Combined heating systems using one type of fuel and different heating devices

Most often, one type of heating devices is used in apartments - central heating radiators, which, with a good supply of coolant, provide a comfortable temperature regime. In recent years, water and electric underfloor heating have been increasingly used in addition to them.

Heating system "Leningradka" - scheme of work and installation.

The use of a warm floor as a heating device, due to the fact that heat comes from below and rises up, provides a very high level of comfort. However, you should not completely abandon heating radiators. Professionals in creating heating systems for a country house most often recommend the combined option. The most optimal proportion, according to their recommendations, is when 70% of the heat comes from the arrangement of a warm floor, and 30% from radiator heating. At the same time, the coolant for radiators is heated up to 75 °C, and for a warm floor - up to 60 °C. The profitability of such a combination can be increased if different groups of heating devices are connected at different times. For example, at the beginning of autumn, when it is cool outside, but there are no frosts yet, the house can be heated only due to a warm floor with a minimum coolant temperature. When frost sets in, radiators are additionally used, and the maximum temperature of the coolant is used.

In some rooms, you can do without radiators. But, for example, in swimming pools and rooms with continuous glazing or high ceilings, even at very high floor temperatures, it is impossible to block the heat loss. Therefore, the use of radiators here will be mandatory.

The use of the combined system "radiators + underfloor heating" can be both with electricity and with the use of a heat carrier. In one case, electric radiators are installed and a heating cable is laid under the floor, and in the other case, ordinary radiators are installed, and pipes are laid under the floor.

Convenient convectors and underfloor heating are best used as support heating, which will protect the house from freezing during the period when tenants are absent or to warm auxiliary rooms in the house.

Equipping a warm floor using a coolant, you can use almost any pipes: made of cross-linked polyethylene, metal-plastic, copper, etc. The main task when installing them is to make the right calculation. It is necessary to correctly draw up a pipe laying scheme, correctly calculate the hydraulic resistance, determine the thickness of the pipes and determine the power of the circular pump. The same calculations must be made when installing radiators. Their total capacity, taking into account the use of a warm floor, must fully correspond to the heat loss in the room. In order to make such calculations, it is better to contact specialists.

Combination of types of heating

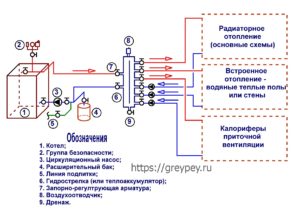

The second way of combining is the joint introduction of types of water heating - radiator and built-in.

Built-in heating is of 2 types:

- Water heated floors;

- Water warm walls.

These types of water heating are used as both main and additional heating. For the operation of underfloor heating and warm walls, it is necessary to install a mixing and circulation unit. The operation of built-in heating complexes is carried out using a special mixer - three or four-way, the unit is equipped with its own circulation pump.

The temperature of the coolant in warm floors and walls usually does not exceed 50C, it flows in a low-temperature regime.The low temperature of the coolant is necessary to heat the floor surface to comfortable values - from 23 to 33C.

Connection of circulation nodes is carried out similarly to radiator heating branches - to risers or to collectors of the appropriate diameter. The most optimal is the connection of built-in heating complexes to hydraulic separators or heat accumulators - in this case, the minimum mutual influence of the radiator system and the contours of the warm floor (warm walls) is achieved.

The use of warm floors creates more comfortable conditions for a person - the heat is concentrated in the zone of his stay. Warm water walls are no less effective, but less popular than water heated floors.

In addition to combining radiators and built-in water systems, quite often the air heating heater becomes the third component of a water heating complex. Along with radiators and underfloor heating, heat is taken from a heat source for the needs of air heating in supply ventilation or an air heating network. The heaters are also connected in the boiler room.

It should be noted that when using different end consumers of heat - radiators, underfloor heating (walls), heaters, heat exchangers for heating pools, indirect heating boilers - it is recommended to connect them to a hydraulic switch or a heat accumulator. These devices solve the issue of hydraulic balancing and different temperature modes of operation, greatly facilitate control and adjustment.

The combination of schemes and types of water heating is a high-quality technical solution that significantly increases the level of comfort in heated rooms. The use of classical schemes is not always the best solution for heating residential premises of a large area and different heights. The combination of individual schemes and types of heating not only increases comfort, but also allows you to diversify the temperature regime in the premises, improves the overall hydraulic structure, and optimizes the control process.

The second direction of combination - the integration of heat sources (boilers of various types, and so on) - has a number of technical features and is considered in a separate publication of our portal.

