Operating rules

In order for the heating element installed in the heating battery to serve you as long as possible, the following rules must be observed:

- Do not use excessive force during the installation process. Do not forcefully tighten the contact nuts and the heating element fasteners. Brittle material may burst.

- The heater is switched on only when there is water in the battery. If liquid enters an already heated instrument tube, a small thermal explosion may occur. As a result, not only the heating element will fail, but the heating battery may be damaged.

- During operation of the device, scale will form on its surface, which must be periodically cleaned. The recommended maintenance schedule is once every three months. If the scale thickness on the heating tube exceeds 2 mm, heat transfer will decrease and the device may fail.

- To exclude possible power surges, it is recommended to connect the heating element through an uninterruptible power supply or a stabilizer. The heater must be grounded during installation.

- Manufacturers recommend using only distilled water as a coolant. In apartment buildings with a common riser, it is unrealistic to comply with this requirement, so it is necessary to clean the heaters from scale more often.

Having decided to install heating elements in your home heating system, choose products that fit your radiators in diameter

In addition, it is necessary to take into account the power of the devices. This will ensure optimal indoor temperature.

When choosing a heating element, you can be guided by the following scheme:

- 20 W/m3. This power is suitable for new buildings that have excellent thermal insulation.

- 30 W / m3 - suitable for apartments in which plastic windows are installed, walls and floors are equipped with reliable thermal insulation.

- 40-50 W/m3. Heating elements with such power are recommended for use in old houses.

Installing a heating element is the best option to ensure comfort and coziness in residential premises. In fact, such a design can be compared with an oil heater, but heating elements provide faster and more uniform heating of all rooms in the apartment. It is worth noting that if the utilities in your city are working at the proper level, it is not advisable to install heating elements. Electricity bills will be quite hefty.

Features of choice

Electric heaters designed for heating batteries can differ in several parameters. Therefore, the choice should be approached wisely

Below we will consider what you should pay attention to when choosing a heating element.

Power is one of the most important parameters, since the heat transfer of the device depends on it. Therefore, first of all, you need to calculate the required power for comfortable heating of the room.

On average, 1 kW of power is required for every 10 m 2. For a more accurate calculation, it is necessary to take into account the region and the heat loss of the room. True, if the heaters are used as an additional heating element, then half the power is sufficient.

Note! It makes no sense to use a heater more powerful than 75 percent of the heat output of the radiator itself, since its capabilities will not be fully used.

Bimetal radiator with electric heating element

Radiator type

Heating elements for aluminum heating radiators and bimetallic batteries do not structurally differ from heating elements for cast iron appliances.

However, the differences are in the following points:

- The shape of the outer part of the body.

- Stub material.

The heating element for an aluminum radiator has a plug with a diameter of one inch. The plug diameter for standard cast iron batteries is 1¼ inches.

Therefore, before purchasing a heater, you should pay attention to what types of batteries it is intended for. This information is usually contained in the instructions that are included in the kit.

Heating element length

An important selection parameter is the length of the heating element. As you might guess, the uniformity of heating of the battery and the circulation of the liquid depend on this. Accordingly, the length is selected depending on the number of sections of the device.

Ideally, the heating element should be 10 cm shorter than the battery. In this case, the heating of the liquid will be carried out as evenly as possible.

Automation

Automation can be built-in and outdoor. It should be noted that a radiator heating element with a built-in thermostat is cheaper than the components separately. However, outdoor electronics tend to be more functional.

The choice depends on the purpose of the heater. If it is to be used as the main heat source, external electronics can be installed to ensure maximum heating comfort. If the device is planned to be used as an additional one, a heating element for heating radiators with a thermostat in one housing is also suitable.

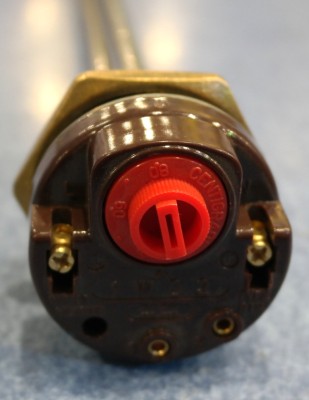

Inexpensive heating element with a thermostat for a cast-iron radiator

Manufacturer

As for the manufacturer, in this case the choice is not so important. The fact is that well-known European companies are not engaged in the production of this equipment. Therefore, on the market, as a rule, you can find products of Polish, Ukrainian and Turkish production.

