Water floor malfunctions

The main reasons why a water-heated floor does not work well are due to flaws during installation. Insufficient heating may be due to low boiler power or incorrect operation of the water pump.

- The running circulation pump vibrates slightly and makes a little noise. If there is power and no signs of operation, the failed pump can be easily replaced with a new one.

- The system may not turn on if air enters it. This problem can be solved with the help of repair specialists.

- With a low boiler power, there may not be enough heat for high-quality floor heating. It is necessary to install a boiler with a power reserve or turn off part of the heating (in rooms that are not used during this period).

- If the floor warms up in places, the vapor barrier is not properly made. It will have to be redone. Poor-quality vapor barrier leads to an increase in dampness in the room and the formation of mold, which is very harmful to health.

Water heated floor does not heat

It's hard to admit, but it's true. A warm floor does not bring joy, but disappointment. Do not rush to scold him, maybe something is wrong with him and can be corrected.

1. The underfloor heating circuit does not work.

a) In the switchboard, ball valves are installed for each circuit. Look, all handles should be located along the pipes (open).

b) The circulation pump does not work. Most often they are located near the boiler (in the switchboard). His work is accompanied by a slight noise and slight vibration. If not, it should be replaced if power is supplied to it.

c) Air has entered the system. You cannot do without the help of a specialist. An unfortunate situation, but fixable.

2. The floor temperature is lowered, insufficient for heating the room.

a) Not enough boiler power. Try to reduce the temperature in other rooms, where possible, and you are few or infrequent. Maybe it's time to clean the boiler, carry out preventive repairs, and revise the temperature sensors.

b) They put a carpet, put additional furniture. Underfloor heating requires open floors, the more the better.

c) Air has entered the system. This happens when the air did not completely block the pipe, but partially.

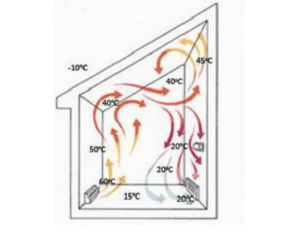

d) During installation, they "saved" on the insulation and now you heat the ground or neighbors from below. Here you need to make a choice either to redo the floors completely with normal insulation, or to install additional heat sources (supply of warm air through ventilation, additionally install radiators, gas convectors, etc.).

3. The heated floor does not heat evenly (spots). This is the worst case. If attempts to free the system from air have not been successful .... Your vapor barrier is poor quality or non-existent. In this case, the floor works for dehumidification, and not for heating the room. How to check it? Put a piece of plastic film 1 * 1m on the floor while the heating is running and glue it with adhesive tape along the perimeter to the floor. If in a day (or earlier) perspiration appears on the film, the joints of the tiles darken from moisture - the floor must be redone in accordance with the technology. I do not recommend installing an additional heat source. Dampness from the floor and heat will lead to the appearance of fungus and mold, with an unpleasant odor.

Teleos-Bud LLC Terekhov Alexanderwww.teleos.kiev.ua

The floor is not warm enough. Low coolant temperature

A typical and common problem that owners of city apartments and private houses have to face when complaining about the unsatisfactory performance of a warm floor is uneven heating. During normal operation, the water circuit must completely and evenly heat the concrete screed or floor covering, creating the necessary conditions for heating the home.

In this case, the problem is the uneven flow of the coolant along the water circuit. Due to the fact that pipelines can have different lengths, due to the same heat carrier supply intensity, the degree of heating of each pipe is different. Usually, before starting in the collector cabinet, the levels of the electric drives are set to the required position.

Before starting the system, the optimal parameters calculated for each circuit are initially set. By measuring the temperature of the coolant in each water circuit, the actuators are set to the appropriate position. Consequently, the heating temperature of the coolant in the system changes, and the degree of heating of the water circuit also changes.

The way out in this situation is as follows. We are looking for a water circuit in which the coolant does not heat the water floor in accordance with the set temperature, then manually increase the flow of boiler water.