(Views 176 , 1 today)

We recommend reading:

How to build a septic tank with your own hands

Ways to save water

Operation of the heating system

Types of water heating

Gas heating convectors

Cottage heating system

What is a combined heating system

Hello to all my readers! In this publication I will tell you briefly about combined heating systems. They are now quite common and are used everywhere. It may very well be that you also wanted to do this in your home. I won't bore you with long introductions and get straight to the point!

A combined heating system is a heating system (hereinafter referred to as CO), which uses several options for heating a room. For example, it can be heating a room using a stove and electric convectors. The latter are used very often to heat the room after the fuel burns out in the furnace. Instead of the design of radiators, an electrically heated floor or a climatic device that acts on heating can be used. Well, the CO option with a traditional heating boiler and a heating pump will be completely exotic.

Combined can be considered CO, which uses two or more heating devices that operate on different fuels. So, for example, in our country a scheme is popular in which the key gas boiler is duplicated by solid fuel or electric. At the same time, I believe that the solid fuel option is better here. Since light and gas can abyss at the same time, and solid fuel can always be nearby in this case.If your CO uses forced circulation of the heat carrier, then you will need an uninterruptible power supply to support the operation of circulation pumps and automation.

Well, if you want complete autonomy from the outside world, then here you can create two things:

- Gravity heating system - the heat carrier in it moves under the influence of gravity.

- Furnace - the room is heated by radiation from the furnace itself, which is made of bricks.

These options have their own pros and cons, but we will talk about this separately in the next articles of this blog. And now it is necessary to consider a more common combination of methods for heating a room.

Heating system “heaters plus underfloor heating”.

It should be said right away that this option is currently used wherever possible. Its fame is explained by the increase in the comfort of living in a private house. You can forget about warm socks and slippers and just walk on the comfortable heated floor.

The essence of such a CO is that the heat loss of the room is divided between the heating devices (or other heat supply devices) with a heated floor. Here, high-temperature and low-temperature heat supply work in pairs. If someone is not in the know, then let me remind you that the temperature of the heat carrier in heating appliances can reach 90 degrees, then for warm floors it should not be more than 50. This makes it possible to achieve the optimal temperature of the floor surface.

Unfortunately, there are many people in our state who like to do first and then think ... Well, or never think at all. So, these people connect warm hydraulic floors (VTP) without an independent circulation group (it is also called a mixing unit). As a result, water heated to 70-80 degrees begins to circulate through the pipes, and the floor covering begins to burn the legs. Of course, you will eventually get used to walking around the house in beach slippers, but it is better to do everything from the very beginning according to the rules. For a better understanding, I suggest you read the publication about common mistakes when laying underfloor heating.

Apart from the VTP, heated floors are used with an electric sample. In most cases, it will be much cheaper to put a wire or mat used for heating in the screed than to haul pipes and make boxes for the collectors. Only electricity bills will increase, but this can sometimes be reconciled with.

Publication results.

In the end, it must be stated that it is possible and necessary to use combined heating systems. You need to start here with a project. A properly designed project will help reduce installation and operation costs. It’s not worth chopping off your shoulder and doing like a neighbor, otherwise you can “fly through” on payments for electricity, gas or coal. I'll break on this! I look forward to your comments and questions

Heating ‘target=”_blank”>’)

Design features

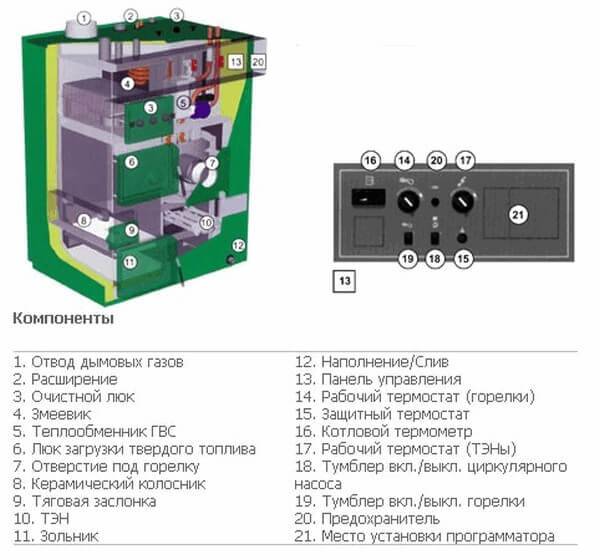

In fact, a combined boiler for a summer residence is the same solid fuel. only additionally equipped with heating element. A bulky unit, in which a large volume is occupied by a wood-burning firebox.