All these heating elements are quite similar in quality, so more attention should be paid to their characteristics. The only thing is that it is better to refrain from purchasing Chinese products, since suppliers often import the cheapest, low-quality models. However, even among them worthy heaters sometimes come across.

Here, perhaps, are all the main points that are important when choosing heating elements for batteries.

The use of heating elements for radiators does not provide any benefit compared to other types of electric heating. However, these heaters are an excellent option for heating all kinds of utility rooms. In addition, they can be used as an additional or emergency source of heat.

You can get additional and useful information on the designated topic from the video in this article.

Comparison of an induction and heating element boiler

1: Induction boiler - manufacturers claim more than 30 years without much maintenance (100,000 hours).

The question arises, where does the data come from if this is a novelty that has only recently appeared on the market?

2: A heating element boiler loses 40% of its power over 4 years of operation, and an induction boiler does not lose at all.

This is what happens - from a 9-kilowatt boiler after 4 years only 3.6 kW remains?

For example, I installed one electric boiler - I have not observed any loss of power for more than 7 years, I have not changed the heaters and generally forgot about them, it heats up perfectly.

3: The heating temperature of the heating element coil is 750°C, which characterizes its fire hazard.

How can a heating element located inside an iron pipe threaten a fire?

Yes, I agree, it gets very hot. But how this affects the fire hazard, I have no idea ...

Is it possible to pull out the heating element, put it on a wooden floor and apply voltage - it won’t work anymore.

4: A large number of sealing connections (heaters, flanges), the need for constant monitoring. What connections and flanges?

For a long time already, people have not learned how to make electric boilers themselves in the normal way - simply and reliably.

In the design that I use, there is only one large nut, where a single / three-phase heating element is screwed - ALL.

No more flanges and seals. There are only suitable heating pipes in the same way as in the case of an induction boiler.

5: A large number of electrical contacts (terminals of heating elements) located in the zone of action of high temperature, constant maintenance of good electrical contact (pull-up, etc.) is required, which complicates the design.

Very interesting ... But what about fewer wires for a three-phase induction boiler? No, just the same.

Three phases - three coils in an induction boiler, each coil has two outputs, for a total of six contact connections. And it also requires “maintaining good electrical contact…”

From my experience, by the way, there are no problems with this. Use the main copper wire of the correct section and when connecting, stretch the contact well.

6: “due to the high watt load on the surface of the heating element, intensive scale deposits and clogging of the boiler and the system with sludge falling from the heating elements occur.”

Whoever does not understand what a high watt load is, look at how water is heated in an electric kettle, this is it.

Only the electric boiler must be chosen correctly.

The elementary inclusion of two heating elements in series at 380 - and there is no watt load.

In addition, now almost always an electric boiler is made with a circulation pump and the water has enough time to remove heat from the heating element.

In addition, this problem is relevant only for very powerful and short heating elements. If the heating element is chosen correctly, there will be no problem with the watt load.

Regarding clogging of the boiler and scale deposits, not everything is so scary. This is not a flowing water heater and heating is a closed system. Of course, during the period of operation, a small coating on the heating element is formed, but it is a small coating, and not a scale crust.

And this almost does not affect the efficiency of the heating element.

TEN and its varieties

Structurally, a tubular electric heater (TEN) is a tube made of carbon or stainless steel with a heat-conducting spiral made of nichrome, a material with high resistance, placed inside. The tube is filled with a special coolant, periclase, which is a good insulator and, moreover, has a high thermal conductivity, and is hermetically sealed. The periclase, being under high pressure, fixes the spiral centered along the axis, so it does not move when the heating element is bent and, depending on the model, is given the necessary shape. Outside, the ends of the spiral protrude, which serve to connect to the mains.

