Determination of heat load

Before preparing materials for the installation of underfloor heating, you need to calculate how much heat to supply to a particular room. This calculation is usually carried out according to the specific characteristic - the amount of heat released per unit volume or area of \u200b\u200bthe room.

The power of the heating system is calculated through the area in cases where the ceiling height of the dwelling does not reach 3 m. The method gives the most accurate result in rooms with ceilings of 2.6–2.8 m. The calculation procedure is as follows:

- After measuring the dimensions of the room, calculate the area in square meters.

- Multiply the quadrature found by the value of the specific thermal characteristic (base - 100 W / m²).

- Apply the regional correction factor to the received power.

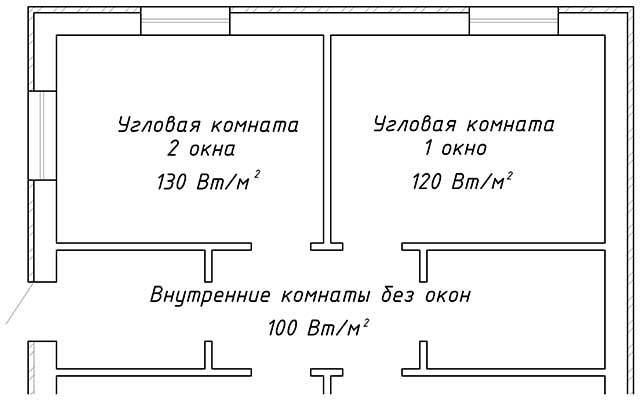

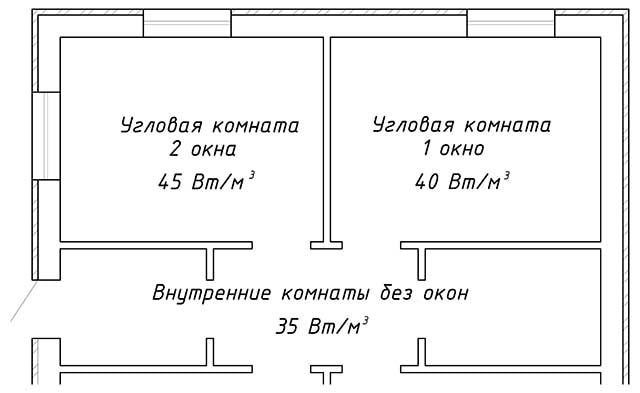

Specific indicators of heat consumption for different rooms

Rooms located in different parts of the house cool differently - corner rooms lose more heat than average ones. Hence the recommendation: take the value of the specific characteristic depending on the type of room:

- for rooms located inside the building or having one external wall with a window, the base value is 0.1 kW/m²;

- corner rooms (2 external fences and one light opening) - 0.12 kW / m²;

- the same corner rooms, but with two windows - 0.13 kW / m².

Apply the correction factor depending on the region of residence. For a cottage built in the southern regions, the value of the coefficient will be 0.7-0.8, in the northern regions - 1.5-2.0.

The calculation of heat consumption by the volume of the dwelling is carried out in a similar way: by measuring, the cubic capacity of the room is determined, multiplied by the specific characteristic. The base value for indoor spaces is 35 W/m3, for corner rooms 40 and 45 W/m3 respectively.

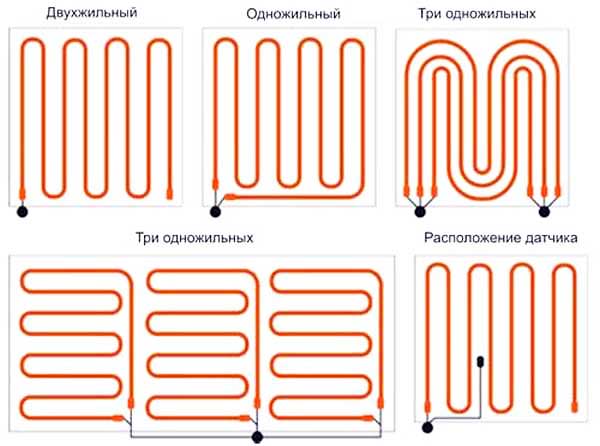

Which cable is better two-core or single-core

The difference between a single-core and a two-core cable is as follows:

- The need to install a thermostat. The self-regulating cable does not require the installation of a temperature sensor and regulator. In this case, heating is carried out in separate sections.