The heat exchanger is arranged somewhat differently than that of a simple wood-burning one: it has a complex shape, heating elements are mounted between the walls, and there is a special hole in the case for connecting electricity.

Working units of the universal boiler electricity / firewood:

- wood fire chamber with a loading hatch. The volume of laying firewood depends on the dimensions;

- ashpit - a chamber under the firebox in which ash is collected. Through it, blowing is carried out;

- damper, with which you can adjust the draft and, accordingly, the flame. Driven by chain drive. When burning firewood, it must be open;

- heat exchanger;

- heating elements;

- temperature sensors. Provide adjustment of the operation of heating elements;

- control pressure gauge;

- chimney, the same as for solid fuel boilers (chimney device for solid fuel boiler);

- automation. is responsible for the mode of operation, regulates the power.

Additionally, boilers for heating on wood and electricity are equipped with a hob (above the combustion chamber). The double-circuit model has the ability to connect a warm floor. The housing has branch pipes for supplying coolant and for return, a drainage system, and safety devices.

How to choose

The first selection criterion is power. The total is calculated as 1 kW for an area of 10 square meters. Correction factor - 0.7-2 (depending on the geographical area: the further north, the more). 25% for the second circuit, 10% for the peak voltage in the network. This is the standard calculation.

In your case, the power is the sum of two figures: electricity and wood heating. You need to prioritize and calculate approximately how long the boiler will work on wood, and how much on heating elements. It is also not worth choosing a boiler with a power that greatly exceeds real needs: it will cost more and there will be extra costs during operation.

If the heating is predominantly wood burning, the size of the combustion chamber is important. It's a matter of your convenience: how often you have to update the bookmark.

Combined heating boilers electricity-wood can have one or two circuits. The choice depends on your plans: whether you need hot water supply, whether there will be a warm floor. Boilers with a coil mounted directly into the furnace are considered more economical.

Dimensions and weight. Determine in advance where the boiler will stand. Will it be possible to fill in his own screed for him. The mass, among other things, depends on the material of the heat exchanger - cast iron or steel.

Cast iron models have high inertia - they heat up longer, cool down longer. They are considered more durable due to corrosion resistance. But more fragile, sensitive to sudden changes in temperature. Steel is susceptible to corrosion, but is more stable in terms of temperature. And less weight.

Grid-irons happen ceramic, steel, pig-iron, pig-iron with a ceramic dusting. The heat resistance of cast iron is higher; it is a universal option for all types of solid fuels. Coated honeycomb grates are optimal for bulk fuels that require more oxygen to burn.

The special valve in a design provides silent work. The presence of a built-in fan will increase the efficiency of the boiler and simplify the exhaust device for the installer. Models with a top-mounted fan are considered more durable: the bottom one wears out faster due to dust that enters the device from the floor.

Automation is electronic and mechanical (with manual control). Since, in the presence of heating elements (and a circulation pump), the boiler is in any case volatile, it is hardly worth saving on automation.

It is better to use electronic, it has more functions: almost everything is automated, except for laying firewood. It is even possible to remotely control heating elements (what are Gsm modules for heating boilers).

Combined home heating systems

Most often, the resource asks questions about: How to connect the radiator heating system and underfloor heating together? In this publication and video review, I will share with you my own experience of how I make such combined heating systems.

To connect heaters and underfloor heating, I use three main methods. However, first you need to understand one thing - the main problem of heat supply is that there is actually a minus of the heat carrier. A problem caused very often by a narrowing of the diameter of the supply pipes.

Connecting combined systems with a manifold

The first method that I use to connect combined systems is to connect various heating systems using a main distribution manifold.Everyone knows that this is the best option. Under the conditions that the collector itself is made and selected correctly. It is not always possible to do this with factory collectors, since a number of models are limited by the number, size of the leads and the cross section of the collector itself.

In order to help in solving this problem, you can order such a collector personally or make it yourself. The distribution manifold allows you to connect the required number of heating circuits and heat sources with the diameters of the pipelines and the cross section of the manifold that we need. Thus, we acquire a combined heating system. At the same time, we also get exemplary hydraulics of the heating system. On the collector, you can similarly carry out several options for connecting the heating floor circuit.

For example, you can simply install a pump to supply a heated floor directly on the manifold, install a check valve, and install a temperature switch on the return line, which will turn the pump on and off when the set temperature is reached. This is the most common method, and in my experience this method is suitable for concrete systems. heated hydraulic floor tile, stone and so on.

