Diesel boiler fuel consumption

Before you buy a boiler for heating your home, you should determine what power it should have and decide what type of boiler will be optimal for operation in your particular case. Naturally, people who are accustomed to urban comfortable conditions are unlikely to give preference to a solid fuel boiler. But with the connection of an easy-to-use gas boiler, difficulties may arise if there is no gas branch in the area or if it is too far away. In this case, diesel heating boilers may be an acceptable option, the fuel consumption of which we will calculate in this article.

The indisputable advantages of this type of heating devices include their autonomy, ease of operation, the relative cheapness of fuel, ease of installation and the ability to do it without special permission.

When buying a diesel heating device, you should take care of arranging a special room equipped with ventilation to accommodate the boiler, and you will also have to provide a place to store fuel containers. As containers, you can use plastic or metal (steel) containers with a volume of 4-10 tons, depending on the cubic capacity of the premises that need to be heated.

Special bunkers are used to store fuel containers. Their installation can be carried out in the building itself or outside it. Guided by the rules of fire safety, fuel tanks should be buried in the ground. This will prevent troubles that may arise in the spring with a high location of groundwater (tanks empty during the winter can float).

The second positive point is that the temperature of the fuel will not drop to temperatures that create increased loads on the fuel pump. As a result, the owners will be able to get some savings on electricity.

Calculation example

Given that the consumption of 1 kg of diesel fuel will provide a heating device power of 10 kW, simple calculations can be performed.

You can calculate the required amount of diesel fuel using a simple formula: coefficient 0.1 X burner power. The result will show how many kilograms of fuel will be consumed within 1 hour. If the room has an area of 100 sq. then for its heating you will need a boiler with a capacity of 10 kW. Next, we calculate by the formula:

0.1 X 10 \u003d 1.0 kg of diesel fuel per hour.

Thus, operating at full capacity, the boiler uses 1 kg of fuel in one hour, and 24 kg per day.

The approximate duration of the heating season lasts 100 days, during which it will be necessary to operate the heating device at full power and another 100 days at half power, then the amount of diesel fuel required for the season can be calculated as:

(100 X 24) + (100 X 12) = 3600 kg. will be the fuel consumption of diesel heating boilers per season with a room area of 100 m²

With a careful attitude to the diesel boiler and the implementation of basic recommendations for operation, its service life can reach fifty years.

What determines the fuel consumption of diesel heating boilers

If you decide to install a heating boiler, you need to decide what type of boiler you need and what its power should be. It's a little hard to imagine that a city dweller, accustomed to comfort, will choose a solid fuel boiler. Undoubtedly, it will be gas. And if the gas line is so far away that connecting to it will result in huge sums? Then choose the most optimal option in this situation - heating a country house with diesel fuel. It remains only to find out what is the fuel consumption of diesel heating boilers.

The choice of a diesel heating boiler has an important advantage, its autonomy, which, in addition to ease of management, also saves diesel fuel.This is certainly a more economical option than, say, electricity.

Installation of this boiler does not require special permission.

Of course, they also have certain disadvantages. First of all - the need for a special container in which fuel will be stored, a room with an exhaust hood for installing the boiler.

Combustible fuel will have to be stored in special bunkers, steel or plastic fuel tanks. Their volume depends on the volume of heated premises, as well as the required level of their thermal protection. On average, the volumes of these containers range from 4 to 10 tons.

You can install them in an isolated room inside the building or outside it. According to the fire safety rules, the containers, if hydrogeological conditions allow, should be buried in the ground. They should also be buried because if there is groundwater nearby, half-empty tanks in the spring can, as they say, float up. and yet, at lower temperatures, the viscosity of the fuel increases, which increases the load on the fuel pump, therefore, more electricity is spent on pumping fuel.

It is possible to approximately calculate the consumption of diesel fuel based on the following ratio: it is possible to obtain a thermal power of the boiler of 10 kW at a consumption of diesel fuel of 1 kg / h.

You can calculate the consumption of diesel fuel required for heating and as follows: by multiplying the burner power by a factor of 0.1. The resulting figure will show the amount of diesel fuel (in kilograms) consumed in 1 hour.

Let's calculate the approximate consumption of diesel fuel for heating a house with an area of 150 square meters. m. The power of the boiler required to heat such a house is 15 kW.

Let's do some simple math:

It turned out that at full power of the burner, the boiler burns 1.5 kg of diesel fuel in 1 hour, and the daily consumption, respectively, is 24 x 1.5 = 36 kg.