Tens for heating can be divided into groups according to several parameters:

- According to the type of heating surface, they are tubular, ribbed, rod, flat and tape:

- tubular electric heaters are used in all electric heaters in which the heat carrier is heated as a result of the conversion of electrical energy and heat. They are made of carbon and stainless steel, copper, titanium, usually from 20 to 600 mm long from a tube with a diameter of 6 to 18.5 mm of any configuration and power;

- tubular finned electric heaters are used in thermal curtains and convectors for heating gas or air, which heats the room. Ribs made of metal tape are attached to a steel heating tube with special fasteners perpendicular to its axis. The branched outer surface allows, at a lower temperature, weight and overall dimensions of the heating element, to increase its heat transfer;

- band heaters made of sheet aluminum or stainless steel are used to heat a flat surface, such as underfloor heating, but most often in industrial production;

- flat heaters are produced with a spiral in a ceramic heater for heating flat surfaces also in industry;

- rod heaters are designed to work in the holes of metal parts.

- According to the type of working medium, they can be used for heating water, air, gas, metal, oil, various aggressive media in production.

- By scope, household heating elements are produced for boilers, heating boilers, radiators, ovens and electric stoves, washing machines and electric kettles, etc.

In addition, heating elements varying in power from 15 to 15,000 W per unit surface may have additional options: thermostats and automatic shutdown sensors in case of overheating.

Types and principle of operation

There are 2 main types of electric boilers:

- Electrode.

- induction, -

At the same time, all the rest are just modifications of one of these types. An electrode boiler is often also called an ion boiler, since it converts electrical energy into thermal energy.

The design takes up a minimum amount of space, and it is fixed directly on the pipe, it does not even have to be attached to the wall. Just in case, they put it on 2 screws, but this is not necessary.

Outwardly, it looks like a small piece of pipe, the length of which is about 40 cm. There is a metal rod in the end part of the heater, and on the opposite side the heater is welded or there is a special branch pipe in it, due to which the coolant is transferred through all the system.

The design provides for the presence of 2 branch pipes, where pipes for return and supply are inserted:

- One of them can be located in the end part, and the second is installed at a right angle in the side part.

- They are often installed from the side parts perpendicular to the rest of the structure and in such a way that they become parallel to each other.

This boiler has the following principle of operation: the cathode (positively charged electrode) and the anode (negatively charged electrode) are placed in the coolant. Being energized, they start the movement of ions. Their polarity changes from time to time, in particular, one charged ion will change its charge from one to another about 50 times per second.

This eventually leads to the fact that friction occurs in the liquid due to such movement of ions, which causes an increase in temperature.

This technology leads to some disadvantages:

- The coolant in any case will be energized.

- It will have to be prepared before filling into batteries in terms of salt content.

- It is strictly forbidden to use non-freezing liquids in the heating system.

Induction boilers operating on electric current heat the coolant using a magnetic field that arises from electric current.

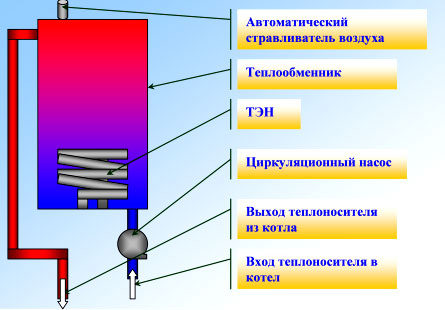

This whole design is quite simple and includes the following elements:

- frame;

- insulation;

- core, where the coolant will warm up;

- coil;

The key difference from the electrode design is that in induction boilers, the liquid is completely isolated from conductive elements, so it will not be energized.

The coil winding made of copper wire is connected to the network through a special control system. This creates a magnetic field in the coil. It will heat up the pipe, which acts as a core, and it will already give off a certain amount of heat to the water. At the same time, the body of the heating boiler will still remain cold, since there is a layer of insulation in its design.

It should also be said that the core is not made straight, but has a curved shape, sometimes in the form of a spiral, so that the coolant passes through it much longer. The service life of such a boiler is at least 25 years. After this time, the pipe, which is the core, will rust.