Other options for connecting combined systems

The next way to connect several heating systems is to install a three-way valve with manual or automated control in front of the pump. Again, you will have it all nearby and in one place.

Another way that can be used for combined heating systems is to install ready-made factory-made pneumatic water pressure units for radiator heating systems and underfloor heating on the collector

Here you need to take into account the axial size of the connection of such stations and order the collector itself in size

The next way to connect combined heating systems (radiator heating systems and underfloor heating) is considered to be a common supply pipeline with a network pump. Such a pump for the most part presses into the heating devices, and underfloor heating at the same time involves installation on the distribution manifolds of factory mixing modules for underfloor heating systems. Here, an important condition is a specifically good choice of the diameter of the supply and return pipelines. From practice, I can say that on three floors of two hundred squares each, I used a PPR pipeline dm 50 mm, while the connection of floor collectors and heating appliances was implemented with a PPR pipeline dm 32 mm.

And the last way to connect combined heating systems, which was also implemented by me, is that you only have heated floors. Then a pipeline of the required diameter is selected. On the floor collectors, you mount mixing modules, separately three-way valves with a pump or a pump through a temperature switch. The pumps each pull themselves from a common pipeline.

Do you have any questions? Take a look at the video below

What heating devices are combined in the system

Since gas is the most affordable and cheapest fuel in many regions of our country, there are no problems with choosing a heater. The main thing is to choose high-quality equipment with the necessary power. However, the problem of choosing heating equipment is relevant in settlements where there is no gas pipeline nearby.

In this case, the following heaters and their combinations can be used:

- The use of liquefied gas is not cheap, but this option can be used for critical situations. In this case, a gas boiler model is used, which can be converted for use with liquefied gas by replacing the nozzle.

- An oil-fired boiler is suitable for those homeowners who can afford to buy diesel fuel. Such units are capable of heating large areas.

- In all other cases, a long-burning solid fuel boiler is considered a good option.

- A condensing boiler can also be a profitable solution for a private house. It is very fuel efficient and has a high efficiency. These are non-volatile models that have electronic burner ignition systems.

Second option

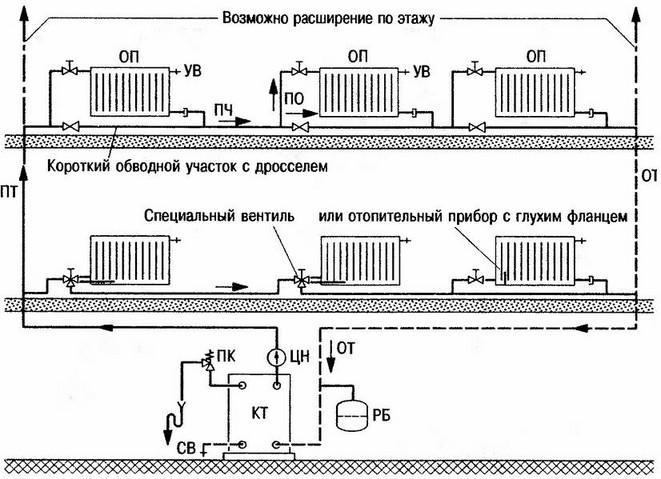

Radiators are connected according to a single-pipe scheme; in this embodiment, the heating process proceeds as follows:

- The return from the first pipe is the supply for the second. Of course, such a system is imperfect, because you can have three or four radiators, in which case the coolant for the last radiator will no longer be hot enough;

- such a system all the more requires the connection of a warm floor, since its efficiency may not be sufficient to warm the entire building. Here you need to connect it to the supply, but for this you will need a thermostatic mixing unit to control the temperature.

Heating systems of a private house.

80 degrees (namely, this is the temperature in the supply) is too much for a warm floor, simply because it is uncomfortable for a person.

