Vapor barrier of roof and walls. Where is it placed and why is it needed

Let's consider another situation. Steam got into the structure, moves outward through the layers. Passed the first layer, the second ... and then it turned out that the third layer is no longer as vapor-permeable as the previous one.

As a result, the steam that got into the wall or roof does not have time to leave it, and a new “portion” is already supporting it from behind. As a result, before the third layer, the vapor concentration (more precisely, saturation) begins to grow.

Remember what I said before? Steam moves from warm to cold. Therefore, in the region of the third layer, when the saturation of the steam reaches a critical value, then at a certain temperature at this point, the steam will begin to condense into real water. That is, we got the "dew point" inside the wall. For example, on the border of the second and third layers.

There was an obstacle in the way. The saturation of the steam has increased and there is a possibility of condensation

This is exactly what people often observe, whose house is sewn up from the outside with something that has poor vapor permeability, such as plywood or OSB or DSP, but there is no vapor barrier inside or it is made of poor quality. Rivers of condensate flow along the inner side of the outer skin, and the wool adjacent to it is all wet.

Steam easily enters the wall or roof and "skips" the insulation, which usually has excellent vapor permeability. But then it "butts" against the outer material with poor penetration, and as a result, the dew point is formed inside the wall, right in front of the obstruction to the vapor path.

There are two ways out of this situation.

- It is long and painful to select the materials of the “pie” so that the dew point does not under any circumstances end up inside the wall. The task is possible, but difficult, given that in reality, the processes are not as simple as I describe now.

- Put a vapor barrier on the inside and make it as airtight as possible.

It is along the second path that they go to the west, they make an airtight obstacle in the way of steam. After all, if you do not let steam into the wall at all, then it will never reach the saturation that will lead to condensation. And then you don’t have to puzzle over what materials to use in the “pie” itself, in terms of the vapor permeability of the layers.

In other words, the installation of a vapor barrier is a guarantee of the absence of condensation and dampness inside the wall. At the same time, the vapor barrier is always placed on the inner, “warm” side of the wall or roof and is made as tight as possible.

Moreover, the most popular material for this "they" is ordinary polyethylene 200 microns. Which is inexpensive and has the highest vapor permeability, after aluminum foil. Foil would be even better, but it's hard to work with.

In addition, I pay special attention to the word hermetic. In the west, when installing a vapor barrier, all joints of the film are carefully glued

All openings from the wiring of communications - pipes, wires through the vapor barrier, are also carefully sealed. The overlapping vapor barrier installation, which is popular in Russia, without gluing the joints, can give insufficient tightness and, as a result, you will get the same condensate.

The vapor barrier does not let steam into the wall and, accordingly, the probability of getting enough steam for condensation is greatly reduced

Unglued joints and other potential holes in the vapor barrier can cause a wet wall or roof, even if the vapor barrier itself is present.

I also want to note that the mode of operation of the house is important here. Summer country houses, in which you visit more or less regularly only from May to September, and maybe several times in the off-season, and the rest of the time the house is without heating, can forgive you some vapor barrier flaws.

But the house for permanent residence, with constant heating, does not forgive mistakes. The greater the difference between the external “minus” and the internal “plus” in the house, the more steam will flow into the external structures. And the greater the likelihood of condensation inside these structures. Moreover, the amount of condensate as a result can be calculated in tens of liters.

Is the metal in LSTK frame houses protected from corrosion?

The cost of anti-corrosion materials for metal structures is not much

exceeds the price of the same funds to cover #663300 structures. brick buildings

can not be taken into account, due to the high costs of the "stone technology" itself

Condensation in a frame house

What is LSTC? These are light steel thin-walled structures.

(up to 3 mm) used for the construction of prefabricated buildings. Represents

thin galvanized profile similar to the profile used for fixing plasterboards.

It is equipped with insulation that fills the distances between the racks of the frame. Humidity

buildings directly depends on how water vapor is removed from the walls. At the frame

houses, the "dew point" occurs in the walls, but the condensate is removed from there through the system

ventilation of panels, as well as creating a gap between the vapor barrier film

and wall cladding. Such facades are called ventilated. In frame houses "dot

dew" is located inside the wall of the building, and the problem of condensation is solved competently

designed panel ventilation system.

