Switching to plastic products from cast iron pipes

Cast iron sewer pipes that go to the riser from the toilet have a cross section of 123 mm, and from the sink in the kitchen and bathroom - 73 mm. Plastic products of orange or gray color differ from the elements of the cast-iron sewer system with a diameter of 50 and 110 mm, respectively.

When replacing an old piping or connecting a new toilet, it becomes necessary to connect plastic pipes to a cast-iron riser, which has a larger diameter. To solve this problem, a special rubber cuff is bought, it is installed in the cleaned socket of the sewer system.

Dismantling and cleaning of cast-iron socket pipes

To perform dismantling work that is associated with the removal of the old cement composition at the junction of the socket and pipe, you need to stock up on a mount, a flat screwdriver, and a hammer.

Tapping gently on the handle of the screwdriver with a hammer, slowly release the connection of the elements of the sewer system from the cement mortar. When the solution layer is completely removed, a wooden stick is installed in the pipe

By lowering and raising it, they loosen the fixed location of the cast-iron pipe, and with little effort they take it out of the socket

Deposits, plaque, rust are removed with a metal brush, which is mounted on an electric drill. To clean the cast-iron walls, a chisel or a flat screwdriver is also used. The smoother and cleaner the walls of the socket are, the more reliable and better the pipes made of various materials will be connected.

Installation on the socket of the rubber cuff

Reliable fastening of the cuff in the sewer socket is ensured with the help of a sealant, which is applied to its walls. Sealant must be applied in a thick layer on the outer surface of the cuff, then it is installed in the socket hole.

Carefully tapping the cuff on the edge with a hammer, you need to achieve tight adhesion of the walls of the two elements of the sewer system. A little technical vaseline is applied inside the cuff, which makes it easier to push the plastic tee into the outlet socket

Then you need to connect a pipe or corrugation to the tee, thereby connecting the toilet to the sewer system.

Connection with corrugation

A corrugated pipe, which is intended to connect the toilet to the sewer system, is used if you simply cannot use other materials. Installation is carried out in this way:

- a toilet bowl is installed at the selected place;

- outline the areas for drilling the floor covering, marking the places with a pencil installed in the holes that are in the plumbing fixture;

- the toilet after marking is set aside to make holes for the dowels at the marked points;

- install the dowels in the holes made, while fixing the stable position of the toilet bowl;

- one end of the corrugated pipe is inserted into the sewer hole, treating the docking area with silicone sealant;

- the second end of the corrugated pipe is put on the toilet flush;

- perform all other installation manipulations and test the plumbing fixture for strength;

- having drawn water into the drain tank, and having made a control drain, check the reliability of the connection;

- the absence of leaks indicates the hermetic connection of all elements.

Before installing the appliance, check the levelness of the floor covering. During the detection of a height difference, make a self-leveling screed. Otherwise, after installation, the toilet may stagger.

It is recommended to coat the seam between the plumbing fixture and the floor base with colorless silicone.This will prevent dirt from getting under the product, which will greatly facilitate the cleaning of the bathroom.

General rules

After all the necessary elements are purchased, you can proceed directly to the installation of a plumbing fixture. Despite the fact that all the operations for installing and connecting the toilet to the system are simple, their high-quality implementation will save the homeowner from problems during the period of further use of the device.

Before starting work, turn off the water supply to the flush tank. Replacing a toilet bowl with a new one is much easier than installing a structure from scratch. With this option, it is necessary to select connecting elements similar to those previously installed. It is not worth creating a new type of connection without the need, because the purchased parts may not match the diameter of the outlet pipe, and the installation of the device will be inconvenient.

Prior to installation, all construction work in the room must be completed. If, after installing the toilet bowl in the toilet, the floor level rose, then the connection of the device with the system must be carried out using a corrugation or an eccentric cuff. The final fixing of plumbing must be carried out after the toilet bowl has been previously connected to the sewer.

Connecting with corrugated products

Starting a conversation about how to connect the toilet to the sewer, first of all, experts pay attention to corrugated products - plastic pipes and different models of cuffs. To understand the full functionality of these helpers, you need to consider their advantages and small disadvantages.

- Low price.

- During operation, it can take convenient forms, due to its ability to bend and stretch.

- A great helper for the temporary connection of any plumbing devices.

- The small area of the room is not an obstacle to connecting plumbing to the sewer using this material.

- Direct installation does not require additional knowledge and skills.

- In case of mismatch between the types of socket and the release of plumbing, you can use these products and connect the toilet bowl to the sewer pipe without serious consequences.

Disadvantages of soft models:

- Low level of strength, which can lead to damage to the walls of the corrugation.

- Short period of trouble-free operation. In the case of prolonged use, the pipe sags. As a result, frequent blockages occur in the problem area.

- Only open works and installation. For installation in the wall of a building, other options must be used.

How to connect the toilet to the sewer with your own hands

In a private house, the toilet connection scheme is simplified by the fact that even if a cast-iron pipe is used as a sewer pipeline, it can be replaced with a plastic one. The rationality of such a replacement arises only if the cast-iron pipe is operated for a sufficiently long period of time.

In the apartment, the connection of the toilet bowl to the cast-iron sewer is carried out due to the hopelessness of the situation. Replacing a cast-iron sewer along with the main riser will not only be expensive, but also requires a major overhaul in the apartments. That is why many resort to replacing the cast-iron pipe to the main riser with a plastic one. Consider what are the possible ways to connect the toilet to the sewer.

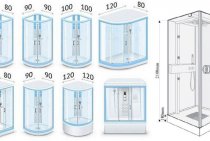

How to connect a toilet to a sewer

The outlet of the toilet bowl is standardized, and therefore there are no problems when buying a connecting pipe. Connecting the toilet causes difficulties when you need to connect the pipe to the sewer pipe. Typically, the sewer pipe has a diameter that is larger than the toilet outlet.Before installing the toilet, you need to consider what diameter the sewer inlet should be, and what, in addition to the toilet, will need to be included in the drain. In addition to the branch pipe, the connection also involves the use of adapters, cuffs and fittings.

Pipe fittings Advantages and disadvantages

The toilet bowl is selected taking into account the outlet of the pipe outlet and the location of the sewer riser, while calculating how to connect the plumbing fixture with minimal time and material costs. Otherwise, it will be necessary to completely redo the sewer, fitting it to the features of the drainage system of a particular model.

Different devices for connecting the toilet to the sewer pipe provide variability in the installation work. When the connection with the sewerage is made using vent pipes, it is possible to achieve a visual visibility of the unity of the toilet bowl with connecting elements made of the same material (porcelain, ceramics, sanitary ware, etc.).

Cuffs-eccentrics, which are made of polymers, are a design of two branches, in which the axes are shifted relative to each other. Cuffs can be bought in different lengths, so you can easily choose the right part for connecting the toilet to the sewer system, which has different socket and sewer pipe outlet parameters.

Corrugations or corrugated pipes have an elastic shape, due to which the parts can be compressed or stretched, as well as bend at any angle. All these properties facilitate installation work, during which the master only monitors the inclination of the corrugation to ensure normal patency.

A plastic or cast-iron sewer pipe is connected to the toilet using a rubber cuff, which turns out during installation, this guarantees a tight connection. Be sure to use a sealant to enhance the reliability of the connection. It turns out a very strong connection that can last for a long time.

Connecting the toilet with your own hands is done according to the scheme, and the master must have the following tools available:

- Screwdriver Set;

- a set of wrenches or one adjustable;

- knife, hammer, tape measure;

- saw for metal;

- cement, a little tow, sealant;

- sandpaper;

- dowel;

- perforator.