- The presence of an electromagnetic field. Some varieties of single-core cables have a high-quality Teflon coating. The protective layer effectively reduces the level of radiation. The remaining types of single-core wire create an electromagnetic field of greater intensity, so they are recommended for use in walk-through rooms, hallways, balconies, baths, saunas, etc. In warm two-core floors, radiation is completely absent, which makes operation completely safe for living quarters: bedrooms, children's rooms, etc.

Some manufacturers, in an effort to reduce the cost of self-regulating underfloor heating, change the internal structure, leaving only a heating matrix and minimal insulation. The correct method for selecting a self-regulating cable is related to the need to determine whether the cable has external insulation and a copper shield layer. The presence is indicated by the marking CT, CF, CR.

Calculation example

Consider how to calculate the power of an engineering system that needs to be installed in the kitchen of an apartment located on the ground floor of a five-story building.

Let's say the kitchen area is 20 m2 (the width and length of the room are 4 and 5 m, respectively). Electric underfloor heating will act as the main source of heat.

First of all, you need to make a furniture layout plan on paper. According to the scheme, it is necessary to calculate how much space will be occupied by kitchen furniture and appliances, which are heavy. A standard refrigerator occupies approximately 0.4 m2. As for kitchen furniture, which, as a rule, has a width of 60 cm, to calculate its area, it is necessary to multiply the width by the length. We get: 0.6*5=3 m2.

You should also take into account the fact that the engineering system cannot be laid close to the walls.There should be a gap of at least 5 cm, and it is better to leave 7-8 cm free

It turns out that about 0.8 m2 will go under the indents.

As a result of these simple mathematical calculations, we determined that the area on which the heating element can be laid is about 15 m2.

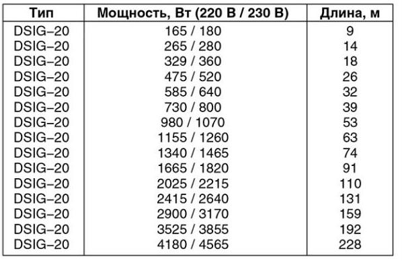

Now you can calculate this parameter. For this, the area, which is 15 m2, is multiplied by 180 watts. The main heat source must have 2700 watts. Accordingly, you should purchase a cable with a power of at least 2.5 kW.

If the engineering system will act as an additional source, then it will be enough to purchase a cable with a power of 2 kW (15m2 * 140 W). By analogy, you can calculate the required power of the engineering system for each room.

Benefits of infrared underfloor heating

Modern designs of infrared floor have a number of undeniable advantages. First of all, they are distinguished by simplicity and speed of installation. Installation of floors, on average, takes no more than two hours. They do not require a tie-down device. These floors are easy to install under carpet, linoleum or laminate. The thickness of the film is only 3 mm, therefore, it does not affect the height of the room at all and does not reduce its volume. The film coating material is highly reliable.

Compared to other types of underfloor heating, infrared construction allows significant energy savings. In addition, there are many positive physical properties. Infrared floors help to ionize the air and eliminate various unpleasant odors. They absolutely do not affect the humidity of the air and do not dry it.

This type of underfloor heating can be used as the main or additional source of heating for houses and apartments. In the first case, film coverage is at least 60-70% of the total area of the room. With additional heating, any area is covered, on average, this value is 30-50%. Infrared floors are installed in walk-through corridors throughout the area, provided there is no furniture. In rooms with furniture, the film is installed as needed, in free places.