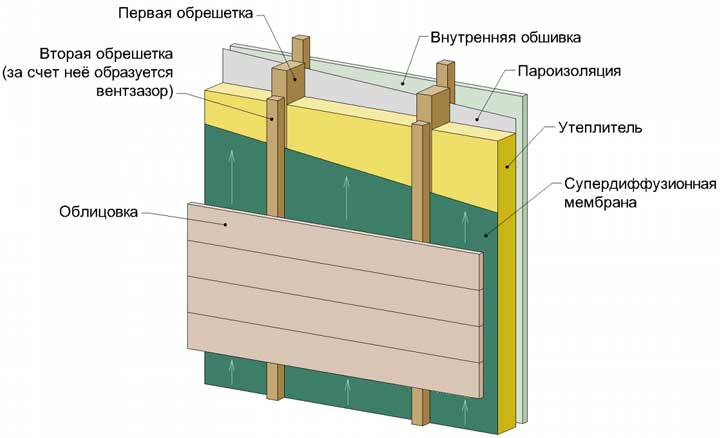

- The panels are protected from moisture coming from inside the house with a vapor barrier

film. - Outside, the frame filled with insulation is wrapped

vapor-permeable windproofing, which releases contained in the panels

moisture outside, and protects the insulation from weathering and getting wet. - Additionally, a ventilated gap is made between the film

and external cladding, in which conditions are created for the occurrence of air

traction. The air flow removes water vapor.

The frame in the LSTK technology is a galvanized thin-walled profile,

reminiscent of used when installing drywall. It is equipped with insulation

mineral wool, which fills the distance between the racks of the metal frame. Thermal conductivity

walls of the building depends on the thickness of the profile material, the thinner the metal, the less

heat passes through it. The humidity of the structure depends on how the walls are drained

water vapor. In frame houses, the "dew point" occurs in the walls, but the condensate is removed

from there through the panel ventilation system. From the inside of the frame house there is a vapor barrier

film. Outside the house, a frame filled with insulation, covered with wind and waterproofing,

easily releasing the moisture contained in the wall panels. He (heater)

perfectly protects against weathering and wetting processes. Well, the last measure -

creating a ventilated gap between the vapor barrier film and the wall cladding,

involving air draft. With airflow, it's easy

and water vapor is quickly removed from the wall. Such facades are called ventilated.

Cold bridges in frame structures

How to build a light and durable frame of a metal house and avoid

corrosion, cold bridging and condensation? With the advent of high quality

insulation, insulating and vapor-permeable protective materials have been developed

concepts for the construction of metal frame dwellings. According to research, holes in

profile walls significantly reduce heat loss through the walls of the building due to elongation

the path of the heat flow and the features of the edge properties of the slots, which have a difficult

form. In addition, the thickness of the profile material affects the thermal conductivity. The thinner

steel, the less heat loss. They become comparable to losses in buildings

with wooden frame.

Dew point in a frame house

In metal frame houses, the "dew point" is

inside the wall of the building, and the problem of condensation can only be solved with proper

designed panel ventilation system.

- The panels are protected from moisture coming from inside the house with a vapor barrier film.

- Outside, the frame filled with insulation is wrapped with vapor-permeable wind-proofing,

which freely releases the moisture contained in the panels to the outside, and protects

insulation against weathering and wetting. - Additionally, a ventilated gap is made between the film and the outer lining,

in which conditions are created for the occurrence of air draft. Airflow

removes water vapor.

Choice of vapor barrier film

The scheme of the vapor barrier of the floor of a frame house.

Ordinary polyethylene (PE). This is the simplest, but reliable vapor barrier. It is quite cheap and is sold at any hardware store. The choice should be made in favor of high-strength polyethylene (strength is measured in micrograms). When buying a film, you need to make sure that it is tear-resistant. PE has its advantages - it is perfectly glued with adhesive tape, which makes it easy and quick to create a reliable vapor barrier.

