Register designs

Each individual register is welded from one or more pipes arranged vertically or horizontally. Material with a diameter of 32–200 mm is used (usually 32–80 mm). The choice of the size of the register section is limited by the power of the boiler - water in wide volumetric tanks does not warm up to the desired level. The length and number of pipes depends on the parameters of a particular room: area, insulation, the presence of other heat-releasing elements in the room. In order for the heat transfer from the panel to be maximum, the distance between the two pipes during welding is made 5 cm larger than their diameter. Thus, the area from which heat is radiated into space increases. At a smaller distance, a register of smooth pipes will spend heat on heating itself, and at a larger distance, there will be air “holes” in the created thermal “wall”, the efficiency will decrease. Pipes are connected to each other by welding (less often by threaded connection) with thin transverse tubes - branch pipes.

There are various designs of this type of heat transfer elements: heating registers made of smooth pipes (round or shaped) and finned tube. The last option is a heating element on which perpendicular metal plates are welded at high frequency. This was done to increase the heat transfer area and increase the efficiency of the device. The appearance of the finned tube leaves much to be desired, more often it is used for heating non-residential premises. In apartments, they prefer to replace the ribbed structure with a more “civilized” version.

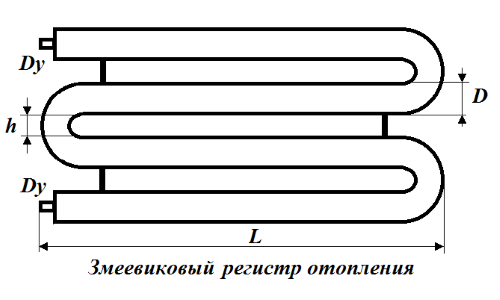

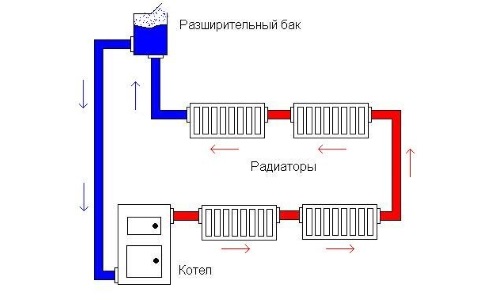

Horizontal register. The shape of the horizontal registers are S-shaped (serpentine) and sectional, which are several parallel pipes forming one section. In fact, a single-pipe S-shaped system is heating from pipes without batteries. If the installation of the pipeline is carried out with a slight slope - 0.05%, then the pump for the system is not required, the water circulates naturally. When using a horizontal register, any connection is possible - top, diagonal, bottom or side.

Vertical option. Vertical registers and radiators are a series of vertically welded thin tubes. In this design, pipes of large diameters are not appropriate, since they are installed more often where space is limited - for example, when replacing batteries with registers as a result of attaching a loggia. A circulation pump is required to move the fluid vertically. The main advantage of these samples in comparison with horizontal ones is the aesthetic appearance. A neatly welded vertical heating radiator can become a decoration of the room on its own or with the use of decorative elements.

Registers from a profile pipe

A profile pipe in cross section forms a shape other than a circle: a square, a rectangle or an oval. You can make registers from any type of profile. Although the products are more compact and more attractive in appearance than analogues from round pipes, the manufacturing process is somewhat more complicated. For this you will need:

- rectangular pipe with a section of 60 * 80 mm (or another type of profile);

- inch pipe for jumpers with a section of 25 * 25 mm;

- plugs for a profile pipe;

- Mayevsky's crane to eliminate the "airiness" of the system;

- grinder, hacksaw;

- welding machine.

The sequence of actions in the manufacture of a three-pipe sectional register from a rectangular profile is as follows.

A rectangular pipe is cut into pieces of the desired size in the required quantities.

Markings are made on the cut metal segments for cutting holes, into which jumper pipes are subsequently welded. Holes are cut.

For jumpers, 4 inch pipes (25 * 25 mm) are used.

Plugs on a profile pipe are cut from sheet metal 3 mm thick. The dimensions of the rectangular plugs along the perimeter are 1.5 mm smaller on each side than the section of the profile pipe - to fill the space with a weld.

The pipes are laid out horizontally, jumpers are applied strictly along the holes.

The lintels-pipes are point-wise “tacked” by welding: 3 points are made so that in the process of further work there are no kinks or distortions.

