Furnace firebox with pellets manually

One of the simplest and cheapest formats for using such pellets involves manually adding fuel to the furnace. For many people, this process seems unnecessarily complicated and incomprehensible, since the first time it is not possible to calculate the exact amount of fuel and the time to add it.

After a few times, you will be able to understand the features of the process and easily control the power of the flame and the “working” combustion temperature.

It is possible to heat the stove with pellets in a conventional stove without significant modifications:

- The easiest way is to install a specialized basket in the oven. It has a fine-mesh structure, which prevents burnt pellets from falling into the ash pan. The cost of such products is extremely democratic, so every owner of the furnace can afford it.

- If you want to do the work yourself without buying additional products, then you should manually reduce the gaps between the grates. To do this, you need to re-digest the grate with a decrease in clearance or install a special mesh, which is made of thickened wire.

Using a pellet stove burner

Pellet burners are a universal device that fully automates the process of fuel supply and maintains a predetermined temperature.

Today on the market you can find a large number of models that have successfully proven themselves. They can work both with the use of electrical energy and with the use of compressed gas. The first option is safer, since the power supply can be instantly limited in the event of an emergency.

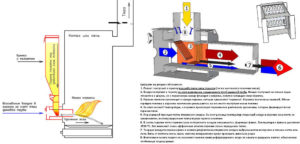

Example of a pellet burner

An important feature of such burners is an automated fuel supply mechanism that does not require outside intervention. All that needs to be done is to enter the settings, check their correctness, if necessary, change them to the required values, and then only control the presence of fuel

Modern pellet burners have several main parts, including:

- Transport fuel supply mechanism;

- Ignition and fire control systems;

- Microprocessor for automated control of the combustion process;

- The body itself.

The cost of such products is quite high, but the comfort that they give is worth the money spent!

Device and principle of operation

In a brick oven

Installing the burner in a brick oven is quite simple:

- Actually, the burner body is inserted into the furnace, and then carefully fastened with screws and other materials.

- Usually there is no gap between the furnace mouth and the burner wall, however, if there is a hole of large diameter, it is recommended to seal it with specialized sealants.

- If the burner is electrically powered, the power cable must be protected from high temperatures. It is usually removed from the furnace and direct exposure to the flame, so no further modification of the design is required.

- The last step is to fix the pellet storage chamber on top of the burner. The case has a special mechanism, so you only need to install it in the appropriate slots.

Installation examples in the photo:

In a metal oven

Installing a pellet burner on a metal stove is practically no different from a brick version

The only thing to pay attention to is to prevent contact of the burner body with the walls of the furnace, as high temperatures can lead to failure of the mechanism.

Pellet burner installed in a potbelly stove with a bunker

Pellet loading technique

It is quite simple to heat a simple brick oven with pellets. If the burner has an electric ignition mechanism, then you just need to press a special button.Cheaper models do not have this functionality, so a gas burner is used.

The rules of the firebox are quite simple - you should evenly and slowly enough to supply fuel. If a large amount of ash is formed, then the feed rate should be reduced, since the pellets simply do not have time to burn out, but melt under the influence of high temperature.

Tags pellet split, pellets, garage heating, pump, heating elements

Comments 28

Hello ... what would you recommend about such a burner ?!

since they are selling and it seems like a well-known company should work for us, the boiler is still with pressurization and forced automatic feeding, here everything works due to the traction and weight of the pellets

... well, yes, there is no gas in the house either, and even propane cylinders - in the winter they fill up strictly in a certain amount (a crushed country!), So I’m thinking of buying pellets - only the prices are over the cloud - and then I recently got on the market! - and a hydraulic accumulator for what at all?

supposedly the boiler drives water in a small circle always more than 60 degrees constantly through just a hydraulic accumulator - a small circle, and already how much is taken into the system and what temperature is needed

Propane is strange - take as much as you like from us

... in severe frost - yes, they limit it (two gas stations, not enough for everyone), queues gather, it even comes to fights, people ride to neighboring villages ... the village of Staromyshastovskaya is our nominal, 25 km from Krasnodar

trouble. it's easier for us of course

how much water (coolant) in the system?

estimated 2000 l

Very cool description!

