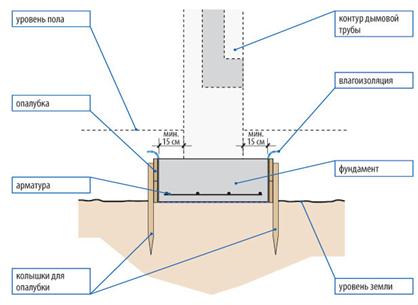

Foundation dimensions

Calculation of the foundations of chimneys is carried out on the basis of the overall dimensions of the chimney.

The standard chimney foundation has the following parameters:

- at least 40 cm below ground level;

- 15 cm from each edge more than the dimensions of the chimney.

Method for determining the dimensions of the foundation

Builders of industrial chimneys make a complete calculation of the chimney: the foundation, its height, cross section, and so on. It is carried out on the basis of the formulas proposed by SNiP "Foundations and Foundations", and takes into account all the parameters of the pipe and the depth of soil freezing in the area of \u200b\u200bthe chimney installation.

It is quite difficult to independently calculate according to the formulas presented in the documents. Therefore, you can use the base parameters presented above, or resort to the help of qualified designers for the calculation.

Determination of the area of the base of the foundation should be carried out in accordance with the instructions in clause 1.1.3.

preliminary dimensions

foundation with a round sole should be determined by the formula:

,

where: D - diameter of the round foundation; e

– eccentricity (see clause 1.1.3), A –

value determined by the formula:

,

where: NII

- design vertical load at the level of the edge of the foundation; R' - value determined by the formula:

,

where: R is the design soil resistance of the base,

determined by adj. 3 SNiP 2.02.01-83*, depending on the type of soil and its

physical and mechanical characteristics; γm

- the average value of the specific gravity of the foundation and soil on its ledges,

it is allowed to take equal to 2 t/m2; d

- the depth of the foundation.

preliminary

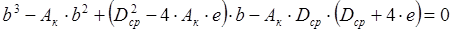

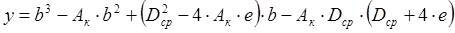

the dimensions of the foundation with an annular sole should be determined by the formula:

where: DWed is the average diameter of the ring; b - ring width; ATo

- value determined by the formula:

Received cubic

equations are conveniently solved graphically, for which these equations

lead to the following form:

and

Further

build graphs of functions, in the first case y= f(D), and in the second y= f(b).

Intersection points of the obtained graphs with the axis Y (y = 0) will correspond to the desired values D or b, respectively.

Next, take the final dimensions of the foundation with

taking into account the modularity and unification of structures and determine the pressure at the edges

foundation soles (edge pressures), and average pressure along the foundation sole

according to the formula:

,

where:GfII - the calculated value of the weight of the foundation; GgII - the calculated value of the weight of the soil on the ledges

foundation; A is the area of the footing of the foundation.

If the eccentricity of the resultant is displaced

relative to one of the main axes of the rectangular base of the foundation, edge

pressure is determined by the formula:

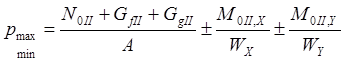

,

where W

- the moment of resistance of the area of the base of the foundation, equal to the foundation with

round sole:

,

for foundation with ring

outsole:

,

where:

R - the radius of the foundation with a round sole, D

and d - respectively outer and inner diameter

foundation with an annular sole.

The values found must satisfy the following conditions:

; ; .

If the eccentricity of the resultant is displaced

relative to both main axes of the rectangular base of the foundation, edge

pressure is determined by the formula:

Found

values must satisfy the conditions:

; ; .

If

the pressure values along the base of the foundation do not satisfy the conditions, it follows

increase the footprint of the foundation.

Check

foundation pressure on a weak underlying soil layer should be carried out in

in accordance with the instructions of clause 1.1.4.

Definition

foundation settlements should be carried out in accordance with the instructions of paragraph 1.1.5.

It should be noted that with a foundation diameter of 10 m or more, to determine

foundation settlements should use the calculation scheme in the form

linearly deformable layer.

Check

foundation on the action of frost heaving forces should be carried out in

in accordance with the instructions of clause 1.1.6.

Definition

foundation roll under the pipe is made in accordance with App. 2 to SNiP

2.01.02-83*, as for a rigid foundation.