WATCH VIDEO

The product is installed vertically. All lintels are fully welded.

Mounting methods

A home-made heating battery is assembled from separate pipes by welding or threading. The first option is preferable and stronger than the second, the welds can withstand a pressure of 13 atmospheres. Registers for heating are assembled into finished products, and then connected to the heating circuit. The device is mounted on the wall with brackets; for installation on the floor, supports are welded from below. The assembly process of a sectional product takes place in several stages:

- Cut the required number of pipes of the desired dimensions.

- Markings are made on the blanks, marking the points of connection of the nozzles.

- Connect pipes and fittings.

- Plugs are welded, a drain valve is installed.

- The product is connected to the heating system.

Advice. The branch pipes are located closer to the edges of the register - the circulation of the coolant in this case will be more intense.

"Samovar" for heating. In some cases, a home-made register is supplemented with a heating element and an expansion tank - an independent heating device is obtained, called a samovar. It does not communicate with the general heating system, it heats the room autonomously from a 220 V network. The sufficient power of the heating element is 1.5 kW, which is slightly more powerful than a kettle. For convenience, a thermostat is connected to the electric heating element. You can make a samovar with your own hands from round or shaped pipes, models can be stationary or portable, used to heat an unheated change house, pantry, garage. In these cases, it is better to use not water, but antifreeze or oil as a coolant.

Expert answers

Tori:

plastic pipes and aluminum radiators.

LegendaSporta:

polypropylene.

mu.rza:

we bought polypropylene. each has its pros and cons. read here, a very informative article about pipes

vladislav ushkalov:

Igor Shkurny:

Polypropylene ... take less with it ... unless of course there is a soldering iron !!!!

Lizard:

I bought a house with completely defrosted metal pipes and cast-iron batteries. I chose, consulted, changed to polypropylene and aluminum batteries. Bought one cast iron. and what? It was she who cracked in the very frosts (there was no heating, and there was antifreeze in the pipes, but it did not help). Changed it to aluminum. Further, in the well next to the house, there is a water pipe for five houses, each with its own valve, the pipes are all iron. Rusted like hell. When it broke again, I raised a storm, collected money from the people, and the local master replaced the filling of the well with polypropylene again. Now we are all calm. So polypropylene is probably more reliable. Some people claim that pipes made of polyethylene (very dense) are even more reliable, and they are not afraid of frost at all, but I don’t know.

Cloths:

iron pipes are 3-5 times cheaper, in terms of reliability they are much more reliable than propylene and plastics. The disadvantage is corrosion of the metal from the inside, which cannot be eliminated in any way, but if the water is not drained from the system, then after cutting a 20-year-old pipe, it is as good as new inside (I have cut old pipes from heating more than once—-there is almost zero corrosion inside. And heating devices are more aesthetically pleasing aluminum and bimetal.The cast iron of the USSR is no longer in vogue, and the material consumption is terrifying)))

Sergei Rudin:

Look here: agrosad m /catalog/tverdotoplivnie_kotli_1

solo:

In a private house AOGV.) There are no other options, as it were.

Andrey:

reformulate the question. A radiator heating system is one thing, but pipes and batteries are a completely separate issue.

Alexander Bonn:

Gas boiler, steel radiators, welded pipe. Energy consumption: 10 sq m = 1 kW. For a private house, they combine underfloor heating (1st floor) and radiators. But there must be an emergency heating system (electric or solid fuel).

Alasseia:

the question of heating a spherical house in a vacuum no information about the source of energy supply, no information about the house itself what would I advise - a project for heating your bungalow made by a specialist

F F:

Boilers, boiler equipment. Heating 2 x storey building. : // forum .domostroy /#gazosnabjenie-vodoprovod-otoplenie-konditsionirovanie Gas wall-mounted boiler Heating, plumbing, sewerage of a house or cottage. Heating 2 x storey building.

alexm66:

The question is very general: what is better, a foreign car or a VAZ - what money and opportunities are there for. I think the main criterion is the reliability of the equipment, and a competent installer will be able to make a workable system out of it, and an illiterate one will ruin any "luxury" equipment.

Best Answers

drinker in the thorn bush:

If done aesthetically, steel registers are better. If the registers are already mounted, close behind decorative grilles.

Technical Box:

Smooth-pipe contouring for good circulation and a large volume of coolant.

Uncle from the Future...

