Content

-

slide 1

Devices of the magnetoelectric system

The torque arises as a result of the interaction of the magnetic field of a permanent magnet and the magnetic field of the coil (frame) through which the current flows

-

slide 2

1 - permanent magnet

2 - pole pieces

3 - fixed core

4 - moving coil

5 - semiaxes associated with the frame

6 coil spring

7 - arrow

8 - counterweights -

slide 3

In the gap between the pole pieces and the core, an MP is created, in which there is a movable rectangular frame wound with a thin copper or aluminum wire on the frame. Helical springs, designed to create a counteracting moment, are simultaneously used to supply current to the loop. The frame is rigidly connected to the arrow.

-

slide 4

The angle of deviation of the arrow of the device is directly proportional to the current passing through the frame - the scale is uniform

Can only measure direct currents -

slide 5

Devices of the electrodynamic system

The torque arises as a result of the interaction of the magnetic fields of the fixed and moving coils with current.

Their work is based on the phenomenon of dynamic interaction of two conductors with current. -

slide 6

1 - fixed coil; 2 - moving coil

3 - axis; 4 – spiral spring;

5 - arrow; 6 - scale -

Slide 7

The angle of rotation is proportional to the product of the currents in the coils, and the scale of the electrodynamic device is not uniform.

Purpose of electrodynamic devices

measurement of alternating and direct currents and voltages (ammeters, voltmeters)

power measurement (wattmeters)

frequency meters and phase meters -

Slide 8

Advantages

have high precision

suitability for operation on direct and alternating current

Flaws

do not tolerate shock, shaking and vibration

uneven scale

high power consumption

sensitive to the influence of external MF, frequency and temperature -

Slide 9

Electromagnetic system devices

1 - ferromagnetic core, mounted on the axis of the device

2 - spiral spring

3 - weights-counterweights

4 - fixed coil

5 - air damper -

Slide 10

To create a torque, the action of a magnetic field created by a current in a fixed coil is used on a movable ferromagnetic core

Purpose

1. measurement of alternating and direct currents and voltages (ammeters, voltmeters)

2. power measurement (wattmeters)

3. measurement of frequency and phase shift between current and voltage

Measurement range: currents – 0…200 A voltages – 0…600 V -

slide 11

Advantages

1.large overload capacity

2.Easy design, high reliability

3. low cost

4.possibility of direct measurement of high currents and voltages

5. Work in DC and AC circuits -

slide 12

Flaws

1. uneven scale

2. large self-consumption of energy

3. susceptibility to the influence of external magnetic fields and temperature. -

slide 13

Electrostatic Instruments

Based on the principle of interaction of electrically charged conductors (capacitor).

1 - fixed cameras

2 - spiral spring

3 - axis with pointer

4 - two movable plates -

Slide 14

They can only measure voltage directly. Suitable for DC and AC voltage measurement

Advantages

not sensitive to frequency

when measured at DC, their own consumption is almost zero

suitable for measurements in DC and AC circuits

high torque (allows them to be used as self-recording instruments).

View all slides

Content

-

slide 1

The work was carried out within the framework of the project: "Improving the qualifications of various categories of educators and the formation of their basic pedagogical ICT-competence" under the program: "Information technologies in the activities of a subject teacher"

pptcloud.ru -

slide 2

I've done the work:

Leontievsky Anatoly Borisovich

Teacher of additional education MOU secondary school No. 4

Station of Young Technicians

the city of Iskitim

Novosibirsk region. -

slide 3

electrical engineering

Members:

Children from 11 to 16 years old

Fundamental Question: What do we know about (Electrical Engineering).

Study topic: Household electrical appliances.

Informational resources:

Internet resources, printed publications, multimedia applications.

Subject studied: -

slide 4

electrical engineering

-

slide 5

Objectives: To help students improve their knowledge and skills in electrical engineering, to interest in technical creativity, so that the student chooses a further

path to education.