First meeting

The name itself suggests that the boiler is based on the principle of electromagnetic induction. To understand the essence of the process, it is enough to pass a large current through a coil of thick wire. There will definitely be a strong electromagnetic field around the device. And if you put any ferromagnet (a metal that is attracted) into it, then it will heat up pretty quickly.

The simplest example of an induction heat source is a coil wound around a dielectric pipe. It is only necessary to place a steel core inside. A coil connected to a source of electricity will heat a metal rod. Now it remains to connect the device to the line through which the coolant circulates, and the primitive induction boiler will begin to generate heat.

The whole principle of operation can be described in a few sentences. Electrical energy generates an electromagnetic field. Under the action of electromagnetic waves, the metal core is heated. Excess heat from the rod is transferred to the coolant (ethylene glycol, oil or water).

Intensive heating of the liquid generates convection currents. The hot coolant tends to rise, and its strength is sufficient to operate a small circuit. In long lines it is necessary to install a circulation pump.

Heating elements for heating radiators

Heating elements for heating radiators are distinguished by a thin flange and a narrow heating element. They are installed on cast iron and aluminum radiators, they can be made in different capacities and differ in the length of the heating element. The package includes a protective cover that protects the heating element from moisture.

Since the tube is coated with chromium and nickel during the manufacturing process, the heating elements for radiators are durable and reliable. The capillary thermostat allows you to precisely control the heating temperature, and two temperature sensors protect the device from overheating. Modern heating elements have additional functions, such as "Turbo", when the device operates at maximum power for some time to quickly warm up the room, or "Anti-freeze", designed to maintain a minimum temperature of 10 ° C for a long time.

Installing the heating element in the radiator is quite simple: remove the plug from the lower flange of the heater, screw it into the heater hole, install the thermostat and connect the power supply to ground. The passport for the device must indicate the tightness requirements, if not observed, the radiator may be energized, and this is life-threatening. Advantages of installing heating elements in a central heating system:

- protection of the premises from freezing;

- protection of the system from damage in severe frosts;

- efficiency, because all energy is converted into heat;

- pulse operation, which saves electricity;

- high accuracy of temperature control;

- additional useful features;

- democratic price.

Pros and cons of using heating elements for home heating

The main disadvantage of this heating method, as in the case of other electrical appliances, is the cost of operating costs. Electricity is still the most expensive source of heat (unless, of course, you have the opportunity to use free solar or wind energy, and you are connected to the main power grid). Another disadvantage is the impossibility of repair in case of failure of the spiral. However, there are some positive aspects, which in some cases may become a priority.

- Environmental friendliness of the heating system. When using electric heaters, there is no need to store and store any kind of fuel, and there are no harmful combustion products that enter the environment;

- The possibility of autonomous installation of the heating system in the absence of access to other thermal resources (for example, gas);

- Small dimensions and a large selection of models in terms of power and functionality;

- Possibility of automating the heating process: installation of heating elements with a thermostat;

- Low purchase and installation costs. There are models, the cost of which does not exceed 1000 rubles. And the installation of heating elements in heating radiators can be done independently.

And finally, a few tips for self-installation of tubular electric heaters. How to properly embed a heating element in a heating system? First of all, you need to choose the right model by measuring the diameters of the radiators where the heating element is supposed to be installed and making power calculations. Then carefully read the instructions for the device, which should indicate whether additional sealing is required or not. This is one of the most important points, since contact of the conductor with the heat transfer fluid will cause your radiators to be energized, and this is dangerous for residents. If the manufacturer indicates the need for additional sealing, then it must be done. In addition, the use of electrical heating devices without grounding is unacceptable.

Location of heating elements in a cast-iron radiator

The installation of heating elements in cast iron radiators has a number of features. They are associated with the diameter of the pipe and the direction of the thread. In general, the procedure for installing heating with heating elements in an existing system is as follows: disconnect the heating system from the heat source, drain the water, install the heating element, fill in the coolant, check the system's performance. When using heating elements with thermostats in the system of heating radiators, it is also necessary to check their performance after installation. It is also advisable to install water sensors and check the angles of the radiators. Since air congestion can significantly affect the operation of the entire system and disable the heating element.

