Garage roof insulation technology from the outside

Since the room itself is not always heated, it is essential that the material itself retains its insulating ability at any room temperature. An equally important point concerns machine exhausts and vapors from fuels and lubricants, which accumulate over time on roofing insulation and can reduce their degree of fire resistance.

That is why it is worth choosing mineral wool or fiberglass as a heater. If the installation of the insulation layer will be carried out in the garage with your own hands, it is worth considering the option with penoizol or foam plastic, which are easy to use in work. The same materials are resistant to possible deformations and retain their original elasticity throughout the entire service life.

The internal location of the heater

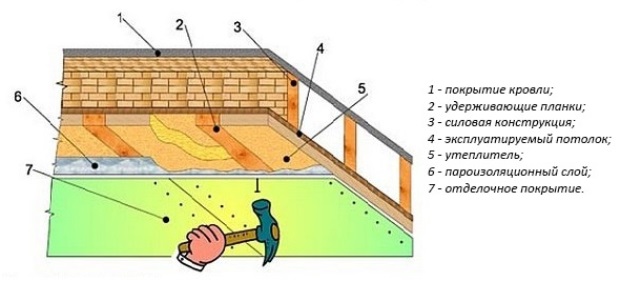

When figuring out how to insulate a flat roof from the outside, do not forget that insulation can also be done from the inside. This solution is especially relevant in the presence of an unused or technical attic space. In this option, all the necessary materials are attached to the ceiling from the inside. However, this does not relieve the need for arranging external waterproofing.

This method of insulation is less effective than the external one, but, in some cases, it may be the only possible one. Here, all the components of the structure and their layout will correspond to the classic external insulation, with the only difference being that they will be located not from bottom to top, but from top to bottom, in reverse order.

Thermal insulation of a flat roof, what materials to choose

Recommendations for material selection are the same as for any other design. For these purposes, basalt wool or extruded polystyrene foam is used. Let's analyze their features

- Environmentally friendly product

- Passes steam, allows the roof to breathe

- Good thermal insulation

- High density, can be laid for exploitable surface

- Fireproof, does not burn, does not melt, does not emit harmful substances

- Large weight, initially it is necessary to calculate the load

- Hygroscopicity, if the waterproofing is damaged, it will absorb moisture and lose its properties

- High price

Flat roof insulation with polystyrene foam

- Light weight, easy to mount, transport, does not increase the load on the foundation

- Low price

- Not susceptible to moisture

- Good thermal insulation

- This is an artificial material.

- Burns or melts, in most cases does not meet fire safety requirements

- Doesn't let steam through

More often, basalt wool slabs are still used to insulate a flat roof. Since this is a more reliable and durable way. Also, it allows not only to isolate the premises from the cold, but also saves from the heat in summer, which cannot be said about other materials. And thanks to the vapor permeability and the fact that the plates are made from natural raw materials, a favorable microclimate is created indoors.

Two roofing cake recipes

The main difference between the two methods is in the place occupied by the waterproofer. In a classic roof, it crowns the entire structure, and in an inverted one it fits under the insulation, acting as a protection for the floor slab, and not for the heat-saving layer.That is why mineral wool is not the most suitable place here - the fiber board will have to be carefully protected from atmospheric moisture.

Classic roofing (order from bottom to top):

- Vapor barrier from inside the room, if necessary.

- Concrete floor slab (roofing over rafters laid parallel to the base is possible)

- Sloping cement screed or PENOPLEX layer, mounted at an angle of 2-4% on stops (cut from the same material) or PENOPLEX SLOPE

- Insulation in one or more layers (staggered). The manufacturer recommends laying a special separating material under the plates and on top of them.

- Waterproofing is most often a durable polymer roofing material. For the option of laying directly on PENOPLEX, a roofing membrane, for example, Plastfoil, is excellent.