Tasks:

1. Give theoretical knowledge on the basics of electrical engineering.

2. To instill practical skills necessary to perform electrical work.

3. Teach how to use electrical measuring instruments.

4. Acquire skills in designing various devices and models.

5. Make visual aids.

6. To form the ability to adapt in the conditions of modern life.

Targets and goals -

slide 6

a set of wires, cables and cords with their associated fasteners, supporting protective structures and parts, which serves to transmit electric current from a power source to a consumer source.

Wiring -

Slide 7

Wiring

Types of electrical wiring

closed

open -

Slide 8

Wiring devices - a group of electrical devices, which include switches and switches, electrical two-way connectors (sockets, plugs), clamps (contact blocks), cartridges for incandescent lamps and automatic and fuse fuses.

Wiring devices -

Slide 9

Wiring devices

clamps

sockets

lampholders, etc.

circuit breakers -

Slide 10

A fuse is the simplest device that protects the electrical network from short circuits and significant overloads.

circuit breakers -

slide 11

circuit breakers

circuit breakers

thermal

electromagnetic

combined -

slide 12

Some electrical appliances have a very versatile application and are used in both industrial and domestic electrical installations. Such devices include electric motors, which are direct current and alternating current.

electric motors -

slide 13

electric motors

alternating current

direct current -

Slide 14

Household appliances are electrical appliances used in the home. The list of electrical appliances is very large. All devices are similar in design and operating principles, have a number of distinctive features from each other, that is, they are diverse in their designs even within the group.

Appliances

-

slide 15

household electrical appliances

iron

kettle

TV set

mixer -

slide 16

During the lesson, a general concept of electrical engineering, its scope, and its possible use was revealed.

lesson summary

View all slides

Presentation on the topic Types of heating. The device and operation of water heating. transcript

1

Types of heating. Device and operation of water heating

2

The purpose of the lesson: The purpose of the lesson: Mastering PC 2.2 "Maintenance of heating devices, forced ventilation and air conditioning, electrical equipment, refrigeration units" Mastering PC 2.2 "Maintenance of heating devices, forced ventilation and air conditioning, electrical equipment, refrigeration units"

3

Purpose of heating The heating system is used to maintain normal temperature inside the car, regardless of the outside temperature The heating system is used to maintain normal temperature inside the car, regardless of the outside temperature

4

Types of heating Water Combined Water Combined Electric Electric

5

According to GOST and the requirements of sanitary and hygienic conditions, the temperature inside the car must be

6

With a water heating system, the car is heated using heating pipes located along the entire car, in which hot water circulates.

7

Hot water heating device Heating boiler Tank expander Heating pipes Hand pump Heating pump Shut-off valves and cocks Measuring instruments Air heater

8

The principle of operation of the heating system Solid fuel burns in the boiler, water is heated and enters the tank expander Solid fuel burns in the boiler, water is heated and enters the tank expander

9

The expander accepts excess water. From it there are two branches of heating pipes along the entire car.

10

Each branch of the heating pipes goes along the upper part to the opposite end of the car, then goes down, forming risers

11

From the risers, the heating pipes run along the bottom of the car along the side walls and join the bottom of the boiler

12

The heating system of the passenger car is provided with a hand pump, which is located in the boiler room and serves to replenish the heating system with water.

13

To increase the speed of water through the pipes, a heating pump is provided in the car. In the boiler room there are measuring devices thermometer and hydrometer, which respectively measure the temperature and water level in the heating boiler

14

Heating boiler device

15

Rules for kindling the boiler Check and replenish water in the heating system Check and replenish water in the heating system Clean the firebox from slag and ash Clean the firebox from slag and ash Place firewood and chips on the grate, ignite with paper Place firewood and chips on the grate, ignite with paper As it burns firewood, first throw a briquette or small coal, then coarse coal

16

Boiler water temperature dependence on outside air temperature Outside air temperature Boiler water temperature +5; ;-15+70; and below +90;+95

