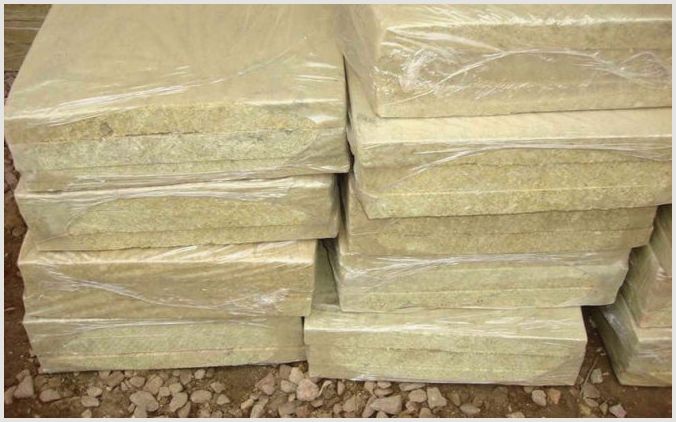

Suitable sizes of mineral wool in slabs

The mass of advantages of mineral wool contributes to its widespread use in the construction process. To accurately calculate the amount of material needed, you need to be informed about the dimensions of the plates. If, when choosing thermal insulation materials, you need to know the number of squares, then when choosing wool, you need to pay attention to the dimensions of the plates.

Standard plates have the following dimensions: 1000 by 500 mm. In each case, you can choose the appropriate thickness of the plates. The number of plates is determined by the size of the finished building.

Plate dimensions:

- Isover Frame P-32 - 1170x610, while the thickness can vary from 40 to 150 mm.

- Isover Frame P-34 - 1170x565, while the thickness can vary from 40 to 200 mm.

- Izover rigid plate - 1550x1180, while the minimum thickness is 30 mm.

You can calculate the required number of plates already in the hardware store, having previously measured the area of \u200b\u200bthe room. You can calculate the number of mineral wool sheets in advance. Knowing in advance how many sheets are in one package or bundle. If the sheets do not fit, they can be carefully cut. Cotton wool scraps can be used to insulate cracks and joints. The density of the sheets is chosen depending on the required quality of thermal insulation.

Basalt insulation for the facade in Sevastopol

The facade of a house, building and structure is one of the most important elements of the exterior. At the same time, the original decorative finishes of the facade can be complemented by an equally important arrangement, a modern insulation system that allows you to reliably keep the heat and comfort of the living space. Basalt wool for the facade of various types and methods of arrangement is in special demand in the modern market. The impeccable thermal insulation qualities of basalt rock wool allow you to equip comfortable warm housing.

Stone wool is an environmentally friendly natural insulation that has adequately established itself in the modern construction market as a versatile, durable, reliable type of thermal insulation for the facade. At the same time, the material practically does not change its qualities over the course of many years of operation of the building. The hydrophobic properties of the material are of great importance, stone wool for the facade has a bactericidal and fungicidal effect due to the special qualities of basalt.

You can choose natural eco-friendly material for insulation from different manufacturers, you can buy mineral wool for the facade in the most optimal price segment for a wide consumer audience. A wide range of materials for thermal insulation is offered by our online store of building materials, including basalt wool from the world's leading manufacturers.

Pay attention to the following products: Rocklight insulation, Technovent standard, Isovent, LIGHT BATTS.

At prices, basalt wool for the facade compares favorably with other materials for thermal insulation. Therefore, when choosing the quality ratio of mineral wool for the facade, basalt wool has an advantage.

What technologies can be used for thermal insulation of facades?

Modern thermal insulation technologies using mineral wool for the facade may include insulation:

- brick facade, with well or Bavarian masonry, three-layer brick masonry,

- block walls,

- ventilated facades,

- wet facades with the arrangement of light plaster,

- other types of facades.