Bank

foundation i under the action of an eccentric load

is determined by the formula:

,

where: E

and v - deformation modulus and Poisson's ratio

base soil; ke -coefficient,

accepted by adj. …; N and e – vertical

component of the resultant of all loads on the foundation at the level of the sole and its

eccentricity; a - diameter of a round or side of a rectangular foundation,

in which direction the moment acts; km

- coefficient taken into account when calculating foundations according to the scheme

linearly deformable layer at a ≥ 10 m and E ≥ 100 kg/cm2,

accepted by adj. 21.

Chimney Requirements

The chimney removes and disperses harmful products of fuel combustion into the atmosphere

It is important to design and build it correctly. Otherwise, the inner walls will be clogged with soot, ash, soot, blocking the outlet channel and preventing the removal of smoky masses, making it impossible for the boiler room to work.

There are technical standards that clearly regulate the parameters of chimneys:

- Brick structures should be made in the form of a cone with a height of 30 to 70 m, a diameter of 60 cm. The minimum wall thickness is 180 mm. In the lower part, gas ducts with revisions for inspection must be equipped.

- Metal pipes used for the installation of chimneys are made of sheet steel 3-15 mm. The connection of individual elements is carried out by welding. The height of the chimney should not exceed 40 m. The diameter can be from 40 cm to 1 m.

- To ensure the stability of metal structures, brackets or anchors are installed at a distance of 2/3 from the height of the pipe, to which extensions are attached.

- The height of the chimney (regardless of the material of manufacture) should be 5 m above the roof of buildings located within a radius of 25 m.

The dimensions of the structure are calculated taking into account the volume of the furnace and climatic conditions, so that draft is provided at any air temperature.

Principle of operation

In order to maintain a constant fire in the furnace of the boiler room, air must continuously flow to it. In this case, the products of fuel combustion are removed with their further dispersion in the atmosphere. Both of these processes are provided by natural traction.

Chimneys for boiler rooms work on the principle of the physical law of communicating vessels - the mass of low-temperature air is greater than that of heated air in the form of a column of the same height. Thus, a cycle takes place in which clean air enters the boiler, pushing the treated air through the chimney.

In providing thrust, the height of the structure, the temperature inside and outside, as well as atmospheric pressure play an important role.