Electric heaters for heating types

TENS were invented at the end of the nineteenth century in America. A patent for this was obtained in 1896. The very first products were a spiral insulated with a ceramic material and inserted into a metal tube. Such electric heaters for heating were practical products, but unsafe to operate. Mass production of these devices began 50 years after the invention. Since that time, heating elements have been widely used and have become one of the most popular heating devices powered by an electrical network. Since then, they have changed a lot, become more perfect - you can see how they look now in the photo. Modern devices are noticeably different from the very first models, but the principle of their operation has remained unchanged.

Calculation of the consumption of individual types of fuel

We calculate the required amount of fuel for a building with an area of 250 m2, with a ceiling height of 3 m, that is, V = 750 m3.

For Russia, the heating season actually lasts at least 250 days. During this time, gas and liquid fuel boilers operate approximately 6 hours a day, that is, a total of 250 × 6 = 1500 hours.

For these boilers, we use formula (1), we assume that γ=0.02 kWh/m3.

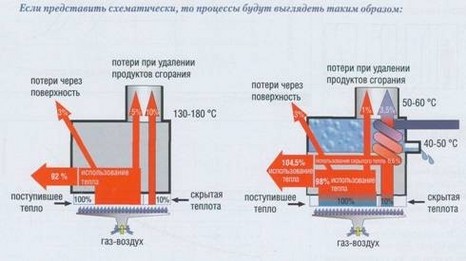

The principle of operation of the pyrolysis boiler.

ordinary gas boiler;

The hourly rate is:

SG\u003d (750 0.02 / (9.45 × 0.9) \u003d 1.764 m3, which for 1500 hours of operation will be 2645 m3.

For a gas condensing boiler, the volume of gas consumed will be 2480 m3.

diesel fuel boiler;

The hourly rate is:

Sdt kg\u003d (750 0.02 / (11.7 × 0.85) \u003d 1.51 kg, which for 1500 hours of work will be 2262 kg.

Diesel fuel consumption in liters will be equal to:

Sdt l\u003d (750 0.02 / (9.33 × 0.85) \u003d 1.89 liters, which for 1500 hours of operation will be 2837 liters.

For solid fuel boilers, this mode of operation is not suitable. These boilers operate continuously, only for pyrolysis boilers it is necessary to take into account breaks for laying a new portion of firewood.

conventional wood-fired boiler;

Working continuously throughout the heating season, that is, the operating time (in hours) for the heating season will be 250 × 24 = 6000 hours. According to formula (1), we have:

Sothers\u003d (750 0.02 / (2.78 × 0.7) \u003d 7.7 kg, which for 6000 hours of work will be 46.2 tons.

Figure 1. The combustion process in a conventional and condensing boiler.

wood fired pyrolysis boiler.

A conventional pyrolysis boiler has a combustion chamber with a volume of 0.1 m3. The required hourly consumption of firewood will be:

Sdr feast\u003d (750 0.02 / (4 × 0.9) \u003d 4.17 kg.

To determine the consumption for the heating season, it is necessary to calculate the operating time of the boiler on one firewood tab. Approximately 20 kg of firewood will enter the chamber with a volume of 0.1 m3. That is, one load is enough for 5 hours of work. If the loading time is 30 minutes, then during the day it is necessary to perform 4 loads of 20 kg each, a total of 80 kg per day. During the heating season, this will amount to 20 tons. That is, a pyrolysis boiler is more than twice as efficient as a conventional one.

Now, knowing the cost of each type of fuel, it is easy to find out which fuel is profitable to use in the area of residence.

Preventive measures in case of breakdowns of heaters

During the operation of the heating elements, the heating coil is gradually destroyed. That is why heating elements that are produced for heating batteries must be chosen with a maximum service life of 10 years. Also, as a preventive measure, follow these rules during the operation of the heating elements:

- Do not pour tap water into pipes or heating radiators, as this may cause scale build-up on the surface of the heating element. Only distilled water should be used;

- it is mandatory to install a residual current device, to which you can connect both one and several heating elements at once. If an accident occurs, it will quickly turn off the electricity, and no one and nothing in the apartment will be harmed;

- it is not recommended to frequently turn on or off the device when heating, this will shorten its service life;

- if you observe static electricity on the battery, be sure to check the heating element for leaks;

- it is strictly forbidden to install a heating element in a boiler or radiator without grounding.