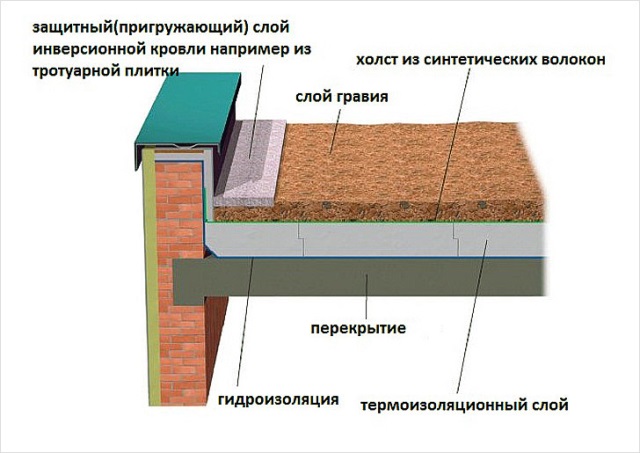

This "pie" option is interesting if you are not going to use the space of a flat roof. The classic roof is just a roof. It is much more profitable to complicate the installation stage a little, but in the end to get a solid and functional space. To do this, you need an inverted roof (order from bottom to top):

- Concrete floor slab or rafters

- Sloping cement screed or PENOPLEX SLOPE

- waterproofing membrane.

- geotextile layer.

- Insulation in one or two layers (staggered).

- Geotextile anti-root layer.

- Gravel ballast layer - it "presses" the layers to each other, preventing them from moving. In the case of a green zone, it also performs a drainage function.

- (Optional) filtration layer.

- (Optional) soil layer.

Here is a variant of the very popular all over the world "green" roof. But the soil layer can be replaced with ceramic tiles or decking.

In this case, the heat-saving material also serves as a carrier, it bears the main load from the equipment that will be placed on the roof, from the weight and active movement of people, shock when some objects fall on the surface and, of course, atmospheric. PENOPLEX is perhaps the only available material that is capable of this.

How to insulate a concrete roof with your own hands

To avoid condensation, it is necessary to protect cold concrete structures from warm air, which contains a lot of moisture. When the air is cooled, moisture vapor forms in the form of condensate. Insulation of reinforced concrete slabs can be done inside and outside, while the stages of work, types of heat-insulating and finishing materials will differ. Consider the insulation of a flat concrete roof step by step.

How to insulate a concrete roof from the outside

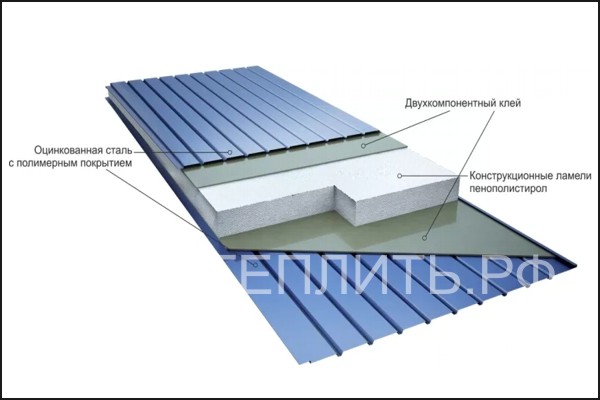

The structure of the sandwich panel with expanded polystyrene insulation

The simplest and most reliable way to insulate a flat roof from the outside is to use sandwich panels. As can be seen from the photo, such a panel consists of two sheets of galvanized or painted corrugated board, between which there is polystyrene foam. On the one hand, sandwich panels are reliably protected from moisture and mechanical damage, able to withstand heavy loads, and on the other hand, they have low thermal conductivity.

Laying sandwich panels will require the involvement of construction equipment, which will significantly increase the cost of the work. A simpler option, when you can insulate a concrete roof on your own, is the use of expanded polystyrene with rolled waterproofing, for example, roofing material. This technology is shown in the video at the end of the material. Such insulation of plates can last more than one year, the main thing is to check the waterproofing.

How to insulate a concrete roof from the inside

Photo. How to insulate a concrete ceiling and floors with foam

It will be much easier and cheaper to insulate this structure from below, provided that you do not need to disassemble the expensive finishes on the ceiling.The easiest and cheapest way to insulate any surface is to use foam boards, despite the fact that this is a highly flammable material. If the ceiling is planned to be sheathed in the future, then this will not be a serious problem, especially if you use drywall sheets in the finish.

