Advantages and disadvantages

According to the assurances of the manufacturers, the use of induction heating boilers for heating the house is a solid advantage in the complete absence of disadvantages. Let's try to figure out where is the truth and where is the marketing ploy.

1. High efficiency. Efficiency up to 99% is typical for all types of electric boilers.

2. Maximum protection against scale. Since there is no direct contact between the induction winding and the coolant (unlike the heating element), scale can form only inside the pipes. But closed systems are characterized by a consistently low amount of salts. That is, there are no prerequisites for the formation of deposits.

3. Saving resources up to 35%. Before you buy an induction type boiler and install it, remember that its main task is to convert energy into heat. To generate 1 kW, according to the law of conservation of energy, it is also necessary to spend 1 kW of electricity. The only difference is in the heating rate - the induction unit operates faster by about 20-30%.

4. The complete absence of detachable connections in the design, which eliminates the possibility of leakage. Not entirely true: the boiler includes 4-6 components connected in a block. The cost of the VIN induction heating system includes the boiler itself in a collapsible case, a control cabinet, a safety group (sensors and relays) and capacitors, pressure relief valves, a set of contacts for connecting external devices.

5. High degree of electrical and fire safety. This is true, but you need to ensure that there is no leakage, and the amount of thermal carrier remains constant. Otherwise, the device will heat up very quickly and there is a risk of explosion.

6. Does not have elements subject to mechanical wear, so the validity period is more than 30 years. Firstly, the core is durable, but the lacquer insulation on the primary winding (toroidal) is subject to aging. Its service life is 7-10 years. The result of the destruction will be an inter-turn circuit with the corresponding consequences. Secondly, induction boilers are a relatively new product that has not been tested by time, the statement about 30 years of operation is hardly true.

7. Compatibility with other systems. You can connect underfloor heating, gas or wood-burning boilers.

Tricky meter that saves electricity. It pays off in 2 months! Everyone needs to know this in order to save money!

8. Do not require a separate room and ventilation.

9. Do not need preventive work. Boiler - in any case, equipment with many sensors, relays, terminals, which periodically need to be changed, tightened. Of course, compared to gas boilers, this is insignificant.

Thus, most of the positive qualities correspond to other types of electrical units. Now let's analyze the shortcomings identified over several years of operation.

1. Cost. The price of an induction boiler SAV 5 kW is 40,000 rubles. Whereas the heating element Protherm Skat 6 kW is 23,000.

2. Significant weight with small dimensions. Since even the smallest unit weighs from 20 kg, it is recommended to mount them on the floor or hang them on a load-bearing wall using strong brackets.

3. The electromagnetic field generates strong interference in the long, medium and VHF bands. Although manufacturers claim that they do not affect the human body, health and medical officials claim the opposite. It is not for nothing that the SNiPs fix the standards and rules for the location of devices with a high level of radiation.

4. To work in the heating system in a house with 2-3 floors, a powerful circulation pump is required.

Why you need an inverter

VIN type water heaters

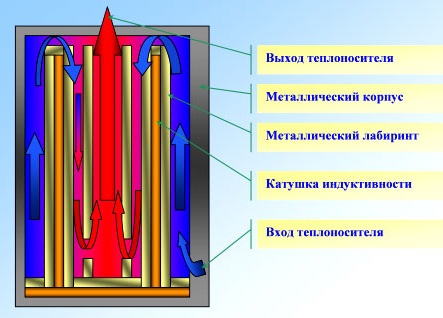

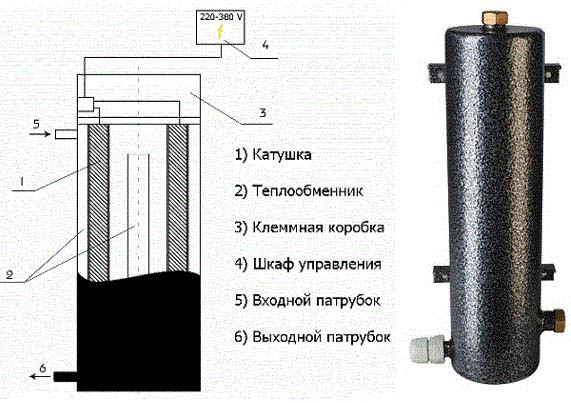

The heart of the unit is a coil, consisting of a large number of turns of insulated wire, and placed vertically in a cylindrical body in the form of a vessel. A metal rod is inserted inside the coil. The housing is hermetically sealed from above and below by welded covers, terminals for connecting to the electrical network are brought out. A cold coolant enters the vessel through the lower branch pipe, which fills the entire space inside the vessel. The water heated to the required temperature goes into the heating system through the upper pipe.