17

Safety precautions when servicing the heating installation It is forbidden to use flammable liquids when melting the boiler It is forbidden to use flammable liquids when melting the boiler It is forbidden to dry clothes in the boiler room, and also store brooms and rags It is forbidden to dry clothes in the boiler room, and also store brooms and rags It is forbidden to throw away on the go slag and ash on the train It is forbidden to throw away slag and ash while the train is running When servicing the heating installation, the conductor must wear overalls When servicing the heating installation, the conductor must wear overalls

18

Domino task match the nodes of the heating system and their purpose 1. Heating boiler 1. Serves to replenish the heating system with water 2. Heating pipes 2. Takes excess water in the heating system 3. Hand pump 3. Increases the speed of water movement through the pipes 4. Tank expander 4 .Controls the water temperature in the boiler 5. Thermometer 5. For circulation of water in the heating system 6. Hydrometer 6. Controls the water level in the boiler 7. Heating pump 7.Solid fuel burns and water heats up

19

Right answers

Presentation on the topic Electrical meters Electrical meters are a class of devices used to measure various electrical quantities. transcript

2

Electrical measuring instruments are a class of devices used to measure various electrical quantities.

3

Classification Ammeters - for measuring current strength Voltmeters - for measuring voltage Ohmmeters - for measuring electrical resistance Multimeters (otherwise testers, avometers) combined devices Wattmeters and varmeters - for measuring electric current power; Electric meters for measuring consumed electricity

6

Electrical measuring instruments are based on the interaction of magnetic fields.

7

They take a light aluminum frame 2 of a rectangular shape, wind a coil of thin wire around it. The frame is mounted on two semi-axes O and O', to which the arrow of the device 4 is also attached. The axis is held by two thin spiral springs 3. The elastic forces of the springs, returning the frame to the equilibrium position in the absence of current, are selected such that they are proportional to the angle of deviation of the arrow from the position balance. The coil is placed between the poles of a permanent magnet M with hollow cylinder tips. Inside the coil is a cylinder 1 made of soft iron. This design provides a radial direction of the lines of magnetic induction in the area where the turns of the coil are located (see figure). As a result, at any position of the coil, the forces acting on it from the side of the magnetic field are maximum and, at a constant current strength, are constant.

8

By increasing the current strength in the frame by 2 times, you can see that the frame will turn at an angle twice as large. The forces acting on the frame with current are directly proportional to the current strength, that is, by calibrating the device, you can measure the current strength in the frame. In the same way, the device can be set up to measure the voltage in the circuit, if the scale is calibrated in volts, and the resistance of the current loop must be chosen very large compared to the resistance of the circuit section on which we measure the voltage, since the voltmeter is connected in parallel to the current consumer and the voltmeter should not divert a large current so as not to violate the conditions for the passage of current through the current consumer and not to distort the voltage readings in the studied section of the electrical circuit.

9

Voltmeter: the needle turns in the magnetic field of the magnet

10

VOLTMETER - a device for measuring voltage in a section of an electrical circuit. To reduce the influence of the included voltmeter on the circuit mode, it must have a large input resistance. The voltmeter has a sensitive element called a galvanometer. To increase the resistance of the voltmeter, an additional resistance is included in series with its sensitive element.

11

AMMETER - a device for measuring the current flowing through a circuit section. To reduce the distorting effect on the electrical circuit, it must have a low input resistance. It has a sensitive element called a galvanometer. To reduce the resistance of the ammeter, a shunt resistance (shunt) is connected in parallel with its sensitive element.

12

OMMETER - a device for measuring electrical resistance, which allows you to read the measured resistance directly on the scale. Modern instruments for measuring resistance and other electrical quantities use different principles and give results in digital form.

13

Meters are electrical measuring instruments for accounting for electricity supplied by the station to the network or received by the consumer from the network for a certain period of time.

14

Magnetic field in nature and technology. Magnetic field in nature and technology. Use of a magnetic field. Use of a magnetic field.Magnetic field in nature and technology. Magnetic field in nature and technology. Use of a magnetic field. Use of a magnetic field.