If we take into account that for the entire heating season the boiler operates for about 100 days - at full capacity, and another 100 - at half capacity, as a result, we get: (100 x 36) + (100 x 18) = 5200 kg, i.e. a little more than 5 tons of diesel fuel.

With proper operation of a diesel boiler, it can last about 50 years.

How much fuel does a generator for a cottage consume

When buying a generator set, it is logical to ask about its efficiency, namely: how much fuel does it consume per hour?

This value can be found in the technical documentation of each model.

Keep in mind that the figure in the documents for the generator is the consumption at 75% load at a temperature of 20 ° C.

As you might guess, these are ideal conditions for operating the generator and the most economical mode, so any changes in parameters make adjustments to fuel consumption.

- pressure, air composition, humidity and air temperature. Low ambient temperature increases the viscosity of the fuel, which leads to incomplete combustion of the fuel and reduces the efficiency of the generator.

- fuel quality. Poor fuel quality will force the owner to add fuel to the generator tank more often.

- condition of filters, oil, grease, etc. Clogged oil and fuel filters will significantly increase fuel consumption;

- deterioration of the engine and other components;

- load below 40% capacity or overload. At a load of less than 40%, fuel consumption is unreasonably high. Therefore, using the generator idle is uneconomical. Fuel consumption increases at full load.

Pay attention to the latest criteria. Everything is clear with overload

But underloading the generator also does not benefit him.

For example, a 6 kW unit should not be used only for lighting - this will give an unreasonably high cost of kW and have a bad effect on the operation of the generator engine. Underloading is considered less than 40% of the nominal, so you should not buy a generator with an excessive power reserve. Other things being equal, the consumption of a diesel generator is less than a gasoline one.

Therefore, gasoline generators are more often used for short-term operation; it is not economically viable to use them for permanent operation. Diesel generators can become the main source of energy, working for a long time and consuming less fuel.

Gasoline is used in small installations - starting from 0.75 kW, diesel models can be found from 3 kW.

In figures, fuel consumption looks like this: Generator Gasoline Diesel 5 kW 2.3 l 1.4 l 6 kW 2.7 l 1.9 l 10 kW 4.9 l 3.0 l In addition to the fact that diesel engines themselves are more economical , the Bosch injection system is installed, which additionally saves fuel up to 15% and reduces smoke and CO content in exhaust gases. The principle of operation of the system is as follows: injectors inject fuel directly into the combustion chamber.

This increases the pressure in the chamber and gives high torque with less fuel consumption - up to 15%.

The latest development of the system was the use of a laser to produce holes in the injectors. Now the fuel atomization has become more finely dispersed, due to which mixture formation is more accurate, and the fuel burns more efficiently with minimal emissions to the atmosphere. Returning to the issue of generator load, let's turn to the numbers.

Consider how fuel consumption depends on the load using the example of a diesel and gasoline generator of the same power - 3 kW. Load, % Consumption l/h, Gasoline generator Consumption l/h, Diesel generator 75 1.6 l 1.0 l 90 1.8 l 1.15 l Knowing what affects fuel consumption, you can make the operation of the generator as economical as possible:

- use the generator in optimal weather conditions;

- carry out maintenance on time;

- monitor the quality of fuel;

- keep the load at least 40% and not more than 80%.

vi. the procedure for determining the standards for specific fuel consumption in the production of electrical and thermal energy

The specific fuel consumption standard (NUR) for the supplied electric energy is calculated on the basis of individual standards for diesel generators (DGs), taking into account their power, operating time, load characteristics, technical condition, and the amount of electricity consumption for the auxiliary needs of DPP.

The standard is set in grams of standard fuel for the supply of one kilowatt-hour of electrical energy, g of reference fuel / (kWh).

66. The choice of the composition of the operating equipment and the distribution of loads between individual DPP units is based on the principle of minimal fuel consumption for the production of electrical energy while maintaining the conditions for reliable power supply to consumers. When calculating the NOR, fuel and energy costs are not taken into account, caused by deviations from the rules of technical operation and operating modes of DPP equipment, for the construction and overhaul of buildings and structures, installation, commissioning and adjustment of new equipment of power plants, for experimental and research work.

67.

Calculation of the amount of fuel for a diesel heating system

Attention! For modern liquid fuel heating units with imported burners, it is necessary to purchase high-quality fuel, which must correspond to the season of use. To determine the volume of the fuel storage, it is necessary to first calculate the approximate consumption of diesel fuel for a certain period of time

To determine the volume of the fuel storage, it is necessary to first calculate the approximate consumption of diesel fuel for a certain period of time.