I’m not completely oriented in your tariffs and prices, respectively. In general, is it more profitable than state centralized gas supply or not?

it turned out to be cheaper than heating from central heating, you can’t run your own gas, otherwise we would certainly have sat on gas

that is, despite the fact that gas is more expensive, would you choose gas if it were possible?

I have a private house that is heated by 2 gas-fired boilers, the cost for gas is much less than for pellets. I am telling you now, as a person who has encountered this. For comparison, a house of 200 m2, for gas with cooking they give like 6,000 rubles a month , even if we interpolate by area, take the worst thermal insulation as a condition, I think we won’t reach 30000

plus do not forget the tariffs for individuals and legal entities, they differ and decently

oh ... no, I was always sure that gas is more expensive anyway ... Although you have cheaper gas tariffs, unlike ours

If you believe all the forums, only firewood can be cheaper than gas, moreover, cut down personally, dragged on your hump, chopped, and thrown personally into the boiler. Moreover, all this must be done between work, family and rest.

I will answer everyone at once. I heat two rooms in different buildings: - the first is 240 m2, the ceilings are 3.5 m, a separate building, the gates are lit, there are 6 windows, very poor thermal insulation, in winter the snow from the central heating, when heated, did not lie in any frosts - the second 85 m2, ceilings 5 m, located inside an unheated workshop, deaf (only gates)

The second workshop is 7 degrees warmer than the first one. The first workshop did not have time to insulate before winter. The holes were only patched

When they were heated from the central heating, it didn’t matter, in the workshop it was always + 12-14 in any frost

Last year, the heat of the first workshop was 22 per month. This year a second shop appeared. They counted on 25 for one and proportionally 10 for the second. Didn't guess! The new owner of the boiler house gave a calculation - 60 and 25, respectively, per month, plus a recalculation is possible due to frost.

It is difficult with gas, although it is not far away, but for a circle there is only a broach and a project under the lam.

Since I wanted autonomy, the pyrolysis boiler was dismissed. Only pellets remained. I buy pellets myself 6-6.3 per kg, winter and season, so I’ll stock up in the summer. A bunker of 90 kg is enough to keep in frost -25 for 6-7 hours during the day in the first workshop from 3 to 7 in different places. With the same frost in the second workshop, it is 5-7 degrees warmer. I set the night mode twice as economically, the same volume is enough for 10-12 hours. I didn’t measure it more precisely, usually a ton per week flies steadily.

So the alignment, heating comes out at 25-30 kilorubles, plus the delivery of pellets and defects with laying and cleaning. The system got up at about 300, taking into account the creation of a new heating system in the second workshop.

Is it possible to heat a conventional stove with pellets

It was previously mentioned that pellets are very active in everyday life, however, a special furnace and burner system is required to ensure a normal flame and a uniform heat transfer process.

Despite a number of limitations, pellets can be burned without much difficulty in a conventional stove, but the advantages of fuel are often lost in this format of use.

The main positive features of the material are:

- Long burning time;

- Low emission of smoke and toxic substances;

- High amount of thermal energy;

- Burnout uniformity.

Most often, minor modifications are required according to proven schemes. All of them differ from each other in their complexity, cost of implementation and the need for additional equipment. Despite all the difficulties, already in the first hours after the upgrade, you will be able to forget about the difficulties that haunted you before.

Advantages and disadvantages of fuel briquettes

Let's see what good fuel briquettes are for furnaces, and what are their main pros and cons. Let's start with the positives:

With the storage and warehousing of eurofirewood, you are unlikely to have problems.