Presentation on theme: THE TRADITIONAL METHOD OF HEATING A ROOM IS CONVECTIVE HEATING Convective heating - heating a room with water radiators

2

CONVECTIVE HEATING IS A TRADITIONAL HEATING METHOD FOR ROOMS Convective heating means heating a room with water radiators (registers) and supplying warm air (air heating). Since the air rises and creates a "thermal cushion" in the upper part of the room, excessive consumption of thermal energy is inevitable to maintain a comfortable temperature in the workplace.

3

The elevated air temperature in the upper part of the room leads to high heat losses through the roof and building envelope.

4

High rooms (above 15 m) are practically impossible to heat efficiently using convective heating methods. Heating is slow, and to ensure comfort, it is necessary to heat the entire volume of air in the room. This causes the low efficiency of traditional heating methods in large workshops.

5

To date, one of the most progressive and efficient methods of heating large industrial premises is infrared (radiant) heating.

6

Infrared heating is based on the principle of thermal radiation. Infrared heating is carried out using infrared emitters. Infrared emitters with a surface temperature of 700 to 2000 °C are called "light" and are closer to light in wavelength, and emitters with a surface temperature of about 400 °C are called "dark". Thermal radiation is the transfer of thermal energy from a source with a higher temperature to a receiver with a lower one.

7

Emitters can be advantageously placed only above the place where people are and provide them with the necessary temperature conditions.

8

After turning on and heating up to the nominal temperature, the radiators begin to emit waves that pass through the air with very low losses and fall on the floor, where the radiation energy is converted into heat. This means that the air is heated a second time, from the floor, which thus becomes the warmest place in the building.

9

Local infrared radiant heating systems run on natural and liquefied gas and electricity. These systems are able to provide comfortable production conditions.

10

Modern infrared gas heating systems operate automatically, without requiring attention from the operating personnel. After installation and adjustment for 15 years, periodic inspections can be limited. As a result, repair and maintenance costs are reduced to 3-5% of the total costs for radiant gas heating systems compared to 20-40% in alternative air heating systems with centralized distribution of the heat carrier (heating water or steam).

11

Saving budget funds for heating from 30 to 70%; Energy saving, gas consumption up to 40% compared to traditional space heating systems; Convenient use (the possibility of zone heating when programming the temperature of each zone separately and independently of each other) and simple service; Direct heating of the system, not air, which creates significant energy savings, the infrared heating system is silent and does not create air movement; Payback period from 1 to 2 heating seasons;

12

Saving gas, heat energy during non-working hours and weekends - the ability to heat different zones with different temperatures; The comfort temperature is achieved at a lower air temperature due to the radiant component; Achievement of a comfortable level of heating in 5 minutes after switching on; The minimum need for electricity. Electricity is needed only when the system is started (no more than 45 seconds after switching on); No environmental pollution; Service life more than 20 years.

13

References 1. Infrared gas heating. Tekhpromstroy. Gas system of infrared (radiant) heating. Uralstroyportal Pshenichnikov V. M., Shkuridin V. G.Infrared gas heating of industrial enterprises. Nortech Engineering Group Infrared heating. Energy efficient heating. Infraprom.

Presentation on the subject Technology on the topic The object of study is heat-saving technologies The subject of study is the heating system of the MBOU Far Secondary School The goal is to improve the temperature regime at school.. Download for free and without registration. transcript