The thermal conductivity of steel is 5 times less than that of aluminum .. This means that with the same surface area of \u200b\u200bthe device, the heat transfer from steel will be lower than that of aluminum .. That is, it will have to be made 5 times larger in size ..

Alexander:

The advantage of a smooth register with a large open surface area is that it maintains efficiency at low coolant temperatures, which cannot be said about modern aluminum ones at temperatures of 40 and below. The disadvantage of a register that has a high heat capacity is that this heat capacity prevents precise control. and what fraction of the day the return temperature can be no higher than 40C or you have an automated pellet plant with a bunker for several days.

ip:

The best option for hydraulics, along with registers, is cast-iron radiators. They have a slightly larger surface area relative to their volumes and linear dimensions compared to registers. If you need to heat a room without windows and without furniture along the walls, then the registers will be good, and if there are windows , then it is worth putting cast iron under them and it will block the heat loss of the room for a couple with a DN50 pipe around the perimeter. The calculation of cast iron comes down to a set of sections in the ratio of two sections per linear meter of the street wall for the first floor and one and a half for the second with the first heated one. Good luck.

Anatoly Bananan:

I think that aluminum heating radiators teplofresh /catalog/alyuminievye-radiatory-otopleniya are best suited for a private house. Such radiators are of two types - cast and extruded. Extrusion is more suitable for heating systems where antifreeze is used, as these radiators are more durable and are made of aluminum of a sufficiently high purity.

Maria Lamyr:

I think that stainless steel decorative mesh is perfect for you, it is both beautiful and durable! By the way, decorvesta is a good store with similar products!

pavel mokrov:

The thermal conductivity of steel is less than that of aluminum, so it's better to take an aluminum radiator, look here tallosplav /catalog/alyuminievye_radiatory/.

Sectional registers made of smooth tubes

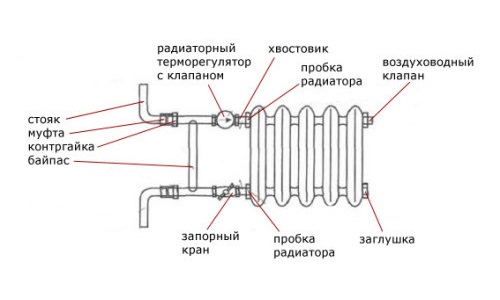

Sectional registers are in very good demand among owners of private houses. Such devices consist of pipes that are interconnected and closed with plugs. The energy carrier passes through the upper pipe, enters the next, and eventually enters the outlet line.To increase heat transfer, transitions between sections are tried to be made as close to the edge as possible. Shell plugs can be elliptical or flat. The inlet pipe can be made for flange, thread or welding.

The design of sectional registers includes a threaded fitting, to which a special bleeder is attached to remove air from the system. Pipes for sections can have different diameters (from 25 mm to 40 cm), so choosing the right option is not difficult. Reducing pipes usually have a smaller diameter. In addition, one of the most important conditions for the operation of such installations is the pressure in the system, not exceeding 1 MPa.

Structural features

Most often, radiators are made of smooth steel pipes. Welding of smooth pipes is registered and serpentine. Registered pipes can have 2 types of pipe connections - this is a column and a thread. Column - the connection of each pipe to each other on both sides with the help of jumpers. When connecting the "thread" jumpers are installed alternately, then on one side, then on the other. This ensures a serial connection, and the coolant flows around all the pipes in turn.

The heater radiator can be welded not only from round, but also from square pipes. They are not much different, but they are more difficult to work with and have higher hydraulic resistance. Although such radiators are much more compact.

The area of contact between the metal and air in this case is much larger, which increases heat transfer. Such heating registers do not look very presentable, but they heat the room well, despite the temperature outside the window.

Pipes and a radiator in the heating system of a private house ...

From the wording of the question, it is not entirely clear whether the private house is yours or belongs to the customer ...

If we assume that the house belongs to the customer of the work, then in order to avoid claims on his part, everything should be done in accordance with the project (contract).

If you equip your house with a heating system, then its elements should be chosen, taking into account durability and ease of maintenance, of course, taking into account the “issue price” available to you personally. Usually everything turns out when the work is done according to a ready-made project that suits everyone.