- Ease of storage - thanks to its neat shape, eurofirewood and other briquettes can be folded into neat, even masonry;

- High calorific value of fuel briquettes - when compared with ordinary firewood, they give one and a half to two times more heat. Due to this, it is possible to save on fuel when firing furnaces and boilers;

- Briquettes are a long burning fuel for stoves of any type. Pressed sawdust burns one and a half to two times longer, reducing the number of approaches for laying new portions of fuel. If there is an ordinary stove in the room that burns on wood for 2-3 hours, then with fuel briquettes this time will increase to 4-5 hours;

- Uniform burning, without unnecessary noise and embers shooting in all directions. In addition, the fuel briquettes used to fire stoves emit less smoke and generate less ash, reducing cleaning labor;

- Low formation of resins - due to this, clogging of the chimney is reduced;

- The duration of storage of fuel briquettes for furnaces varies from 1 to 5 years - it all depends on the manufacturing technology;

- High environmental friendliness - no chemical reagents are used in the production of briquettes;

- The volume of briquetted fuel consumed in one heating season is 1.5-2 times less than the volume of firewood used for the same time period.

Fuel briquettes intended for heating furnaces burn smoothly and softly, with the release of a large amount of heat. They do not clog stoves and chimneys, burn almost 99%.

Unfortunately, there are some drawbacks too:

We do not recommend storing briquettes on the street, they can become damp and deteriorate.

- Fuel briquettes used for heating furnaces are not afraid of dampness. At the same time, they still do not like direct contact with water;

- Some types of briquetted fuel do not tolerate long-term storage - their shelf life is limited to one year from the date of manufacture;

- The cost of purchasing fuel may be higher than the purchase of conventional firewood - it all depends on the manufacturer;

- In some regions and localities, it is more difficult to purchase fuel briquettes for heating boilers and stoves than to buy a truckload of ordinary firewood;

- The cost is slightly higher than the cost of ordinary firewood. But due to the high calorific value and long burning, you can save a little.

Despite all this, briquetted fuel continues to gain its popularity.

all about biofuels and solid fuel boilers

- All categories

- General information 225

- Peat briquettes 8

- Fuel briquettes 59

- Charcoal 36

- Firewood 34

- Wood pellets 90

- Husk pellets 16

- Straw pellets 21

- Peat pellets 13

- Wood chips, shavings, waste 41

- Chimneys 45

- Energy complexes 8

- Fireplaces, stoves for home 208

- Accessories 17

- Pyrolysis boilers (furnaces) 25

- Solid fuel boilers 111

- Heating, energy saving 125

- Projects and services 3

- Collection and disposal of waste 20

One of the most popular questions about wood pellets: Is it possible to use them to heat a conventional boiler or a wood-burning stove?

Use fuel pellets in conventional solid fuel boilers, it is not only possible, but also necessary - this is extremely convenient and very profitable. drown pellets you can also use a Russian stove, solid fuel stoves (such as "Burzhuyka", "Bulleryan"), etc.

In solid fuel boilers (furnaces) with a grate system, you only need to reduce the size of the grate slots so that not burned granules did not fall into the ash pan.

This can be done in several ways: by replacing the grate, by placing a wire mesh over or under the grate, by inserting overlays into the slots of the grate, etc.

Also, you can not replace the grate and lay down the wire mesh. There are special baskets for this.

For use in boilers (furnaces) with a grate are better suited pellets 8 mm in diameter. Ash content granules it does not matter as much as when using specialized pellet burners, since ash sintering does not occur in conventional boilers.

In addition to ease of use, another advantage in burning granules in conventional boilers, this is a significant fuel saving. Because pellets (unlike firewood) can be poured into the firebox in any quantity, it is very easy to control their combustion, which means that you can fine-tune the boiler for optimal performance. After all, an incorrect calculation of the load of ordinary firewood can lead to boiling of the coolant, water hammer and, as a result, to the failure of both the boiler and the entire heating system.

In addition, when using fuel pellets, the space required for storage is reduced: 1 cu. m pellet weighs about 700 kg, and 1 stock cubic meter of dry birch firewood weighs about 400 kg. So for the same weight pellets take up 60% less volume than firewood. Plus, do not forget that the calorific value pellet twice as high as dry firewood.