Thermal insulation of facades can be carried out in accordance with the climatic zone in which the dwelling is located. No less important criteria for calculating the thickness of thermal insulation for a facade can be the thickness of walls, enclosing structures, decorative finishes and elements.The choice of the optimal thickness of the insulation and the required type of building mixture allows you to ensure the appropriate quality of the future thermal insulation of the facade.

The technology for arranging thermal insulation with light plaster may provide for the consistent execution of construction work:

- for high-quality cleaning of walls and applying a primer,

- applying the adhesive mixture under the insulation,

- installation of thermal insulation boards from a well-known manufacturer,

- fastening dowels, which are selected in accordance with the thickness of the mineral wool boards,

- arrangement of waterproofing composition,

- installation of facade reinforced glass mesh,

- decorative or mosaic wall plastering, paint application from world famous brands.

The simplest technology is the arrangement of thermal insulation of the facade with a brick cladding. In this case, the insulation is placed between the bearing wall and the cladding, made of well or Bavarian masonry. But in any case, basalt wool allows you to reliably insulate the house and equip a comfortable home according to European standards.

Basalt insulation for the facade in Sevastopol Basalt insulation for the facade in Sevastopol The facade of a house, building and structure is one of the most important elements of the exterior. At the same time, the original decorative finishes of the facade

Classes of mineral wool insulation

State Standard No. 52953, updated in 2008, defines 3 classes of materials that are suitable for mineral wool: glass wool (wool based on fiberglass), slag wool (slag wool) and basalt wool.

Despite their own general similarity, these heat insulators stand out both in terms of production technology and physical qualities.

glass wool

This particular material means a lot of people when they mention mineral wool. This demand is necessarily caused by its low price. Wool based on glass fiber has a fiber structure, while the length of the fiber is approximately 15-45 mm, and the width is 5-15 microns. Thermal conductivity index 0.04 ± 01 W/m*K. This thermal insulator keeps its own temperature at temperatures up to 450 °C, and tolerates short peaks up to 500 °C perfectly. The maximum minimum is 60 °C.

The fabrication of the material consists in drawing fibers from the glass melt. The resulting structure has non-standard properties: fragments of fibers dig into the skin, irritate the mucous membranes and respiratory organs, so it is imperative to use protective equipment when working with glass wool. At the same time, special protective clothing must be disposable, since it is not possible to clean it from the remains of the material.

slag wool

This type min. cotton wool is also performed by drawing fibers from raw materials, which are mountain slags. The thickness of the formed fibers can vary within 5–13 microns, and the length is more stable - 16 mm, with an error of a couple of units. When compared with other types of mines. wool, it contains the lowest fire resistance: the maximum possible temperature is 300 °C.

When this limit is exceeded, slag wool loses its structure (sintering), and at the same time, its own physical properties. When using this material, one must not forget about its susceptibility to absorb moisture (high hygroscopicity), due to this, for some insulation works, slag wool can be used exclusively in combination with complete protection against the negative effects of moisture.

As in the previous case, the basic raw material adds negative properties to this type of heat insulator: mountain slags have a high acidity, due to this, in the event that cotton wool comes into contact with a small amount of moisture, it releases acidic compounds that help actively form corrosive damage to structural metal elements.

Under normal conditions, slag wool has a thermal conductivity of 0.47 ± 0.01 W / m * K, which is considered the worst indicator among mineral wool. Also, such stable indicators are very convenient when calculating the insulation of rooms.

Basalt wool

And in this version, the production technology remains unchanged - pulling microscopic fibers. The difference lies solely in the basic raw materials: this time it is a variety of mountain rocks, such as gabbro, limestone, diabase with a certain proportion of impurities, the percentage of which reaches 35%. The fibers have similar parameters as those of slag wool.

The heat conductivity of this heat insulator can vary greatly depending on the brand, ranging from 0.077 to 0.11 W / m * K. The highest allowable temperature at which this insulation retains its physical properties is 600 ° C. Also, this material is more convenient to use than glass fiber-based slag or wool, since its fibers are not susceptible to destruction and do not pose a threat to human health.