Now in order. And so the pipes:

"... which pipes to choose: steel or ferrous metal?" There are only two types of ferrous metal - steel and cast iron. Cast iron differs from steel only in the percentage of carbon in the alloy and usually in the presence of certain alloying additives. Pipes for heat-water-gas supply systems earlier (in the last century) were produced only from steel of various grades. This was due to their relatively low cost and the ability to quickly install systems. However, the advantages of steel pipes ended there. The main disadvantage of steel pipes is their poor resistance to corrosion damage and, as a result, low durability. Therefore, if there is a desire to leave a reliable working heating system as a legacy, then I do not recommend using ferrous metal pipes.

Currently, polymer and metal-polymer pipes are produced for use in heat-water-gas supply systems. Their structural difference is the reinforcing layer. Some use fiberglass, others use metal (usually aluminium).

Their main advantage is the impossibility of recycling the material in natural conditions. It is this quality that determines their exceptionally high resistance to corrosion damage. In addition, polymer pipes have a lot of other advantages compared to steel pipes. When operating under passport conditions, the service life of polymer pipes is at least 50 years.

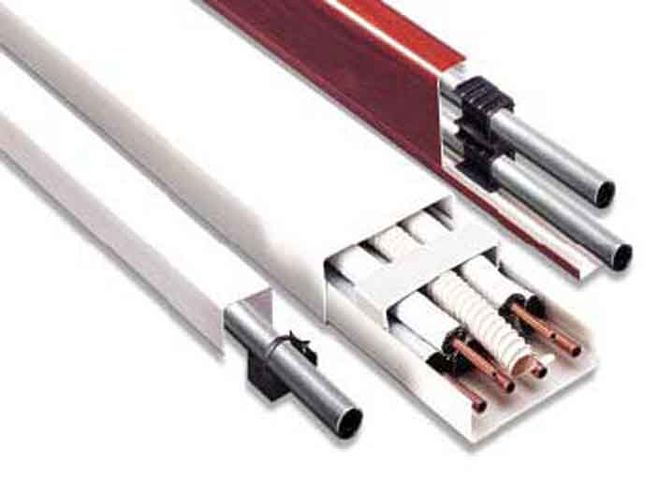

In accordance with modern design standards, pipelines of all systems must be laid covertly. In interior design, pipelines of engineering systems are not used.Pipelines of engineering systems are fixed on the elements of the supporting structures of buildings, in specially equipped channels, behind decorative lining. In extreme cases, pipes are laid in special plastic boxes.

And now about: “which radiator is better to buy for a private house, the area of \u200b\u200bthe house is about 60 square meters?”

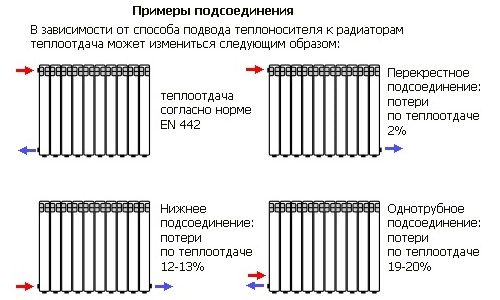

Let me suggest that you need a heater in the house, and not a source of thermal energy. If so, then it is usually chosen according to two parameters - according to the required power and as an element of the interior of the room, of course, based on financial capabilities. The power of the heater for a “normal” dwelling made of stone-reinforced concrete structures with “standard” thermal insulation is selected at the rate of 1 kW per 10 sq.m of area. But it is far from a fact that the temperature in the room after such a “selection” will be comfortable. Usually, one heater is installed in each room. In rooms of large volumes and taking into account the requirements of space-planning solutions, several heating devices can be installed. If a decision is made to use radiators of standard designs as heating devices, then most likely they will need to be covered with decorative grilles, which will inevitably reduce their efficiency.

To date, in terms of design and technical characteristics, the most efficient heating device is a fan coil unit. None of the radiators can be compared with it in terms of efficiency and heat dissipation.

Fan coil units are currently being produced a fairly large number of models, which differ significantly in terms of a number of capacities and appearance. All of them easily and naturally fit into any interior.

That's basically all about which pipes and radiator are better in the heating system of a private house ...

If you have any questions, I will answer in a private message. Good luck!

Main selection criteria

Any specialist has a whole arsenal of tools that help him make the right choice. Each type of pipe has both positive and negative characteristics. Therefore, given them, it is not difficult to find the optimal solution. Much also depends on knowing what heating systems exist and what engineering conditions must be met.