You can use non-combustible, basalt insulation, but attaching it to the ceiling will be much more difficult. It will be necessary to make an additional frame from profiles, as well as protect the mineral wool with a vapor barrier. In the video at the end of the article, we have selected a video clip for you, where one of the craftsmen shares his way of insulating the concrete roof of the garage from the street, using polystyrene foam boards, plywood sheets and roofing material for thermal insulation.

outdoor installation

With this approach, all layers of insulation and waterproofing are located on the outside of the floor. Accordingly, it is required to create such a heat-saving "pie" that can withstand all temperature and climate changes. There are two main types of flat roofs, insulated in different ways:

The classic roof is insulated according to the standard scheme and the layers are laid in the following order, counting from the bottom up:

- Floor slab

- Vapor barrier film

- insulation

- Waterproofing

This scheme has a significant drawback - external waterproofing requires periodic maintenance and repair. It is produced every two or three years and this entails additional costs, although such a roofing device is slightly cheaper than another option - inversion.

This type of roofing is considered more expensive to install, but it can withstand temperature extremes better and does not require such frequent repairs. Its fundamental difference from the classic version will be a different scheme for laying layers and arrangement:

- The first will be, as in the previous case, the floor slab

- Then - screed

- Next up is waterproofing.

- Next up is a heater.

- A special film is laid on top - a filter

- Expanded clay or gravel covers the cake, at least 50 millimeters thick

This solution allows you to protect the waterproofing gasket and significantly increase its service life.

How to insulate the roof of a brick garage

Fiberglass provides low thermal conductivity due to its fibrous structure. The material is made from glass, which is melted and drawn into thin threads. Fiberglass does not burn, decompose or rot. However, the material should not be subjected to mechanical stress. During installation, you should work in personal protective equipment so that fiber particles do not get on the mucous membrane and skin.

Mineral wool (basalt) insulation resembles fiberglass in structure, but differs in the source material (basalt rocks). Mineral insulation is a more plastic and elastic material. With proper installation, the insulation will last for decades for a long time. But when laying, it is necessary to protect the mineral wool with a vapor barrier from moisture ingress and a finish from mechanical damage.

Expanded polystyrene is very popular due to its ease of installation and low cost. All polymeric heaters are made according to the same technology - the porous structure of expanded polystyrene allows you to retain heat for a long time. Technoplex does not absorb moisture and can withstand significant mechanical stress, but expanded polystyrene is afraid of direct sunlight and is easily flammable.

Why insulate a flat roof

Having dealt with the main issues, let us summarize the need for these rather complex and expensive works. As mentioned above, this design is used mainly for non-residential facilities or similar apartment buildings. In private housing construction, it is not necessary. Not only does such a design weigh more than a classic pitched one, but there are also difficulties with water drainage.Its only plus is the cheapness of polymer-bitumen roll materials, but this is covered by expensive insulation.

So, why do you need thermal insulation of a flat roof:

- Preservation of heat in winter, and maintaining a comfortable temperature in summer, this is especially true in the absence of a technical floor

- Savings on heating and air conditioning, as a consequence of the previous paragraph

- Multi-layer coating virtually eliminates leaks

- Exclusion of accumulation of condensate and, as a result, extension of the life of the roofing

How to insulate the roof of the garage with your own hands

With internal thermal insulation of the roof, we advise you to pay attention to mineral heaters. This insulation does not support combustion, but requires additional protection with a vapor barrier film.

The best option for roof insulation is the thermal insulation of the garage roof with mineral wool even at the stage of construction, as with self-insulation of the attic with mineral wool from the inside.