If a diesel heating boiler is used for heating, what fuel consumption per hour can be calculated using a simple formula - a factor of 0.1 must be multiplied by the power of the unit. This means that to ensure the operation of a diesel heating installation with a capacity of 10 kW per hour, 1 kg of diesel fuel will be consumed.

To heat a house with an area of 200 m 2 located in central Russia, approximately 5000 liters of diesel fuel will be needed per season.

Why diesel boilers are unprofitable, and how to reduce their operating costs

In view of the constant rise in the cost of fuel, its use for heating is in many cases even less profitable than heating with electricity. Many consider the disadvantages of boilers with liquid burners, and the fact that even models of the most famous manufacturers often consume more fuel than stated in the passport. However, heating costs can be reduced by following a few tips.

I follow them constantly and am completely satisfied with my boiler:

Do not use diesel fuel intended for automobile engines. There is a special furnace for boilers, it is cheaper, but for burners that are not precision, unlike the fuel equipment of diesel engines, there is no difference, they do not differ in calorific value during the combustion process.

A decrease in boiler efficiency is often due to misadjustment of the air-fuel ratio. Therefore, you need to periodically adjust.

Different fuels may require different settings, so I only buy one brand and only one company.

Follow the same principles as I did and do not be offended in many cases for no reason at various models of oil boilers.

+ Pros: Possibility of fully autonomous and automatic operation, low price of burners.

Cons: Expensive fuel.

Fuel consumption rates for 2019 recommendations of the Ministry of Transport of the Russian Federation

The last amendments to these rules were made in 2015. For 2019, enterprises that have a fleet of vehicles can calculate fuel consumption on their own, or taking into account the instructions of the Ministry of Transport of the Russian Federation.

The thing is that for 2018 it was indicated that the standards established by the Ministry of Transport of the Russian Federation are not mandatory, but only recommended. Therefore, the company's accountant can decide for himself how best to calculate fuel consumption.

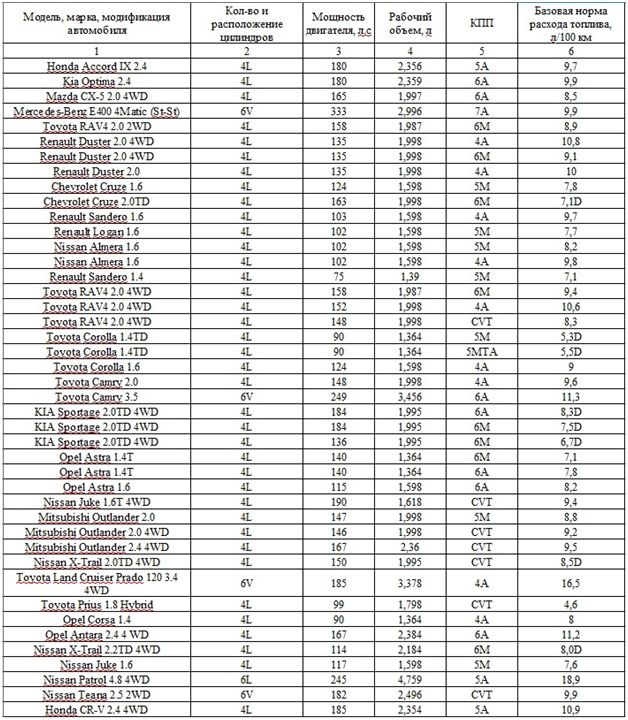

Fuel consumption rates recommended by the Ministry of Transport of the Russian Federation:

This table is an abbreviated version. You can find a complete list of car brands at.

In order to find out the standard values of fuel consumption for a particular car, you need to know the type of transport (car, truck, tractor or special purpose). After that, you need to open the desired table and find the exact make of the car (gasoline consumption rates for a particular car have already been calculated for you).

If for the car, due to its performance characteristics, it is possible to apply an increasing surcharge, it is added to the consumption rate of gasoline / gas / diesel fuel.

Fuel consumption rates for diesel generator sets

It is known that the unit produces one kWh of electricity, using about 200 g of diesel fuel.

To calculate, you need to multiply the generator power figure by the fuel mass. For example, with a diesel generator power of 5 kW, a liter of fuel will be consumed per hour (5 X 0.2).