Heat carrier heating scheme

Due to its design, when connected to the network, the heat generator constantly operates at full capacity, since it is not rational to supply the heating installation with additional voltage regulation devices. It is much easier to use cyclic heating and use automatic shutdown / on with a water temperature sensor. It is only necessary to set the required temperature on the display of the remote electronic unit and it will heat the coolant to this temperature, turning off the hot water induction element when it is reached. After the time has elapsed and the water has cooled down by a few degrees, the automation will turn on the heating again, this cycle will be repeated constantly.

Since the winding of the heat generator provides for a single-phase connection with a supply voltage of 220 V, induction-type heating units are not produced with high power. The reason is that the current in the circuit is too high (over 50 amperes), it will require laying cables of a large cross section, which in itself is very expensive. To increase the power, it is enough to put three water heating installations in a cascade and apply a three-phase connection with a supply voltage of 380 V. Connect a separate phase to each cascade device, the photo shows a similar example of induction heating.

Heating with induction boilers

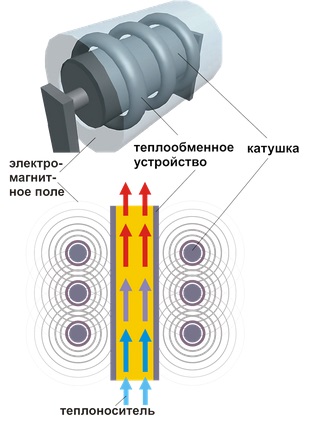

Design features of Sibtekhnomash heaters Using the same effect of electromagnetic induction, another company develops and manufactures water heaters of a slightly different design that deserves attention. The fact is that the electric field created by a multi-turn coil has a spatial form and spreads from it in all directions. If in the VIN units the coolant passes inside the coil, then the Sibtekhnomash induction boiler device provides for a spiral heat exchanger located outside the winding, as shown in the figure.

The winding creates an alternating electric field around itself, eddy currents heat the coils of the heat exchanger pipe in which water moves.Coils with coils are assembled in a cascade of 3 pieces and attached to a common frame. Each of them is connected to a separate phase, the supply voltage is 380 V. The Sibtekhnomash design has several advantages:

- induction heaters have a separate collapsible design;

- in the zone of action of the electric field there is an increased area of the heating surface and a larger amount of water due to the spiral circuit, which increases the heating rate;

- heat exchanger piping is available for flushing and maintenance.

An example of connecting an induction boiler

Despite the differences in the design of the heat generator, its efficiency is 98%, as in heaters of the VIN type, this efficiency value is declared by the manufacturer himself. The durability of the units in both cases is determined by the performance of the coils, or rather, the service life of the winding and electrical insulation, this indicator is set by manufacturers within 30 years.

Installation of the induction device

The system with an induction boiler is equipped with a circulation pump, an expansion tank, shut-off and adjustable equipment (ball valves, etc.). In private houses, as a rule, a typical connection scheme is used.

Installation of induction boilers is carried out in accordance with the instructions or technical data sheet. The device is located strictly vertically, the lower inlet pipe is connected to the return pipe, the upper one - to the supply pipeline. Only metal or metal-plastic pipes are used.

If you decide to install an induction electric boiler with your own hands, do not forget about grounding. A security group, a control cabinet are installed in the immediate vicinity, filters, a circulation pump and a flow sensor are installed at the inlet.

Overview of induction boilers

On the Russian market, induction-type electric boilers are represented by CJSC NPK INERA (brand SAV), LLC Alternative Energy (brand VIN), NPK Miratron (brand Miratron).

Reviews of SAV induction electric heaters are equally positive and negative:

“The SAV boiler heats the water in the heating system faster than the heating element, but it also cools down immediately - the small inertia affects. Savings are achieved by adjusting the performance by automatics: first it heats up at maximum, and then it turns on at half power to maintain the temperature of the liquid.