Calculation of cable footage and laying step

To determine the length of the heating conductor, it is necessary to take into account some features:

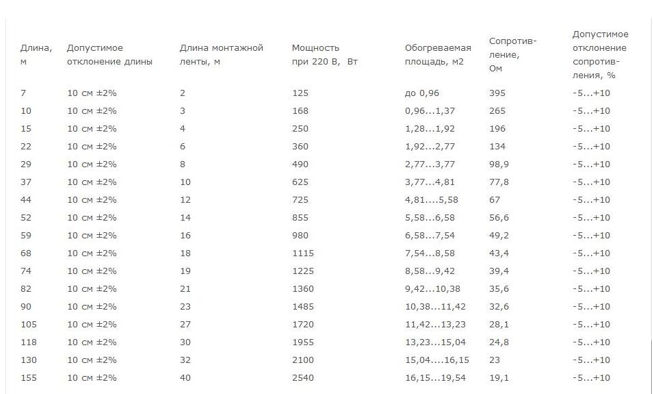

- manufacturers offer fixed-meter cables with different power (from 9 to 20 W per 1 linear meter);

- so that the heater can give off heat and not burn out in the floor, the circuit cannot be laid under stationary furniture and appliances without legs;

- for laying in the bathroom or on the balcony, the cable conductor is taken with a margin of 15-20%.

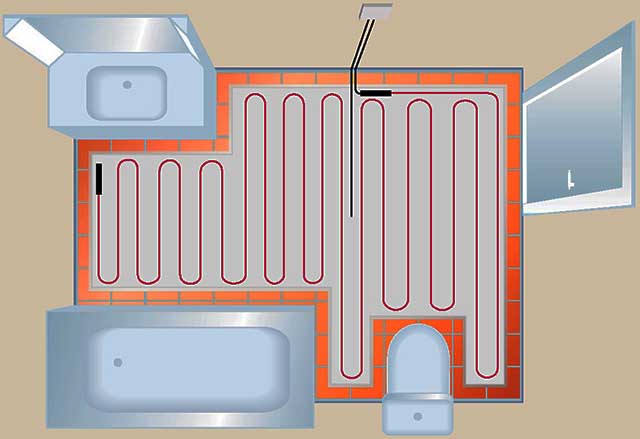

Scheme of laying resistive cable in the bathroom

Having found out the need for thermal energy for heating a particular room, calculate the electric floor heating according to the instructions:

- Select a cable from the catalog, focusing on the previously obtained thermal power and adding a margin of 15%. Record the total length of the conductor.

- Draw a scale plan of the room on paper.

- Place on the sketch furniture and household appliances that are closely adjacent to the floor and interfere with normal heat transfer. Observe the actual dimensions of cabinets, washing machines and other equipment.

- Subtract the area occupied by the furniture from the total quadrature. The task is to place a heating conductor selected from the catalog on a free area.

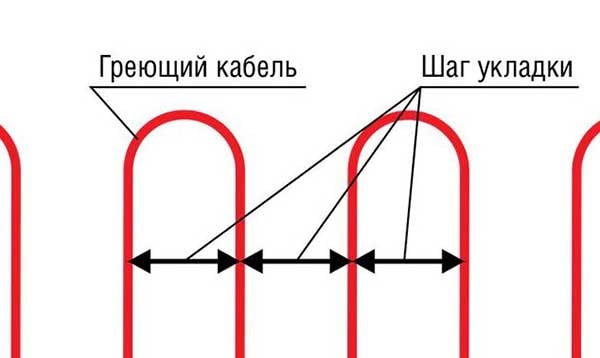

- Divide the remaining area by the length of the cable heater to get the installation spacing in meters.

The layout rules in residential and auxiliary premises are different. For example, in the living room or bedroom, the first heating line is moved away from the furniture at a distance of 10 cm. In the bathroom or on the balcony, the cable is laid close to the cabinets and plumbing so that the legs do not feel the temperature difference on the floor. Be sure to consider this nuance when planning. The expert will tell you more in the video:

Since the heating mats are sold in mesh strips (rolls), the laying step does not have to be counted.But keep in mind another point: the heat transfer of 1 m² of the mat is limited, you cannot increase the power. But to reduce it - no problem, just cut the grid between the conductors and push the cables apart.