Here is a list of the main initial data that must be taken into account when choosing pipes for heating:

- The presence of a forced or gravity heating system

- Laying method - internal or external

- Complex or simple system configuration.

- System pressure power

- Maximum water temperature

Below is a list of existing options. It will help you decide which pipes to choose.

How to make registers from round pipes with your own hands

This option is the most widespread of all the above designs for several reasons: manufacturing does not require specific skills, round pipes are commercially available, and the product layout is simple. Required materials and tools:

- round pipes of the desired diameter (40–70 mm);

- branch pipes Ø 25 mm;

- end caps;

- drain valve;

- grinder, hacksaw;

- welding machine;

- measuring tool.

Standard quad radiator

If it is planned to manufacture an autonomous "samovar", then an additional purchase of a heating element and an expansion tank will be required. The scheme of work on the manufacture and connection of the device is as follows:

- The choice of the model suitable for a particular case: horizontal or vertical heating radiators.

- Determination of dimensions, drawing up a diagram.

- Purchase of materials.

- Welding of the product (or less often assembly with a threaded connection).

- Leak test.

- Connection to the heating circuit system.

Below are recommendations for the independent production of registers from round pipes.

Any plumber or person who has the skill of assembling pipes or wiring according to a pattern or scheme will be able to mount the product.

For the manufacture of registers, drawings are not required, a simple diagram or drawing is enough to give an idea of what kind of design the output should be.

It is important not to succumb to the temptation to "weld the pipe thicker." The larger the pipe diameter, the more water will have to be heated, and this is an additional load on the boiler plus an unjustified increase in the heating bill

The optimal conditional diameter of the pipe is Ø 32 mm.

You can increase heat transfer by increasing the distance between the pipes - add 5 cm to the value of the pipe diameter.

The most reliable connection is welding. If a thread is used, then UNITEC plumbing linen or adhesive-sealant, which is specially designed for threaded connections in plumbing systems, is used as a gasket.

Types of registers for installation

The most commonly used products are cast iron, steel and aluminum. The most common aluminum Their advantages are as follows:

- resistant to corrosion;

- have a minimum weight;

- long period of use;

- no joints and joints from welding;

- high heat dissipation.

In the manufacture of aluminum registers, monolithic casting is used. Such products are most often installed in residential and office premises. If you need heating in production, it is better to install registers made of steel or cast iron, as they are more durable. Heating systems can be either stationary, in which the coolant is heated by a boiler, or mobile. In such registers, special protection against accidental electric shock is installed. Steel heating registers are not characterized by high heat transfer, but they significantly benefit from budgetary cost, ease of processing and a large selection of sizes.

Stainless steel registers are also used, but they have low heat transfer, so they need a lot of pipes to make them, which is quite expensive. In heating systems, where all wiring is made of copper pipes, registers are installed from a similar material. They have the highest heat dissipation. It is 4 times higher than steel. Copper has a high ductility, so it is easy to bend it in the right places. Welding is required only at the connection points of the different parts. Copper registers have quite serious drawbacks - these are the high cost and the need to comply with the terms of use. In order for copper registers to serve for a long time, the following conditions must be observed:

- there should be no solid particles in the coolant;

- there should not be other metals incompatible with copper in the system;

- grounding is installed in the system to prevent corrosion;

- since the metal is very soft, special protection is needed for the registers.

Cast iron registers are massive and heavy, so you need to install strong racks under them. Cast iron is a very brittle metal and can be damaged by a strong impact. Because of this, cast iron registers need protection in the form of casings, which significantly reduces heat transfer and increases their price. Installing them is quite difficult. Cast iron is a chemically neutral material, and he does not care what coolant is in the radiator.

The most budgetary and reliable material for registers is steel.

Practical heating registers what to choose for a house and an apartment

On the market, everyone can choose heating registers for installation in an apartment or private house. On sale there are structures made of metal horizontally arranged pipes, interconnected by special jumpers, due to which water moves through the heater. Modern registers have a higher heat transfer than traditional Soviet batteries. The most popular aluminum registers have the best technical characteristics.Home-made batteries are used in small apartments or rooms, ensuring proper heating of the available space.

Production material

If we make a selection depending on the material of manufacture, then the registers can be classified into the following categories:

- steel;

- aluminum;

- Cast iron.

