What components are included in the weather heating control system

As part of weather automation, the following components are used:

- pump equipment;

- safety valve;

- drive unit;

- certain type of controller;

- outdoor temperature sensor;

- temperature sensor for heating system;

- check valve;

- stop valves;

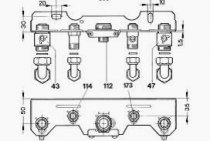

- collector;

- fitting;

- mixing units;

- terminals.

The most important element of the system that controls the operation of other equipment is the controller.

There are the following types of weather-dependent control units:

- The main controller has special terminals and can control the operation of one or two boilers at once. There is a built-in timer. The device has 6 control circuits for heating devices and 2 circuits of independent circuits.

- The expansion controller is programmed with 2 hydraulic circuits. It comes without a built-in timer and does not regulate the operation of the boiler. Usually it is used as an additional device if the main one does not cope with the functions assigned to it.

- The mixing circuit unit is programmed with only one hydraulic circuit operating independently. There is a built-in timer and the possibility of organizing weather-dependent control with one single circuit.

- The master controller for the buffer tank has terminals for controlling one boiler, which is connected to the heating system via a buffer tank. It is equipped with a timer.

Saving thermal energy

Now more and more people are thinking about energy saving issues. And this is not surprising - why overpay for heating when you can save on it? The easiest way to save thermal energy is to install meters (thermal energy metering units). This method has been used for 10 years and allows to reduce payment for thermal energy by 20-30%. Practice has shown that, on average, the installation of a heat energy metering unit for an apartment building pays off within one heating season. If you have already installed a thermal energy metering unit and felt the effect it gives, do not stop. We can go further on this issue. There are several ways to reduce energy consumption, and as a result, reduce your costs.

The main ways to save energy: automatic control of the temperature of the coolant in the heating system and reduction of heat losses from building envelopes.

The first way to save energy, obtained by installing an automatic control system, is due to two factors. Firstly, automatic control allows you to maintain the optimum temperature in the room, based on the outdoor temperature, reducing the flow of heat carrier from the heating network during periods of sharp temperature fluctuations. This happens due to the reuse of part of the coolant in the heating system of the building, since a much smaller amount of coolant from heating networks is required to provide the required temperature. This option is suitable for residential, public and administrative buildings. Secondly, for industrial enterprises, thanks to automatic control, we can set the heat carrier temperature we need at a time when the room is not in use (at night, holidays and weekends). Thus, there is a reduction in the consumption of thermal energy, and, consequently, savings in thermal energy.The approved norms for the consumption of thermal energy currently do not reflect the real picture of the consumption of heat carrier by buildings and are overestimated.

Installing a heat metering unit allows you to proceed to the calculations for the actual amount of energy consumed, as well as to reduce its consumption.

Regulation of the coolant supply by the energy supplying organization is not carried out in full, which leads to a clear overspending of the energy resource, and as a result of heating costs.

The presence of a well-functioning automation system for the release of thermal energy directly in the building, as well as the proper organization and adjustment of the heating system, can significantly reduce the consumption of thermal energy for heating needs. When connecting the heating system of the building according to a dependent scheme (without central heating), heating costs can be reduced by up to 50% during the transition period, and when connecting the heating system according to an independent scheme (regulation at the central heating), costs can be reduced by 10-15%, depending on the quality of regulation at the CTP. Also, the device for automating the supply of thermal energy will achieve optimally comfortable conditions inside residential premises, improving the living conditions of residents.

Get a full description

Weather control heating

Tired of paying more? There is a way out!

The system of weather regulation of heat supply makes it possible to save up to 35% of heat energy consumption. If we foresee that an apartment building (management company, housing cooperative, HOA) pays for heat supply during the heating season about 1 million rubles a month, then the residents will feel the savings in four weeks!

Call: +7 (423) 297-11-68, 200-58-78 and in 10 minutes you will know more than in 3 hours of searching on the Internet.

How it works?

