Types of heating cable

- Resistive. Easy to operate, efficient and cheap. But if one section fails, then the whole system does not work.

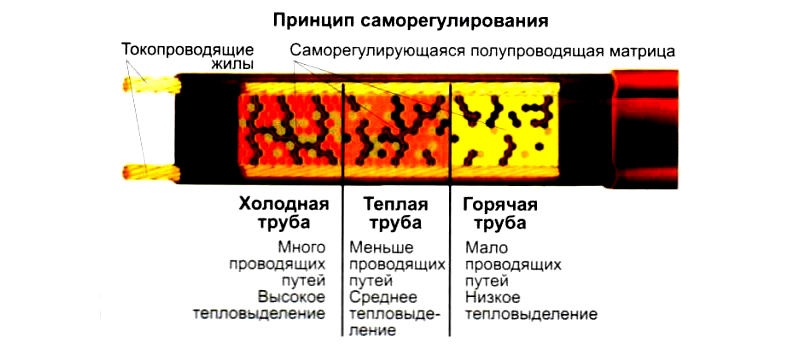

- Self-regulating. The principle of operation is to change the electrical resistance depending on the temperature of the cable. At low temperatures, the resistance of the cable matrix, and hence its power, increases. Accordingly, heat transfer increases. And vice versa.

There are a large number of heating cables from various manufacturers on the market. The Dinso trademark is rightfully considered the most popular, under which reliable and efficient products are produced.

You should not deal with laying the cable yourself. We recommend entrusting the installation of electrical equipment to the specialists of our company, who will perform the work efficiently and quickly.

Or in unheated rooms, you need to warm it up. Otherwise, there is a possibility of its freezing, and in the cold period the object runs the risk of being left without water supply. This problem is successfully solved by installing a heating cable for pipes.

It is laid in a special way inside the pipeline or wrapped around the circumference. Manufacturers offer products of various lengths (from two to twenty meters). This makes it possible to heat the ground section of the system, or its part in the area of soil freezing.

Considering how the heating cable for pipes works, it should be noted that everything is quite simple.

The heating element is heated under the influence of a passing electric current, and works by converting this energy into heat. A characteristic feature of this line of products is that they do not carry energy, but only receive it. The conversion is carried out without the use of fuel and oxidizer.

Resistive cable

The heating of the water supply through the use of such a cable is realized on the surface or inside the pipes. Temperature sensors are installed outside the plumbing system. If the temperature drops below the set level, then the heating is switched on. After reaching a certain temperature threshold, the system turns off.

Resistive type heating cable can be of linear or zonal design. In the first case, we can talk about the sectional design of the product. The zone cable is characterized by the presence of two conductive elements arranged in parallel. The top layer of such a product is presented in the form of a spiral of small diameter.

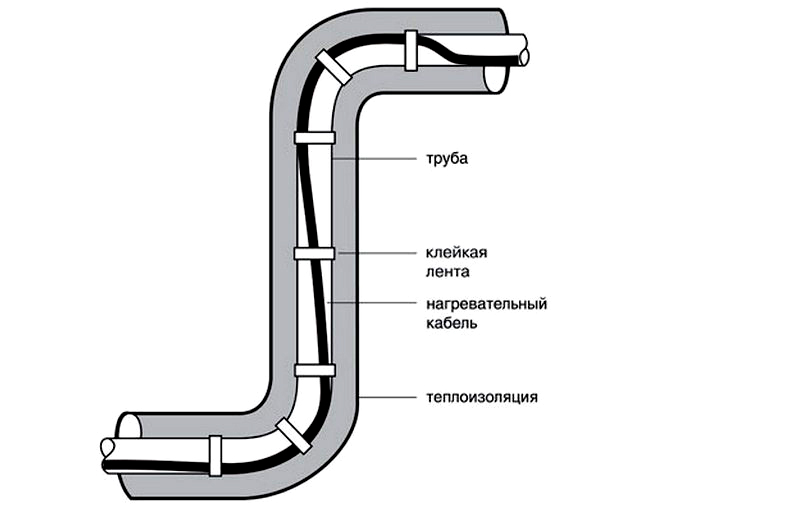

Gasket technology

The technology of laying cable in pipes must be maintained to the smallest detail. A well-conducted laying allows you to create a line that operates smoothly for a long period at any ambient temperature.