Specialized vapor barrier membranes. These membranes cost significantly more than polyethylene film. For their device, double-sided tapes, reinforced tapes and mastics are offered. There are vapor barriers with a foil coating, reinforcement, a condensing surface, etc. You can choose the right membrane for certain tasks. For example, a reinforced vapor barrier can be installed without outside help, since a sheet stuck with a stapler can be easily pulled to the other end of the room and not spoiled.

A foil vapor barrier membrane is recommended for use in baths where it is necessary to reflect energy deep into the room. A specialized vapor barrier membrane is an advanced polyethylene film that provides a tight vapor barrier. It performs the functions of a vapor barrier very well, provided that the sealing is of high quality. Before buying, you must carefully study the properties of specialized vapor barrier membranes.

Installation and installation of a vapor barrier membrane on the outside of the frame house

In this case, moisture vapor and dampness, passing through the wall, form condensate on the surface of the membrane, and this leads to dampening of the material. Outside the walls of the frame house, a windscreen is mounted, and unlike the vapor barrier membrane, it perfectly passes moisture and dampness vapors.

Frame house without vapor barrier

Such heaters as polystyrene foam, ecowool and polyurethane foam allow you to apply such a solution. But in this case, it is necessary to ensure sufficiently good ventilation of all rooms to remove excess moisture. The best option would be to install a forced exhaust ventilation system.

Double vapor barrier effect

Basically, this effect occurs in damp or technical rooms, when all walls are finished with special plastic panels, tiles or oilcloth, and other poorly breathing materials. As a result, moisture and dampness are trapped between two materials with little vapor barrier. To avoid this effect, use a special air gap between the wall and the finishing material, as an example, pre-sheathe the bathroom with rails, and then attach the finishing material to them. Or do not install vapor barrier in these places at all, so that dampness and moisture can easily escape through the walls, but if high humidity and dampness are constantly present, there is a risk of it accumulating in the wall. This solution is usually used for the temporary use of buildings, summer houses and cottages, and so on.

Vaporization scheme designs

To date, there are two main design schemes for the vapor barrier of the walls of a frame house.

- The first is that the vapor barrier membrane is attached to all wooden frame racks, then, on top of them, the interior decoration of the living quarters with plasterboard or clapboard is carried out.

- The second - a vertical or horizontal crate is installed on top of the vapor barrier film, which provides an air gap of 4-5 cm from the frame wall.

Consider which of these design schemes is more correct.

There are many opinions on this matter. Firstly, many of the building materials that are used in Canada or the United States are not found on our market, or they are sold at a huge price. Secondly, the difference between building materials brought from abroad and domestic manufacturers can be significantly huge!

Provided there is sufficient ventilation to remove excess moisture and dampness contained in the air, wall design is not that important, because proper vapor barrier of a frame house is just an additional insurance. The construction of the walls of a frame house without a certain air gap, it is advisable to use for the construction of those buildings that will be operated only in the summer or used temporarily - cottages, dining areas and guest houses, various workshops, and parking lots. But in this case, it is necessary to make ventilation, or at least install a ventilation duct, be sure to provide for conclusions from the bathroom, kitchen area, and technical rooms.

And in conclusion, we note that vapor barrier films or membranes are produced by a number of construction companies, but the most famous manufacturers are TechnoNikol, Izospan, Tyvek.

https://youtube.com/watch?v=k-mLaZrSgso

Which side to lay the vapor barrier

And you take an ordinary vapor barrier film, then you won’t need to look at the wrong side. But if you have already taken a specialized steam film, then look at the instructions. EVERYTHING is written there. Just don't be lazy or force the builders.

In addition to the manufacturer, no one knows how to properly lay the vapor barrier of his production, each of them has its own notes. But it is logical that the part with his brand was inside and we could see it, they did their best for us!

Everything is simple with Izospan-B. A rough surface inside, moisture remains on it, the smooth side of this vapor film is placed against the insulation.

This concludes the questions about how to lay the vapor barrier. You can go to the website of the vapor barrier film manufacturer and look at the exact information there, for example, on the Yutafol website (Isospan does not have a normal website).

Board for frame house

10 comments

Last year, during September-December, a frame house was erected to me, foolishly I asked him to immediately sheathe the entire OSB, DSP from the inside.