An example of calculating a warm electric floor in a bedroom of 18 m² with a heat consumption of 2.16 kW:

- Since cable heating is planned to be combined with a radiator system, the thermal power is divided in half - 2.16 / 2 = 1.08 kW falls on the floor circuit.

- We select a two-core cable DEVIsafe 20T with a specific power of 20 W / m. Taking into account the margin, we take a ready-made conductor 60 m long with a heat transfer of 1.2 kW.

- Stationary furniture occupies 3 m² of bedroom space. 15 m² remains, then the laying step will be 15/60 = 0.25 m.

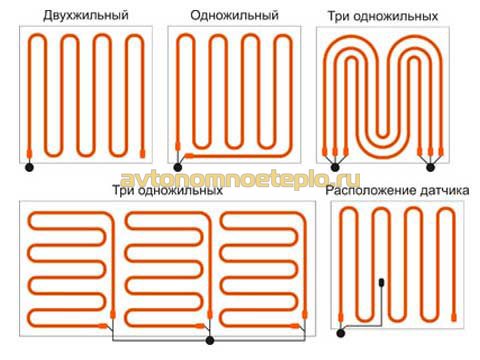

Possible layouts of cable circuits

Subtleties to be aware of

The typical scheme by which power is calculated gives an objective result only if the room is properly insulated. Thermal insulation is understood not only as laying rolled materials under warm floors, but also as installing double-glazed windows on windows.

Therefore, before installing the system, it is necessary to insulate the room. This will prevent unwanted heat loss. Particular care should be taken to insulate rooms that are located on the ground or have a basement under them.

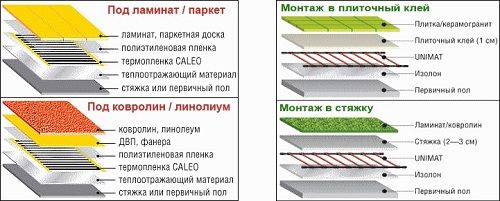

It is necessary to choose thermal insulation based on the selected engineering system. Under infrared floors, only foil thermal insulation can be installed. Otherwise, part of the heat will be spent on heating the rough base or the neighbor's ceiling.

Another very important point that you should pay attention to is the step of laying the heating element. If you have infrared floors or heating mats in front of you, then this item can be skipped.

They are rolled material, the basis of which is a special mesh or film. On this basis, a heating element is fixed.

If you opted for cheaper cable systems, then the cable will have to be laid manually. In this case, the laying step will have to be determined independently. You can not bother and do everything by eye. But in this case, the system may not work effectively. And it will be quite difficult and costly to redo everything.

Let's consider how to determine the heating cable laying step using the example described above. The power of the electric underfloor heating should be 2700 watts. The length of the cable in this case should be about 130 meters. To calculate the laying step, it is necessary to multiply the useful area of the room by 100, and divide the resulting number by the length of the heating cable. We get: 15*100/130=11.5 cm. This is the laying step.

To simplify installation work, you can purchase a special mesh on which you can first fix the heating cable. If the cable is not fixed during installation, it will move. As a result, the laying step between the turns will change. As a result, uneven heating of the base.

Calculating power for an engineering system is quite simple

It is important to properly insulate the room, choose a base insulation that is compatible with the engineering system and correctly approach the issue of arranging heavy furniture, under which the heating cable cannot be placed.

https://youtube.com/watch?v=J8GJC6lEL-c

Mounting methods

The heating cable must eventually be covered on all sides with mortar/tile adhesive, this can be achieved in three ways:

fill. The most correct way in my opinion. It consists in pouring a mini-screed 1-2 cm over the mounted cable. The resulting screed will be suitable for any floor covering. To implement this option, a couple of centimeters of height should be provided when pouring the main screed, in places where there will be a warm floor. For work, mixtures are used that allow pouring such thin layers.If the screed is initially poured into one level and raising the floor level is unacceptable, then this method is not suitable.