This technology looks like this:

- Preparation for laying. It involves cleaning the pipeline from traces of rust and contamination.

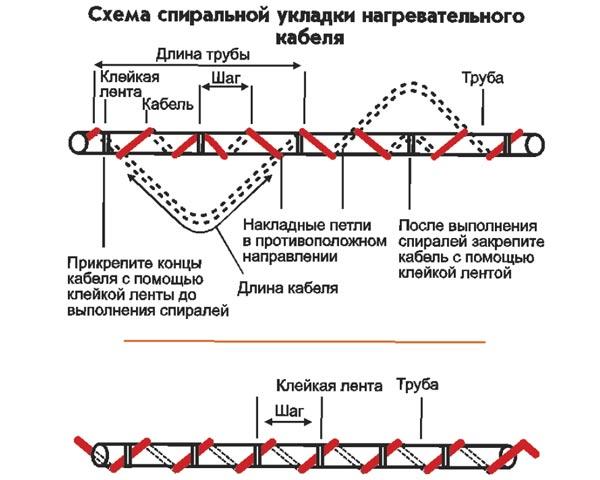

- Cable laying by one of the selected technology methods - pulling parallel to the pipeline, or winding it in a spiral. In the second case, a large amount of material will be required for work, but for this task it is used with a small diameter.

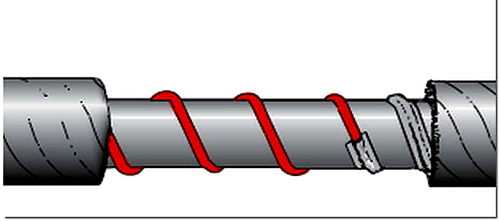

This gasket runs along the pipe

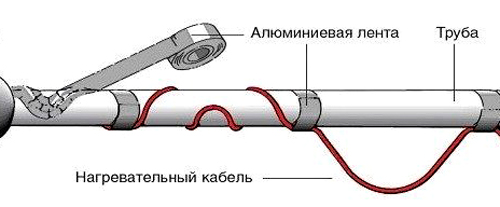

And this is a gasket made in a spiral.

- The next step is to fix the cable wire on the underside of the trunk with a special tape.

- Insulation laying.

- Power connection.

Upon completion of work, markings are made on the insulation of the water supply and indicate information about the presence of heating of the network.

How to mount a heating cable inside a pipe

Heating pipes from the inside with a cable is only possible if the pipe diameter is at least 20 mm.

We list the main nuances when installing heating cables in pipes:

The heating cable is installed inside the pipe as follows:

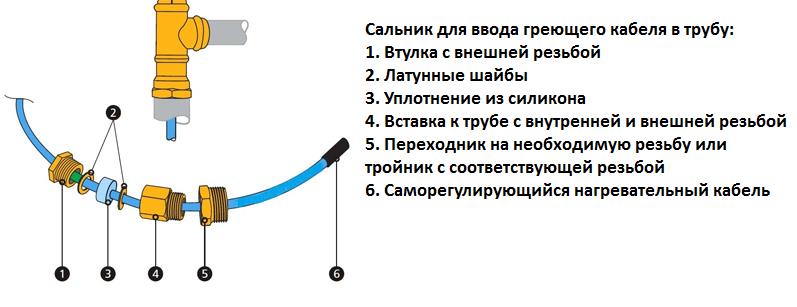

at the point of entry into the pipe of the heating cable, a saddle or tee is installed;

the pipe tie is screwed into the saddle;

the heating cable is inserted into the tie-in.

The length of the heating cable must be equal to the length of the pipe section to be heated.

It is important to make all measurements as accurately as possible.