The consumption will certainly increase if the unit is operating at the limit (75% of the rated power and above). For example, if your generator set has a power of 5 kW, then the total power of all equipment connected to it should not exceed 3.8 kW. In diesel generators located outdoors or in rooms without heating, fuel thickens at low air temperatures, and then its consumption also increases.

In addition, remote control requires good ventilation, and the diesel oil itself must also be of good quality. A variety of impurities, sulfur - all this also contributes to overspending. The eighth and ninth columns, united by the heading “DG operation at idle”, are filled in with passport data on the average idle time of the diesel generator and average fuel consumption at idle. They are filled in with passport data on the average idle time of the diesel generator and specific race 3.2. 2.6.

Determine the fuel consumption of a diesel power plant

Fuel consumption is the parameter that you probably pay attention to first of all when choosing a diesel power plant. Your future costs depend on it.

However, the figure indicated in the equipment passport does not reflect the real picture.

Your future expenses depend on it. However, the figure indicated in the equipment passport does not reflect the real picture.

Consumption can be either less or more than the declared indicator. The fuel consumption of a diesel power plant depends on its power, the number of phases, the cooling system, and the type of fuel itself recommended for use.

The main factor that you should be interested in is power. The higher it is, the greater the cost.

There is nothing difficult in calculating the approximate fuel consumption of a power plant. So, for diesel, the standard consumption is 200 g per 1 kWh.

It will take 1 kg of fuel to generate 5 kWh. For gasoline generators, this figure is 350 g per 1 kWh. Thus, in order to calculate the fuel consumption of a power plant, it is necessary to use the formula 0.2 kg N kWh.

For example, for a station operating at a power of 7.5 kW, the consumption will be 1.5 kg per hour. How much will it be in liters? It all depends on the fuel you are using.

Light fuel will need more, heavy fuel (for example, fuel oil) - more. To convert to liters, find information on the density of the fuel you have chosen.

It seems that everything is simple: calculate the consumption according to the formula and purchase the required amount of diesel fuel or fuel oil. But the real figures will still differ from the calculated ones.

Much depends on the conditions, in what mode and on what fuel the station operates.

It also affects her condition.

- Mode of operation Like any internal combustion engine, a DES engine consumes much more fuel during intensive operation. So, if the generated power is higher than 75% of the nominal one (the one indicated in the passport), fuel consumption (and the wear and tear of the equipment itself) increases significantly. If, for example, the rated power of the power plant is 5 kW, it should feed appliances with a total power of 3.75 kW - no more. If too few devices are connected to the station, and no more than 35% of the generated electricity is consumed, its efficiency will gradually decrease. Consequently, its consumption will be higher than that of the new station.

- Fuel quality The better the fuel, the less impurities it contains, the lower the consumption. Experienced diesel power plant owners advise pouring diesel fuel in advance - this way it will settle and be cleaner.

- Operating conditions In winter, the generator is best kept in a heated but well ventilated area. At low temperatures, the fuel becomes viscous, the efficiency of the engine decreases and, accordingly, consumption increases.

- The state of DESN is the lowest fuel consumption of a diesel power plant, you can only calculate immediately after its purchase. The worse the condition of the generator, the greater the consumption. It is affected by clogged filters - oil, gasoline, poorly adjusted carburetors (or another unit that controls the fuel supply process), etc.

The higher the power of a diesel power plant, the more closely you need to monitor its consumption - the difference between calculated and real indicators can be significant.

For me, a diesel boiler is beneficial

I constantly read negative reviews about diesel boilers, and so I want to dissuade everyone. It has been in the country for many years, there are no problems with it. The house is large, two-story, with an area of approximately 145 sq.m. in winter he eats no more than 12 liters per day, while at home Tashkent. A year ago, I spent underfloor heating at 3 kW and a couple of converters, each at one kW, and so the fuel consumption was reduced to 6 liters per day. At the same time, the temperature outside reaches -25 C. I take fuel on a call, a fuel truck arrives and pours as much as needed into the tank, if you take more than 500 liters, then delivery is free.

The boiler is made of steel, power is approximately 25 kW, double-circuit model.We live with my family in the country only on weekends, the house is completely heated in an hour of boiler operation. So I can say with confidence that he has more than enough power. In general, I am satisfied with the boiler.