2

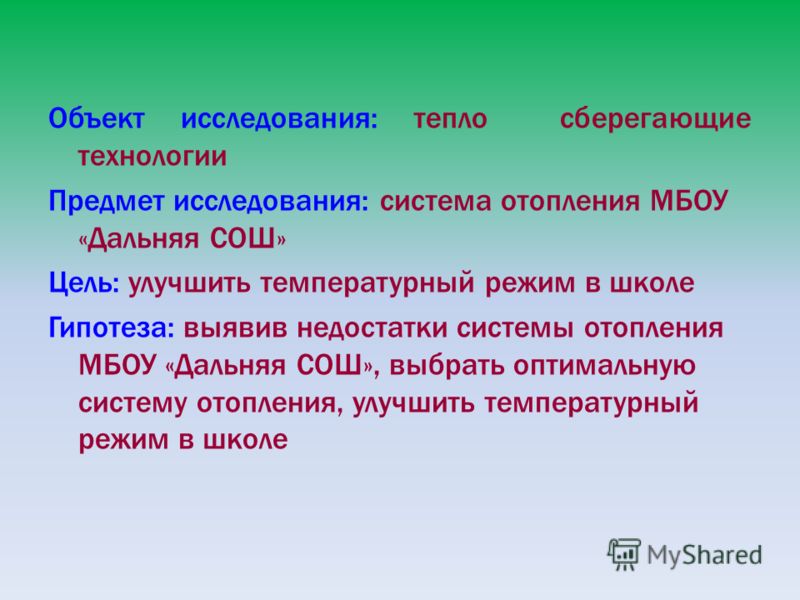

Object of study: heat-saving technologies Subject of study: heating system of MBOU "Dalnaya secondary school" Purpose: to improve the temperature regime at school Hypothesis: by identifying the shortcomings of the heating system of MBOU "Dalnaya secondary school", choose the optimal heating system, improve the temperature regime at school

3

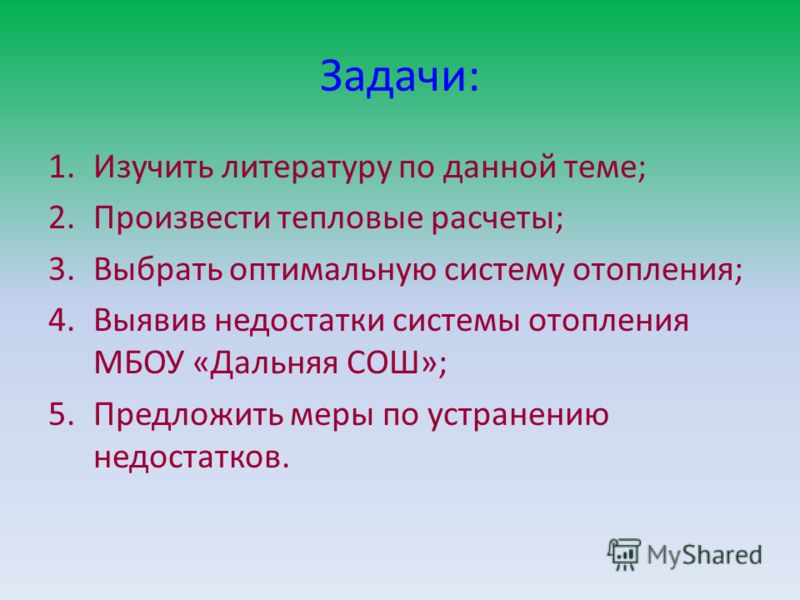

Tasks: 1. To study the literature on this topic; 2. Make thermal calculations; 3. Choose the optimal heating system; 4. Revealing the shortcomings of the heating system of the MBOU "Far Secondary School"; 5. Suggest corrective action.