It is unacceptable to lay the heating cable inside the pipe through shut-off valves.

It is forbidden to fix the supply cable and the coupling using the penetration from the kit and the gland when the cable is inserted into the pipe.

All work requires utmost care and accuracy to prevent damage to the cable sheath. Sharp parts, such as fitting threads, must be covered with factory tape during installation.

Be sure to place a warning label in the place where the heating cable was installed inside the pipe.

If the wire is chosen correctly and the work is carried out taking into account all the recommendations, you will not be bothered by problems such as freezing of the water supply and a decrease in pressure in winter.

Domestic winters are sometimes so severe that the sewerage and water supply system freezes. At the same time, the water supply to the house does not just stop, the consequences can be much sadder. Pipes can be broken by ice and all communications will have to be laid again. A reliable and economical way to prevent disaster is to use a self-regulating plumbing heating cable. This simple method of heating will keep the system even in the conditions of the far north. How the device works, its types and basic principles of installation - in this material.

How to calculate the length and wattage of a self-regulating pipe heating cable

Each device installation option has its own characteristics. There are two ways to place the wire: outside and inside the pipe. External installation is possible when laying engineering networks. If the pipes are already in the ground, it remains only to apply an internal lining and use a self-regulating wire.

What you need to know for calculations:

- P wire (indicated on its side);

- pipe dimensions;

- type of heat insulator;

- temperature fluctuations in the area of residence.

The formula looks like this:

Cable length = Safety factor x pipe length x heat loss / P wire

Preliminary calculations can be made based on power indicators: D up to 25 mm - 10 W per meter, up to 40 - 16 W, up to 60 - 24 W, up to 80 - 30 W, above this indicator - 40 watts per meter.

If you place the cable outside the water supply, you can increase the heating using a different location:

- parallel (suitable for thin pipes);

- serpentine (quickly warms pipes);

- spiral winding (used for temperature stabilization).

Pros and cons of the device

Like any device, the heating wire has its advantages and disadvantages. You should know about the first, and fight the second with the help of competent installation and proper operation:

|

pros |

Description |

| Uniform heating | The cable heats up along its entire length, the heating is uniform and gradual. |

| Reliability | Elements of the system are resistant to sudden voltage drops in the network. Several degrees of protection prevent overheating even when overlapping. |

| economy | The power consumption for such a system is relatively low, moreover, savings are achieved due to self-regulation. |

| No length restrictions | The heater works effectively regardless of the length. |

| No need for maintenance | The device is autonomous and practically does not require maintenance, except for cases of mechanical damage. |

| Ease of installation | You can install the cord inside or outside the pipe on your own, without involving hired specialists. |

What to choose Best options

Cable with built-in sensor and thermostat - Arnold Rak

Country of origin Germany.

Specifications:

- Power - 16 W / m.

- Plug for Euro socket with grounding.

- Built-in sensor and thermostat.

Description and features: Prefabricated structure is completely ready for operation. The device is equipped with a thermostat, has increased protection against freezing.

Prevents freezing of water pipes and key components in winter. As soon as thermal insulation is installed over the cable, it is ready for use.

The product is easily fixed on the pipe and is easy to use. The heating system automatically starts at temperatures below +2, as soon as the heating reaches 10 degrees Celsius, the equipment turns off.

Devi pipeheat self-regulating cable

Country of manufacture: Denmark.

Country of manufacture: Denmark.

Specifications:

- Power - 10 W / m.

- Rated voltage - 230 V.

- Europlug.

- Braid resistance: 18 Ohm/km.

- Possible temperature range from + 85 to -40 degrees Celsius

Description and features: This is a two-core shielded wire.

The design has sixteen current-carrying cores. The main feature of the cable is that it can be used both inside the pipe and outside.

The insulation is made from food grade plastic. The length directly depends on the needs of the client. Range from 1 meter to 300. Included is a regulator with a temperature sensor.

The insulation is made from food grade plastic. The length directly depends on the needs of the client. Range from 1 meter to 300. Included is a regulator with a temperature sensor.