+ Pros: Fast warm-up, simple and convenient

Cons: None for me

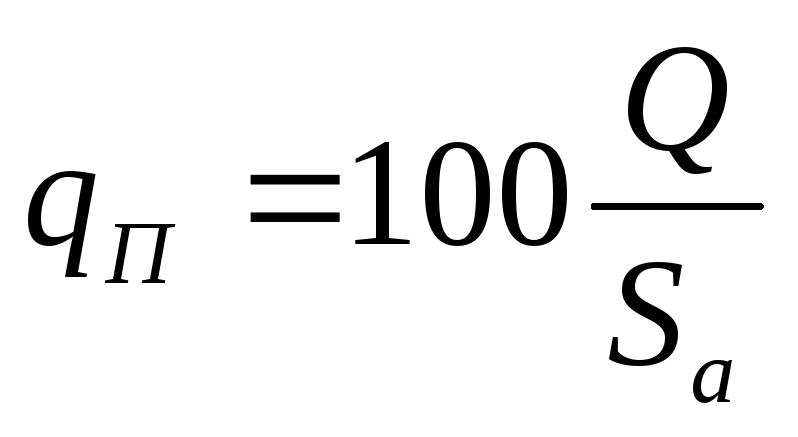

1. Fuel economy meters

Fuel

vehicle economy is assessed

two groups

meters. The first group includes

fuel gauges

economy of the car itself

the second - meters

fuel efficiency of the engine

car.

Meters

the first group are fuel consumption

in liters

per unit of vehicle mileage (track

fuel consumption) qn,l

on the

100 km, and fuel consumption in grams per

unit of transport work

qn,

g/(t∙km) or pass.-km.

TO

the meters of the second group are

fuel consumption in kilograms

per hour of engine operation (hourly consumption

fuel) GT,kg/h,

and specific effective fuel consumption

in grams per kilowatt hour

qe,g/(kW∙h).

Consider the indicated

fuel economy meters.

Travel expenses

fuel

where

Q

— general

fuel consumption, l; Sa—

car mileage, km.

V

the specified expression by the unit of mileage

are 100 km of track (assumed

for cars in Russia and many

European countries).

Travel

fuel consumption - easily determined

size, but not

taking into account the useful work of the car.

So, for example, a car

who transports the goods spends more

fuel,

how

car without cargo. Therefore, according to

formula it turns out

less economical than

car making

empty flight.

Fuel consumption per

unit of transport work

,

,

where

mrp—

weight of transported cargo (number

passengers), kg (pass); Srp

- mileage of the car with a load, km; RT

— fuel density, kg/l.

Consumption

fuel per unit of transport work

more correctly

evaluates fuel economy

car. However, practical

the use of this value is associated

with certain

difficulties due to the fact that

transport work,

performed by a car, not always

can be accurately measured.

hourly consumption

fuel

,

,

where

Td

- engine running time, hours

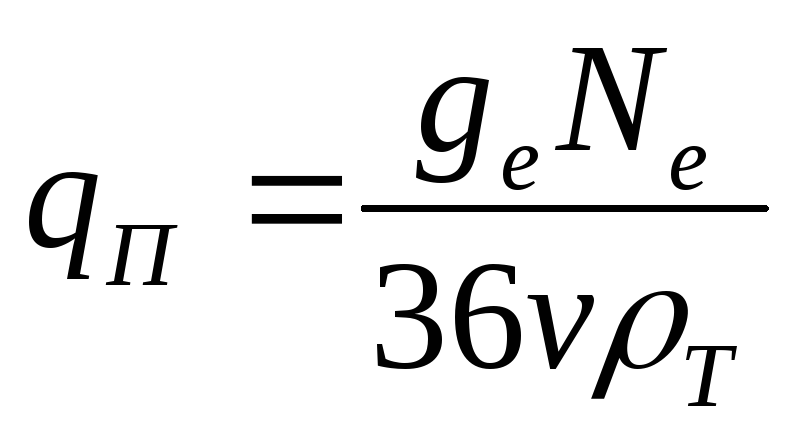

Specific effective

fuel consumption

,

,

where

Ne

— effective

engine power, kW.

WITH

taking into account the specific effective consumption

fuel define it

travel expense:

where

magnitude geexpressed

in g/(kW∙h), Ne

— vkw,

a

v

— v

m/s.

History reference

The first generation rolled off the assembly line in 1950, at that time the model's carrying capacity was 860 kg, which was a lot. The windshield of the model is divided into 2 parts, and in front of the car there was a large Volkswagen badge.

The second generation has become significant for the entire model. A new version of the Volkswagen Transporter appeared in 1967, the designers retained the main features of the chassis and design. The popularity of the 2nd generation was huge, approximately 70% of the cars were exported. The main differences are a modified line of engines, large sizes, and a modified suspension. The release of the model was stopped in 1979, but in some countries, namely Mexico and Brazil, they began to produce this modification in 1997, and stopped production in 2013.