4

Relevance

8

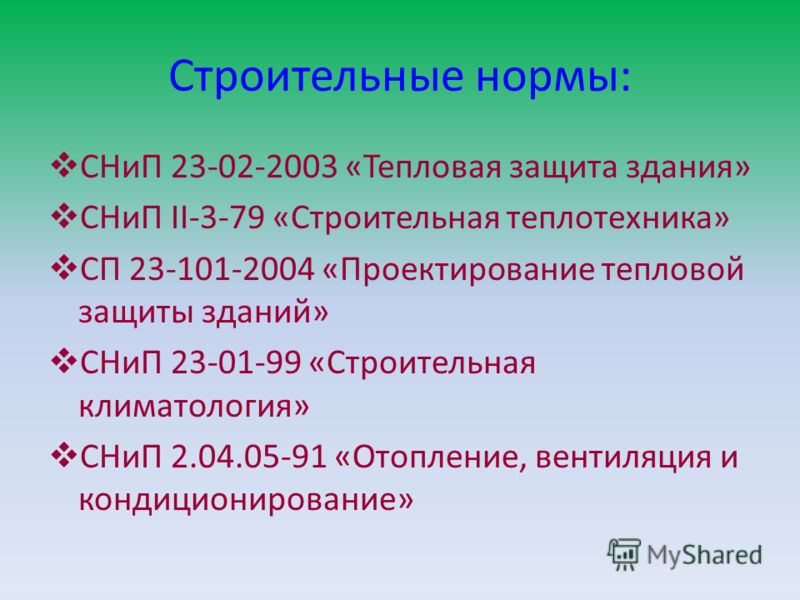

Building codes: SNiP "Thermal protection of the building" SNiP II-3-79 "Construction heat engineering" SP "Design of thermal protection of buildings" SNiP "Construction climatology" SNiP "Heating, ventilation and air conditioning"

9

Heating system MBOU "Dalnyaya secondary school"

10

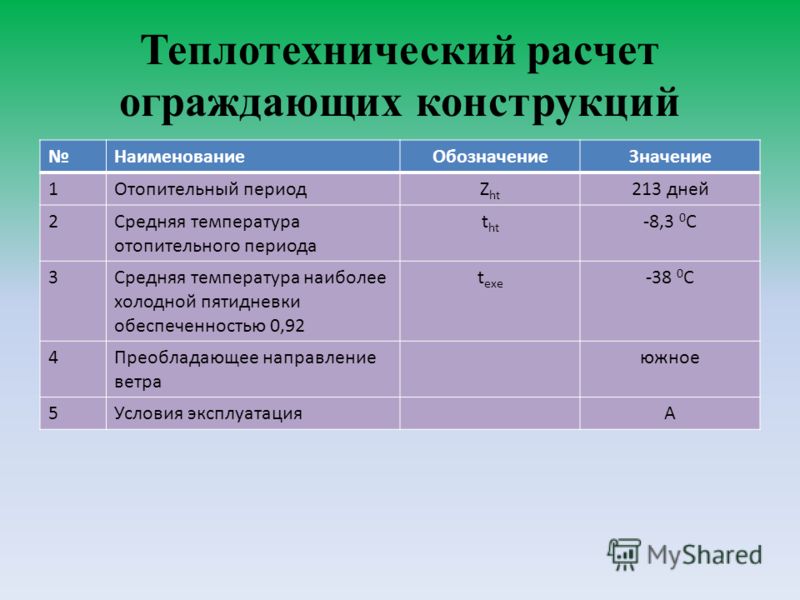

Thermal engineering calculation of enclosing structures

11

Heat transfer coefficient of external walls Name Layer thickness, m Density, kg/m3 Thermal conductivity coefficient, W/m 0 С 4. Lime0, .7