This set allows you to achieve the most rational energy consumption.

Ensto Optiheat 9 (Finland)

Specifications:

- Power - 9 W / m.

- Voltage - 230 V.

- Europlug.

- Green color.

The product is bent at an angle of 35 degrees. To enter the cable inside, you will need the EFPLV1 kit. Due to the fact that the sheath is made of polyethylene, the installation of the wire inside the pipe does not affect the quality of the water in any way.

- Length from 2 to 20 meters.

- The euro plug is connected to the cord.

- For installation inside a pipeline, the RLK1 is required.

- Country of manufacture: Finland

Nexans Defrost Water Self-Regulating Heating Cable

Specifications:

- The maximum ambient temperature in non-working condition is 65 degrees Celsius.

- Braid resistance - 18.2 Ohm / km.

- Voltage 230 V.

Description and features: Most often this product is used as a heating cable in pipelines with drinking water. Self-regulating cable is reliable, resistant to bending and long service life.

Another distinctive feature concerns the installation, the cable can be mounted with an overlap. This will not cause it to burn out. The degree of heating directly depends on the temperature of the pipe.

The design uses tinned copper, a semiconductor matrix.

An aluminum strip acts as a screen. The insulation is made from thermoplastic elastomer. Installation can be carried out at a temperature of at least 10 °C.

Thermo FreezeGuard Ready Kit

Specifications:

- Service life - 20 years.

- Power - 15/25 W (depending on modification).

- Voltage - 230 V.

- The maximum operating temperature is 65°C.

Description and features: The product is used not only in pipelines, but also in water metering units, drain systems, as well as in other objects that are subject to freezing.

A distinctive feature of the cable is a high-quality LongLife matrix. Thanks to it, the self-heating cable can be used without a thermostat.

The matrix provides a different level of heating depending on the temperature in a particular section of the pipeline. If we take into account the main pipes, such a solution will result in significant cost savings even in the short term.

Connection and installation methods

It is very important to lay a self-regulating wire along the entire length of the pipe. There should be no places where, for one reason or another, the product does not come into contact with the surface of the pipeline (external installation)

A relay must be connected to the system. It will be responsible for temperature control.The user will be able to set suitable temperature indicators depending on changes in the external environment.

After the cable is installed, insulation and insulation are mounted. Naturally, the structure must be grounded.

The main thing is that the wire does not have a tensile force exceeding 25 kilograms. The pipe itself must be securely insulated. Leaks and damage are unacceptable.

It is also necessary to avoid contact with sharp objects that can break the integrity of the insulation. Crossing the cable can cause irreversible damage. There are two types of mounting:

- Internal - the self-heating cable is pushed into the pipeline. The pipe is wrapped with aluminum tape. Entry is via a gland.

- External - the cable is laid in a linear or spiral method, fixed with a special tape.

If the wire for heating the water supply is laid over the pipe, then the calculated power should be in the region of 17 W / m. When mounted inside, this indicator fluctuates at the level of 10 W / m.

Connecting the equipment is pretty easy. In the absence of a braid, it is enough to power the cable from the network. If there is a ground shield, then it is connected to the ground.

Then it remains to insert the plug into the socket. If the wire is securely packed, then you need to remove the outer sheath and twist the shielding braid to get to the matrix.

Then we release the cores, the ends are inserted into the sleeves, the resulting structure is fixed.

Installing the heating cable on the pipe

- Preparation for installation. Cleaning pipes from rust and dirt.

- Do-it-yourself installation of a heating cable according to one of the options:

- Installation of one or more parallel strands of heating cable directly on the pipe. The number of threads is selected depending on the creation of the required power.

- Spiral cable installation. A more expensive option, used when using pipes of small diameter and in the case of a sufficiently long heating cable.

- Fastening the heating cable to the bottom of the pipe requiring heating with a special tape.

Advice! Try to fix the cable so that it is as far as possible from the bottom of the flanges or other connecting elements that can pass water. This will prevent liquid from entering the operating elements of the heating system in case of depressurization of the connection.