Common to these three classes is an exceptionally large sound insulation, which is caused by a loose structure with a decent amount of internal cavities, and reaches 95%. Also any brand min. cotton wool has in its composition from 2 to 10% of binder impurities, in the role of which phenol-formaldehyde resin very often acts.

Over time, this substance can evaporate and fill the room with harmful phenol vapors. However, on the other hand, the high content of such impurities improves the protection of the heat insulator from the damaging effects of water. The above temperature limits indicate only the conditions under which the material changes its own structure, since each type min. cotton wool does not support open combustion, which makes materials of this class an excellent choice in terms of fire safety.

Stone wool properties, applications

What is stone wool: structure, properties

To understand the properties of this material, it is necessary to study its structure. So stone wool is a fibrous, heat-insulating material, which is similar in structure to basalt (a natural material). Among its positive properties are:

Sound and heat insulation

Due to the high porous qualities, basalt wool has good thermal insulation properties: it is warm in winter and not hot in summer. And due to the fact that the cotton wool fibers are woven randomly, this prevents the passage of sound waves.

This material has absolute incombustibility due to the fact that during production it undergoes heat treatment and withstands temperatures up to 1000C. This indicator is very important, since safety should come first. A lot of sad facts are known when the same foam plastic flared up like a salute or a match.

The service life of such a heater is not limited: having insulated the walls with cotton wool, you will forget for a long time what it is like to be cold indoors in winter.

Moisture resistance and vapor permeability

Cotton wool also has high moisture resistance and high vapor permeability.

Such material is absolutely harmless to humans and the environment.

Application of stone wool

With such excellent properties, stone wool has become a heater, which is in the top of the best and is used for insulation:

- roofs, walls, ceilings,

- partitions, floors, basement,

- facade.

The material is also used as a thermal insulation of industrial equipment, tanks, pipelines of heating networks, and as a heat-insulating layer in hinged ventilated facades.

As for outdoor use, in this case, cotton wool is used as a plaster-type insulation.

cost of stone wool

The price of stone wool is an order of magnitude higher than that of polystyrene, but there is also a benefit, as these are two different materials in terms of thermal insulation properties.In addition, the cost of cotton wool depends on such parameters:

- density,

- thickness,

- the size,

- compound. If the cotton wool contains slags that reduce the physical qualities of the insulation, then the price of the product is lower,

- release form: roll, plates, cuttings.

And the last argument in favor of basalt wool is easy installation without effort.

How to insulate walls with stone wool - in our next article.

Stone wool for walls You have decided to insulate the walls of the house, garage, but do not know what material to choose for this. Let's consider stone wool (basalt) as a reliable insulation.

How the appointment of mineral wool affects its size

- reduce heat loss in winter;

- protect from overheating in summer;

- to preserve the elements of the supporting structure of the building from the effects of negative environmental factors;

- increase the life of the building.

These tasks are quite within the power of inorganic heaters. From a solid list of materials of this kind, mineral wool is in special demand. Mineral wool has long been successfully used in construction.

Giving preference to this type of insulation, the consumer receives the following advantages:

- thermal conductivity index 0.035 W/mk, one of the best;

- qualitative dielectric properties;

- high rates of vapor permeability;

- best fire resistance parameters;

- low hygroscopicity;

- high resistance to aggressive environments.

This material can be used for wall insulation, both inside and outside. It is used for roofs, attics and basements, internal partitions. Its dimensions have the same standards as the distances between the guides where the mineral wool is laid. If there are violations of standards in construction, there is also a need to adjust the size of the insulation.

Please note: mineral wool manufacturers produce their products in sizes maximally adapted to the standards of modern construction.

We calculate the required amount of insulation

Will foil wool be needed, what mineral wool materials will be needed at all and whether it is possible to optimize costs.

For example, we calculate the required amount of insulation on the roof.

Stage one:

- calculate the roof area;

- add the area of attic walls and partitions;

- add 3% to the amount received.

