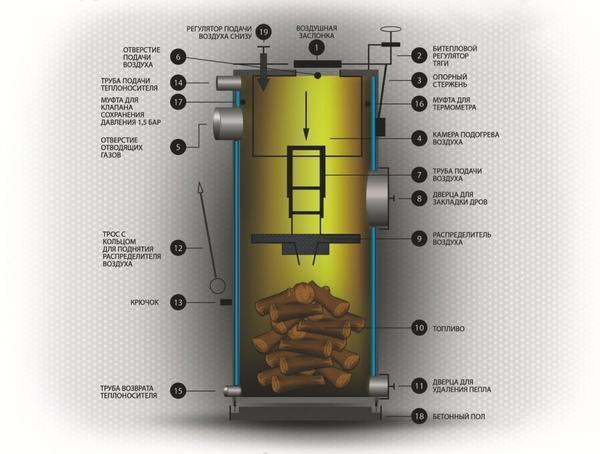

High efficiency, and therefore economical fuel consumption in such installations is achieved by dividing the combustion chamber into 2 compartments. There are several designs of pyrolysis furnaces. For example, this.

Upper chamber. It is loaded with fuel and its combustion. The peculiarity is that it is necessary to provide a lack of oxygen. Under this condition, the process of decomposition of the product slows down, and in fact, only its carbonization occurs (economical consumption!) and increased gas formation is initiated. Actually, this is what is called pyrolysis.

Down Cam. It receives volatile substances from the 1st compartment, which, due to the additional air supply, burn out, releasing heat. Only an insignificant part of it is spent on maintaining the pyrolysis process, and the rest is used to heat the coolant.

The figure illustrates well the main working cycles of the pyrolysis boiler.

In some models, the cameras are located on the same level.

Actually, the point is not in an engineering solution, but in the assembly of an installation in which it is possible to implement a pyrolysis process, that is, to ensure long-term combustion of fuel. And the choice of a specific scheme is at the discretion of the master.

Features of manufacturing a pyrolysis boiler

materials

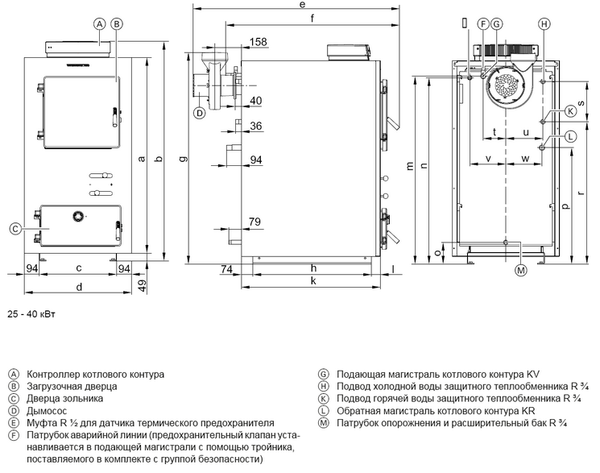

The body of the pyrolysis boiler is best made from sheet steel (from 2 mm, depending on the design power). Models of boilers that are assembled from a thick-walled pipe are hardly suitable for heating a private house. Basically, such installations heat various utility rooms, garages or temporary huts.

Larger pyrolysis boilers are mounted on the model of most heat generators - rectangular in shape. In some cases, if the model is powerful, it is advisable to lay out its walls (from the inside) with fireclay bricks.

Dimensions of pyrolysis boilers

One of the most interesting and "mysterious" questions on this topic. All calculations are made in relation to a particular house, its heating system, with all its nuances, schemes, and so on. The author will not give mathematical calculations and asks to take a word. It is better to entrust the design of a pyrolysis boiler to a specialist. The development of documentation costs money, but in any case it will be cheaper than purchasing a commercially manufactured plant.

The specifics of the operation of pyrolysis boilers

Without knowledge of some of the nuances of using such equipment, it makes no sense to start manufacturing such a model of a heat generator.

Quite "rigid" criteria for the moisture content of the combusted fuel. For example, for firewood, the maximum value is 33±2%. What is it connected with? An increase in temperature initiates the evaporation of the moisture contained in the product. Naturally, the steam will begin to mix with pyrolysis gases and negatively affect the intensity of the combustion process. The use of wet fuel sharply reduces the efficiency of the installation.

Not all types of solid fuels are suitable for combustion in pyrolysis boilers. Taking into account the specifics of their work, only materials characterized by high gas formation during combustion can be used. The lack of volatile substances affects the efficiency of operation of pyrolysis models. Simply put, a lot of firewood is consumed, but the sense is minimal.