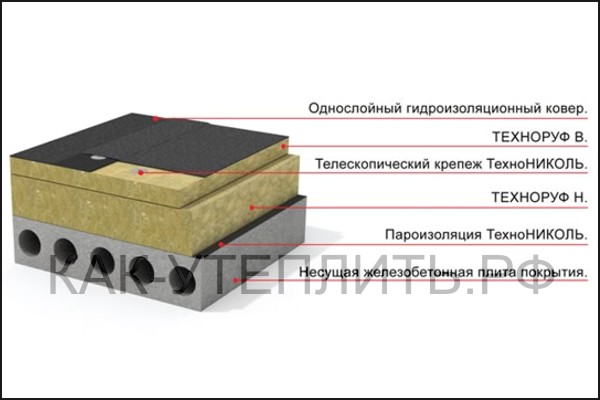

How to insulate a pitched garage roof

Technoruf is a modern material that is used as the top layer for thermal insulation of shed roofs. The material is not combustible, it can be used without loss of performance at temperatures from -60 to +400°C. The use of waterproofing when laying Technoruf mineral wool is mandatory. All grades of Technoruf mineral wool are characterized by high density and low thermal conductivity.

https://youtube.com/watch?v=rfVVA284DP4

How to insulate the roof of the garage from the outside

It is quite difficult to make the thermal insulation of the garage roof from the street so that it lasts for a long time. Therefore, manufacturers every year offer different solutions to this problem. A layer of polystyrene foam or mineral wool insulation for external thermal insulation is located between the roofing and the reinforced concrete slab, but the material should be protected from mechanical damage and moisture.

When insulating the roof of the garage, the sequence of laying materials should be strictly observed. To begin with, a hydrobarrier, a heat-insulating layer and a vapor barrier are laid. If the ceiling is a reinforced concrete slab, then the heat-insulating materials are attached directly to the roof. Mineral wool is distinguished by fire safety and high heat-saving capacity and sound absorption.

Expanded polystyrene can be fixed to a flat roof from the outside or from the inside with dowels. Joints between styrofoam or extruded polystyrene foam boards should be foamed. It is advisable to lay the expanded polystyrene boards in two layers in a checkerboard pattern so that the second layer overlaps the seams of the previous layer. Thus, you will reduce the risk of cold bridges in the thermal insulation layer.

How to insulate the roof of the garage from the inside

When laying the thermal insulation inside, it is necessary to pre-treat the wooden floors with an antiseptic, and the reinforced concrete slab with mastic. Installation of expanded polystyrene on a concrete roof slab is carried out on a mounting foam with additional fastening on dish-shaped dowels. For a shed and gable roof made of wood, slab insulation is placed between the rafters, and all seams are foamed.

For laying mineral wool, a frame should be built on the ceiling. Many manufacturers produce boards of increased rigidity, which are easily inserted between the rafters. If rolls or slabs of mineral wool with a low density are used, then the insulation should be laid on the hemming of the roof. After laying the mineral wool, it should be protected with a vapor barrier membrane from moisture penetration.

On the video at the end of the material, you can take a closer look at the entire technology of the work. Recall that when insulating a garage, ventilation of the room should be provided. The fact is that in a warm and humid room the car will rust faster. Do not forget to also insulate the garage door with high quality, since most of the heat in the winter is lost through this structure.

How to insulate the concrete roof of a garage, at home

Outside, you can use expanded polystyrene and mineral wool boards of increased rigidity, for example, Technoruf from the well-known company TechnoNIKOL. External insulation of a concrete roof is preferable when a fine finish of the ceiling is made inside the room and additional costs will be required for the dismantling and installation of the finish. In addition, high-quality waterproofing of the insulation will be required, as it will be exposed to moisture all year round.

Photo. Scheme of laying mineral wool slabs on a flat roof

If waterproofing is well laid on the outside, then work can be carried out from the inside. In this case, you can use cheaper mineral wool with a reduced density, as well as foam boards. Please note that work inside is accompanied by the loss of some ceiling height in the room. And mineral wool must be additionally protected with a vapor barrier membrane from moisture contained in the air.

How to insulate a flat roof

Let's just say, the choice is not rich. It’s not that the assortment is small on the market, but in practice, only three alternatives are most often used. Let's make a reservation right away: such a roof is not a place for mineral wool. It does not meet the requirements for rigidity, nor for hygroscopicity, nor for ease of installation: it must be covered with a layer of concrete screed, and this gives an additional load on the building, complicates and lengthens the construction cycle.