With the onset of the 80s, the 3rd generation of the Volkswagen Transporter came out, in which there was a lot of new:

- Increased wheelbase.

- Increased dimensions and load capacity.

- The motor remained behind the car, as in the second generation.

- A lot of additional equipment appeared, including electric mirrors, power windows.

Later there was a restyling, so the car survived the introduction of all-wheel drive and air conditioning. The main disadvantage of the Volkswagen Transporter is the poor quality of the metal, some parts quickly became rusty.By the 90s, the version had become unpopular, so manufacturers had to create a new generation.

The 4th generation of the Volkswagen transporter caused a sensation among many fans of the brand and model:

- Completely changed the look and design.

- All models were front wheel drive.

- You could buy all-wheel drive.

- Several types of body, for freight transport and for the transport of people.

At the end of 1990, there were small changes, and the Volkswagen Transporter was somewhat modified.

The 4th generation was replaced by the Volkswagen Transporter T5, which debuted in 2003. Technical upgrades have been added, engines are equipped with new injection, supercharger and more. More expensive modifications had an automatic transmission.

The latest generation of the T6 received few major changes compared to the Volkswagen Transporter T5. The technical components have not changed much, the bodywork and decor elements have changed somewhat.

Kiturami 13 dear

I decided to take an inexpensive diesel boiler Kiturami 13 for myself. The installation was carried out by specialists, the installation was carried out in the basement. At first I used it for pleasure, I want to separately note that a very detailed instruction with a block diagram of the boiler is attached to the boiler. I also want to warn everyone that the boiler is very noisy, so if you are going to install it directly in the house, then keep in mind that you will not be able to sleep in silence. I always buy diesel fuel at gas stations. As for work, then the boiler has no equal.

It quickly heats up the room, keeps the heat well. For me, the only drawback of this boiler is the high cost of maintenance, a lot of money is spent on diesel fuel. On the coldest days it could take more than 700 rubles a day, a huge amount flows out in a month. I advise only those who do not care about budget costs, only those who have warmth in priority.

+ Pros: heats well

Cons: very expensive service

Diesel Generator Fuel Consumption

Fuel consumption is the parameter that is paid attention to when choosing a generator in the first place. It affects the future cost of purchasing fuel.

However, the data indicated in the passport is an ideal picture that does not reflect the real situation.

different for different types of equipment. At the same time, only one thing can be said with certainty: diesel units consume half as much fuel as gasoline ones. With an increase in the number of connected consumers, the fuel consumption of both diesel and gasoline power plants increases.

However, the operation of the unit at idle, i.e. without connected devices that consume more than 30% of the generated electricity, it does not bring any benefit: the winding of the generator part begins to heat up, reducing the life of the device. Old and worn-out diesel generators have many times higher fuel consumption than new ones.

In addition, the quality of fuel matters, so you should not save on it.

Regular cleaning of fuel and oil filters reduces fuel consumption.

Calculation of fuel consumption of a diesel generator To find out the amount of fuel consumed, it is necessary to refer to technical calculations.

The generator needs to process about 0.2 kg of resources to generate 1 kWh of electricity. The mass of fuel is multiplied by the power of the generator declared by the manufacturer. Thus, at a power of 5 kW, 1 liter of fuel is consumed per hour, and at 9.4 kW, about 1.8 liters. When the diesel generator is operating at full load (75% of the rated power), fuel consumption increases.

This can be avoided if you do not connect equipment with a power of more than 3.8 kW to a 5-kilowatt generator. Factors affecting the fuel consumption of a diesel power plant

- At low temperatures, the fuel becomes viscous, significantly reducing the efficiency of electrical equipment;

- improper supply of air-fuel composition reduces the efficiency of the generator by 25%;

- good ventilation ensures high performance of the device;

- fuel quality - the presence of impurities and sulfur reduces the efficiency and increases fuel consumption of diesel power plants;

- preliminary (a few hours before the start of work) refueling improves the operation of the device.

There is no single fuel consumption rate for diesel power plants.

Each model consumes a different amount of fuel, which depends on a number of factors:

- environment;

- unit dimensions;

- fuel quality;

- filling process;

- the degree of deterioration of the generator.

It is possible to minimize the consumption of resources by adhering to the operating rules, the above recommendations, as well as timely maintenance of the diesel power plant.