The technology is as follows: 1. Logs, external walls, ceilings - 200x50, partitions - 100 * 50 2. Everything is tightened with vapor barrier from the inside, walls and ceiling along logs / racks, then OSB 9mm without air gap 3. Insulation is completely filled everywhere 150 or 200 mm . 4. The floor arrangement is as follows: a vapor barrier is laid on top of the logs, then boards 150x40 with a gap between them of 3-4 cm, OSB 18mm on top. and CSP (in su)

Question from a reader: The following problem has arisen. Since the boards were naturally damp, plus they were also covered with fire and biological protection, everything was built already in a cool / rainy, wet period, it turned out that the boards (150x40) were apparently laid wet and immediately covered (with a floor). It turned out a thermos: vapor barrier on the bottom, OSB on top, which also does not allow moisture to pass through.

I climbed to check and came across the fact that mold / fungus went on the boards. Now I have to remove OSB / DSP, treat the boards with two liquids (neomide bleach and bioprotection for outdoor work), in addition, I will have to tear off the boards, since the bottom plane cannot be processed. In this regard, the question is: should the vapor barrier be left or removed, or replaced with a vapor permeable membrane, for example, isospan A? Lay a vapor barrier or membrane on logs or boards. I have three floors, the top one is cold.Accordingly, my question concerns the floor of the first and second floors.

Second question. How to ventilate the distance between the boards and is it necessary? Maybe it makes sense to bring the vapor barrier of the walls only to the floor (to the top or bottom of OSB / DSP), and then leave the opportunity to circulate air from the vent gap between the boards (150x40) into the walls / partitions? Now the vapor barrier from the walls is the transition to the floor. There are no gaps.

the floor of the second floor - there is no need for a film at all. film of the first floor - the film is needed. the boards can be processed and laid back, let the moisture disappear and close again, I think there should be nothing wrong with them in the end. it is not necessary to ventilate the floor, the frame house must be airtight in itself, but ventilated.

Good day! I plan to build myself a frame house on two floors with a cold attic (Since it is not necessary to do vapor barrier on the ceiling of the first floor, the question arose: the walls (1st and 2nd floor) will be in vapor barrier, and how to isolate steam from entering the insulation in the interfloor ceiling (in places where the lags rest on the second upper harness)?

Good day, Sergey. These areas will require a lot of fiddling! you have to bypass the lags with a film + gemertic. There were decisions on the forumhouse in the topic of Roswood!

Thank you. I will look for. Your articles are very informative!

Maxim, good afternoon! I am building a frame house with my own hands, while relying largely on your articles. I plan the cake of the outer wall as follows: 1) siding 2) crate 22-25 mm 3) osb 3 9-10 mm 4) crate 22-25 mm 5) Tyvek hydrowind protection 6) ecowool 150 mm (frame racks) 7) vapor-permeable film 8) lathing perpendicular to the frame racks with insulation with basalt wool and electrical wiring 9) plasterboard sheets There were several questions based on this construct: - in fact, all the steam that we do not let out will be concentrated in 50 mm of basalt wool, is this correct? - Will it be necessary to additionally somehow beat OSB3 sheets with film?

Sheathing between OSB and Tyvek is not needed, plus Tyvek is outside OSB

Maxim, thanks for your reply.

Good day, when insulating a frame house with mineral wool, I began to use a hydro-vapor barrier film hotrock d, do you think it can be used as a vapor barrier?

So, you must have heard about waterproofing, wind protection and vapor barrier - that is, about films that are placed in insulated roofs and frame walls to protect them. But here further, often begins a complete "steam-hydrodisgrace".

I will try to write in a very simple and accessible way, without diving into formulas and physics. The main thing is to understand the principles.

Diffuse vapor barrier membranes

This vapor barrier has the ability to change (slow down-accelerate) the penetration of vapors through its structure. Such membranes are usually used where there is too high a risk of moisture getting into the frame wall cake. For example, you have chosen a wet facade as an external finish, which is finished with impenetrable facade materials (clinker tiles, stone, etc.).

Scheme of the principle of operation of the vapor barrier.

Water vapor from the air, getting into the cake, or atmospheric moisture that got behind the exterior finish, will cause the destruction of the insulation and the frame of the building due to high humidity. For a frame house, a humidity index above 19% is considered fatal. Moisture cannot get out due to the properties that these facade materials have that do not allow vapor to pass through. In this case, you will need to purchase diffuse films.

In normal mode, diffuse film is a classic vapor barrier that blocks the passage of air vapor from inside the premises to the outside through ceilings and walls. But if the humidity inside the frame house rises, then the diffuse film allows the steam to return inside the house from the insulation, thereby saving its structure. If a diffuse vapor barrier is being installed in your home, drywall interior cladding should be installed through a drywall profile or wood batten vent.

This is where the steam from the wall insulation will go. Diffuse membranes cost several times more than a simple vapor barrier. Also, for its device, branded mastics and adhesive tapes will be required.

In order for a cheap or expensive vapor barrier to perform its direct functions, it is necessary to install it correctly, carefully gluing all overlaps and joints. Only in this case will a strong vapor barrier layer be formed. Thanks to high-quality vapor barrier at home, any insulation will perform its functions for many years.

The problems of building construction of frame houses are very often associated with errors in the construction of this simple structural component - vapor barrier. It is best not to allow anyone to this process, but to do everything on your own, with the help of relatives or friends. It will take only a few days, but you are guaranteed to avoid the problems of poor quality and improper installation of the vapor barrier.

Views: 2 389

Vapor barrier in a frame house is carried out to protect heat-insulating materials from moisture, which can affect them indoors. It should be noted that the main requirement for the installation of any insulation is its high-quality and maximum tight fit to the walls and floor of the frame. If water gets on it, the material will lose its positive properties, change its shape and its effectiveness.

Naturally, the overall insulation of the home will also suffer. The only correct and reasonable solution to avoid such situations is the use of vapor barrier. The article describes in detail how to lay it, the features of construction work and what, in fact, this component is.

How to avoid mistakes with films in a wall or roof

Fear has big eyes, in fact, with films in a wall or roof, everything is quite simple. The main thing to remember is to follow the following rules:

In a cold climate (most of Russia), vapor barrier is always placed only on the inside, "warm" side - be it a roof or a wall

Vapor barrier is always made as tight as possible - joints, openings of communication penetrations are glued with adhesive tape. This often requires a special adhesive tape (usually with a butyl rubber adhesive base), as a simple one can peel off over time.

The most effective and cheapest vapor barrier is 200 micron polyethylene film. Preferably "primary" - transparent, it is easiest to glue the joints on it with ordinary double-sided tape

Buying "brand" vapor barriers is usually not justified.

Vapor-permeable membranes (superdiffusion, windproof) are always placed on the outside, cold side of the structure.

Before installing the membrane, pay attention to the instructions for it, as some types of membranes are recommended to be installed with a gap from the material to which it is adjacent.

Instructions can be found on the manufacturer's website or on the roll of the film itself.

Usually, in order to avoid mistakes with “which side” to mount the film, manufacturers roll the roll so that by “rolling” it from the outside along the structure, you automatically mount it with the correct side. For other applications, before starting installation, consider which side to place the material.

When choosing a vapor-permeable membrane, you should give preference to quality manufacturers of the "first and second tier" - Tyvek, Tekton, Delta, Corotop, Juta, Eltete, etc.

As a rule, these are European and American brands. Membrane manufacturers of the "third tier" - Izospan, Nanoizol, Megaizol and other "isols", "brains", etc. as a rule, they are much inferior in quality, and most of them generally have an unknown Chinese origin with the brand of a trading company stamped on the film.

If in doubt about the use of the film, go to the manufacturer's website and read the instructions or recommendations for use. Do not trust the advice of "sales consultants". Refers mainly to the materials of the "first and second echelon".There are often a large number of errors in the instructions of manufacturers of the third echelon, since in fact they only sell films, without producing them and without doing any kind of development, so the instructions are written “on the knee”

The specifics of laying a vapor barrier

It may seem that everything is simple here, you just need to fix the protection on a vertical surface and control which side to turn it relative to the interior space of the room. Fasteners are carried out by means of a construction stapler, and the joints are sealed with adhesive tape. In fact, there are a number of other nuances that should be taken into account. The following are common mistakes that are unacceptable during work:

- - disregarding even minor breaks in the insulator;

- - laying the component with minimal folds;

- - poor gluing and sealing of seams;

- - Wrong choice of working side;

- - the use of not construction, but packaging tape.