In conclusion, we can point out that the cheapest model (and low power) costs around 48,000 rubles. In conclusion, we can point out that the cheapest model (and low power) costs around 48,000 rubles. And it’s not yet a fact that such a pyrolysis plant will completely suit the owner. For example, dimensions in accordance with the chosen place for installation. If you think about it, then making a pyrolysis boiler with your own hands, according to individual drawings, is a good solution to the problem of heating a private house, especially if it is impossible to connect it to the gas supply line.

Device

Any burner has one goal - to create a powerful flame to heat the air or water jacket of the boiler. At the same time, the combustion power itself can be adjusted independently.

The pellet burner has similar goals. The device is a wind tunnel into which solid fuel is supplied and combustion air is forced. Fuel is fed into the pipe using a special screw-type conveyor. The fuel itself before burning is in the hopper. The bunker can have a different volume, and it depends on the volume how long the burner can burn on its own without human intervention (fuel addition).

Pellet burner device: 1 - Pellet enters the burner under the action of gravity; 2 - Air enters the burner due to the vacuum created by the chimney draft; 3 - Pellet combustion occurs in the combustion chamber, which is called the "basket"; 4 - Due to the high temperature, thermal decomposition of wood occurs in the basket,which forms the flow of combustible gases; 5 - A secondary air flow passes under the basket; 6 - In the burner nozzle, the flow of combustible gases and secondary air is mixed, forming a torch; 7 - Solid combustion products are ejected from the burner into the ash pan of the boiler or furnace by a stream of secondary air; 8 - Ventilation of the supply channel does not allow hot gases to diffuse up the channel and destroy the pellet, ensuring a stable supply of pellets.

Pellet burner device: 1 - Pellet enters the burner under the action of gravity; 2 - Air enters the burner due to the vacuum created by the chimney draft; 3 - Pellet combustion occurs in the combustion chamber, which is called the "basket"; 4 - Due to the high temperature, thermal decomposition of wood occurs in the basket,which forms the flow of combustible gases; 5 - A secondary air flow passes under the basket; 6 - In the burner nozzle, the flow of combustible gases and secondary air is mixed, forming a torch; 7 - Solid combustion products are ejected from the burner into the ash pan of the boiler or furnace by a stream of secondary air; 8 - Ventilation of the supply channel does not allow hot gases to diffuse up the channel and destroy the pellet, ensuring a stable supply of pellets.

Air is forced into the combustion zone by means of injection by means of a fan.

The combustion chamber in the burner can be round or rectangular. Round burners are the most common due to their ease of manufacture. Outside, a pipe branch pipe is attached to the combustion chamber, through which fuel is supplied from the conveyor.

The design also provides for an ash pan in which combustion wastes accumulate. In the process of burning pellets, a little ash is formed, therefore it is necessary to clean the ash pan no more than once a week with the active use of the burner.

There are several types of pellet burners, each of which has its own advantages and disadvantages.

Flare type

Initially, the device was used to generate heat by burning grain, later it was converted to burn solid compressed fuel.

- Small overall dimensions;

- Can be used in conjunction with boilers in which the combustion chamber is small;

- Simplified operation;

- Increased reliability;

- Poor quality pellets can be burned.

- Low power compared to other burners;

- The flame is directed horizontally, due to which it heats the boiler locally.

Bulk type

Unlike the previous model, they have increased power and high efficiency. The disadvantages of the device include a complicated design, large overall dimensions, dependence on the quality of the pellets used.

Fireplace

Such designs are mainly used in domestic conditions, installed in fireplaces and boilers. The principle of operation of the device is as follows: pellets fall into a special bowl, where they are burned under the action of air supplied from below.

The disadvantages of the model include the size of the device and the need for point adjustment for proper combustion.

Detailed analysis of the scheme

According to the scheme presented above, our do-it-yourself pyrolysis boiler will consist of the following parts:

Apart from the fan, such a controller is the only electronic thing in the entire unit. It is strongly not recommended to save on it.

- Electronic controller controlling the fan for the boiler;

- Door for loading firewood (you can do it yourself or buy it ready-made);

- Ash pan door;

- Blower fan (purchased in the store, creates traction and draws pyrolysis products into the afterburner).

Of the controls - directly the controller and handles for opening / closing the doors.

The procedure for manufacturing a pyrolysis boiler

Before proceeding with the manufacture of the boiler, check out some useful tips. Subject to their observance, the finished equipment will be as productive, efficient and economical as possible.

Helpful Tips

- The system must be equipped with a valve to control the intensity of movement of the coolant.

- To increase heat transfer, it is better to make the coolant pipe curved, for example, in the form of a coil.

- The opening for fuel loading should be rectangular. In this case, the door of the opening should be equipped with a steel plate for sealing.

- To control the intensity of the incoming air flow, the system is equipped with a limiter.

Instruction

Pyrolysis boiler drawing

First step.From sheet metal we cut out the walls of the boiler body in the amount of 4 pieces. In the front wall we cut out holes for the combustion chamber and ash pan.