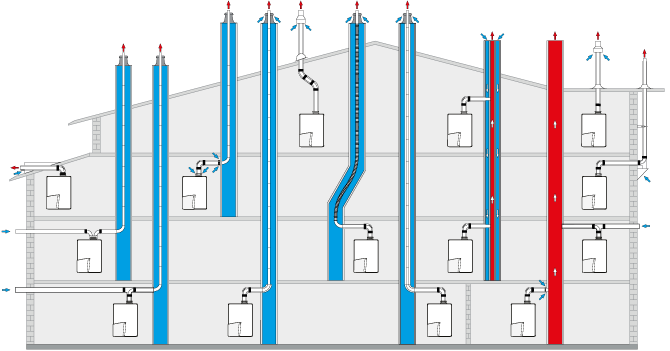

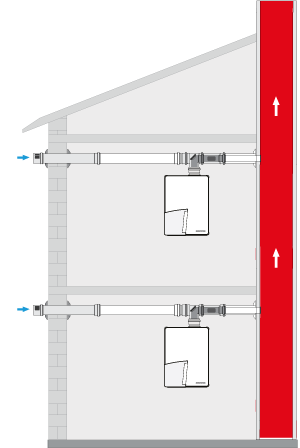

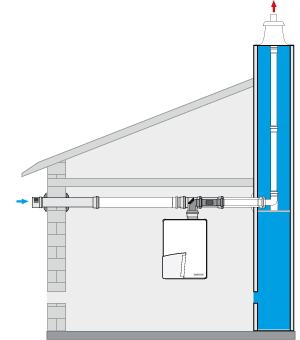

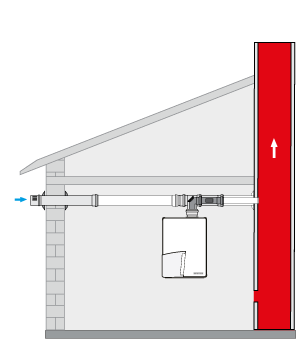

Basic schemes for installing chimneys for condensing boilers

All chimney schemes for condensing boilers are divided into two main types: with air intake for combustion from the room and from the street. Naturally, these types of smoke exhaust and the requirements for them are described in domestic regulatory documentation, but in the documentation for boilers there are usually names according to European standards. The chimney with air intake from the boiler room is designated as “Bxx”, from the street - as “Cxx”. The first index varies depending on the specific scheme, the second - on the location of the fan relative to the boiler heat exchanger. In all modern condensing boilers, the fan is located in front of the heat exchanger, which is indicated by the index “3”.Below are the main schemes using wall-mounted boilers as an example:

For domestic capacities, the calculation of the chimney is usually optional, it is enough to follow the recommendations of the boiler manufacturer for the maximum length, taking into account the shaped elements (elbows, tees, etc.). In the case of industrial boilers, a flue gas calculation is mandatory, you can contact the chimney manufacturer for it.

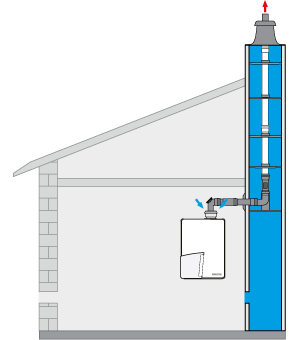

Combustion air intake from the room

|

The easiest way to organize the removal of flue gases. Almost always used for large capacity boilers: industrial or commercial, when floor standing boilers are used. It is also often found in domestic use.

Two main requirements when using such schemes: ensuring the necessary air flow into the boiler room and its cleanliness. For boilers with large capacities, this is usually not a problem, since these points are carefully taken into account at the design stage. In private boiler houses, a situation often occurs when sufficient air flow is not provided; or it is carried out through adjacent rooms, where, after starting the boiler, finishing work continues, which contributes to the presence of fine dust in the air and clogging of the internal elements of the boiler. Naturally, this state of affairs should be avoided or special air filters on boilers should be used. |

|

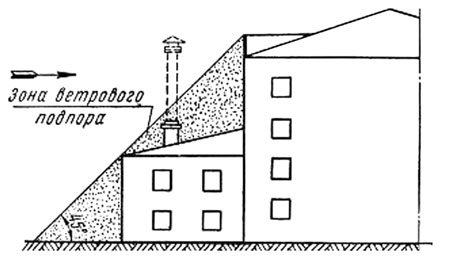

In this case, the chimney must necessarily be led above the roof level from the area of the so-called “wind head”.

This is necessary in order to exclude the influence of air pressure fluctuations on the smoke removal process.

In this case, two main subtypes of the chimney are used: coaxial and separate.

|

|

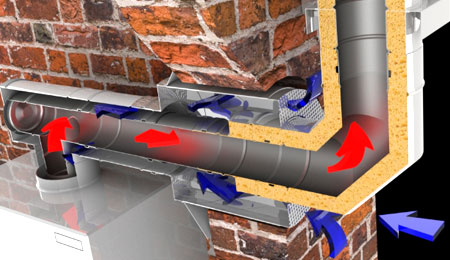

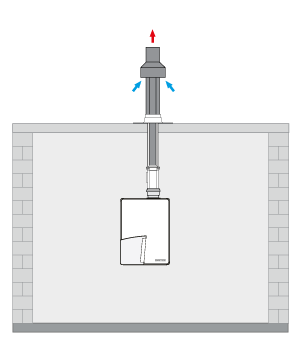

coaxial chimney

As mentioned above, it is distributed mainly in domestic use with wall-mounted boilers. In a private house, a coaxial chimney is especially convenient in that it is enough to simply bring it horizontally beyond the wall, without constructing a vertical shaft that extends beyond the roof level. This is possible due to the fact that the air intake and smoke exhaust areas are located side by side in the same pressure zone, and thus are not affected by the wind.

There remains, however, the question of dispersion of flue gases in the atmosphere. Emissions from modern condensing boilers are environmentally friendly, but the chimney must comply with regulations for distances from windows, doors, ventilation grills, and adjacent land. In order to combine the convenience of installing a coaxial chimney indoors and using a double-walled pipe outdoors, you can use special adapter kits.