If you follow these simple rules, then your heating system in the apartment will not only work efficiently, but will not pose any threat. It is also highly desirable before inserting the heating element into the heating system, to take care of the thermal insulation in the room. This will increase the life of the device, and also save a lot on electricity.

When to use a heating element

Do-it-yourself heating element for batteries is better not to use for heating, as this does not comply with technical safety standards. For example, in them it is extremely difficult to independently prevent a short circuit when current enters the coolant.

A metal coil acts as a heating element. having a high electrical resistance. This coil is in a metal sheath filled with oil.Thus, during the operation of the element, a better heat transfer coefficient can be ensured. During connection to the mains, the coil heats up and transfers energy to the shell, which acts as a heat exchanger between the water and the heating element.

Heating elements for heating are used in such cases:

- when creating heating systems where there is no main. To do this, you need a heating element for a heating radiator with a power adjustment function;

- when they are part of electric boilers. Heating elements for boilers are factory-made, but very expensive, sometimes they can be made by hand. The main heating device in this case is a special heating element for the boiler, which is characterized by high power and is designed for voltages up to 380 V;

- for rapid heating of the room. Heating with electric heating elements, unlike those used with gas boilers, is characterized by the fastest possible heating of the coolant.

Electrical appliances for heating have compact dimensions and can be successfully mounted in such units as:

This significantly reduces the dimensions of the entire heating system, which is very important for small apartments. However, heating on home-made structures is quite expensive, and this is its key drawback.

The main type of heating

- They are used in small rooms with a non-permanent stay of a person in them, for example:

-

- utility rooms;

- garages;

- various kinds of workshops.

Tip: with this use case, the heating element is installed in a radiator filled with low viscosity oil.

The refusal to use water in the heater is due to the possibility of its freezing at low temperatures. Such a heater is identical to an oil cooler and does not need to be connected to a central or local heating system. Oil circulation occurs exclusively inside the heater.

Universal heating element for heating radiators with thermostat

- Another use case is for occasionally visited country houses or summer cottages. The device is created according to the same principle as in the first case, but more devices are installed.

- In regularly heated houses, buildings, offices and cottages with no centralized heating system. In this case, the main source of heat is also a heating device with a heating element installed inside.

Tip: if the room is heated all the time, instead of oil, you can pour water inside the device and use a heating element for a radiator with a thermostat.

Auxiliary heating of a private house

If there is a centralized heating system in the house that uses a single water circuit, tubular electric heaters can be used for auxiliary heating of the coolant.

Possible applications:

- With boilers using coal or firewood as the main fuel element, heating elements can be used to heat the coolant. This is especially true in those moments when there is no possibility of servicing the boiler and filling it with fuel.

Radiator heater with built-in thermostat to maintain the set temperature in the room

- In heaters operating on liquid fuel or liquefied gas, heating the coolant with heating elements will not be more expensive. And in the case of installing a two-tariff meter for electricity, savings are also possible, the nightly tariff is usually much cheaper than the daytime one.

Auxiliary apartment heating

In multi-storey buildings, offices or various types of industrial and utility rooms with connected central heating, it is also possible to install heating elements in batteries. This method of heating is used if the central heating supply cannot provide the required parameters of the coolant in the radiators.

But this type of installation of heating elements has several negative points:

it is not possible to legally use cast-iron radiators with a heating element connected to the central heating system, since it is very difficult to obtain such permission from a service organization;

A heating element with a thermostat for a cast-iron radiator should be slightly less than the heater in length

- the high cost of work on the re-equipment of the heating system;

- it is not economically feasible during operation, since the additionally heated coolant will leave and heat other apartments. If, however, the radiator is blocked from the flow of coolant from the central heating system, heating bills will still have to be paid.

Installation of a heating element in the lower part of a cast-iron battery