The presence of at least one of the above miscalculations can lead to the fact that after a couple of years the insulation will become unusable, absorb moisture and cease to perform its primary functions. Ultimately, there will be a need to re-insulate the house, including walls, floors and roofs. Of course, this will result in considerable financial investments.

According to the installation technology, the vapor barrier membrane is applied to the surface from top to bottom, and cut into strips. It is recommended to overlap the edges by at least 100mm. Be sure to glue the indicated places with a special tape for vapor barrier, which ensures the tightness of the protection.

The adjunction of the material to the wooden elements of the walls and floor is carefully controlled. Gluing and fastening along the edges is done. The installation of the membrane to the wood frame component is carried out with a construction stapler or with galvanized nails.

About the vapor barrier of frame houses

The vapor barrier of frame walls differs from the vapor barrier of the walls of conventional houses in that the insulation is laid not on a flat surface, but on a crate formed by wooden components or profiles. In cross section, such structures may look like this:

- 1 - external surface treatment with clapboard, siding or OSB boards;

- 2 - insulation from the penetration of moisture and wind;

- 3 - frame elements;

- 4 - vapor barrier material;

- 5 - components that save heat;

- 6 - crate;

- 7 - interior decoration of the house.

Please note that about 65% of this "pie" is thermal protection. Maximum attention to its arrangement, compliance with the laying technology, the use of high-quality vapor barrier will save both materials and frame elements of the house

Why do we need films in the roof or frame wall

To understand this, you need to add a little theory.

Let me remind you that the purpose of this article is to explain “on the fingers” what is happening, without delving into physical processes, partial pressure, molecular physics, etc. So I apologize in advance to those who had five in physics. In addition, I will immediately make a reservation that in reality all the processes described below are much more complicated and have a lot of nuances. But we need to understand the essence.

Nature has already decreed that in the house the steam always goes in the direction from warm to cold. Russia, a country with a cold climate, has an average heating period of 210-220 days out of 365 a year. If you add to it the days and nights when it is colder outside than in the house, then even more.

Therefore, we can say that most of the time, the steam movement vector is directed from inside the house, out

It doesn’t matter what we are talking about - walls, roofing or lower floors. Let's call all these things in one word - enclosing structures

In homogeneous designs, the problem usually does not occur. Because the vapor permeability of a homogeneous wall is the same. The vapor easily passes through the wall and out into the atmosphere. But as soon as we have a multilayer structure consisting of materials with different vapor permeability, everything becomes not so simple.

In a single layer construction, there are no obstacles in the path of steam

Moreover, if we talk about walls, then we are not necessarily talking about a frame wall. Any multilayer wall, even brick or aerated concrete with external insulation, will already make you think.

Surely you have heard that in a multi-layer construction, the vapor permeability of the layers should increase as the steam moves.

What will happen then? Steam enters the structure and moves in it from layer to layer. At the same time, the vapor permeability of each subsequent layer is higher and higher. That is, from each subsequent layer, steam will come out faster than from the previous one.

Multilayer construction, with an increase in the vapor permeability of the layers towards the direction of vapor diffusion

Thus, we do not form an area where the vapor saturation reaches the value when, at a certain temperature, it can condense into real moisture (dew point).

In this case, we will not have any problems. The difficulty is that to achieve this in a real situation is not easy enough.

Is it possible to make a frame wall breathable, provided that all the required insulations are present?

Here it is much more realistic. The fact is that if you put a rather thick layer of breathable material on the vapor barrier, then the wall will be breathable. For example, drywall makes any wall breathable. Two layers of drywall make the wall even more breathable. A layer of boards (25 mm), and lining (12 mm) on them will also make the wall more or less breathable.

Here are a couple of schemes for a breathing frame (but with vapor barrier and insulation between the frame and the exterior). We go from the room to the street:

Scheme No. 1

- clapboard

- boards obliquely

- vapor barrier

- Insulation (absolutely any. Cotton wool, for example)

- Exterior insulation

- Anything