Electric floor problems

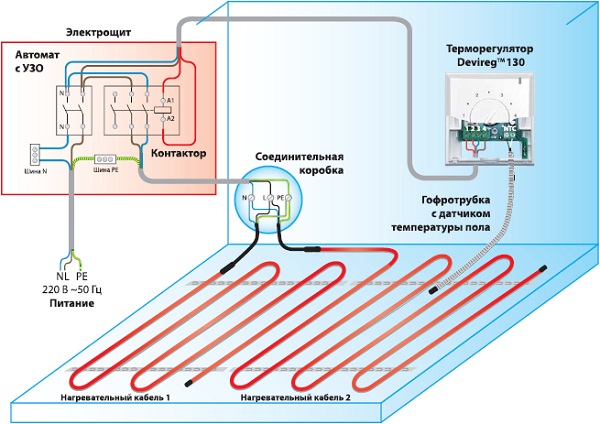

Electric underfloor heating consists of a heating cable and a thermostat. Therefore, why the system does not work depends on their proper functioning.

If the warm floor has stopped heating, it is possible that the heating cable was damaged during the pouring of the screed or during installation. To check the integrity, it is necessary to disconnect the terminals on the side of the thermostat and measure the voltage between the heating conductors. The discrepancy with passport data should not exceed 5%.

- Turning off the temperature sensor with low floor heating indicates improper installation. The sensor either touches the cable or is close to it. The temperature of the floors can differ from the set one by no more than two degrees. You can measure it with a special thermometer.

- The thermostat or temperature sensor may be defective. You must first make sure that the terminal connection of the circuit elements is reliable. Then the output voltage is measured, it should be equal to the supply voltage. Having determined the malfunction, the broken unit is replaced.

For such a system, you can do the repair of a warm floor with your own hands, without resorting to the help of specialists. You only need basic knowledge in electrical engineering and certain measuring instruments.

Why the water heated floor does not heat malfunctions and their elimination

Water heating built into the floor is a rather complex system of interconnected components. If the water heated floor does not work, the reasons may be different.

First of all, you need to know the main elements of this type of heating:

- Pipes are pipelines through which a coolant circulates, transferring heat to the floor surface.

-

Bypass.

- Circulation pump.

- The collector and electric drives of the inlet group, which serve to regulate the flow in the circuits, as well as a balancing valve, designed to mix heated and already given off heat water.

- Thermostats and thermostats that allow you to regulate and maintain the desired temperature. In the event of a breakdown, both cooling and critical overheating of the system are possible.

It is worth taking into account possible flaws in the installation. It will be problematic to eliminate such a malfunction as, for example, an insufficient amount of insulation and high heat losses, because you will have to lift the floor covering of a warm water floor, dismantle the screed and pipes.

Also, if a warm water floor does not heat, the reasons may lie in incorrect calculations during design and, as a result, incorrectly selected system components in terms of parameters. It often happens that there is not enough energy for proper heating. In this case, it is a matter of low mains voltage or insufficient boiler power.

However, we will consider the most characteristic breakdowns, the places and causes of their occurrence, as well as ways to solve the problem.

Pipeline damage

A breakthrough of a water heated floor is manifested in a leak and often a sharp drop in pressure in the pipes. A leak not only reduces the amount of coolant in the system, but is also fraught with floor destruction, flooding of neighbors and property damage.

After determining the place of leakage, it is necessary to carefully locally dismantle the floor covering and screed. The method of eliminating the leak comes down to excising the damaged section of the pipe and replacing it with a new, whole one. The technology depends on the type of pipes used.

Before dismantling the coating and cutting the pipe, you must first shut off the coolant supply to the circuit (on the collector), and then completely drain the water from the circuit. After repair, the circuit is started. It is mandatory to check the soldering or connection for tightness.

Before warming up a water heated floor, it is necessary to deaerate it.

Uneven heating

In cases where the water-heated floor does not heat well, the reasons may lie in the uneven distribution of the coolant in the circuits. This is due to the fact that the contours, as a rule, have different lengths. If the rate of water supply on the collector to each loop is the same, then the coolant will take more time to pass through a longer circuit. Accordingly, in such loops, water cools faster.

In this case, you will have to be patient, because how long the water heated floor warms up depends on many factors (the device and thickness of the “warm cake”, the temperature and intensity of the water supply, the temperature outside the windows, the material of the floor covering, what power the heater is chosen for warm water floor, etc.).

Automation tools will help facilitate control and adjustment, namely temperature sensors and servo drives on the manifold valves connected to an external thermostat - an analyzer that sends commands to the manifold to adjust the water supply to the loops.

Sources

- https://eurosantehnik.ru/ne-rabotaet-ne-greet-vodyanoj-teplyj-pol.html

- https://ZnatokTepla.ru/teplyj-pol/pochemu-ne-greet-teplyj-pol.html

- https://samelectrik.ru/pochemu-teplyj-pol-ne-nagrevaetsya-i-kak-reshit-etu-problemu.html

- https://teplota.guru/teploizolyatsiya/ne-greet-teplyj-pol.html

- http://netholodu.com/teplyj-pol/elektricheskij/nagrevaniya.html

- http://netholodu.com/teplyj-pol/vodyanoj/neispravnosti.html

Reason 1. Lack of thermal insulation

The most common reason why a warm floor does not cope with the functions assigned to it is that you simply forgot to properly install thermal insulation, or did not install it at all. Often, a conventional polyethylene foam substrate is used as thermal insulation. And the substrate is simply not intended for thermal insulation of warm floors. Instead, you need to use polystyrene foam 5-10 cm thick.

How to fix?

Learn one thing. You will have to pay extra for a warm floor. But perhaps the situation will be corrected by a higher temperature supply to the warm floor and the use of more powerful heating equipment. But don't overdo it. The maximum temperature should not exceed 70 degrees. And it doesn't have to be permanent. Otherwise, the pipe will quickly become unusable.

Why the underfloor heating does not work reasons The underfloor heating stopped working

For complete comfort, many residents of megacities order a system of underfloor heating. But after installation, you may suddenly find that the underfloor heating does not work. Naturally, water floor heating cannot be repaired on its own, but what are the first steps to take?

Underfloor heating does not work: causes and methods for their solution

The first thing to look for in case the system is not functioning is the switch. It will help to understand why the underfloor heating does not work. Perhaps there is simply no electricity due to the operation of the circuit breaker. It happens that the line is damaged and this leads to its sudden operation. Modern underfloor heating systems (most models) are equipped with special screens that indicate by a set of characters that they are turned on. It is also a good idea to check the voltage using the terminals. However, a turnkey high-quality warm floor should not receive accidental breakdowns or accidents.

Often, even with the presence of voltage in the system and the normal operation of the switch, it is noted that the warm floor does not work. Then the whole point may be in the elements of the underfloor heating system, the regulator or even the sensor. You need to know which of these elements are where. After all, when buying, you were not only interested in which warm floor is better, but also in what each of the devices does. The system is tested like this. Measure the current resistance.The value must be equal to the resistance of the cable selected as the heating element.

Measuring cable voltage is easy. You can follow this procedure for the heating film. The voltage is divided by the resulting resistance. The resulting value is the current that is in the underfloor heating system. If you multiply it by 220 volts, you can get the power that the underfloor heating system needs. These values are also specified in the system passport. They need to be compared. If the resulting figure differs upwards, then perhaps you are dealing with a short circuit or simply damage to the insulating layer. This can also manifest itself in the uneven operation of underfloor heating.

Since the cost of work involves a warm floor, it is not recommended to fix the problems on your own. You can do more damage. It is better to call our specialists from the Savard company, who will quickly determine the cause and eliminate the breakdown. At low power levels, the cause of the malfunction may lie in the breaks. Of course, they cannot be repaired on their own.

By the way, some unscrupulous sellers of this system not only do not say exactly how much a warm floor costs, but they also do not provide a passport for it, so it is impossible to compare the data. In such cases, you have to take the average value.

If the data obtained indicate that there is no voltage at all, then we can conclude that there is a short circuit. The complexity of the repair lies in the fact that it is impossible to identify a malfunction in the concrete screed. After all, you have to get the cable and replace it. You will have to completely remove the screed and re-install. The film floor in this regard allows you to carry out repairs quickly and easily.

Often the reason lies not in the floor itself, but in the sensor. After inspecting the floor, we move on to it. The sensor is essentially a resistor, that is, it has resistance. Based on the resistance and temperature indicators, it is easy to calculate how correctly the system temperature sensor works.

If the regulator is damaged, you will know about it from the messages on the monitor. By the way, damage to the regulator is the most easily replaceable incident, since this element of the system is not located in the floor and not under the concrete screed. It is enough just to pull it out of the tube and replace it. The most unpleasant thing that can happen is that a small section of the wall on which it is attached will be damaged. By the way, the price of this item is very reasonable.

The regulator is checked with a multimeter. It will also be necessary to set the maximum temperature for the system. The terminals should show voltage. If you switch to the minimum temperature, then the voltage in the terminals should disappear.

It is not recommended to carry out any repair work if the warm floor suddenly stops working. It is better to call the specialists of our company, who will quickly and efficiently perform all the work for you.

Heating is not full

Sometimes consumers do not immediately pay attention to the fact that something is wrong with their floor heater. It's on but doesn't heat well.

The warm floor is electric, depending on its type, has the heating parameters set by the manufacturer.

On average, if the installation was done correctly, then for:

- infrared film floor heating time will be 10-15 minutes;

- heating mats filled with glue will reach the temperature set by the thermostat in 6-8 hours;

- a cable floor “recessed” into a thick screed will need a day to warm up.

In the event that the system took more time, or it never reached the specified parameters, the reason for this may be:

- Incorrect installation of the temperature sensor. If it is placed too close to the heating element of the structure, it will force the thermostat to turn off before the flooring warms up.

- The sensor itself may fail, so it must be checked without turning off the thermostat.

- The reason may be low voltage, which can be avoided by installing a stabilizer.

- The floor can take a long time to warm up if the heat loss is higher than the system has time to generate. This can happen in the absence of thermal insulation.

- Initially, incorrect calculations can significantly reduce the power of a warm floor.

As practice shows, in order not to ask in the future the question of how long the electric underfloor heating takes to heat up, it is necessary to make the correct calculations at the stage of its installation and lay the system, taking into account all the layers of the “pie”.

infrared coating

Infrared film floors are the most advanced way of heating. However, during their installation, certain nuances may also arise.

The system is connected to the network by wires attached to a copper bus running along the entire edge of the film. They are connected with clamps. With insufficient contact, oxidation of the metal occurs. Gradually, the circuit breaks, and the floor may stop heating. To correct the situation, the contact must be replaced and securely fastened.

- Film floors regulate the degree of heating with a thermostat. Accordingly, its failure leads to improper operation of the floors. This is an easily repairable unit.

- If the quality of heating deteriorates, the underfloor heating is checked by measuring the current consumed by the device. Deviation from the specified in the passport more than 10% indicates a breakdown of the heating elements. A broken tape can only be replaced. You can temporarily add the heating temperature of the remaining elements using a thermostat. However, this is a temporary measure.

There are a number of causes of failure inherent in all types of floors:

- Initially, you need to check the correct connection of the underfloor heating directly to the network. Only after making sure that the input voltage is present, you can further look for a breakdown.

- The main reason for heat loss is a small layer or complete lack of thermal insulation. Heat goes down (heats neighbors or the ground), and does not heat the floor. During installation, it is necessary to take into account the working conditions of the floors.

- By measuring the resistance of a warm floor, you can easily calculate its power. Comparing the calculated value with the passport value, we can say with confidence about the presence of short circuits and insulation damage (power is more than passport) or cable breaks (power is less).

Underfloor heating is considered a low-temperature heater. The maximum surface temperature is 30°C. At higher temperatures, the floor covering (laminate, parquet) may deteriorate.

When using two heat sensors, heating in the room is more efficient