Glue layer. When the tile is laid, and everything else is permissible to raise the level of the subfloor by 1-2 cm (do not forget, the tile itself will add at least 1 cm), the tile is placed on top of the cable on a thick layer of glue. It is necessary to consider this option as a last resort, because there will be a significant drop at the border of the warm zone.

Shtroblenie. The most difficult and dreary way, however, when raising the screed level is unacceptable, is the surest. First you need to mark the lines where the heating cable will go. It is also necessary to take into account the strobe for the corrugation with a temperature sensor and the coupling with a cold connecting cable. After marking, you need to attach some kind of thread / rope to the lines to check the length of the strobe. You need to be sure that the entire cable will fit into the future strobe, otherwise you need to change the layout.

After chasing, the dust is carefully removed and the surface is primed. The wire is laid in a strobe, the depth of the strobe should allow applying 3-5 mm of coating solution over the cable.

The temperature sensor in the corrugation is also mounted in the strobe, the corrugation must be plugged from the end (wrap it with electrical tape). The end of the corrugation should be located between the heating conductors, not far from the edge of the heating zone (but not at the edge). The optimal distance of the temperature sensor is 30-50 cm from the edge, deep into the warm area.

When the wire is laid, the strobes are sealed with tile adhesive, or a mixture of self-leveling floor. If you plan to lay linoleum, it will not be superfluous to apply a finishing layer of 1-2 mm of self-leveling floor.

Floors should be checked or operated no earlier than one month after completion of all wet processes with the floor (pouring, laying tiles). Switching on earlier will not damage the cable itself, but may cause the grout/adhesive to crack.

Conclusion

- The heating cable is recommended for underfloor heating. The most preferred application is a direct heating system or "thin floor".

- Among the variety of heating cables, it is best to use a two-core resistive cable in terms of price-quality ratio.

- The choice of the desired cable with the required power density, its length and laying step are obtained as a result of calculations.

- It is unacceptable to change the length of a resistive cable section (except for zonal cable).

About film heaters

The calculation of the amount of infrared film is much simpler and comes down to the selection of the heating material in terms of size and specific heat transfer:

- Calculate the room's need for thermal energy (section one of this publication).

- Sketch out the layout of the room with stationary furniture. Calculate the size and quadrature of the free area.

- Film warm floors are laid out with an indent from the walls of 15-20 cm. Draw these stripes on the sketch and subtract their dimensions from the free area.

- The last task is to place an infrared film of the required total power on the remaining area. Select rolls of the required width and heat transfer from the manufacturer's catalog.

Keep in mind that the thermal film can only be cut across, guided by special lines (interval - 250 mm). Adjacent canvases can be laid end-to-end or with a calculated interval, but not overlapping. For the bedroom from our example, the amount of film is calculated as follows:

- The required heat transfer of the floor circuit is 1.08 kW. If you take a product with a heat output of 130 W / m², you will need 1080 / 130 = 8.3 m² of film heater. Taking into account the stock - 9 m².

- Roll width - 0.5 m. To collect 9 squares, you need to take a film 18 m long.

- Since there is 15 m² of free space in the bedroom, this type of heater is quite suitable.

Installation

To install an IR film floor, you must perform a series of sequential steps:

- First of all, it is necessary to develop a project and make all the necessary calculations.

- Get all the necessary materials and tools.

- Install the IR floor.

- Start the system and check operation.

- Perform a clean finish.

Area calculation

The main distinguishing feature of the infrared film floor is that it is not installed under furniture. Therefore, when calculating the amount of material that will be required and choosing the location of the film, it is necessary to subtract the area where the film will not be laid.

When calculating the heated area, keep in mind that the IR film is laid at a distance of 100 mm or more to any vertical surface.