Second step. We cut holes for pipes and a smoke exhauster.

Third step. We connect together all the metal walls, with the exception of the back. To do this, we use a welding machine. We carefully grind the joints between the sides of the future heating boiler.

Boiler walls

Door

Ash pan

Fourth step. We assemble the boiler heat exchanger in accordance with the diagram presented. We weld pipes.

Boiler

Fifth step. We insert the heat exchanger into the boiler body. We make sure that the connections are tight using a compressor. In the absence of leaks, we weld the back wall of the housing.

Sixth step. Installing the grate. It will divide the boiler body into 2 chambers. In one (lower) the load will smolder, in the second - gases will burn. We complete the lower chamber with an air duct, and then we cover it with fire-resistant bricks on each side.

The body of the pyrolysis boiler from the inside

Seventh step. We mount the doors of the ash chamber and the firebox. They should fit as tightly as possible to the body.

Eighth step. We install the assembled boiler on a previously laid out brick support platform.

Ninth step. We connect the chimney. It is recommended to wrap the smoke exhaust pipe with mineral wool for insulation.

Tenth step. We connect the water circuit to the unit.

Eleventh step. Install the blower pump.

Boiler

Do-it-yourself pyrolysis boiler

Additionally, the boiler can be automated by installing a system of temperature sensors and regulators. They will control the intensity of the air supply.

Exhaust near the boiler

Automation unit (pump, exhaust and sensors connected)

Production of a pellet burner

Pellet plants are often ignored by buyers due to their high cost compared to gas and electric equipment, and the problem is solved by making the device at home.

The combustion chamber can be equipped with a square or round pipe. It is better to give preference to heat-resistant steel that can withstand elevated temperatures, the wall thickness should be at least 4 mm.

The self-made installation is fastened to the boiler with a flange plate made of heat-resistant steel with a thickness of 3 mm or more.

A container for supplying fuel to the combustion chamber can be purchased or made by hand. The best option is to immediately make an installation in which fuel will be supplied automatically. To do this, we place an auger in the purchased pipe of the desired diameter. The rotation of the device will be carried out due to the bearing, gearbox and engine running at low speeds.

Additionally, a fan is purchased in the store, which will pump air. The fan is mounted on a plate, which is made depending on the size and design of the door of the boiler used in your home.

It is also important to take care of adjusting the amount of incoming fuel and the volume of air blown by the fan, otherwise the home-made device will work unstably. In home devices, the adjustment of the air supply force and the number of pellets is done manually

This method is inconvenient due to the fact that it requires constant supervision of the burner.

For automation, an electric incandescent element and a photo sensor are purchased. The first device ignites the flame in case the pellets are extinguished and also regulates the activation of the device. The photo sensor monitors the appearance of the flame: if the flame is stable, the sensor sends a signal to the incandescent element to stop ignition.

To automate the system, a filling sensor is also purchased.It will notify the electronic filling of the device about the degree of filling of the combustion chamber with pellets.

Pellet burners are modern equipment for boilers that improve the environmental friendliness of the process and reduce fuel costs. At the same time, the equipment itself in the store has a high cost. For basic household needs, it is better to give preference to home-made devices, the operation of which, if necessary, can be automated.

natural

Natural draft pyrolysis boilers are preferable to forced ones at capacities up to 25-30 kW. They are, of course, cheaper, and the loss in efficiency of 5-10 percentage points in terms of heating costs at such capacities is almost not felt, but power supply is not required. All you need is a chimney with good draft, at least 5-6 m high. If you plan to install a boiler instead of an old Dutch flue or an undermark, then a natural draft boiler is the best option.

However, there is also a choice between two different types. The first one (lower left in the figure with boiler diagrams) - with separate supply of primary and secondary air. The second (in the same place on the right) - with a single air flow.

Do-it-yourself operation of a long-burning pyrolysis boiler

Setting up the correct functioning of the boiler after installation also has its own characteristics. Normally, the boiler does not smoke. Before the first start-up, the boiler is connected to the chimney and filled with water. The boiler is equipped with a thermostat to control the temperature of the liquid. To mount the thermometer in the boilers, special holes are provided.

Boiler switching sequence:

- The fan is connected to the mains and checked for operability. The air dampers should be in the middle position.

- A small amount of paper and wood chips should be placed in the feed hopper. The chamber doors will need to be closed.

- The chimney damper opens, the fan turns on and the paper is set on fire.

- After the firewood is ignited, the nozzle is blocked.

- Combustion control is carried out through the lower combustion chamber.

- After boiling the liquid, you will need to turn off the fan. The flame will go out, and the water will begin to cool.

The installation of the boiler provides for compliance with safety rules. It is better to mount the device in a separate boiler room. Equip the device on the basis of brick or concrete. An interval between the boiler and the walls is provided - from 20 cm.