- Thermal insulation installation. Care must be taken to ensure that the "cold" end of the heating cable remains outside the insulation layer.

- Supplying power from the electrical panel (socket) to the heating cable. In the case when the installation of the heating cable on pipes is carried out in a place remote from the electrical panel, a junction box should be used.

Additional compliance with certain conditions will allow for high-quality installation of the heater and get the greatest effect of heating communications:

- Since plastic pipes are devoid of an aluminum layer, you should first wrap them with foil tape. After that, the entire surface of the pipe will be heated evenly.

- Sections of the heating cable, not exceeding 1.4 m in length, should be mounted to pipeline valves, mounting flanges. This will make it possible, if necessary, to easily disconnect the pipe system.

- The resistive heating cable must not be crossed to avoid burning it. This does not apply to self-regulating heating cable as it is non-flammable.

It is necessary to ensure the maximum possible protection of the heating system from moisture, using thermal and waterproofing for this.

It is imperative to provide markings on the insulation of the pipeline indicating the necessary information about the presence of a heating cable on the pipes.

Water pipes located at a depth, at a minimum temperature, are subject to freezing.This leads to disruption of the functioning of the entire plumbing system. To minimize the likelihood of such a risk, you can install a heating cable for the water supply. This element can be located inside or on the surface of the pipes. The possibility of using a heating cable of different lengths allows heating the entire system or a separate part of the water supply system located in the freezing zone.

HEATING pipes with a heating cable

A pipe heating system based on a heating cable is used to prevent freezing of the pipeline in winter, this is an ideal way to relatively inexpensively ensure uninterrupted drainage of liquids at sub-zero temperatures, or to ensure that a certain temperature is maintained inside the pipe.

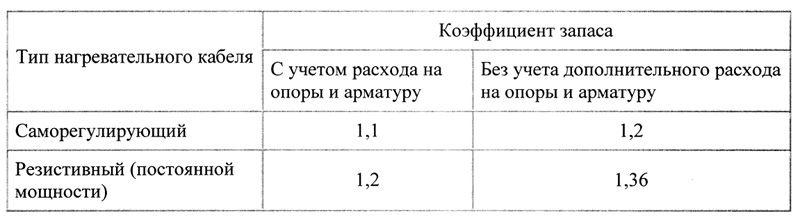

Types of heating cables for heating pipes

Self-regulating - a cable whose design includes a semiconductor matrix that changes resistance depending on the ambient temperature. The lower the temperature, the higher the resistance and heat dissipation. A huge plus is the local change in cable power, that is, heating occurs only in that section of the pipe where it is needed at the moment. Peak power can exceed the rated power twice! (assuming a quality product is used). Depending on the type of insulation, it can be used both outside and as a heating pipe for supplying water inside. A set of any length can be made to order. The kit includes: a self-regulating cable connected with special heat shrink sleeves with a three-meter power cable for connecting to a power outlet. At the end of the self-regulating cable there is a heat-shrinkable sealed cap.

Resistive is a cable of constant power based on the principle of operation of conductors with high resistance when current is applied to which heat is generated. The higher the resistance and current strength, the greater the heat dissipation. It happens single-core and two-core, sold in ready-made segments.

Attention! To avoid overheating of the resistive cable, avoid interlacing and contact, there must be a distance between the turns of the cable. It is forbidden to cut the wire - this will lead to failure of the entire segment

Not subject to local repair - in case of mechanical damage, the entire section changes. For more efficient heating and savings, we recommend using a thermostat that will turn off the system at positive temperatures and turn on at negative ones.