- Expanded clay or perlite sand. The only advantage of this option is the cost. These are the most affordable materials that have served as a heat insulator for centuries. However, having made such a choice, you will be forced to get out of a number of nuances. Firstly, if the slope is not set by a layer of sand-cement screed over the floor, it is simply impossible to form the desired angle for moisture drainage using loose expanded clay or sand. Secondly, it is unlikely that it will be possible to achieve the same layer thickness over the entire surface of the roof. And this will directly affect the thermal conductivity of the finished roof. Thirdly, it is simply inconvenient to work with such material and cover it with the following layers, this stretches the construction time.

- Foam glass. This type of insulation has appeared relatively recently, so it is not yet necessary to talk about some kind of established practice. It is made from glass broken into crumbs: the raw material is heated in a furnace to 800-900 degrees, foamed by burning a gas-forming agent (hard coal), and then slowly cooled. The result is a durable material with a cellular structure. It is produced in the form of blocks, which are cut into small plates.

Foam glass has proven itself in the insulation of flat roofs of a large area - industrial premises, multi-storey buildings, as well as an insulator in the construction of swimming pools and buildings with difficult temperature conditions.

- low coefficient of thermal conductivity;

- steam resistance;

- absolute incompressibility, which plays a significant role in commercial construction and equipment of exploited roofs;

- service life of at least 100 years;

- absolute resistance to moisture, chemical and biological effects;

- ease of installation - the plates are laid on ordinary building mixtures.

But there are also significant disadvantages:

3. Extruded polystyrene foam. The undisputed leader in the issue of flat roof insulation of any structure - from a garage to a giant workshop or a skyscraper with an equipped helipad. Many experts, describing the technology of mounting a flat roof, do not even consider other options. And this is absolutely justified.

EPPS, popularly "extrusion" or "foam" (common noun from the most popular brand PENOPLEX), the closest relative of construction foam. It is made from the same polystyrene granules, however, using a different technology, which results in a rather thin, light, and at the same time strong and dense plate with closed cells.Inside the cells there is a gas, which prevents the transfer of heat, as well as the conduction of noise. Of course, all these indicators directly depend on the quality of the material. It is not without reason that the term PENOPLEX, and not some other brand, went to the people - this is the largest production of XPS in Russia with stable quality.

Advantages of PENOPLEX for a flat roof:

- the lowest coefficient of thermal conductivity allows you to protect the house as much as possible from heat loss and isolate the roof from excessive heating (it is because of this that the waterproofing usually wears out: the roofing material is constantly subjected to compression from the outside cold and stretching from the heat from the room);

- with the help of plates it is easy to form an even and stable slope;

- forms a monolithic heat-insulating contour without gaps, and hence cold bridges (for this, the edge of the plate is given an L-shaped shape);

- high strength and absolute moisture resistance make PENOPLEX an ideal basis for the installation of an exploited flat roof, and also save on vapor barrier;

- resistance to chemical and biological influences, as well as a wide range of operating temperatures, allow the roofing cake to serve for at least 50 years;

- installation with PENOPLEX boards is quite fast compared to other types of insulation.

The disadvantages of this material, which are manifested in other types of work, do not play a noticeable role in this case.

Therefore, we will consider the procedure for installing a flat roof using classical or inversion technology using the example of PENOPLEX.

Tips from the masters on how to insulate the roof of the garage

A warm garage is one of the main factors determining the sound "health" of a car. One cannot but agree with this, because the cause of the appearance of condensate is sudden changes in temperature. And condensate is the number one enemy of the anti-corrosion protection of metal and, of course, can cause significant damage to the car. But how to insulate the roof of the garage, what material will be “warmer”?

The roof is the main component in the protection system of any building from adverse weather events. Therefore, it is not enough just to insulate it, it needs constant prevention from leakage, dampness and more. How to properly insulate the roof of the garage so that it performs its functions in the best possible way. There is no need to “discover America”, as for any type of structure there are already specially developed building codes and rules that indicate the optimal conditions for keeping cars.

https://youtube.com/watch?v=NrbYylCqtLQ

Flat roof right and wrong

A flat roof in Russia has a worse reputation. According to the inhabitants, it must necessarily leak, because rain moisture and snow have nowhere to go compared to a pitched roof truss. Water must certainly accumulate and every second test the strength of the waterproofing layer. And this means - constant repairs, spending, strength, nerves ...