An outside air meter (located on the shady side of the street) measures the outside temperature. Two sensors on the supply and return pipes measure the temperature of the heating network. A regular programmable controller calculates the desired delta and, by controlling the valve (KZR), changes the speed of the heat carrier flow. To protect against total shutdown, the valve is provided with protection. To eliminate stagnation of risers (air penetration), the internal circulation pump moves the heat carrier in the system through the check valve. The weather control unit is also equipped with an automated Mayevsky crane. If the heat pipe system does not have the required differential (which happens very rarely), then the problem is easily eliminated by installing an automated balancing valve.

The system has a full-bore circulation pump and guarantees 100% absence of interruptions in heating in winter.

In the event of an unplanned shutdown of the pump and other dangerous situations that affect the automatic weather control of the heat supply, the dispatch system allows you to immediately respond.

How much does a weather control system cost?

The cost of a weather control system mainly depends on the equipment used (foreign or domestic). You can learn all the pros and cons of using foreign or our equipment from the professionals of the Solutions Group in technical terms.

Heat supply regulator RISE RO-2M

06/13/2016 temperature control of the heat carrier in heating systems and hot water supply (DHW), control of the operation of pumps as part of individual and central heating points, as well as automatic boiler plants in private buildings.

Heat supply regulator RISE RO-2 vent

Management of the operation of ventilation systems of the supply type and temperature regulation of air in administrative and industrial premises.

Controller for heating systems and hot water supply (DHW) TRM132M

Controllers for heating systems and hot water supply TRM132M in combination with primary converters, the MP1 increase module and actuators are designed for monitoring and temperature regulation in heating circuits and hot water supply, displaying the measured temperature and operating modes on the built-in indicator and generating control signals for the built-in output elements and output elements of the module MP1.

Heating ‘target=”_blank”>’)

Heating control system A is designed to solve the following problems

- • inefficient use of energy resources in buildings of medical institutions, hotels, administrative centers, etc., and, as a result, the absence of a saving function;

- • change of room temperature by only 1 C˚ increases heat consumption by 5%;

- • creation of unfavorable living conditions in the premises;

- • non-compliance with the requirements of the legislation on temperature standards;

- • shorter service life of equipment due to increased load;

- • increased costs with decentralized management.

How the system works

The thermoelectric actuator (1) controls the hot water supply to the radiator. It is connected to the room controller (2). The room communicator-regulator has a built-in temperature and humidity sensor (+ up to 3 remote sensors can be connected), displays the current room temperature and controls a thermoelectric drive* to maintain the set temperature. It has a built-in ZETA radio terminal, which provides wireless data transmission to the heating control room.

*One communicator-regulator provides control of up to four thermoelectric actuators.

(1)  (2)

(2)

Features of the heating control system "A +"

Centralized heating control

Centralized remote control of the heating of the entire building from one point, taking into account the status and operation of each of the devices. Ability to control up to 65 thousand heating control points.

Wireless

The exchange of information between devices over a radio channel operating at unlicensed radio frequencies and ultra-low powers. Self-organizing network with signal relay.

System control from a mobile device/tablet

The ability to control via Wi-Fi via mobile devices (phone, tablet) for individual temperature settings by the consumer in a particular place.

Easy installation, quick start

Does not require wall chasing, no dust and dirt. Easy implementation of the system in an already functioning building with a completed renovation. The system is easily programmable, allowing the choice of equipment in accordance with the individual requirements and wishes of the customer.

Low payback periods

The economic effect is noticeable after a month of system operation. The payback period of the entire system is from 2 to 3 years at the current cost of energy resources.

intellectual

Automatic analysis and optimal control of the power of heating devices, taking into account the specified parameters. Self-learning, the system adapts to operating conditions: types of premises, power of heating devices, environmental conditions.

Preset schedule

Individual programming. Ability to set the temperature program by the hour and depending on the day of the week in each individual room.

online regulation

Round-the-clock remote temperature control. System performance monitoring. System for monitoring and preventing accidents.