Selecting the required power

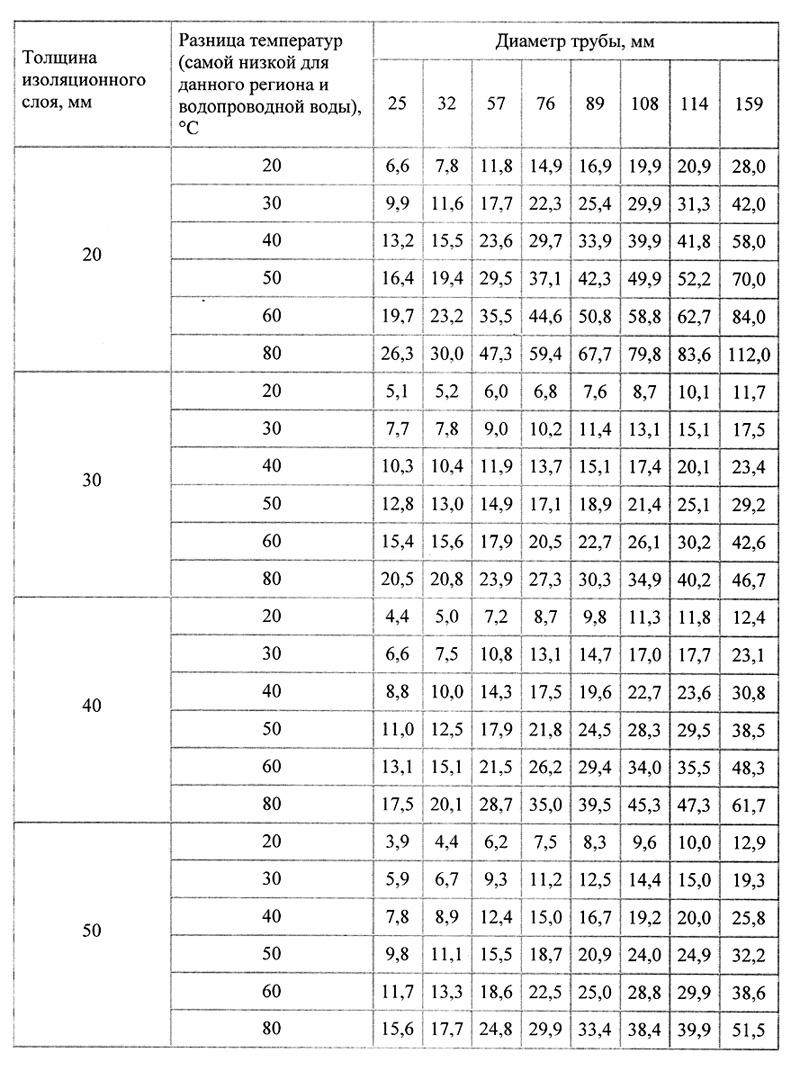

The choice of cable power directly depends on the diameter of the pipe, the thickness of the thermal insulation and the ambient temperature. To prevent the liquid from freezing, it is necessary to compensate for the heat loss of the pipe. To calculate the required power, you can use a typical table or an online calculator.

The choice of cable power must be taken very carefully and there are several reasons for this:

- Excessive cable power can lead to overheating and premature failure of the heating system. In extreme cases, melt plastic pipes!

- With less power than necessary, the system will not be able to cope with the heating of the pipe, which will lead to freezing.

It is important to correctly calculate the required power for your pipe, because it depends on how efficient, economical, safe and durable the pipe heating system will be!

To calculate the heating inside the pipe, you can choose the minimum insulation values, because. the cable will be in direct contact with the liquid. The given loss values refer only to pipelines. In practice, heat losses at valves, flanges, etc. must be taken into account. An appropriate cable length must also be taken into account, which compensates for heat losses in these places. The heating cable must be equal to or slightly more than the value given in the table.

Features of this heating system

The heating cable for water supply pipes is arranged as follows.

- Lived inside. This is the main element of the heater for the water supply line. It is made of an alloy that has a high electrical resistance.

- Protective coating of the main core. Manufactured from an insulating polymer fitted with a solid aluminum shield. A screening mesh made of copper wire can also play this role.

- The general protective coating for heating for water supply pipes must create reliable protection of the constituent structural elements from the influence of the environment.