Sergei Boldovsky, Alexandrov.

“The CAB 5 boiler, according to the assurances of the sellers, operates from the outlet. In fact, to work above +60 ° C, he needs a three-phase power line and an RCD. After a failure or a decrease in the voltage in the network, the automation turns off, you have to start it manually. When contacting the manufacturer, they offered to replace it. I have the same problem with the boiler I received."

According to reviews, the vortex induction heater VIN to a certain extent corresponds to the declared characteristics.

“I installed VIN-7 2 years ago. No complaints, works fine. I did not notice savings as such, but scale does not form. In general, except for the price, it is no different from ordinary boilers.

Alexander Sokin, Rostov-on-Don.

According to buyers, the noiselessness of induction boilers is a conditional value.

“I connected the underfloor heating system to the Miraton 6 boiler. It heated up very quickly, but the hum is constant, unpleasant. The controller fails, the set temperature level does not support.

Selection Guide

1. When choosing a boiler, emphasis should be placed on the correct technical calculation of heat loss at home. This is the first and main parameter.

2. The second criterion is the number of phases. Single-phase can be connected directly to the outlet, three-phase - only a separate power line. Grounding is carried out in any case.

3. You should also consider how the induction boiler will be operated. If it is required to maintain a reduced stable temperature, a low-power device of 2.5-6 kW is sufficient.

4.Some manufacturers offer to separately purchase a mode programmer, a GSM remote control unit and others. With their help, the operation of the boiler is optimized, and the cost increases accordingly.

We offer you to watch an introductory video review of induction electric boilers:

The device of the vortex induction boiler

In fact, this technical solution is far from new, the phenomenon of electromagnetic induction, due to which electric induction heating boilers function, was discovered by M. Faraday back in 1831. Simply, thanks to modern materials and technologies, the phenomenon has been taken as a basis and implemented in water heating installations relatively recently.

Water heating occurs due to eddy currents (Foucault currents) appearing in the core of the coil. They are formed under the influence of an alternating electric field created by the turns of the coil with an alternating current with a frequency of 50 Hz. The core is made in the form of a pipe, and the coolant flows through it when heated. In fact, the device is an induction converter of electrical energy into thermal energy with an efficiency of about 98%. The diameter of the wire from which the coil is made, the number of turns and the dimensions of the core are calculated in such a way as to heat water up to a maximum temperature of 95 ºС and at the same time prevent overheating of the winding.

Overview of induction electric boilers and do-it-yourself installation

Device and features

The issue of choosing a boiler for heating a house is often decided by the availability of a heating source. Electricity, of course, is not the cheapest fuel, but it is quite common. Industry offers 3 types:

1. Heating elements - a tubular element heats up the coolant in the tank. The main plus: performance up to 99%. The disadvantages are the short service life of the main part and the rapid appearance of scale, which reduces efficiency.

2. Electrode - as the name implies, electrodes act as heaters. As a result of the reaction with magnesium-calcium salts dissolved in water, a current is formed that heats the liquid. Efficiency - up to 98%, small size, but the thermal fluid must be diluted with electrolyte.

3. Induction (vortex) - a heat generator operating on the principle of induction. Let's consider them in more detail.

The device of an induction type electric boiler is not difficult. There is a system of steel pipes enclosed in a copper winding - a step-down induction transformer. In the process, an electromagnetic field is formed that heats the core with the coolant inside. According to the company, water reaches a temperature of +70 °C in 7 minutes.

The outer casing is made of durable steel with a heat-resistant powder coating. The kit also includes an inverter (a converter made of semiconductor material), a thermostat with an internal sensor, and a control unit. It is mounted only in closed systems, regardless of the type of thermal carrier (water, antifreeze, antifreeze, oil).

Technical characteristics of the induction boiler for the heating system (household series):

On the Internet, you can often find recommendations from the folk "Kulibins" on how to build an induction heater with your own hands from tiles. Such designs do not stand up to criticism, are short-lived, often dangerous to the health of others, and the efficiency barely reaches 50%. Industrial models are more complex, safer to use, completely different materials are used in production.