Where is the stereotype from? From a very distant past.

In the USSR, flat roofs were used in the construction of multi-storey administrative and utility buildings, as well as residential buildings from three to twelve floors. Until now, in advertisements for finding an apartment, they write the sacramental: “Not the last floor,” because it is firmly entrenched in the mind that the roof will leak, the ceiling will get wet and turn black. Proven by practice. In those days, the issue of energy efficiency of buildings was not on the agenda, and therefore no one particularly cared about how to get rid of the minuses and turn them into pluses. Year after year they patched roofing material, whitewashed ceilings, scolded the material, hands and those who came up with the idea of building flat roofs, and that's it.

Meanwhile, already in those years it was possible to build truly aesthetic and practical roofs, including in the private sector. Moreover, such a roof has a number of advantages over pitched ones:

- the final area is significantly smaller, which means that the consumption of materials is also reduced;

- there is no need to build complex roof structures, as well as in the attic - there is no need to ventilate;

- it is easier to work on erection: all manipulations are performed on a plane, and not under a serious slope;

- more convenient to use: you can walk on it, you can fix solar collectors, antennas, external units of air conditioners on it, as well as organize an additional recreational area - a solarium, barbecue, even a swimming pool;

- there is no risk of snow melting, and you won’t have to clean the roof from it: with the right construction technology, the snow cover will become an additional heat-insulating layer, and in the spring it will melt and gently descend into a properly organized drain in streams;

- gives more options for architectural solutions.

Strictly speaking, a flat roof is not flat at all, it has a slight slope of 2 to 4% to drain water. The slope can be centripetal, then moisture, flowing from the edges to the center, like in a kitchen sink, enters the internal drain pipe. Or there may be a reverse slope, when the edge of the roof is 2-4% below the central point, the ridge. Then rain or melt water goes into the gutters and downpipes located on the facade. Therefore, a properly arranged roof should not leak.

The second prerequisite for a “correct flat roof”, which was not taken into account at all before, is insulation. Indeed, from 30 to 40% of heat loss occurs precisely through the roof: warm air collects under the ceiling, and if it does not meet a barrier, it easily leaves your house.

Another side of this coin: it is the warm air from the room that heats the ceiling and melts the snow accumulated outside. Alone, the waterproofing withstands this pressure for some time, and then the layer begins to collapse and require replacement. At the same time, the ceilings are covered with black and white painting of the fungus.

Therefore, although the device of a flat roof is more budgetary, it is impossible to save on technology. All layers of the roofing cake must be in place and made of materials of good quality. But what it will be depends on what kind of design you choose. They are distinguished on the basis of:

- Constructive division into attic and non-attic. From the names it is clear that we are talking about whether you want to equip the roof space or not.

- Functional division into operated and non-operated. The installation of a roof that will be actively walked on, on which furniture and appliances will be erected, lawns will be laid and swimming pools will be installed, is significantly different from the arrangement of an uninhabited roof in the future.

- The division according to the method of insulation into traditional and inversion. That is, the layers are stacked in the usual or reverse order.

All classifications are closely related and influence each other. For example, an exploitable green roof, that is, on which a plant carpet will appear, requires inverse laying of the “pie”. And the attic allows you to use both methods.

Whatever tasks you solve, constructive or functional, the insulation will be the basis for the execution of any option. It acts not only for its intended purpose - with its help the very slope of 2-4% is formed, and the strength of the upper layer is also ensured. So the choice must be taken as responsibly as possible.

How to insulate the roof from the outside or from the inside

The choice of the method of thermal insulation of the roof on the garage - from the inside or from the street, depends on the design of the roof and the material used. Each thermal insulation material is unique in its own way, which allows the use of various technologies for thermal insulation of the roof.

Do not choose polymeric and flammable materials, it is better to pay attention to fiberglass or basalt wool

To insulate the roof of the garage from the inside, you will need to pre-install the crate on the ceiling, lay the thermal insulation in the frame, lay the vapor barrier to protect the insulation from moisture, and finish the ceiling. To insulate the roof of the garage from the outside, you will need a moisture-resistant material (extruded polystyrene foam or Technoruf). External insulation will protect the concrete roof from freezing.