For water pipes, you can buy a variety of types of heating systems. In building stores, their choice is very wide. The price is based on the number of lived inside.

How to connect a heating cable inside and outside communications

Fixing the wiring over the pipe is possible only in the process of laying networks. If the nets are already under the ground, consider whether it is worth spending money on excavation or whether it is better to use the second, internal option.

outdoor installation

With an external location of the heating wire, the fastening occurs with the help of aluminum tape. It not only firmly presses the cable to the pipe, but also acts as an additional heat insulator.

There are several winding options, consider them in more detail:

|

Winding option |

Image |

Peculiarities |

|

This option for the location of the wire is suitable for areas with a harsh northern climate. The pitch of the coil of the cord is five centimeters or more. In this case, when calculating the length of the wire, you need to multiply the length of the pipe by 1.7. | |

|

This type of winding will also require an additional length of cord, about 1.4 times the length of the pipe. The snake itself will not stay on the surface, it must be secured with tape. | |

|

This is the simplest but least efficient way. The cord is laid along the pipe and is equal to its length. |

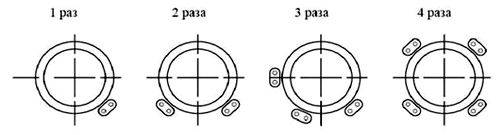

On nodal connections, the following types of winding are used:

Laying a heater inside the pipe is justified if communications are installed earlier and there is no way to remove them for external processing. This method of heating has its own nuances that will have to be taken into account:

- the internal clearance of the pipes will decrease;

- blockages may appear due to an increase in plaque on the cable;

- installation of the cord is possible only on straight pipes or communications with a small bend.

Despite all the difficulties, the internal type of gasket also has advantages: an easy installation method and low energy consumption.

The sequence of laying the heating cable for the water supply inside the pipe

|

Photo |

Description |

|

A gland and spurs are put on the wire |

|

In the required place, a tee is installed to enter the cable into the system |

|

The cable is pushed to the place that is most exposed to low temperatures |

|

The gland is fixed and insulated. |

The final stage - connection and thermal insulation

An important stage in the installation of pipe heating is connecting the cable to the mains. First of all, it is necessary to protect the ends of the core from moisture with the help of heat shrinkage. How to connect the ends of the wire, see the video:

In order for the device to work without interruption, a thermostat and an RCD should be connected.

After connecting to the network, it is necessary to install reliable thermal insulation. For these purposes, you will need polyurethane insulation, cut along.

They wrap the water and sewer network.

- For water supply pipes, an external cable with a power of at least seventeen watts per meter is required.

- Oversized cables consume a lot of electricity, so consider whether you need to take the system more powerful than required.

- For plastic pipes, you should purchase a self-regulating heating cable for plumbing.

- The selection of cable power depends on the diameter of the pipe and the laying method.

- For internal heating of a pipeline in the central part of Russia, a cable power of ten watts and a heater three centimeters thick are sufficient.

Calculator for calculating the length of the heating cable for underfloor heating

Reading time: 2 minutes No time?

The house should be cozy and warm. This task is best solved by "warm floors". Previously, electric underfloor heating was considered exotic. Now he is preferred in the construction of multi-storey buildings, cottages, summer cottages and even baths. It can serve as the main heating system of the home, as well as in the form of additional comfort. The popularity of underfloor heating is due to their high cost-effectiveness. The initial costs are minimal, and the ongoing work does not cause difficulties. Installation of a "warm floor" should begin with the calculation of the required power of the heating system. For underfloor heating to be effective, you need to know the length of the resistive cable. For these purposes, we offer a special convenient calculator.

Electrical cable installation

Calculation of the length of the heating cable using the calculator

Necessary explanations

When calculating the cable length using the calculator, you must enter a number of requested values:

- Purpose and location of the premises. "Warm floor" can serve as the main type of space heating or serve as an additional one. It is necessary to indicate the data that the work is carried out on the ground floor, on the ground, or the floor will be located above the heated room.