In the case of modernization of an existing boiler room with brick chimneys, there is a version with a coaxial pipe to the zone of this chimney. Further, a new stainless steel pipe is laid inside it (single-walled can be used). Air intake is carried out through the gap between the steel pipe and the brick chimney.

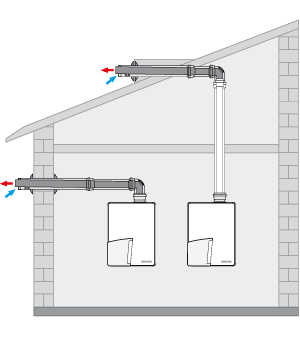

Separate chimney for combustion air intake

|

|

The most diverse version of the organization of the chimney in terms of execution options. Nevertheless, it is rare in private construction and industrial boiler houses. Since for condensing boilers in the first case it is usually easier to use a coaxial chimney, in the second - air intake from the room.

Often found in apartment buildings with separate heat generators for each apartment, according to the following scheme:

For the choice and purchase of a chimney for a condensing boiler, please contact our representatives.

Foundation construction

Necessary materials

Before building the foundation, it is required to prepare all the necessary materials, which include:

- sand;

- gravel or broken brick;

- concrete mix. The grade of concrete B15 is optimal, but a higher class of mixture can also be used;

- metal reinforcement with a cross section of at least 12 mm;

- heat-resistant brick;

- any waterproofing material.

Main stages

Foundations for chimneys are built according to the following scheme:

- a place is chosen for installing the furnace and chimney. It is desirable that the chimney does not come into contact with the walls of the residential building, since additional condensation may form with such an arrangement. The foundation of the furnace and chimney should be located at some distance from the foundation of the house;

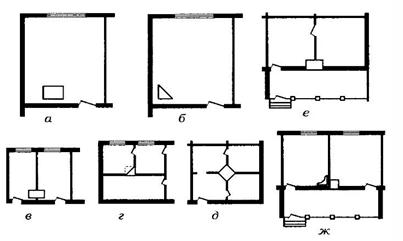

Optimal options for the location of the furnace and chimney in a residential building

- in the place of the proposed installation of the furnace and chimney, a pit of appropriate overall dimensions is dug;

- formwork is set around the perimeter of the pit, which can be made independently from improvised boards;

Formwork is required to strengthen the walls of the prepared pit and, accordingly, reduce its size, as well as to facilitate the process of pouring concrete mixture.

- the bottom of the pit is approximately 20 cm covered with a mixture of sand and gravel (broken brick). Thanks to this operation, it is possible to level the bottom of the pit and establish a “cushion” for the future foundation;

- the sand and gravel mixture is covered with a layer of waterproofing material to reduce the formation of condensate that can destroy the concrete pour;

- metal rods are laid as reinforcing elements. The use of bars is a prerequisite for pouring, as reinforcement helps to increase the strength of the concrete base;

The initial stage of building a foundation for a chimney

When using a waterproofing material, the reinforcement should be located at a distance of 5 cm from each layer. If the foundation is poured without additional waterproofing, then the distance between the reinforcing layers can be increased to 7 cm.

- concrete is being poured. The thickness of the concrete layer should be 200-300 mm. Concrete must be level or slightly above ground level;

The main stage of foundation construction

- the foundation for the chimney is laid with another layer of waterproofing;

-

further, it is advisable to perform brickwork to the level of the floor of the dwelling. Some builders neglect this step. However, additional masonry will give the chimney additional stability and almost completely eliminate seasonal fluctuations in the structure, which will lead to fewer losses and lower maintenance and seasonal restoration costs.

You can get acquainted with all the stages of building a foundation for a chimney and a stove on the video.

The construction of a foundation for a chimney is required only when installing a massive structure. Most often, the foundation is equipped immediately for both the stove (fireplace) and the chimney. The design does not require an exact calculation. It is enough to know the general rules for the installation of foundations.

Chimney types

Three main structural types of chimneys, each of which has a specific scope:

- single wall;

- double-walled (sandwich);

- coaxial.

Single wall chimney

From the name it is clear that these are just pipes and fittings from the corresponding material. It can only be used indoors or in thermally insulated channels (for example, chimneys during reconstruction). It is usually used for flue gas emissions when the air is taken from the boiler room.