12

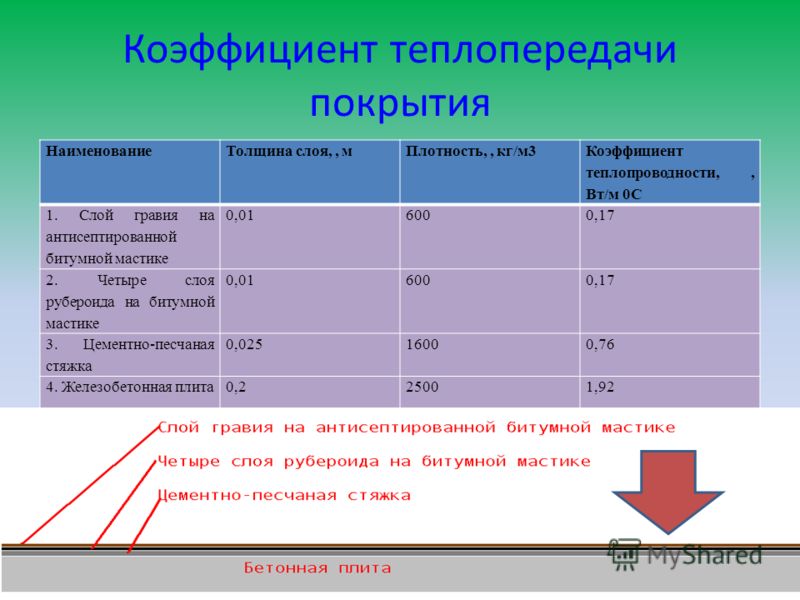

Coating heat transfer coefficient Name Layer thickness, m Density, kg/m3 Thermal conductivity coefficient, W/m 0С - sand screed 0.76 4. Reinforced concrete slab 0.225001.92

13

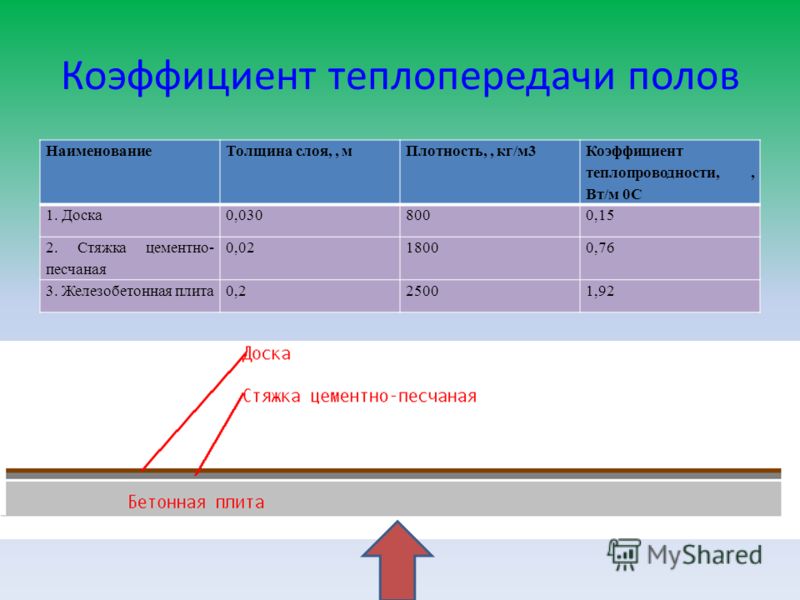

Floor heat transfer coefficient Name Layer thickness, m Density, kg/m3 Thermal conductivity coefficient, W/m