When the size of the desired area is identified, the next step is to calculate the power.

| Film power | 150 W/m² | 220 W/m² |

|---|---|---|

| Main source of heating | At least 95% of the area | At least 70% of the area |

| Additional heating source | At least 60% of the area | At least 40% of the area |

| Type of flooring | laminate, linoleum, carpet | parquet, carpet |

Energy calculation

The amount of money spent on heating with an infrared floor is calculated based on the electricity tariff in your area.

Installing a thermostat allows you to reduce the cost of infrared floor heating by about 35%.

Power calculation

If the area of the room that is planned to be heated with a film floor is very large, several sets of IR film will be required to install such a system. In such a situation, you need to sum up their power.

Using several sets of IR film Ptot = P1+P2+…+Pi Using part of the set Ptot=1.10*L

where, Ptotal is the total power of the film floor, W; P1…Pi is the power of a single set of film, W; L is the length of the infrared film used during installation, m; 1.10 - film floor power conversion factor.

Calculation of the number of thermostats

The main purpose of the thermostat for infrared floor heating is to regulate the degree of heating.

If you connect several sets of film floor at once, then several thermostats are needed at once, since the power consumed by the warm floor is summed up.

It is recommended to install the thermostat at a height of 15-20 cm, above the level of the final coating.

It is better to place the thermostat on the wall, which is perpendicular to the direction of the strips.

There are two ways to connect:

- Zoning and connection of each zone to a separate thermostat.

- Connect solid state relay or magnetic starter. It is impossible to carry out such a connection on your own, here you need the knowledge and skills of an electrician.

Underfloor heating cable or mat

The choice primarily depends on whether the installation will be done by hand or it is planned to invite specialists. Easier to install heating mats. For laying cable floors, it will be necessary to carry out work on the manufacture of a screed, connection to the power supply system, etc.

It will be necessary to take into account that the heat transfer of the mats is somewhat lower than that of the cable, respectively, a greater consumption of electricity will be required.

If you plan to use professional installers, it is recommended to use a self-regulating shielded underfloor heating cable. The high cost will pay off due to the long service life and the absence of harmful effects of the electromagnetic field on humans.

Step by step installation plan

So, the installation of a heating cable consists of several stages:

- Foundation preparation. A cement-sand screed must be poured on the subfloor, the thickness of which is at least 3 cm. To lay the wire connecting the thermostat to the system, you will have to drill a channel with a diameter of 2 cm.

- Installation of a heat-reflecting substrate.

- Laying the reinforcing mesh to which the cable will be attached. If this step is omitted, then the wire will need to be fixed on the mounting tape. We must not forget that the product does not fit under the furniture.

- Wire laying.

- Heat exchanger installation. It is placed in a special corrugated tube and placed in a pre-made strobe.

- Pouring cement screed. It should have a small thickness, only 4 cm. After the thermal cable is hidden under the solution, it is necessary to check its performance: ohmic resistance and insulation resistance. Laying the floor covering can be carried out only after the mortar has dried well - not earlier than after a month.

Step-by-step technology of cable underfloor heating

Step-by-step technology of cable underfloor heating

That's all the features of choosing and installing a heating cable for underfloor heating. In any case, before work, you need to consider all the nuances of laying. And finally, a video of the installation with detailed comments:

Rules for laying IR underfloor heating

It is necessary to adhere to a few simple rules for laying IR underfloor heating:

- The first film line must be located at a distance of at least 100 mm from the wall and no further than 400 mm.

- The step of the film cutting line is 250 mm, it is impossible to cut the film in other places.

- The distance between adjacent film strips should be 10 mm or more.

- The permissible length of the floor strip is 8 m.

Under the laminate

When laying a film underfloor heating under a laminate, follow the rules:

- So that the infrared film does not overheat, it must be distributed in areas where there is no furniture.

- In order for the room to warm up with maximum efficiency, the film floor must cover the area at least 70%.

Scheme of installation of IR underfloor heating for various types of floor finishes

Next, you need to draw a plan for the location of the heating elements. On paper, reflect the location of the furniture and heating film.

Laying is done on a surface that is leveled before that.