Often it is also used to make a channel for supplying air to combustion from the street. These air ducts, of course, are not subject to special requirements for temperature and chemical resistance and tightness. That is, they can be made from almost any available material. However, from the point of view of uniformity and ease of installation, the same type of single-wall chimney is usually used as for flue gas emissions.

Single-wall chimneys must not be used outdoors under any circumstances.The main problem is the constant formation of condensate in the channel. From the point of view of chemical resistance, as noted above, this is not scary, but there is a great danger of freezing the liquid inside the chimney and, as a result, narrowing the flow area of the pipe. The drop in natural draft due to the cooling of flue gases for this type of boilers is not critical, as powerful fans are installed in them, providing a high value of the residual pressure.

Double-walled chimney (sandwich)

The elements of this type of chimney consist of two concentric pipes of different diameters, the space between which is filled with a heat-insulating material, usually fire-resistant stone wool.

There are no special requirements for acid and thermal resistance to the outer pipe, only resistance to atmospheric conditions (precipitation, ultraviolet) and mechanical strength are needed. Therefore, in the case of stainless steel double-walled chimneys, the inner and outer pipes are usually made of different steel grades to optimize cost. There are options with the execution of the outer pipe made of aluminum.

Double wall chimneys can be used both indoors and outdoors.

Due to the low temperature of flue gases and the absence of the likelihood of burns, in the case of condensing boilers, only the outer part of the chimney is usually made as a double-walled version, and for the inside, you can use a regular single-walled pipe.

coaxial chimney

Again, based on the name, it is clear what this chimney is: two concentric pipes with an empty space between them.

The main feature of this type is that it is used both for the emission of flue gases (through the inner pipe) and for the intake of combustion air (through the space between the pipes). Accordingly, when using it, it is not necessary to constantly ensure the supply of combustion air to the boiler room. In addition, the incoming air is heated by flue gases, thereby increasing the overall efficiency of the boiler house.

Laying coaxial chimneys is also allowed only indoors, the length of the outer section in our conditions should be no more than one meter. A common problem in cold winter conditions is the freezing of ice at the end of the chimney. This happens due to the sharp cooling of the flue gases at the outlet upon contact with cold air entering the combustion through the gap between the pipes. To solve this problem, it is possible to cut a section of the outer pipe in the area of the end of the chimney in order to separate the flue gas emission and air intake; or use the factory winter options for the end of the coaxial pipe.

This type of chimney is made of both plastic and stainless steel.

The operation of a water-heating fire-tube boiler is carried out as follows

The fire-tube hot water boiler is filled with circulating water, after which the burner is started. The resulting combustion products spread along the entire length of the flame tube and, having reached the rear bottom, turn in the opposite direction. Moving along the inner surface of the flame tube and cooling, the combustion products reach the front bottom and are distributed through the fire tubes, passing through which and cooling to the design temperature, they enter the gas box, from which they are removed through the chimney. All surfaces of the boiler along the flue gases are involved in the process of heat extraction from combustion products.

During the operation of a fire-tube boiler, as a result of the combustion of fuel, incandescent flue gases are formed, which are reflected from the rear wall and change their direction of movement to the opposite.Having reached the front wall, the gases, interacting with the rotary chamber, change their direction again and go to the convective part. In the convective part, the gases are distributed through the fire tubes, where their flow becomes turbulent by means of turbulators, the speed decreases, which in turn leads to more efficient heat transfer from the gases to the coolant. After leaving the fire tubes, the flue gases are collected together and discharged into the chimney flue.

Brick pipe repair

Repair of any pipe, including the repair of a brick pipe, begins with its inspection. All destruction and cracks in bricks are identified and fixed, and rings are also inspected. After the inspection is completed, the repair begins.

If sections of the pipe are badly damaged, they are shifted. Cracks are sealed with mortar, the rings are tightened, and the pipe is then painted. We also repair and replace, if necessary, related structures, such as fences and stairs, cataforts and signal lights, as well as lightning rods.

If we are talking about repairing a metal pipe, then it also begins with an inspection. Sheets of metal are welded onto the damaged areas, then the entire surface of the pipe is painted with fire-resistant paint. The paint provides anti-corrosion protection for metal chimneys and flues. Additionally, it may be necessary to restore the insulation. Seams and joints are puttied with refractory compounds, welded and side joints are renewed and restored.

The metal pipe can be reinforced with additional structures. The same structures are easy to use as scaffolding for further operation and maintenance of the pipe. It is possible to carry out the installation of a metal chimney and install it inside a brick one, it will be cheaper than an expensive repair of a brick pipe. The brick pipe in this case will serve as a supporting structure for metal gas outlets.

For high-altitude work on the repair of an industrial chimney, it is necessary to involve specialists and companies involved in industrial mountaineering. The Alpstroy-Plus company provides services for a variety of high-altitude works, such as installation at height, reconstruction of industrial facilities, facade insulation, cleaning of structures, as well as repair of pipes, chimneys and drainage systems.

Before starting work, a visit to the site is made, inspection and assessment of the extent of damage, a preliminary estimate of the cost of repairs. After that, the details are specified and the deal is concluded. We guarantee high quality at a reasonable price!

Types of chimneys for boiler rooms

There are several types of chimneys for boiler rooms:

- brick,

- reinforced concrete,

- steel.

Brick chimneys are built in a cone shape for stability. The lower parts are lined with refractory bricks with a gap between the walls to compensate for the expansion of the material under the influence of high temperatures.

Reinforced concrete structures are strong enough, but less resistant to corrosion. During their construction, internal laying is performed to protect against the action of aggressive gases.

Unlike the first two types, a metal smoke pipe for a boiler room can be of several types:

- Classical columns are a concrete foundation with a steel pipe coming out of it.

- Reinforced with trusses are designed for use in large boiler houses. The farm consists of metal rods located along and across. They are connected to an anchor basket that holds the chimney vertically.

- The mast type is a chimney trunk reinforced with a frame firmly held by braces.

- Frameless are designed to provide chimney in private homes. The structures are easy to install and low in height.

- Built-in chimneys are equipped in the walls of the house and reinforced with brackets.

Depending on the complexity of the heating system, all types can be single-stem or multi-stem.

Types of pipes, specifications and parameters

Until some time, specialists used two types of chimneys to equip boiler rooms, but over time, when thermal devices began to work more efficiently and the temperature of the outgoing combustion products dropped, brick chimneys ceased to cope with their tasks. Therefore, in recent years, engineers have given preference to modern modular gas vent systems, made mainly of stainless steel.

Such popularity of modular chimneys is not accidental and is associated with the ubiquity of boilers that run on liquid fuels and gas. For the manufacture of modular boiler chimneys, as a rule, different materials are used: carbon and high-alloy stainless steel, ceramics, aluminum alloys. A feature of modular chimneys is that the device can be mounted already inside existing chimneys: this does not require dismantling the chimney. And, of course, modular chimneys can be autonomous systems that function both inside and outside the premises.

Practice shows that stainless steel chimneys have the best performance. The boiler chimney made of this durable material is corrosion resistant, durable and suitable for any type of gas or oil fired boiler. Other important advantages should be considered the convenience and efficiency of installation, as well as the cost-effectiveness of work in the process of installing, maintaining and repairing chimneys.

Chimneys made of steel are single-circuit and double-circuit. The first just do not require the dismantling of chimneys, since they are liners installed in a brick channel. At the same time, such liners heat up much faster than bricks, and the temperature of the emission of combustion products, as a rule, is higher than the dew point, which reduces the formation of condensate. Double-circuit chimneys consist of two types of pipes - external and internal.

According to the type of construction and method of fastening, they also distinguish:

- Chimneys are mast. Their maximum height is 28.5 m, and the design allows transportation and assembly on site. Differ in high speed of installation. The design uses insulated and non-insulated gas outlets with a diameter of 150 to 550 mm.

- Chimneys are self-supporting. The peculiarity is that they can be used to remove flue gases with temperatures up to 500 degrees Celsius and a vacuum of up to 1 kPa. Compared to other types of chimneys, self-supporting structures are lighter and have better assembly readiness. They do not filter harmful fumes and condensate, which ensures operation with significant positive speeds and fuel pressures;

- Chimneys are wall-mounted. The design of this structure consists of a gas exhaust shaft, a support console and clamps with anchor fastening to the facade of the building. The construction of chimneys of this type provides the lowest costs, since it does not require the construction of load-bearing structures and foundations.