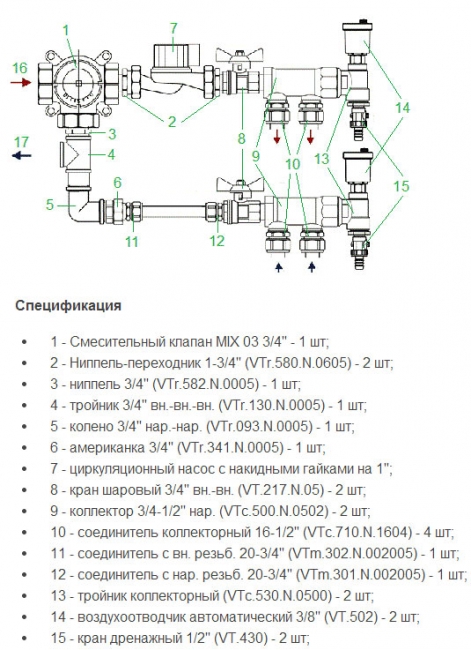

Schemes of mixing units

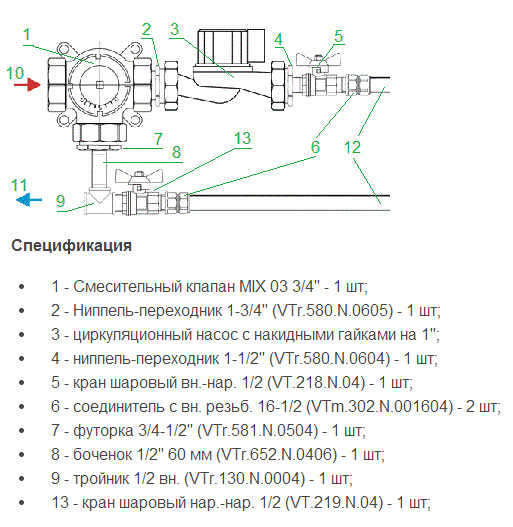

You can see the finished mixing units of the supply units, which are presented in the diagrams below.

- Connectors (No. 6) are connected to pipes.

- The supply of hot coolant from the boiler is connected to output No. 10, and the return is connected to No. 11.

- Additionally, you can supplement the circuit with an automatic air vent.

It is best to connect the supply and return from the high-temperature circuit through an American tap.

- To connect it, the mixing valve (No. 1) is mounted with a “+” sign in the direction of the American tap from the supply.

- The supply and return are connected to American women through connectors with external threads (No. 4 - inlet, No. 7 water outlet).

- The operation of the circulation pump (No. 18) is directed towards the mixing valve (No. 1).

- Underfloor heating circuits are connected to outputs numbered 12 and 22.

Pumping and mixing unit from Valtec

The third version of the collector unit is already suitable for 2-4 heating circuits with an area of 20-60 square meters. The diagram shows an example with manual control.

- To connect, you need to connect the supply from the boiler to terminal No. 16, and the return to terminal No. 17.

- For the system to work well, the length of the loops should be approximately the same.

- The diagram shows an option for 2 circuits, if you need to connect 3 or 4 of them, then the manifolds (9) are replaced with one adjustable manifold and one with ball valves (VTc.560n and VTc.580n).

- The supply is connected through the upper American tap No. 3, and the return is connected to the lower tap.

- The pump must work towards mixing valve number 2.

- The valve itself is installed with a plus sign in the direction of supply from the boiler.

- Contours for a heat-insulated floor fasten to collectors (12).

- 1 mixing unit Combimix (VT.COMBI.0.180);

- 1 manifold assembly for the required number of outlets (VTc.594/VTc.596);

- Circular pump 180 mm;

- 2 fittings (for each circuit) VT.4420.NE.16 of the Eurocone standard for connecting metal-plastic pipes.

The circulation of the coolant in such a collector is shown in the figure.The supply is connected to the upper outlet, the return to the lower. The operation of the pump is directed downward, so the lower manifold becomes the supply for the underfloor heating circuits (orange in the photo), and the upper one goes to the return line (blue).

Single pipe system plus underfloor heating

The design consists of the following elements:

- boiler;

- security block;

- valves;

- circulation pump;

- expansion tank.

The radiator system is made in the form of two branches, and each branch is regulated by a separate riser located next to the connection to the main riser. Each of the radiators is equipped with two valves for supply and return.

This is done so that in the event of a radiator failure, it is possible to replace it without shutting down the entire system.

Underfloor heating is connected to this system as follows:

- from the boiler, the coolant is supplied with a temperature of at least 80 degrees, when it goes back, its temperature is reduced to about 50 degrees. Therefore, the warm floor is connected precisely to the reverse;

- since the valves are installed both on the supply and on the return, you can turn off the warm floor without stopping the operation of the entire system. For adjustment, a bypass is installed on the return pipe, by adjusting which you can send part or all of the coolant immediately to the boiler.

Combined home heating.

This is done when the heat carrier is too hot. The bypass can be closed or opened completely or halfway, you will regulate this process yourself depending on the temperature in the rooms.

The disadvantage of such a system can be considered manual adjustment of the bypass, but, on the other hand, this option is economical, since buying a mixing unit with automatic valves will cost you quite a lot.