The concrete screed should not have drops. So that the heat from the thermal film does not leave, through the floor slabs to neighboring apartments, a thermal insulating substrate (polypropylene) must be laid on the floor, the thickness of which is 3-4 mm and it is covered with foil on one side.

Thermal insulation strips are fastened with thermal insulation tape, and they must also be carefully trimmed along the perimeter of the room.

You can cut the heating film only in the places indicated on it. They are marked with a dotted line and a scissors symbol.

If you cut the film diagonally, you will simply ruin it.

The distance of the film from the wall should be from 10 cm.

The strips of the heating film are laid on the substrate one next to the other with a gap of at least 5 mm, but not more than 1 cm.

It is impossible to bend the heating element at an angle of 90 degrees or more, as it will cease to function.

Wiring diagram for IR floor heating

In places where the thermal film is cut and conductive tires are cut, it is necessary to perform bituminous insulation, which is included in the set of underfloor heating. The contact must be installed in the center of the end of the conductive bus and pressed well with pliers. Using a sharp knife, it is necessary to strip the current-carrying wires by 5-8 mm and clamp them with pliers in the contact terminal, then the entire contact is insulated with bituminous insulation. An infrared warm floor is connected in parallel with copper stranded wires with a cross section of at least 1.5 mm². It is also recommended to install a temperature sensor in order for the underfloor heating automation to work correctly.

At a distance of 20-25 cm from the wall on which you will install the thermostat, using a perforator, perform a chasing. Place the temperature sensor into the hole formed under the heating film.

In order for the sensor to show the correct temperature, it must be laid on a heat-insulating substrate.

After all the above manipulations, the thermostat is connected.

Upon completion of the installation, check the functioning of the IR underfloor heating. All thermofilms should heat up when turned on. Only after making sure, you can lay the laminate on the heating elements.

Under linoleum

Laying under linoleum is similar, but has its own characteristics:

- At the first stage, prepare the base, because.the floor can only be mounted on a flat and stable surface.

- The mats can be cut to 25 cm. The edge is insulated with a special tape. The gap to the pipes of the heating system should be from 30 cm.

- It is necessary to lay the film with copper tires up, it is strictly forbidden to lay joints one on top of the other. The remaining steps are carried out in accordance with the instructions. A prerequisite for high-quality heating is the connection of a thermostat.

- Then linoleum spreads. In rooms that are small in size, the coating is laid and left for a couple of days, after which the edges are pressed with skirting boards.

There are many ways to install linoleum.

When performing work, consider whether it will be necessary to disassemble and transfer the system in the future, and also pay attention to the technical characteristics of underfloor heating

As you can see, infrared film underfloor heating is an excellent option for a heating system, and its installation is not so complicated. Therefore, everything can be done by hand.

In conclusion, useful tips

When purchasing materials for installing an electric underfloor heating, consider the following recommendations:

- The vast majority of heating elements require external regulation. In each room, you need to install a thermostat and an overheat sensor, fixed directly on the cable or film.

- Be sure to lay a layer of insulation under the floor contours if you do not want to heat the ground, ceiling or a neighboring apartment with expensive electricity.

- The thickness of the heat-insulating layer on the ground is at least 10 cm of foam plastic or mineral wool. It is enough to cover the interfloor ceiling with foil-wrapped polyethylene foam 8-12 mm thick.

- If thick coatings are used on the floors - parquet, a board of 25 mm or more, felt linoleum, then the power of the heating elements will have to be increased by 30-40% against the calculated one.

- Prepare copper wires with a cross section of 2.5 mm² for connecting the circuits to the mains. The cables should be long enough to extend the line to the main switchboard.

The line connected to the electrical panel must be protected by a circuit breaker of the appropriate rating. It is better to take a two-pole machine, breaking both circuits - phase and zero.

Today, there are many different heating systems that allow you to reduce energy consumption, so you can save your money. One of the best options is an infrared film underfloor heating. It is a variation of the electric one, but it is more economical and safer.

Infrared warm floor