14

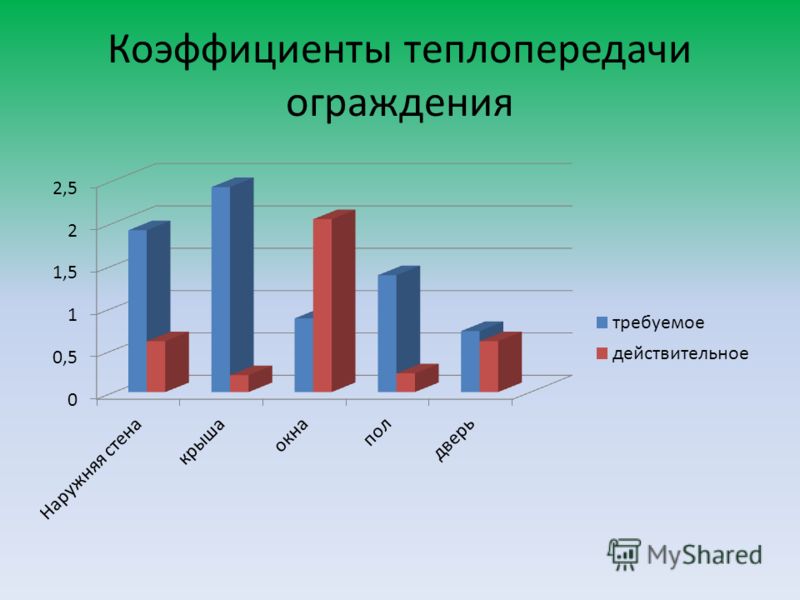

Heat transfer coefficients of the fence

15

Thermal calculation of the cabinet "Technology", "Computer Science", "History" Room number, name and internal temperature, 0 C Characteristic of the fence K, W / (m 2 0 C) n (t in - t n), 0 C 1+ Q OGR, W Name Orientation of sides Size, m b x h A, m Orientation other Technology NSZ5.7x2.7515.681.91550.05 ,10.051, NSV5.7x2.7515.681.91550.05 1, OKS1.9x1.9x310.830.87550.10.051.15600 Floor-11.5x5.765.551, β=0.27 NDVS1.4x2.12.940.72550, 10.051, Informatics NSZ5.7x2.7515.681.91580.05 1, NSS 11.5x2.75-10.83 20.801.91580.10.051, NSV5.7x2.7515.681.91580 87580.10.051, history 9x310.830.87580.10.051.15630 KR-11.5x5.765.552,

16

Heating system selection Vertical two-pipe heating system 1 — HERZ-TS-90 thermostatic valve, through passage; 2 — HERZ-RL-5 balance radiator valve, through passage; 7 - radiator regulator, for example, thermostatic head, etc. 8 - radiator air vent; 9 - heater of any type: 11 - shut-off valve STREMAX; 12 - HERZ differential pressure regulator.

17

Choice of heaters Types of heaters:

18

Determining the dimensions of the heater St Q, WG kg/hn, pcs R, Pa/md 0, mmV, m/s St x3.50.30, St x3.50.30, St x3.50.30, St x3.50 .30.3

19

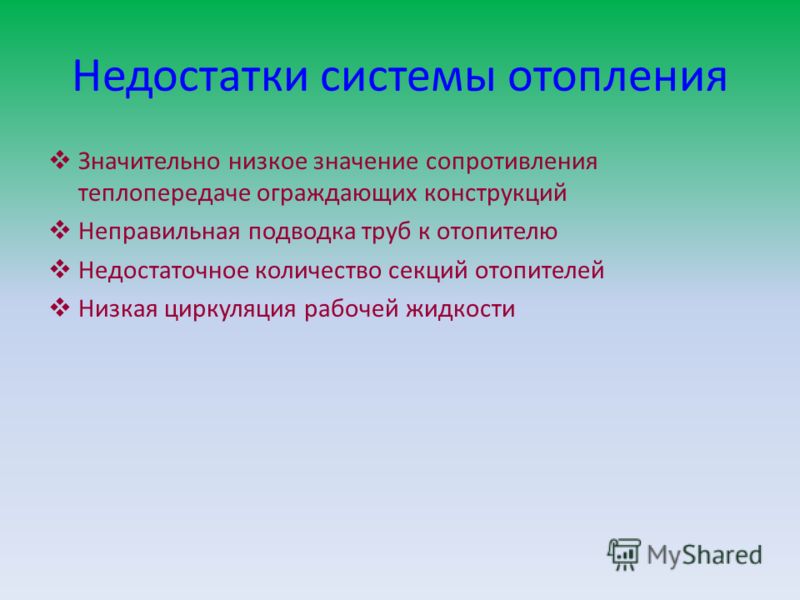

Disadvantages of the heating system Significantly low heat transfer resistance of the building envelope Incorrect piping to the heater Insufficient number of heater sections Low circulation of the working fluid

20

Economic part Name Quantity Unit price Total 1 Cast iron section h=600mm b=160 mm 48 pcs 385 rub./piece rub. 2 Metal-polymer pipe 40x3.5 mm 66 m40 rub./ m2640 rub. 3 Ball valve 32 pcs rub. 4 Air vent 12 pcs. rub. 5 Fittings for pipes 12 sets 2400 rub. 6Other rub. 7total rub.

21

Corrective measures Increase the resistance to heat transfer of the building envelope Proper piping to the heater Sufficient number of heater sections Necessary circulation of the working fluid