How to connect radiators and underfloor heating to the boiler pump and mixing unit

How to combine a radiator heating system and a water heated floor. For one heating boiler. If possible with video accompaniment?

Hello Khalil! In order to simultaneously connect heating radiators and a water-heated floor to the boiler, a collector assembly is required. It can be bought assembled (price 10-20 thousand rubles, depending on the heated area), or, if you have experience, assemble it yourself.

For example, the price of a VALTEC COMBI pumping and mixing unit costs almost 15 thousand rubles, excluding collectors.

Valtec Combi with 180 mm pump

ContentsWhat is a mixing unitSystem elementsTwo-way valveThree-way valveDiagrams of mixing units

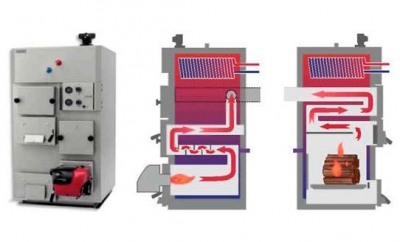

Universal boilers gas solid fuel

Universal gas-solid fuel boilers are the best solution for houses where gas will soon be supplied or there are interruptions in its supply.

How else can you heat houses that are not connected to the gas main? For this, combined heating boilers "gas - solid fuel" are often used. These versatile units burn wood, coal, pellets and many other materials, up to pressed straw. They also work on main or bottled gas. To do this, their design provides for two combustion chambers at once, gas burns in the first, firewood burns in the second.

The combustion products are poured into a special tray, which simplifies the maintenance of the equipment.

Combined boilers operating on solid fuel and gas differ from boilers for gas and diesel fuel in size. To burn wood, coal or compressed fuel, a volumetric combustion chamber is needed, so such boilers are quite massive. They are made of steel or cast iron, floor construction is used. Some models are equipped with devices for automatic feeding of combustible granules.

Who is suitable combined heating boilers for gas and solid fuel? They will be useful to all owners of suburban housing, temporarily not connected to the gas main.Boilers provide efficient heating of residential premises, allowing you to choose the type of fuel. If there is no gas in the house yet, wood, coal and any other available combustible materials are used for heating. As soon as gas appears, it will be possible to immediately switch to it.

Is there a power outage in your area? Do you have a source of inexpensive solid fuel? Then universal heating boilers "gas - firewood" will be an indispensable solution for you. When the gas supply is cut off, you can load firewood into the furnace, light a fire and enjoy the warmth while the neighbors are freezing. When the gas supply is resumed, it remains only to wait for the combustion to complete.

Prices for combined heating boilers "gas - firewood" start at 10 thousand rubles (prices at the end of May 2016), depending on the performance and capacity of the equipment

Please note: boilers with automatic fuel supply are much more expensive

Universal combined heating boilers

In some cases, it is advisable to use universal heating boilers, which provide for the use of not only two types of fuel. These include combined gas-firewood-electricity heating boilers, pellet models.

Pellet Combined Heating Boiler

The defining difference that pellet combined heating boilers have is the presence of several combustion chambers. They are adapted for the use of a certain type of fuel - gas, diesel, firewood, etc. As an additional measure, an electric heating element can be provided, located in one or more chambers of the heat exchanger.

It is noteworthy that in many models of combined heating boilers, gas, firewood, electricity, the pellet burner is removable. Those. the combustion chamber for it can be used for a different type of fuel. Most often it is gas or diesel. The conditions for the use of these energy carriers provide for the presence of forced air injection and the complex design of the heat exchanger for the transfer of thermal energy. These qualities are also characteristic of pellet combined heating boilers.

For the operation of multi-fuel heating boilers, the following conditions must be met:

- Stable power supply. It is needed for the operation of pellet combined heating boilers, gas and diesel burners. Exceptions are the use of solid fuels;

- Organization of fuel delivery to the boiler. The main problem when planning the installation of combined gas-firewood-electricity heating boilers is the storage of energy carriers. Separate rooms are made for cylinder heating or external steel boxes are installed. Diesel fuel is stored in barrels that are connected to a special pumping station.

Before purchasing universal boilers for combined heat supply, it is necessary to analyze the feasibility of their use. Their cost is an order of magnitude higher than the classic single-fuel ones. To do this, make a detailed financial analysis for each type of energy carrier.

When installing foreign and Russian combined heating boilers, you need to correctly calculate the diameter of the chimney. The thrust rating must meet the minimum requirements for each type of fuel.