Stage two. We choose the insulation, the area of the roll of which most corresponds to the area of \u200b\u200binsulation. We consider the material and sheet, and in rolls, and in mats.

Stage three. We divide the roof area by the square of the insulation and multiply the unplanned number of layers. The amount received will determine how many sheets, rolls to buy, how much plate material is required in pieces.

Masters advise: be sure to add 10-15% to the result. Material is always in short supply.

In order not to waste money on cutting off the insulation, carefully calculate the size of the room, carefully analyze everything that is written on the packaging of a particular insulation. However, even if the miniplate or rolled tape has been cut, there is nothing to worry about. Waste will be useful for warming adjoining buildings.

Dimensions are dictated by building codes, such a standard approach greatly optimizes the construction process.

When choosing a heater, it is important to take into account technical characteristics, professional advice on the appointment of a particular material, length, width, thickness and other important indicators. A significant characteristic is the density

Usually it is 11-350 kg/m kV. Wool of the highest density is used for internal partitions, has dimensions similar to other types of insulation

Density is a significant characteristic. Usually it is 11-350 kg/m kV. Wool of the highest density is used for internal partitions, has dimensions similar to other types of insulation.

Watch the video, which explains the nuances of counting and laying insulation:

Classification

Depending on what criterion the classification is based on, heaters are divided into different groups. In the framework of this article, we are interested in density differentiation. In this case, the following types of thermal insulation materials are distinguished:

- Lungs. They are lightweight and have low thermal conductivity. This group primarily includes mineral wool materials.

- Medium. Foam glass can be an example of such a heater. Such heat-insulating materials are usually produced in the form of plates and blocks with high heat and sound insulation.

- Rigid. This is a dense insulation, usually obtained by pressing, for example, mineral wool mats. In addition to low thermal conductivity, they are characterized by wet strength and the ability to withstand heavy loads.

Kinds

As already mentioned, all thermal insulation materials are divided into several types depending on the specific gravity. The scope of its application depends on the latter.

The table shows this clearly:

|

Density class |

Density indicators |

Scope of application |

|

Lungs |

11–35 kg/m3 |

Lightweight and resilient materials that are used to insulate roofs and roofs. |

|

35–75 kg/m3 |

Wall insulation - thermal insulation of walls, partitions, frame structures. |

|

|

75–100 kg/m3 |

Wrapping of pipes of oil pipelines, heating mains. |

|

|

Medium |

100–125 kg/m3 |

External thermal insulation for a ventilated facade |

|

125–150 kg/m3 |

Insulation of concrete and brick walls, floors |

|

|

Rigid |

150–175 kg/m3 |

Sheathing of load-bearing structures |

|

175–225 kg/m3 |

They are laid under the subfloor screed before finishing, they are durable and fire resistant. |

It is important that certain types of insulation have their own classification depending on the specific gravity. For example, according to GOST, polystyrene is divided into grades PSB 15 (density is less than 15 kg / m3), PSB 25 (indicators 15–25 kg / m3), PSB 35 (specific gravity from 25 to 35 kg / m3) and PSB 50 ( 50 kg/m3 or more)

The hardness classification of mineral wool is as follows:

- P-75 (material density, respectively, 75 kg / m3) is suitable for lightly loaded and horizontal surfaces;

- P-125 (the specific gravity of this wool is 125 kg / m3, but insulation with a density of 110, 120 and 130 kg / m3 is also referred to this type) wall insulation;

- ПЖ-175 (density indicators are clear from the name) - high-density material for outer skin;

- PZh-200 (specific gravity is 200 kg / m3 and above) - used for outdoor work, has increased fire resistance.