- Enter data on the floor area where the cable is planned to be laid.

- Using the passport values of the purchased kit, the required cable power is set. Measurements are performed in the calculation of W / m (linear meter).

Length calculation scheme

Heating cables are characterized by different heat transfer coefficients (expressed in watts per linear meter). The product passport must contain this indicator.

When entering data on the area of \u200b\u200bthe room where it is planned to use the "warm floor", the following should be taken into account:

- the cable is never laid in the locations of stationary objects or household appliances,

- the distance from the walls must be at least 50 mm,

- heaters must be at least 100 mm apart.

It is recommended that before starting work, develop a floor plan where it is planned to place the heating cable. This will help in calculating the area required for heating.

After entering all the data, the calculator will give the desired cable length. According to the data received in the store, you can purchase a suitable kit. In addition to the cable length, an equally important parameter is the laying step, for the calculation of which we also offer a special calculator.

Related article:

Save Time: Featured Articles Every Week by Mail

Why heat pipes

Heating pipes are used to protect them from freezing in adverse conditions of extreme winters. Heating of sewer pipelines is mandatory in the following cases:

- pipes are laid outside the building;

- the highway lies above the level of soil freezing;

- there are places where the pipeline passes from the underground to the ground part;

- it is located inside an unheated room (basement, attic, etc.).

Even if the highway is laid, there is a risk of its freezing in extremely cold winters. The liquid transported through the sewer may not solidify completely, but even partial crystallization can lead to blockage

water vessels.

A special cable allows you to heat the surface of the pipes to the optimum temperature and maintain the set indicators throughout the entire period of establishing low temperatures.

As a rule, a pipe heating system consists of:

- suitable type of cable;

- fasteners that ensure a tight fit of the cable to the pipeline;

- power wires that connect the system to electricity;

- electrical elements (couplings, boxes, thermostats).

The cable can be heated up to 120˚C. However, it is worth remembering that this indicator is detrimental for plastic pipes.

In the case of laying plastic pipelines, it is worth choosing a product with a power of no more than 11 W / m of the line.

Types of heating cables

The heating electric cable for heating pipes differs in size, power and type of installation. But, installers distinguish two main types

products:

- resistive;

- self-adjusting.

Resistive, heating cable consists of two cores. A heat-insulating and shielding shell is applied to their surface. The essence of the work of the product is comparable to the principle of operation of the heating element. A resistive-type heating cable has a strictly specified resistance, so it cannot be divided into segments. This makes the installation process difficult.

Heating self-regulating cable can be used for any type of pipeline. Its feature is the presence of a semiconductor matrix. It is placed between the conductors of the current supply. Such a self-regulating heating pipe cable is able to adapt

under environmental conditions in different sections of the sewer.

This allows for a more rational use of electricity, optimizing the efficiency of the system. Self-regulating cable can be divided into segments.

For what purposes is a self-regulating heating cable for plumbing useful and how it works

A heating cable for plumbing is a special type of wire that can change its temperature, focusing on the thermal conditions surrounding it. The colder the pipe becomes, the more the wire heats up.

Where is the system used?

Heating self-regulating cables for plumbing are used when installing roofs, floors, cornices, plumbing and sewerage. There are three applications for this device:

- in individual housing construction for heating engineering networks;

- in the commercial sector for heating pipes and fire extinguishing systems;

- at industrial enterprises operating in harsh climatic conditions.

How the device works

Cable construction:

- conductors made of copper, carrying out voltage throughout the length of the device;

- a heating matrix that regulates the temperature and heats the cable;

- several layers of insulator;

- a metal screen that protects the wire from accidental damage and interference. This screen is grounded;

- protective outer layer.

The multilayer structure of the wire is not susceptible to external influences and has a long service life.

The operation of a self-regulating heating cable is similar to that of resistive wiring. The more the conductor heats up, the more the resistance increases and vice versa, with a decrease in the strength of the electric current, the power decreases.

The matrix in the core of the device regulates the conductivity of the device.

Related article: