What is a monocrystalline solar cell

We have already mentioned that there are two types of panels: poly- and single-crystal. To begin with, consider a single-crystal element - it is more expensive, but more powerful.

Peculiarities

For such a battery, a special silicon single crystal is grown according to the Czochralski method. This material is more expensive than a polycrystalline wafer, but due to its high quality, a monocrystalline module has a higher efficiency. Monocrystalline solar panels, assembled from individual silicon cells, have an operating efficiency that is approximately 20–22%.

Rays of light, falling on the surface of a single crystal of silicon, lead free electrons to directed motion. On both sides of the crystal, wires are connected to it, going to the consumer.

The efficiency of such a plate is quite high, since the rays of the sun do not scatter in it, but are evenly distributed over the entire surface of the crystal. The p-n junction area in the plate is large, due to which electrons penetrate from one part of the semiconductor to another without hindrance.

Price

The technology of growing large semiconductor single crystals is quite laborious, which is why the price of such a battery is always higher than that of a similar product based on polycrystals. The difference in the cost of devices is 10%, which is the main disadvantage of a single-crystal battery.

The price of a monocrystalline panel with a power of 150 W is 5400 rubles, and a 200 W battery of the same design costs 11,700 rubles. Much more expensive than 230W and 300W devices

Design and application

Semiconductor. As a rule, mono- or polycrystalline silicon, supplemented with other chemical compounds that contribute to the formation of the photoelectric effect. It consists of 2 materials with different conductivity, due to which there is a constant movement of electrons between them (p-n junction).

Gasket - the thinnest coating that prevents the free movement of electrons, located between the layers of a semiconductor.

A source of electricity, when connected to the gasket, electrons acquire the ability to overcome it - as a result of this, an ordered movement of charged particles occurs, in fact, an electric current is generated.

Accumulator - stores the received electricity.

Charge controller - performs the function of a distributor of electrical energy flows.

An inverter is needed to transform direct current into alternating current.

Voltage regulator.

To use solar panels as the main source of electricity, it is important that the number of clear days prevail over cloudy ones. For this reason, in most regions of our country, such installations are used mainly as auxiliary ones.

Appearance

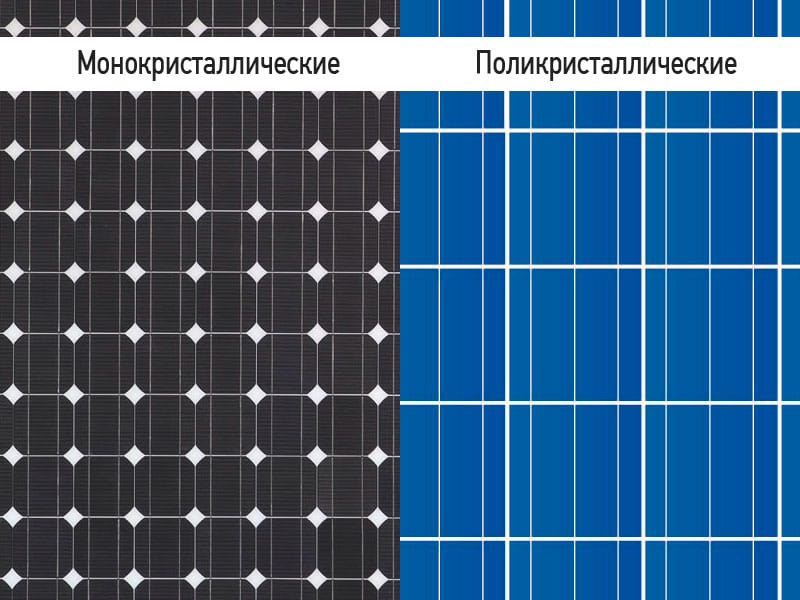

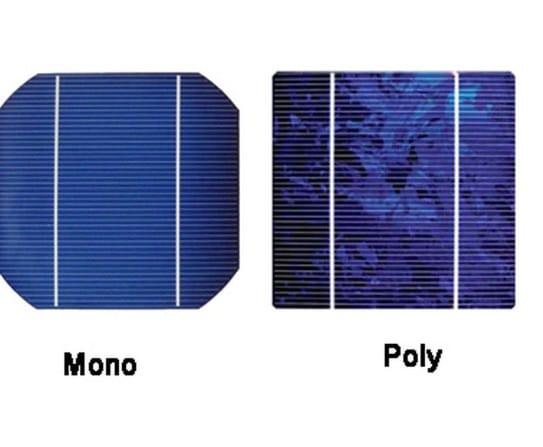

However, the appearance is the first thing that catches the eye. Monocells have a square shape with cut corners and a uniform surface. This is due to the peculiarities of the production and crystal structure of single crystals. When growing silicon crystals, cylindrical blanks are obtained, which, after further processing, are cut into such “pseudo-square” plates. And the uniformity of the surface is determined by the strict crystal structure of the workpiece.

Polycrystalline cells have an even square shape. During their production, at an intermediate stage, prismatic blanks are obtained, which are cut into square (or rectangular) plates. Their outer surface is inhomogeneous due to the polystructure of silicon.

This implies the first difference between modules on mono- and polycells. This is the filling density. Polycrystalline cells fill the entire usable area of the battery, while unused voids remain between monocells. This means that, despite the difference in the efficiency of individual cells, the performance of the polymodule per unit area may be higher.

Which modules to choose

The choice of the optimal option should be made according to a combination of cost, quality and technical indicators. It is wrong to be guided only by the design, such an approach can cause waste of money. It is necessary to meet the needs of the house for electricity, add the necessary margin for unforeseen situations and for a drop in performance with an increase in service life.

You have already made a decision to buy a solar power plant, but you are not sure which is better mono or polycrystalline? In this article, we will analyze all the pros and cons of technology.

Polycrystalline solar panels. Myths and misconceptions

Of course, every seller and manufacturer is interested in selling exactly their product, and therefore, persistent misconceptions have formed on the market regarding certain technologies. Polycrystalline silicon technology is no exception and has characteristic differences from monocrystalline, pure silicon. Hence, many features of poly-batteries are more often interpreted as advantages. But is it? Here are some statements of sellers selling solar panels

:

- "Polycrystalline silicon performs better in cloudy weather!"

- "The service life of poly-modules is the same as that of a single crystal."

- “Polycrystalline solar panels are cheaper and therefore more affordable”

It is worth noting that the first statement in itself indicates that you are not communicating with a professional. Silicon solar cells in cloudy weather have almost the same performance, regardless of technology. Such a quality as "efficient operation at low insolation" can be proud of "non-silicon", amorphous solar cells, the total efficiency of which fluctuates around 6-9%.

Poli - elements are really a little cheaper, since their production process is not laborious and fast. But given the fact that their efficiency is 15-25% lower, in order to achieve a production comparable to MONO technology, the area of \u200b\u200bthe products should be larger. This means higher costs for the product (glass, box, body) and transportation costs. The costs of product installation, the costs of fasteners and switching are also higher. What will be cheaper for you - consider for yourself, but the initial price of the products is not yet a solar power plant.

The resource of their work is also exaggerated. Poly-crystal solar cells reduce efficiency significantly in a shorter period than "pure silicon".

Let us now analyze the misconceptions regarding mono - crystalline solar cells.

Solar panels for the home - the highest efficiency!

The advantages of monocrystalline solar panels are undeniable. But slight fluctuations in price are not always perceived correctly by the end buyer. Solar panels for home

, type mono, is really a little more expensive and is not found in all manufacturers and sellers.

Monocrystalline silicon panels have a number of advantages:

- More compact overall dimensions per watt of power generated;

- Long service life with minimal loss of crystal efficiency (no more than 20%, over 25 years);

- The highest efficiency of energy conversion (from solar to electrical).

Is this not enough to make a choice towards a more advanced and efficient technology?

Film solar panels main differences

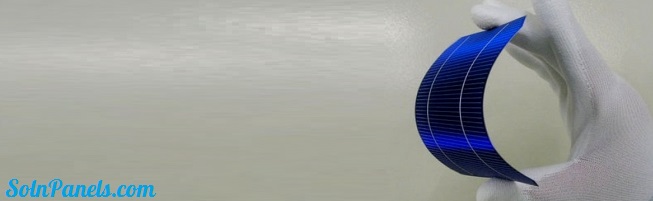

You can immediately understand that film roll solar panels have a large number of differences from crystalline options.

The first thing you should pay attention to is their thickness, it is less than 1 micron, in addition, they are very flexible, this quality allows them to be placed on any surface, even on cylindrical ones.

In addition to these advantages, film batteries have the following advantages:

- They retain operating parameters even in diffused light, as a result, their total energy is increased by 15% in relation to crystalline varieties;

- They have a low cost, which means that their purchase will be budgetary;

- Their work in high-power power systems is more efficient;

- In hot climates, batteries do not reduce their productivity;

- They have a high absorption rate of the solar spectrum in optical form.

Of course, despite all the advantages, like any other installation, film batteries have some disadvantages. Large dimensions can be entered here, in relation to crystalline panels, film ones occupy an area almost 3 times larger. Another disadvantage is that high-voltage type controllers are required to use such batteries.

Features of monocrystalline panels

The monocrystalline system consists of dozens of photocells combined into a single panel. Crystals are obtained by growing - according to the Czochalski method. Each of them is fixed on a fiberglass base, which protects against dust and moisture. The material of the elements is purified silicon. Light-sensitive cells are oriented in one direction, due to which the efficiency of monocrystalline panels is higher than that of polycrystalline ones. Other features:

duration of continuous operation - at least 20 years;

The efficiency of single crystals is on average up to 20-22% (excluding losses of the received electricity), in some cases - up to 20%;

the level of absorption is higher than in polycrystalline panels;

The only disadvantage of single-crystal systems is a higher cost, however, the cost of acquiring them quickly pays off.

With a shortage of space, when it is extremely important to achieve the maximum amount of energy from each square meter, such a solution is preferable.

Features of polycrystalline panels

Polycrystals are obtained by gradual cooling of molten silicon. This technology is cheaper than the artificial growth of single crystals, however, graininess may be present at the edges of polycrystals, which leads to a decrease in their efficiency. The fundamental difference from single-crystals is the heterogeneous structure and color. This is due to impurities and the fact that the system contains crystals of different types. Peculiarities:

The efficiency is lower than that of single-crystal elements - up to 17-18%;

affordable price - the production of polycrystalline panels is less expensive;

the rate of power loss (degradation) of polycrystals is less than that of single crystals.

Thus, if the task is to obtain a certain amount of electricity, when using polycrystalline panels, a large area will be required. There is an opinion that it is more profitable to use them in regions with a predominance of cloudy days - with insufficient sun, polycrystals provide more energy than single crystals.

Comparison of the main characteristics of single-crystal and polycrystalline elements

Each of the systems has its pros and cons. How to determine which is preferable, single or polycrystals? We bring to your attention a comparative table, which discusses the key characteristics of each of the options:

|

Parameter |

single crystals |

Polycrystals |

Conclusion |

|

Temperature coefficient |

0,45 % |

0,45 % |

The power reduction in both types of systems is almost the same |

|

Degradation rate |

By 3% in the first year of operation, in subsequent years - by 0.71%. |

By 2% in the first year of operation, by 0.67% in subsequent years. |

The difference is insignificant, so it can be neglected. |

|

Price |

The high cost is due to the complexity of production. |

10-15% cheaper than monocrystalline cells. |

For many, price is the deciding factor in favor of polycrystalline panels. |

|

Photosensitivity (at light level 600 W/m |

With the same power modules, the difference does not exceed 10%. |

In fact, this indicator can be neglected. |

|

|

Annual output |

According to the PHOTON laboratory, it is slightly higher (no more than 2%) for single crystals. However, more detailed studies have shown that it is not only the type of panel that matters, but also the brand. |

The properties of a particular solar battery are more important - they are the key selection criterion. |

When choosing solar panels, it is necessary to pay attention not only to the type of photovoltaic cells, but also to other criteria: price-performance ratio, declared resource (warranty period), voltage at maximum power, and equipment.

Are there cheap solar panels?

Specialists and scientists are striving to create batteries that will become widely available to the entire population. With small but successful steps, they are approaching this goal and at the same time improving the materials used in this technology every time. Of course, there are also manufacturers who carelessly treat the goods that they offer to customers and knowingly sell low-quality products. This is the main problem if you suddenly want to buy an inexpensive solar battery.

Not only residents of the Russian Federation, but also European countries are convinced that inexpensive installations are offered by Chinese manufacturers. It can be seen that it was Chinese manufacturers that flooded the solar battery market, forcing many large companies to declare themselves bankrupt, which simply could not stand the competition with the Chinese.

So, for example, you need to know which products can be budget and which are not. Cheap monocrystalline panels are unlikely to be found, as these types include the most powerful elements.

Therefore, it is very important to know what characteristics the installation includes.

On the other hand, there are giant companies that, thanks to government subsidies, reduce the cost of the solar panels they produce. These include large German and, of course, Russian production. If you decide to purchase Chinese products, then it is better to give preference to some well-known company that has already justified its name in the market.

What is a solar battery? It is a direct current photovoltaic type generator that converts solar energy into electrical energy. Such batteries use silicon modules - semiconductors.

In order to choose a solar battery for your home, you will need to pay attention to a few of our tips. Namely:

Namely:

When purchasing a solar panel system, keep in mind that it must fit your home. First, the climate of your area plays a big role. The duration of sunlight over the house and, of course, the time of the accumulative regime will depend on it. In order to determine how suitable your territory is, you will need to use an illumination map.

Consider the amount of heat that you want to receive in the end. The best option would be a battery that can cover approximately 40-80 heat needs. Systems that are less efficient will cost an order of magnitude more. It is also necessary to take into account the design and capabilities of the entire system. This can guarantee you the stability of the installation in case of force majeure.

All these calculations are best entrusted to specialists.

Be sure to pay attention to the manufacturer of the battery, as well as the material that was used in the production of the photoelectric cell of the module.There can be both mono and polycrystalline silicon

It is from these qualities that not only the price will depend, but also the efficiency, as well as the service life of the installation.

By following these tips, you will be able to choose the type of installation that is right for your area. But still, it is better that people associated with this field of activity are engaged in your calculations.

Polycrystals and Solar Applications

Monocrystalline wafers are improved and superior to polycrystals.

Due to the flexible structure, they can be placed on the roof of a house or gazebo.

Polycrystalline elements are good for street station,

since they are installed only on a flat surface, for them it is necessary to look after a separate place in the garden. When placed in a gazebo, glazing of panels is not allowed, as this results in a decrease in efficiency. The efficiency of commercially available panels is approximately 18%, which is lower than monocrystalline. Polycrystalline plates suffer efficiency losses mainly due to surface inhomogeneity.

Flexible monocrystalline wafer is convenient

Comparison of single crystal and

So, which solar panel is better - monocrystalline or polycrystalline? To answer this question, you must first understand, but how do they differ?

The photo below shows two main types:

The first thing that catches your eye is the appearance.

Single-crystal elements have rounded corners and a uniform surface. Rounded corners are due to the fact that in the production of single-crystal silicon, cylindrical blanks are obtained. The uniformity of the color and structure of single-crystal elements is due to the fact that this is a single grown silicon crystal, and the crystal structure is homogeneous.

In turn, polycrystalline elements have a square shape due to the fact that rectangular blanks are obtained during production. The heterogeneity of the color and structure of polycrystalline elements is due to the fact that they consist of a large number of heterogeneous silicon crystals, and also include a small amount of impurities.

The second and probably the main difference is the efficiency of solar energy conversion.

Monocrystalline elements and, accordingly, panels based on them have the highest efficiency today - up to 22% among mass-produced and up to 38% for those used in the space industry. Monocrystalline silicon is produced from highly purified raw materials (99.999%).

Commercially available polycrystalline cells have an efficiency of up to 18%. The lower efficiency is due to the fact that in the production of polycrystalline silicon, not only high-purity primary silicon is used, but also secondary raw materials (for example, recycled solar panels or silicon waste from the metallurgical industry). This leads to the appearance of various defects in polycrystalline elements, such as crystal boundaries, microdefects, carbon and oxygen impurities.

Cell efficiency is ultimately responsible for the physical size of solar panels. The higher the efficiency, the smaller the panel area at the same power.

The third difference is the price of the solar battery.

Naturally, the price of a single-crystal battery is slightly higher per unit of power. This is due to the more expensive manufacturing process and the use of highly purified silicon. However, this difference is insignificant and averages about 10%.

So, we list the main differences between monocrystalline and polycrystalline solar cells:

Appearance.

Efficiency.

Price.

As can be seen from this list, for a solar power plant it does not matter which solar panel will be used in its composition.The main parameters - the voltage and power of the solar panel do not depend on the type of elements used, and you can often find panels of both types of the same power on sale. So the final choice is up to the buyer. And if he is not embarrassed by the non-uniform color of the elements and a slightly larger area, then he will probably choose cheaper polycrystalline solar panels. If these parameters matter to him, then the slightly more expensive monocrystalline solar panel will be the obvious choice.

In conclusion, I would like to note that according to the data of the European Association EPIA in 2010, the production of solar cells by the type of silicon used in them was distributed as follows:

1. polycrystalline - 52.9%

2. monocrystalline - 33.2%

3. amorphous, etc. - 13.9%

In other words, polycrystalline solar cells are the leaders in the world in terms of production volume.

Price

Solar panels on different photocells have different costs. Prices for monocrystalline panels are somewhat higher (typically in the range of 10%), due to the more expensive process and the need to use high purity silicon.

Thus, before deciding which modules to choose, you need to decide on the conditions for their use, installation location and budget. In fact, the solar power plant does not care which panel produces current for it, the main thing is the output power and voltage indicators. And these values can be the same for products on different types of cells, they will differ only in surface area. Therefore, if the dimensions are not critical, then you can purchase solar panels of the same performance (on polycrystals), but with a slightly larger area, they will cost a little less.

Characteristics of thin film panels.

The production process of thin-film panels consists in vacuum deposition of a photovoltaic material in the form of a thin film on a substrate-base. Depending on the required characteristics, various types of substrates and types of sprayed substances are used. In particular, the following materials are used for deposition of thin films: amorphous silicon (a-Si), cadmium telluride (CdTe), copper, indium, gallium, selenium compounds - selenides (CIS / CIGS), various organic elements (OPC)

The efficiency of thin-film solar cells depends on the quality and purity of the technological process and ranges from 7 to 13%. With the development of technology and the introduction of innovation, the predicted increase in efficiency will be 3%. In the 2000s, the market for thin-film panels has grown significantly. This is due to the development of technology for deposition of thin films and the development of the level of production in general. Thus, it is becoming easier to buy solar panels, and their price is becoming more affordable.

Advantages of thin film batteries:

- low production cost, therefore, a lower price for the panel as a whole.

- aesthetic appearance of the structure, due to high uniformity.

- the possibility of manufacturing flexible structures

- The number of performance losses due to heating or indirect lighting is reduced.

At the same time, thin-film structures have a number of disadvantages:

— a sufficiently large installation area of the structure is required to ensure the conversion of the required amount of solar energy.

- installation of more panels requires additional mounting hardware and increased installation costs.

- the service life of such panels is lower than that of crystalline counterparts.

And yet, which panels are the most suitable for use in private households to provide electricity to a house or cottage?

In solving this issue, it will not hurt to consult specialists in the field of photoelectronic solar energy converters and conduct a quantitative and qualitative assessment of all factors: from area to illumination of the mounting surface. This consultation will allow you to determine exactly what you need.

With a lack of space for installation, pay attention to monocrystalline batteries with maximum efficiency.Unfortunately, at the moment, on the Russian market of photoelectronic products, in particular, converters, the choice of elements is limited and, most likely, as well as the choice of modules of the required design or film composition

In this case, you may need to order modules from abroad, or buy them in Russia on a pre-order. However, in this case, the price of batteries will be higher.

If it is the price range of materials and work that is more important, then the best option is to use structures on polycrystalline plates. They will allow you to provide fairly good performance indicators and at the same time save some money.

When choosing thin film panels, remember to consider installation requirements. The cost of additional installation work will significantly affect the final estimate.

Having decided on the type and size of solar panels, it remains for you to purchase the required units, install and enjoy using one of the most environmentally friendly ways to generate electricity for domestic needs.

Solar panels

- durable (service life is 25-30 years)

- easy to install

- easy to maintain

- reliable and efficient

The production of modules is based on the use of silicon. Silicon is the second most abundant element in the earth's crust after oxygen. It is difficult to find silicon in nature in its pure form, most often it is found in combination with oxygen - silica (Si02). This chemical element has a high reactivity, and in its pure form is the most important semiconductor in modern radio electronics, computer technology, and alternative energy. Depending on manufacturing technologies, there are several types of panels that are constantly being improved. The most common types of modules are crystalline and thin-film or amorphous panels. Crystalline photovoltaic cells are either monocrystalline or polycrystalline

Monocrystalline panels

A monosilicon wafer is a single crystal in the form of cylindrical, maximally pure silicon ingots, from which rectangular silicon disks are obtained by cutting using the Czochralski method. Monocrystalline elements are squares with rounded or cut corners, uniform in structure, 0.2-0.3 mm thick, dark blue or black with an anti-reflection coating. Monocrystalline solar modules are highly efficient, compact, and have the longest service life.

The technology for manufacturing solar cells from single-crystal cells is quite expensive. This is due to the use of highly purified silicon.

Polycrystalline panels

Polysilicon solar wafers are produced by gradually cooling the silicon substance. This production technology requires less energy and silicon is not of the highest degree of purification. Blocks of polycrystals are processed in the same way as a single-crystal blank. Polycrystalline panels are a block of crystals of different directions, some crystals are clearly visible on the cut, these are regular blue squares with anti-reflective coating or silver-gray without coating, 0.2 - 0.3 mm thick. The efficiency of such batteries is lower (from 13% to 18%).

Thin-film (amorphous) solar panels

The main difference between thin-film or amorphous panels is the deposition of a thin layer of amorphous silicon onto the substrate. The lining material can be either flexible (plastic) or rigid (glass or metal) base. Amorphous panels can be distinguished from other types by their dark gray color, they are flexible, compact and lightweight. The cost is lower than traditional silicon.Such batteries work great in very dusty air, they have enough diffused light. Recent innovations in silicon film development have led to the production of efficient multi-junction solar cells that contain multiple layers of silicon. Different semiconductor materials absorb sunlight differently, thus capturing the entire spectrum of radiation.

Design and application

According to the device, all solar converters are divided into monocrystalline and polycrystalline. The design of each panel determines its effectiveness and cost. World manufacturers of these devices use silicon, cadmium telluride and compounds based on copper, indium, gallium, and selenium as the working fluid. The latest achievements in this area are batteries, the working material of which is gallium arsenide.

The domestic industry for the production of solar generators mainly uses silicon semiconductor wafers. Ready-made modules designed to generate electric current combine a set of cells with their design. Flat panels are installed on special racks with rotary devices, with the help of which the maximum possible angle of incidence of the sun's rays on the semiconductor is set during the day. A cheaper but less efficient option is to use fixed structures set to a certain constant angle.

An important element of any solar assembly are batteries that store electrical energy for use at night or during dimly lit times of the day. Then it comes from the batteries directly to the load, or first to the inverter 12 (24) - 220 V, and then to the consumer, depending on its type.

Expert opinion

Alexey Bartosh

Specialist in the repair, maintenance of electrical equipment and industrial electronics.

Ask an expert

It is profitable to generate solar energy where there are many bright days in a year. Most regions of the Russian Federation are unsuitable for using only solar energy. Solar generators are more often used only as additional power supply devices.

Conclusion

Even though there are differences between different types of modules, there is no clear answer which solar module best suits all possible requirements. The module type is selected depending on the characteristics of your site and installation requirements.

When choosing a module, the question is often asked: which solar battery is better - monocrystalline or polycrystalline, or maybe amorphous? After all, they are the most common in our century. A lot of research has been done to find the answer. Let's see what the results showed:

efficiency and service life

Monocrystalline elements have an efficiency of about 17-22%, their service life is at least 25 years. The efficiency of polycrystalline can reach 12-18%, they also serve for at least 25 years. The efficiency of amorphous is 6-8% and decreases much faster than crystalline, they work no more than 10 years.

Temperature coefficient

In real conditions of use, the solar panels heat up, which leads to a decrease in the rated power by 15-25%. The average temperature coefficient for poly and mono is -0.45%, amorphous -0.19%. This means that when the temperature rises by 1°C from standard conditions, crystalline batteries will be less productive than amorphous ones.

Loss of efficiency

The degradation of solar monocrystalline and polycrystalline modules depends on the quality of the initial elements - the more boron and oxygen they contain, the faster the efficiency decreases. Polysilicon wafers have less oxygen, while monosilicon wafers have less boron. Therefore, with equal qualities of the material and conditions of use, there is no particular difference between the degree of degradation of those and other modules, on average it is about 1% per year.Hydrogenated silicon is used in the production of amorphous batteries. The content of hydrogen is due to its faster degradation. So, crystalline ones degrade by 20% after 25 years of operation, amorphous ones are 2-3 times faster. However, low-quality models can lose efficiency by 20% in the first year of use. This is worth considering when buying.

Price

Here, the superiority is completely on the side of amorphous modules - their price is lower than crystalline ones, due to cheaper production. The second place is occupied by poly, while mono is the most expensive.

Dimensions and installation area

Monocrystalline batteries are more compact. To create an array with the required power, you will need fewer panels compared to other types. So when installed, they will take up a little less space. But progress does not stand still, and in terms of power / area ratio, polycrystalline modules are already catching up with mono. Amorphous ones are still lagging behind them - their installation will require 2.5 times more space.

Light sensitivity

Amorphous silicon modules are leading here. They have the best solar energy conversion efficiency due to the hydrogen content of the element. Therefore, they, in comparison with crystalline ones, work more efficiently in low light conditions. Mono and poly, in poor light, work about the same - they react significantly to changes in light intensity.

Annual output

As a result of testing modules from different manufacturers, it was found that monocrystalline ones generate more electricity per year than polycrystalline ones. And those, in turn, are more productive than amorphous, despite the fact that the latter generate energy even in low light.

It can be concluded that mono and poly solar panels have small but important differences. Although mono is still more efficient and the return on them is greater, poly will still be more popular. True, it depends on the quality of the product. However, most large solar power plants are assembled on the basis of polymodules. This is due to the fact that investors look at the total cost of the project and the payback period, and not at the maximum efficiency and durability.

Now about amorphous batteries. Let's start with the advantages: the method of their manufacture is the simplest and low-budget, because no cutting and processing of silicon is required. This is reflected in the low cost of the final product. They are unpretentious - they can be installed anywhere, and not picky - they are not afraid of dust and cloudy weather.

However, amorphous modules also have disadvantages that override their advantages: compared to the above types, they have the lowest efficiency, they quickly deteriorate - the efficiency decreases by 40% in less than 10 years, and they require a lot of space to install.