Which heating registers are better to choose? Steel registers have become the most common. Their connection to the heating system is carried out by threading or welding. Such devices have good heat dissipation and reasonable cost.

Aluminum registers are much lighter than steel ones. In addition, they are resistant to corrosion, are made without connecting seams and have good heat dissipation. The main disadvantage of such devices is a very high price.

Registers made of cast iron are connected to the heating system using a flange connection. They are fairly easy to install and are cheap. The disadvantages of cast iron products include low inertia, which significantly reduces the warm-up time of the registers.

Calculation of the number of ribs

Calculation of heating registers must be carried out even before they are purchased. The diameter of the pipes is very important: experts believe that pipes with a cross-sectional diameter ranging from 3 cm to 8 cm are suitable for a private house. This decision is due to the fact that a conventional heating boiler is not able to produce more heat, so too large surfaces will not warm up completely .

When calculating, you need to pay attention to the length of one register fin and heat transfer per meter of this length. For example, a meter pipe with a 6-centimeter section can heat one square meter of area.

When calculating the required number of ribs, the result should be rounded up. The calculation of the number of heating registers must also take into account the characteristics of the building. For example, if a building has a large number of windows and doors, or if the walls are thin and poorly insulated, then the number of registers can be increased by 20-50%.

Which metal is better

To begin with, we note that structures of this kind can be intended both for heat transfer, acting as radiators, and for heat intake, when the tubular register is mounted directly in the combustion chamber of a boiler or furnace.

Plus, in some models, instead of a liquid coolant, heated gas is used, for example, a radiator chimney.

- Steel pipes for heating radiators are deservedly considered leaders in this market sector. Of course, the heat transfer of steel is not as high as that of aluminum or copper, it is subject to corrosion and requires regular maintenance. But these shortcomings are more than compensated by the affordable price, as well as a wide range of types and sizes. In addition, it is much easier to cook ordinary ferrous metal than non-ferrous.

- Stainless steel for such structures is used extremely rarely. Apart from the fact that its cost, to put it mildly, is far from the budget, argon welding is used for soldering stainless steel, and not every professional welder can work with it.

Important: in this case, it simply does not make sense to use galvanized iron. Thin zinc coating simply burns out during welding

As a result, an already weak weld is additionally affected by corrosion.

The use of copper tubular registers is justified only in the case of copper wiring around the house. The heat transfer of copper is four times higher than that of ferrous metals, so here we can talk about heating with pipes without radiators, more precisely with a minimum number of radiators. But, firstly, the price of copper is fabulously high, and secondly, this metal is very demanding on operating conditions.

Copper wiring for heating.

-

- Copper systems require a finely purified coolant that does not have hard abrasive inclusions.

- In such systems, fittings should be copper or compatible metals such as bronze, nickel, chrome or brass. Moreover, aluminum and copper are strictly forbidden to combine.

- Copper pipelines without fail require high-quality grounding, as there is a danger of electrochemical corrosion.

- Copper is a soft material, so the system needs extra protection, of course shrouds and shields also cost money.

The cast iron radiator heating pipes shown in the photo are still used in industrial buildings and technical rooms. But the weight of this design is much higher than that of a household cast-iron battery. Given the non-aesthetic appearance and rather low efficiency, they are not popular.

Tubular cast iron batteries.

Tip: cast iron tubular registers are the best suited for installation in the combustion chamber. Optimum heat capacity, low price and unpretentiousness in relation to the coolant make them leaders in this area.

Making a register with your own hands

Homemade registers for heating are quite simple, and special skills are not required in their manufacture. All you need is experience with a welding machine and the availability of basic parts for manufacturing.

When creating registers with your own hands, the following algorithm is used:

- First, pipes of the appropriate diameters are prepared and blanks are cut;

- The internal space of the pipe is being cleaned to reduce the resistance to the energy carrier;

- At the ends, it is necessary to weld the plugs. Some plugs need to be provided with holes;

- It is now possible to connect large diameter horizontal pipes with reduced vertical pipes;

- At this stage, valves are installed that will allow the air accumulating in the system to be removed;

- The last step: cleaning all the seams and painting the surface of the register with oil paint.

Heating registers from a profile pipe will have all the necessary parameters. When assembling portable structures, it is necessary to install a heating element with a power of 1.5-6 W, which can be connected to a power outlet. By connecting the registers to heating boilers, you can increase the performance of the system by installing a circulation pump.