Varieties and forms

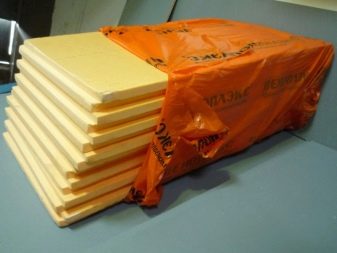

Styrofoam

In its form, it represents polystyrene bubbles filled with air, further pressed into plates of standard sizes: 500x1000, 1000x1000 and 2000x1000 mm. Packing of material - in the form of plates of fixed sizes. Styrofoam is a white board material with a rigid foam structure, containing 2% polystyrene and 98% air. The thickness of such material varies from 20 to 1000 mm.

The material has the following advantages:

The long-term use of polystyrene foam as a heater also revealed its disadvantages:

- on sale there is a material of rather poor quality;

- the material is subject to combustion;

- foam plastic serves as a heater for only 10-15 years (depending on its manufacturer and quality);

- the material is not breathable.

In order to start working with a heater, it is necessary to perform a number of actions that distinguish this type of material from products for other purposes.First of all, it is necessary to carefully prepare the surface to be insulated. To do this, it needs to be cleaned, leveled and primed. After that, you need to make marks with a plumb line for a uniform arrangement of foam plates. Then the foam is carefully lubricated with an adhesive solution and gently applied to the wall.

You do not need to press hard on the foam when laying - it is quite fragile, so damage may occur. Styrofoam plates are laid close to each other. Gaps can be filled with mounting foam. For confident fastening of the plate, it is best to fix it with dowels. A reinforcing mesh is glued on top of such a heater - a final finish is carried out along it.

Penoplex

Such material is better than polystyrene in all its properties, and its installation is simple and convenient for self-installation.

This insulation looks like a waterproof tile with a thickness of 20 mm. The basis of the material is foam styrene, its granules are processed under pressure using high temperatures. The walls inside the house for the installation of foam plastic are prepared in the same way as for the installation of foam plastic (you need to remove dirt and clean, level and prime the surface).

Finishing work:

- primer for facade work;

- basic finish (a variety of plasters can be used, both acrylic and silicone);

- choice of final texture;

- painting.

The easiest way: the surface is leveled, finishing putty is applied, primed, painting is carried out. In construction, material is used with a thickness of 20-100 mm, a width of 600 mm and a length of 1200-2400 mm.

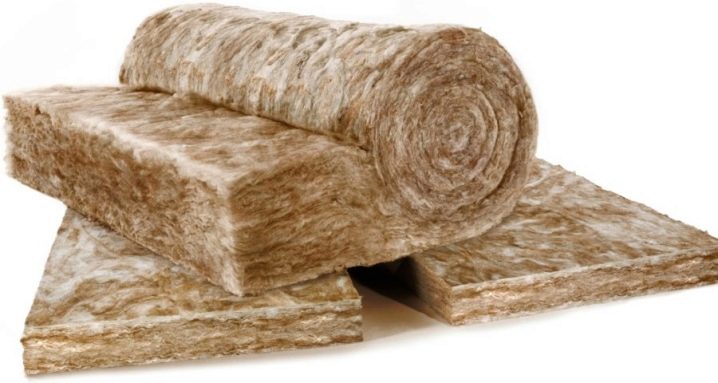

Mineral wool

All types of mineral wool are also suitable for thermal insulation.

Mineral wool properties:

- not combustible;

- heat conductivity is very low;

- rodents do not eat mineral wool, but they love to settle in it;

- service life from 30 to 80 years.

Heat insulators of this class are of three types:

The material is produced in several varieties:

- in the form of plates (mats);

- rolls;

- in formless form.

Dimensions of mineral wool release form and dimensions

The proportion of mineral wool used in construction has increased from 46% in 2010 to 60% today. Starting from the middle of 2017 and in subsequent years, an increase in the production of mineral wool products is predicted.

This success is due to many factors. This is an increase in multi-apartment construction, and the growing popularity of suburban housing, and the growth of industry as a whole. However, an important factor is a thoughtful study of the needs of the construction market by manufacturers.

Knowing the required technical and operational characteristics, sizes and dimensions of mineral wool, understanding what a builder needs to build high-quality housing, allows the manufacturer to produce the products that will be in demand.