Effective

Automatic control of heating in the building - real savings in heat resources costs up to 30-40%.

Specifications:

- • Microprocessor control (autonomous operation according to the internal algorithm, adaptability and self-learning)

- • Built-in WI-FI module for control via mobile devices

- • Built-in 868 MHz radio channel for communication with the central control panel

- • The second built-in radio channel 433/868 MHz for communication with internal control units (remote temperature sensors, remote wireless control panel, window opening sensor, wireless room thermostats)

- • Measurement and indication of temperature and humidity in the room

- • Management of up to 4 actuators (thermal actuators for heating radiators, electric heaters, underfloor heating, etc.)

- • Supply voltage 24V DC or 230V AC

- • Four output channels 24V DC with a total power of up to 35W to power thermal actuators

Equipment and its application

Energy-saving equipment allows you to create systems for various purposes and complexity: single- and double-circuit, with additional functions of pump control or accumulation and processing of statistical information about the course of the regulation process. But behind all this there should be an integrated economic approach, which includes the following parameters: taking into account the mutual influence of objects and heat supply systems, sanitary and hygienic requirements, comfort, lower operating costs, reliability of heat metering and saving fuel and energy resources. Automatic control systems include electronic temperature controllers, temperature sensors, electric drives with a pulse stepper motor, control and shut-off and control valves. The latter includes shut-off and control valves, mixing control valves and control hydraulic elevators.

An important role here is played by temperature controllers, through which the control links are controlled. Since 2010, the temperature controller RT-2010 has been produced, which is an updated and improved version of the predecessor RT-2000A and has the additional ability to install an RS485 interface; actuator for valves and elevators MEP-3500, which differs from its predecessors and competitors not only in design, but also in a set of additional functions.

The scheme with a control hydraulic elevator is very common for facilities that receive superheated coolant from a heat source. It is not allowed to use it only at facilities with hydraulic problems where the pressure drop between the supply and return pipelines is less than 6 meters of water column (0.06 MPa). DG elevators provide high-quality regulation due to the displacement of the direct and reverse heat carriers. The control elevator does not require the use of an additional pump, since one of the elements of its design is a jet pump. Therefore, the use of control hydraulic elevators, especially at housing and public utilities facilities, reduces installation and operating costs and does not lead to emergency situations in case of power failures. In emergency cases, stopping the pump in the heating system requires urgent measures to prevent freezing of the system. The scheme with a control hydraulic elevator is devoid of this disadvantage and the costs of the pump are excluded and for construction and installation work, therefore, it is much lower.

For other heating circuits, there is a large range of shut-off and control valves. If, in accordance with the technical conditions at the site, the installation of a pump is necessary, then the pump can be installed on the return pipeline or jumper. However, this scheme cannot be used at heat points connected to the central heating substation (heat supply schedule - 95˚ / 70˚ С).

The use of shut-off and control valves is most effective in automatic control systems that allow 100% shutdown of the coolant supply. First of all, it is hot water supply.

Open DHW systems are common, they are difficult to adjust. According to our experience, the use of two-way valves does not provide the required parameters in terms of hot water temperature, return heat carrier and noise level. In view of this, we offer three-way mixing valves KST.

On the basis of energy-saving equipment, we also produce compact block heating points, combining many circuit solutions to one degree or another.

One of the most important areas that has recently become relevant and in demand is the dispatching of regulated objects. It is also possible to implement such systems on the basis of equipment. RT-2010, RT-2000A temperature controllers have been developed and are widely used, which are equipped with an RS232 (RS485) interface, through which it is possible to remotely control control systems.

To date, on the basis of regulators, dispatching systems have already been installed and launched, including, in addition to regulation (temperature regulators), also accounting (heat meters).

The developed actuators of MEP-3500 valves can be equipped with a current output, additional relay outputs for determining the position of the mechanism. This significantly distinguishes this drive from competitors. Installing the RS485 interface in MEP-3500 drives allows them to be included in the general dispatching system along with a temperature controller and a meter. Organizations involved in the development of controllers for dispatch control and data collection from objects are already showing interest in the implementation of such a project.

The relevance of automatic control systems for the consumption of thermal energy

It should be noted that steam-water heat supply is very specific, it requires the simultaneous solution of issues of hydrodynamics and heat transfer; in addition, thermal energy is a special type of energy, its parameters must be controlled in both directions from the source to the consumer and vice versa, therefore, we propose to consider the use of automatic control systems taking into account technical and economic priorities.

The economic sense of installing automatic control systems exists both without installing metering devices, and after installing metering devices for thermal energy.

In the first case, the control system, by regulating the consumption of thermal energy, significantly reduces the costs of heat supply organizations, while consumers pay for heat at the approved tariff.

In the second case, consumers pay for the actually consumed heat, taking into account savings, which range from 10% to 30% on average. Common house devices for commercial heat metering are installed everywhere. Installing only heat meters cannot reduce the total costs for the production and transmission of heat energy. Indeed, if heat meters are installed everywhere, consumers will still pay all costs to the heat supplier.

There are large reserves of savings in the social sphere: polyclinics, schools, in public, administrative buildings, primarily because they have periods of absence of people in heated rooms, during which it is possible to set lower parameters for providing heat and hot water without compromising comfort in the working time. Those. during commissioning of the control system, for example, at a school, it is possible to immediately lay down an economical mode of heat consumption by this object for the period of winter holidays.

In residential buildings, programmatic reduction of room temperature is not applicable. But there is the possibility of separate regulation of the facades of one building under different conditions of exposure to sunlight and other climatic factors. For this, two-circuit temperature controllers are used, in each circuit of which the same control program is introduced.

An important factor in energy saving for many facilities is the elimination of autumn-spring overheating, when, for the purpose of preparing hot water, a heat carrier with a deliberately high temperature is supplied to the facilities at positive outside temperatures, above the so-called "cutoff" point of the temperature graph.In houses where there is a boiler for preparing hot water, since during periods when there is no hot water analysis, the coolant circulates through the boiler-heat exchanger in vain, also reducing its operational life, in addition, changes in the parameters of the heat source propagate very inertially through the heating network, which is corrected by in-house temperature controllers . According to sanitary standards, different temperature conditions in the premises are required, and this is not always realized at the same coolant temperature. Taking into account all these factors, it is necessary to modernize heat consumption systems with the help of modern systems of qualitative and quantitative regulation.

In the ideal case, there is an effect from the use of automatic control systems down to each heater, riser, heater, etc. Our more than many years of experience confirms the effectiveness of their application.

Economic efficiency from ITP automation

When designing an IHS, in addition to the requirements of SNiP, the designer must be guided by the technical conditions for the heat supply of the facility with clear data on hydraulic parameters and temperature graphs. Regardless of the manufacturer, automatic control systems may include a set of regulators with sensors, shut-off and control valves and mixing valves, pumps, automation and control cabinets, instrumentation, and other fittings. One controller, where necessary, manages heating and hot water systems.

Consider the use of temperature controllers in residential buildings. When calculating the economic efficiency of using a heating temperature controller with a regulating hydraulic elevator for a 108-apartment building, the savings are 11%, the installation of equipment pays off in 0.78 years. Only one factor was used in the calculation - excessive heat consumption due to autumn-spring overheating. If the second circuit of the control system is involved in the regulation of thermal energy for heating hot water, the economic effect will increase even more.

Economic indicators of the heating and hot water regulation system: the total savings is more than 15%, the payback from the implementation of the regulation system is less than 0.5 years.

Calculations show that for houses with 80 or more apartments, the cost of introducing automatic control systems pays off in less than 1 year. At facilities where the unit costs for energy-saving equipment and its installation are 1 Gcal longer, the payback period increases, for example, if the number of apartments is less than 80 or at small social facilities. Let's take kindergarten as an example. The automatic heating control system includes a control hydraulic elevator and a microprocessor control unit based on signals from temperature sensors. The payback of the project is 0.94 years. The advantages of this scheme:

– high reliability and trouble-free operation even in the event of a temporary power outage, since the elevator also performs the function of a pump; – the possibility of introducing a flexible regulation schedule, taking into account night time, weekends and holidays for the entire heating season; - optimization of thermal comfort in the premises due to the possibility of setting a preliminary heating before working hours; – Mandatory control of the parameters of the return heat carrier.

If a similar facility has hot water preparation and a DHW flow controller is installed, then the unit costs for automation of the heat point will be lower: the same electronic unit is used, a hot water temperature sensor is added to it and a shut-off control valve is additionally used for DHW. The economic effect increases to 30% with a payback of 0.72 years.

All technical and economic calculations, especially when introducing new design solutions, we verify with the help of special monitoring tools, commercial instrument accounting data.

In conclusion, I would like to note that the saving of fuel and energy resources through the use of systems for automatic program control of heat consumption is feasible and economically justified. There is no alternative to this process.

You can buy a wide range of modern automation equipment at competitive prices in our company store.

Currently, the share of payment for HEATING, the largest line in the receipt for utility bills. In this regard, many owners are interested in the possibility of reducing these costs.

One way to do this is to equip the home heating system with an automatic ITP (weather regulator).

The system of weather regulation of heating justifies itself only if a heat meter (heat energy metering unit) is already installed in the house.

It is difficult for power engineers to comply with the temperature schedule (temperatures on the heating supply and return pipelines, depending on the temperature of the outside air). Their goal is to provide as much heat as possible to consumers, so that there is enough temperature for all houses located in the area around the CHP (nearest and remote). Also, at the central heating station, the parameters of the coolant do not change in reciprocity with the time of day (sunny day, night, day of the week, etc.)

Saving heat, heating, heat supply.

What is the cost savings?

- The consumer himself decides when and how much heat to consume.

- Even distribution of heat throughout the house.

- Prevention of overheating and overheating in residential buildings, enterprises.

- No boiling of plate or shell-and-tube heat exchangers.

- Limiting the flow of excess coolant into the house.

- Increase the service life of pipelines, heating systems.

- ITP control online, with notification of emergencies.

- You do not pay for someone else's unused heating during the thaw.

The comfort of living.

- There is no need to use electric heaters.

- Drafts from wide open windows and balcony doors are a thing of the past.

- The stuffiness in the apartment does not annoy.

- Cold batteries are no longer with you.

Automatic control system for heating, heat supply of the building.

The facility operates without permanent attendants, and information is displayed on the dispatch control panel or on a cell phone.

The remote control function allows you to change the system settings at a distance and adjust its operation in manual mode. See system parameters online.

Central heating points provide residents with heat all year round during the heating season. The main task of the ACS ITP is round-the-clock control and management of the supply of heat carrier with constant pressure, maintaining the set temperature in the room. For service efficiency, information from actuators and sensors is collected and transmitted to a single dispatching console via wired (cable Internet) and wireless (cellular) communications. This allows you to monitor the operation of the ACS equipment of the heating point in real time and, if necessary, adjust the operating parameters of the equipment.

Regulators of heat, heating, heat supply

.

Functions of the heat demand control system

Functions of the heat demand control system:

1) conversion of coolant parameters (pressure and temperature) coming from the heating network to the values required inside the building;

2) ensuring the circulation of the coolant in the heating system (hereinafter - CO);

3) protection of heating and hot water systems from water hammer and from excessive temperature values;

4) control of the temperature of the heat carrier supply, taking into account the outside temperature, day and night temperature changes;

5) temperature control in the return pipeline (limitation of the temperature of the heat carrier returned to the heating network);

6) preparation of a heat carrier for the needs of hot water supply, including for maintaining the temperature of hot water supply within the limits of sanitary standards;

7) ensuring the circulation of the coolant in consumer networks in order to prevent unproductive discharge of insufficiently hot water.

Energy efficiency weather regulation of heating systems. 11/20/2017 1000

Weather regulation of heating systems

Heating radiators are the most common appliances for most Russian cities. They bring warmth into the house. We only notice them when the room is cold or hot. Meanwhile, the operation of the heating system in our homes is not only related to the temperature and humidity in our habitat, it also affects our budget.

Central heating system

Fundamentally, the central heating of houses is very simple. There is a boiler that heats the coolant circulating through the heating radiators in the house. They heat the air, while the coolant cools down and returns to the boiler for heating. The system is divided into several circulation circuits. The movement of the coolant is provided by pumps. The most common coolant is water.

The described scheme is simple and understandable to anyone. But for a large number of consumers, it cannot be effective:

In order to create the required comfortable temperature in the premises, control means are used in urban heating networks and individual circuits. They consist of circulation pumps, water and air heating sensors, adjustable valves and mixers.

However, in addition to the above impacts, the operation of heating equipment is significantly affected by weather conditions: temperature and humidity of the surrounding air, wind load.

Stereotypes and misconceptions

Without going into details of the effect of various factors on the quality of solving the problem of providing heat in the human environment, it is difficult to imagine the importance of their influence. Therefore, in the non-professional environment, there are a number of common stereotypes and not quite correct opinions:

Complexities of regulation and management

The structure of automatic control and regulation of heat flows in modern means of heating houses is quite complex.

Networks are laid taking into account the number and types of consumers, they can be open - with the selection of hot water from the system or closed - with the circulation of the coolant only for heating appliances. There are multi-circuit systems in which a heat carrier with a different temperature transfers energy to another carrier through a heat exchanger. However, even in the simplest system, automation of the control of the UUTE is associated with the need to solve a number of technical problems:

Oddly enough, the inertia factor of the system with changing heat transfer parameters is the most significant reason for the overexpenditure of tempo energy. At the same time, the installation of UUTE instead of an ordinary meter does not solve the problem of energy-efficient control of the amount of heat, if weather factors are not taken into account.

Modern possibilities in energy efficiency

Existing technical means make it possible to save 25-35% of the consumed thermal energy due to qualified control of the temperature and circulation rate of the working fluid, taking into account weather factors. The main elements that allow you to take into account weather changes:

To control the parameters and establish effective modes, a large number of automation elements are required. This amount may seem too expensive. However, modern industry produces all the required devices and mechanisms in the form of serial products. The experience of using elements for controlling heating parameters, taking into account weather conditions, shows a quick return on investment. The meter readings of consumed thermal energy will reduce costs immediately after installation.The cost of purchasing the complex will pay off in the first year of its operation, subject to competent installation and configuration.

Some important aspects of the use of UUTE and metering devices

The general house metering device installed in the central heating system only registers the amount of energy consumed by the housing facility. Metering devices save the costs of homeowners only by calculating calories, without reducing the amount of resources spent. For full-fledged savings and building energy-efficient consumption, one of the most significant aspects is the ability to regulate central heating parameters, taking into account weather environmental factors. Such systems are somewhat more expensive than simpler analogues. But they pay for themselves faster, resulting in higher resource efficiency.

The company ANK Group has extensive experience in the implementation of weather regulation at various sites, we are sure that we can help you, quickly and efficiently carry out these works.

Automatic heat control system

After equipping with automatic ITP, each house will be able to individually regulate the parameters of the coolant of the internal heating circuit (battery temperature), according to the specified parameters, depending on the external temperature. It is also constantly at a sufficient level to maintain the circulation of the coolant inside the house, during a low pressure drop provided by power engineers. (Example: Autumn 2013, complaints about cold batteries due to a difference of less than 1 m between supply and return at ITP elevators).

Automatic ITP allows you to save up to 35% (or more) Gcal, and hence money. If we take into account that an apartment building pays several million rubles for heating during the heating season, then saving even 25% pays for the entire system from one season! And with an increase in the tariff (price per Gcal), the payback time decreases.